-

Posts

6,482 -

Joined

-

Last visited

-

Days Won

12

BlueStringPudding last won the day on July 24 2020

BlueStringPudding had the most liked content!

About BlueStringPudding

- Birthday 07/08/1974

Profile Information

-

Gender

Female

-

Location

Hertfordshire

-

Interests

Eating, drinking, floating and being merry. DIY-ing the boat, Greenery, cute furry creatures, and a snifter of Talisker... ah...bliss!

-

Occupation

Chief Executive & Costume Designer n stuff

-

Boat Name

Mabel Stark

-

Boat Location

About the place

Recent Profile Visitors

BlueStringPudding's Achievements

Veteran II (12/12)

743

Reputation

-

BlueStringPudding started following Travelling metal worker/welder recommendations , Which battery setting for MPPT Controller? , All of the things are broken... and 2 others

-

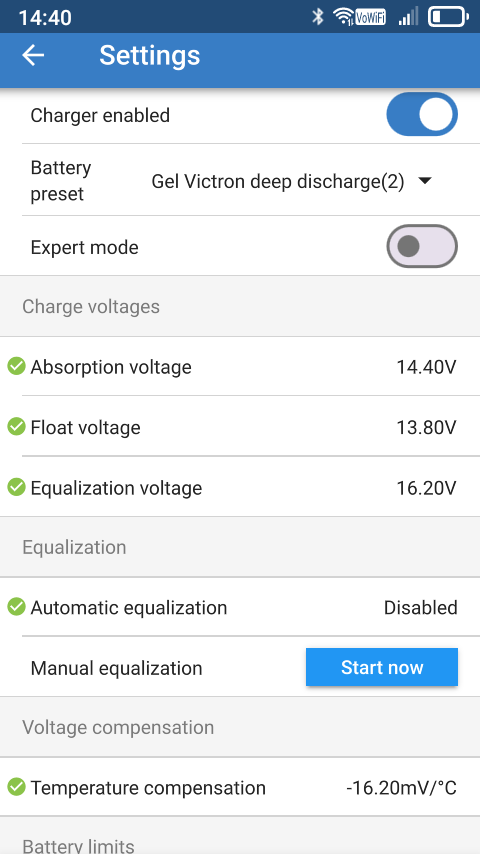

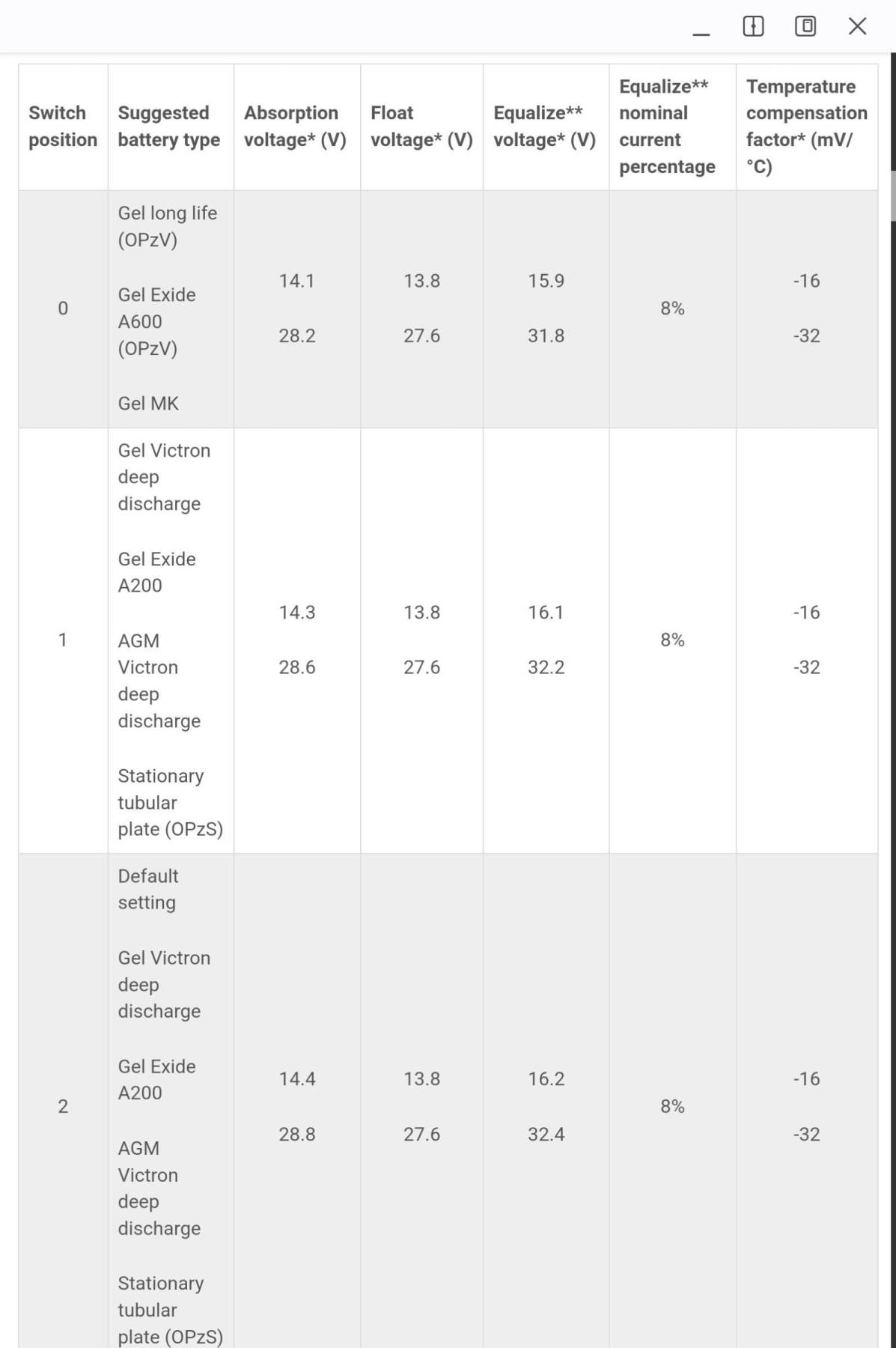

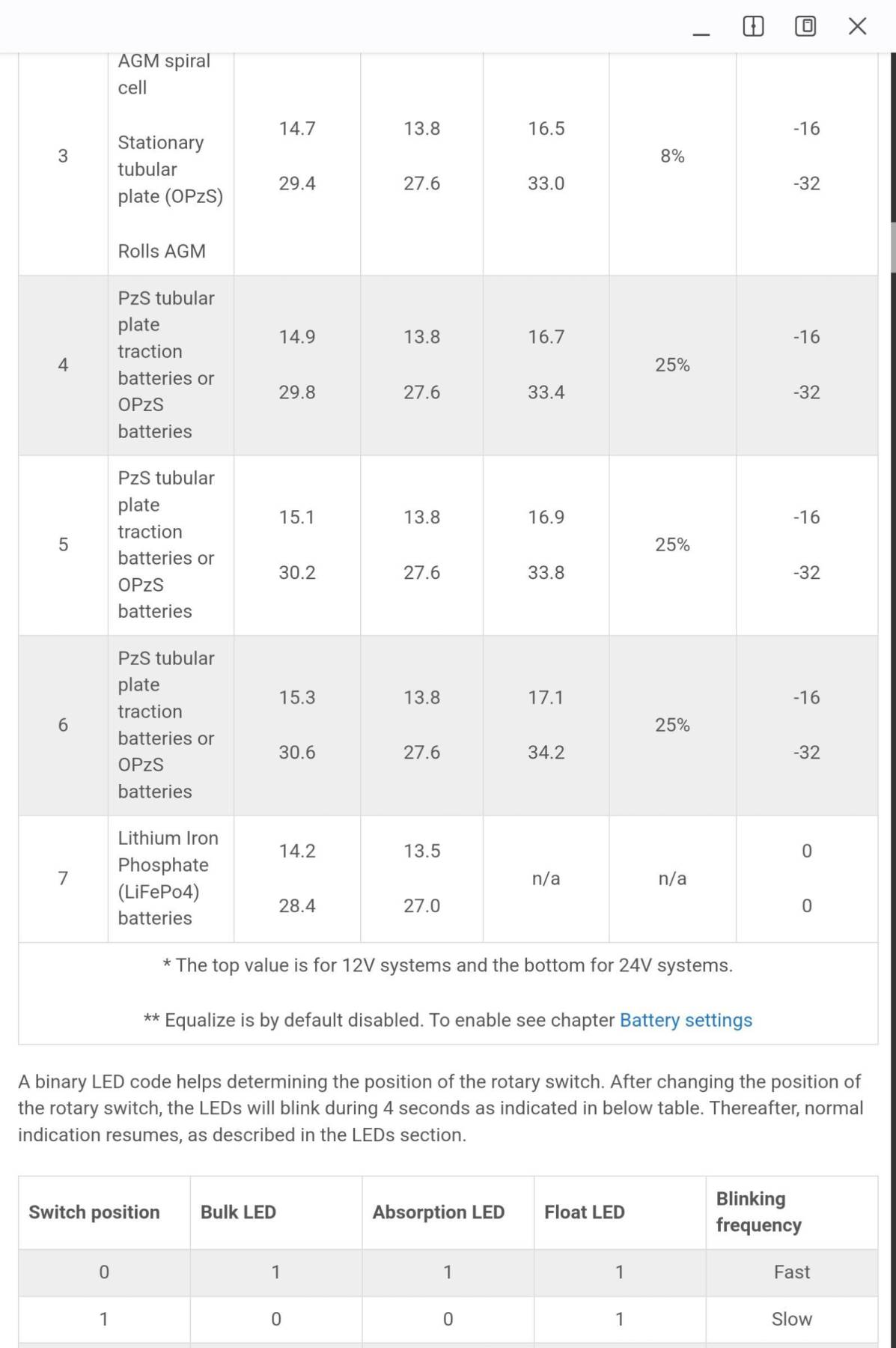

I've got new batteries which are 4 × Numax Sealed Wet Leisure Batteries 12v 105Ah (CXV31MF) My Victron MPPT solar controller gives me the following seven battery options for setting up the controller (see photos) - none of which are to me an obvious match for my batteries, but you guys and gals may know better. Please can you tell me which of these are a suitable setting for my batteries? Thanks

-

Buying new domestic batteries

BlueStringPudding replied to BlueStringPudding's topic in Boat Building & Maintenance

Okay. Thanks. So if I go back to the Advanced Battery supplies website, how can I tell if they've quoted their Ah at c20 or c100 or c-anything else? -

Buying new domestic batteries

BlueStringPudding replied to BlueStringPudding's topic in Boat Building & Maintenance

It sounded so simple. 😟 But I can't find reference to c20 (most online shops don't seem to state it) + good Ah (eg 110 ish not merely 80 ) + unsealed (almost all are sealed) + correct terminal configuration + correct max size + it can be delivered. Nearly everything is sealed or just doesn't state the info I need. The Advanced Batteries website search function doesn't work and trawling through by category seems to show just sealed batteries. Tayna also lacks the info I need. This is too confusing. Please can anyone recommend a specific online retailer of Unsealed, 110Ah ish (at c20) leisure batteries? Then I can trawl through the terminal configurations and dimensions myself to find the right ones? Thanks -

All of the things are broken...

BlueStringPudding replied to BlueStringPudding's topic in Boat Building & Maintenance

Excellent idea. I'm packing my glad rags! 😊 -

What “jobs” can my dog do when on board?!

BlueStringPudding replied to Doodlebug's question in Pets and Animals

Plenty of hoomans would benefit from this level of training too. Come to think of it, I might even sit and be good for a Bonio and a scritch behind the ear. 😄 -

Whinge time: So very many boat jobs to get done all at the same time. My boat is booked in next week for 2-3 weeks of work, and it all feels a bit overwhelming. 😟 Next week is a piece of work that was booked in months ago, so that's alright: it's going to the dry dock for blacking and to put some weld along where my surveyor noticed grooves have been made by the rudder. The week after that it's off to the boatyard to have the engine lifted out (eek!) in order to cut out the leaking corner weld of the skin tank, and weld in a new piece of metal. Since the engine has to be lifted out for that job, the yard are putting new engine mounts on and cleaning up and painting the bilge while it's out It became apparent about three weeks ago that my domestic batteries have died a fairly sudden death. So again, since the engine is out and there's more space to move around in the cruiser stern, the yard are swapping out the batteries for me. This morning I woke up to the smell of hot plastic and traced it, I believe, to one of my MPPT controllers. So today I unplugged all the solar panels (they would need to be off for the battery change over anyway) and i detached the controllers from the batteries too, just in case. So now I'm living with about 8v of power from my kaput batteries, which I'm trying not to use at all. I'm living this week with just the basics: a torch, my neighbour is currently charging a little battery pack for me so I can charge my phone. Fridge is off. Water pump is on a go-slow so I'm trying not to use water at all, but I've got bottled. There'll be no emptying the shower tray or flushing the loo this week either. What fun! Oh, and the hinges on the stern deck hatches are rusted through. It's a job that got cancelled roundabout Covid time, so it's back on the to-do list because all these recent trips into the bilge by kindly neighbourinos is really highlighting how much easier it would be with working hinges! Tree Monkey has kindly offered to do the driving of my boat between its mooring and the dry dock, then a week later between the dry dock and the boat yard, and then eventually from the boatyard back to the mooring. As the skin tank (until repaired) is losing at least 4.5 litres a week now, he'll need to refill the header tank before each trip, which is a bit of a chore but an important one. (Watering can and back up bottles of water are on standby!) Despite being a chore, it's better than cooking the engine which (touch wood) is otherwise working fine. The boatyard offered for me to live aboard while they do the work at the yard, but given there'll be no power for a bit, and a lot of noise, I'll be staying elsewhere for however long it takes. Of course I'll be worrying about it the whole time I'm away, as is the law. 😲 The boat is my baby as well as my home. So that's the end of my whinge. Expect another when the bill comes in! 😄😢😉

-

Buying new domestic batteries

BlueStringPudding replied to BlueStringPudding's topic in Boat Building & Maintenance

Please can you explain what are suitable cyclic depth/c100 etc ratings? I've no idea what these things are. 🤔 Thanks -

It's been a while since I bought new batteries. But my current domestics (4 × 110Ah, 12v, flooded) are deceased. I'm considering getting some sort of maintenance-free batteries for a change. I've got solar via MPPT controller, plus I charge via running the engine. But to be honest, I don't look after them. What type/brand of batteries do you guys and gals recommend? Also, any recommendations for suppliers please? Thanks 😊

-

Where is all the coolant going?

BlueStringPudding replied to BlueStringPudding's topic in Boat Building & Maintenance

Hi all. I thought I would give you an update about the mysterious disappearing coolant. A boaty neighbour who knows his engines has recently returned to the UK after a couple of months away, and bless him, me and one other one of us pounced on him to ask for help with our respective engines! He's a great chap and has been so determined that my engine won't beat him, he's been working on it for three days so far, eliminating possible causes and in the process discovering other, possibly linked problems, and resolving them as he goes. If you want the quick answer to what we think is the main culprit, skip ahead to the last paragraph. But if you want to know what he's unpicked so far, read on: So, the problem we're trying to solve is that the coolant system appears to be losing 600ml plus slowly over about 2 hours, every time the engine cools down, as indicated by the indoor expansion tank, which is connected to the engine and Eber circuits. It's been losing coolant by emptying not through its overflow which would indicate engine overheating, but out through its lower pipework towards the engine, emptying slowly as the system cools. As you know from above, TM and another of my boaty neighbours checked around the engine and there were no obvious leaks that could account for this. Initial checks by this chap could also find no obvious leaks in or around the engine area either. His first thought that the initial overheat in February that started all this (whisp of steam, burnt coffee smell, boiling sound in the pipes) might have been caused by a sticky thermostat valve, but he was happy it was working fine. He was also happy that the head gasket was fine. He did discover an air lock or blockage in the engine coolant system though. (Coolant coming through the pipe at the top front of the engine felt very hot - but never hot enough to be pushed up into the expansion tank or out the overflow pipe from that tank into a bottle. However the return pipes from the skin tank were almost cold and might not have had water in it at all.) He blew through the pipes and skin tank and then flushed through what he could there with water, and now the engine coolant is hot but not too hot at the front, and warm at the return from the skin tank, as it should be. But... as the engine cooled after a few good runs, the expansion tank lost coolant at the same rate as before, every time. To quote him: where is all the water going!? He discovered that the alternator belt between the starter alternator and the water pump wasn't fully on. It felt tight at the top but underneath he could easily turn the pump by hand. So he repositioned the belt and tightened it up. But that was a bit of a red herring with regards to being a cause for possible overheating, because that alternator belt had been changed *after* the initial overheat in February, (the old alternator belt being toothless in places 😲 ) He checked the radiator cap and other parts, and gave any potential risky bits a once over and a clean, but still no improvement. He unblocked two tiny drainage holes in the bulkhead between the stern bilge and the cabin bilge, expecting water to come through from anything leaking the other side of the bulkhead. But there was no water, in fact his screwdriver came out dry. Also, uncovering the inspection hatch in the stern cabin floor showed no water. He eliminated the likelihood of there being a coolant leak from the calorifier by isolating it from the engine (as someone above suggested) joining two engine coolant pipes together to make a closed loop. But as the engine cooled after another couple of good runs, the expansion tank lost coolant at the same rate as before, till it was empty every time. But we still couldn't see where it was going to. Yesterday he eliminated any radiators leaking being the possible cause, by capping off the relevant Eberspacher pipe. But as the engine cooled after another run, guess what? The expansion tank still lost coolant at the same rate as before until it was empty. So his attention went back to the engine area. There was a horizontal line of scale a few inches above the bottom of the skin tank, the baseplate next to it being currently dry. He scraped that scale away and a while later it revealed a slow weeping leak from near the weld. Running the engine made steam come from there, confirming there is a pinhole coolant leak from the skin tank into the bilge. The weeping skin tank leak is extremely slow, just damp, so not the location of 600ml plus coolant lost from the expansion tank every time the engine cools, but I'm pleased it's been discovered. The boat is booked in for some work at the boatyard next month so repairing that is now on their to-do list. Meanwhile, the expansion tank is still losing coolant and being refilled repeatedly, but there's still no water sloshing about anywhere. This morning, he again checked the pressurised header tank that is immediately above the engine and he could tell that the level had gone down a little since yesterday. Again, no puddles anywhere, and the expansion tank in the cabin has emptied overnight as usual. So he undid the pressurised radiator cap as well as the pipes that link the expansion tank inside the cabin to it. When I then filled the indoor expansion tank with water it should have drained out where he was standing by the pressurised engine tank, but it didn't. The pipe between the two was blocked. So after a few hefty puffs he blew the pipe clear and I flushed it through with water Once the expansion tank was full and the connecting pipe clear, it was obvious that the radiator cap even when not under pressure was dripping. When checked last month and again this weekend, the radiator cap appeared to be working fine, but now it's obvious that it just doesn't seal properly. So his prevailing theory about where all this coolant has been going is that it may have been coming out of the knackered radiator cap as steam and/or drips, because the pipe from it into the expansion tank was almost but not entirely blocked - so coolant couldn't expand into the expansion tank. But the coolant wasn't collecting in puddles on the baseplate or anywhere else either to make this obvious. And although the engine thermostat appears to be working fine, on the off-chance that it may have stuck shut in the past, I've ordered a new one and he's going to replace it as a "belt and braces" way to ensure all this shouldn't happen again. So fingers crossed that the case of the mysterious disappearing coolant will have been solved. But we shall see when the parts are replaced! Thanks to TM, everyone here and my three contributing neighbourinos for their help with this. Let's hope these two replacement parts and all the unblocking of pipes and budging of airlocks has fixed it. 🤞 -

I've done that too, in the past

-

Hi. I need to find someone who can repair my cruiser stern deck hatches. They're two large steel hatches and the four hinges have rusted through. The hinges need replacing. Ideally I would like someone whose work comes recommended and who can travel to my boat on the Cov. Any recommendations, please?