Bloomsberry

Member-

Posts

393 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Bloomsberry

-

I did mine in interzone954 after a number of very dissappointing results using bitumen, it's evil stuff and even cures underwater. The surface has to be prepared down to bare metal using a rotary blaster or similar, very time consuming. In 3 days I only had time to do the waterline, weld seams and pitted areas . It was done 16 months ago and is still intact with no trace of any failure. It's coming out again next year to inspect it more closely and tidy up any dodgy areas and treat areas that weren't got to the last time.

-

Can you cancel though ? It's very short notice and I'd have thought you'd at least lose a deposit ?

-

how good is the paint he left behind ? if the seal on the tins wasn't too good it could be a bit 'lumpy' and not produce the finish you might of liked. Might be best to get new tins with good quallity paint in. Anyway, it's a bit late for painting this time of year so would be best to leave this till the spring ?

-

A decent paint job tends to cost around £100 per foot so that costing must be for a 15 foot boat

-

Silver foil fixed to the sides of the hearth immediatly to the sides of the stove do a great job of reflecting the heat. I tried it and couldn't believe how cold the tiles were behind it , it doesn't look too great but it works very well. Could be a solution if you're concerned about the hearth of your own boat.

-

Non slip tape for the gunnels

Bloomsberry replied to Karen Lea Rainey's topic in Boat Building & Maintenance

It looks nice but I'd be happier if the sanded surface went right to the gunnel edge. Personnaly I prefer to have the whole gunnel surface sanded to provide the best grip possible. -

http://www.mmbalmainauto.com.au/PDF/State_of_charge_12_volt_batteries.pdf Chart shows batteries at 12V only have only 25% capacity which is very low indeed. 11.8V means that they are completely discharged which indicates that the batteries appear to be shot.

- 30 replies

-

- pump

- fresh water pump

-

(and 1 more)

Tagged with:

-

Is overplating really that bad?

Bloomsberry replied to Dave_P's topic in Boat Building & Maintenance

So if the significant hull work in 10 years didn't get picked up in a recent survey then who decided it was necessary ? -

Is overplating really that bad?

Bloomsberry replied to Dave_P's topic in Boat Building & Maintenance

I think if you're boat sinks due to the condition of the hull then insurer will reject any claim due to lack of maintenance -

Insulating the engine space?

Bloomsberry replied to blackrose's topic in Boat Building & Maintenance

I've put insulation on the ceiling of the engine bay of my trad, more to keep the engine room insulated during cold snaps than preventing condensation. -

Very nice, looks like you got a great finish. A couple of questions, did you use any thinners with your paint and whose paint did you use ?

-

If the switch on the unit won't turn it off then can only assume it's knackered and none replaceable. IMO options are 1) Fit an isolation switch on the 12V in 2) Replace the inverter

-

And some people have that ting sound configured on their mobile phones when they receive a message so people on the towpath think the ting noise is someone receiving a text instead of a cyclist approaching. So bringing back the "brrrring brrrrring" noise is a good idea IMHO.

-

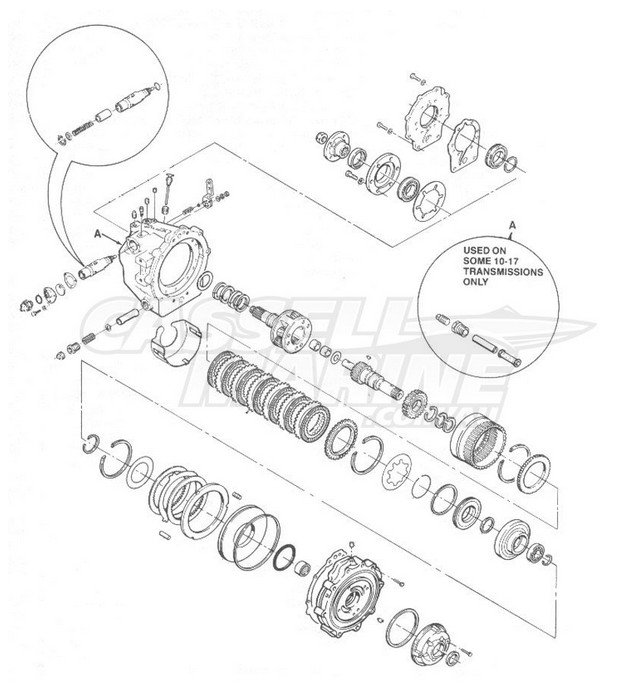

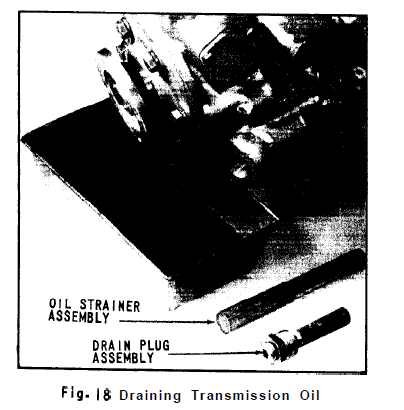

Borg Warner Velvet Drive oil strainer

Bloomsberry replied to Bloomsberry's topic in Boat Building & Maintenance

There may not be after all, found this which seems to show the strainer assembley with a note that it is only used on some 10-17 (71C) models only. I assume area A they are refering to is the coolant return port at the bottom of the drive. Whilst trying to dig out the non existant strainer there was no debris of any kind in the coolant return port area and the oil was discoloured but didn't contain any visible particles which was encouraging. -

STARTED PAINTING - HELP PLEASE!!

Bloomsberry replied to Fozzi in Lancashire's topic in Boat Building & Maintenance

There are 2 types of rollers as far as I am aware, emulsion rollers and acrylic rollers and I assume it is the emulsion rollers you are using which are not the correct choice for acrylic paint ? I had the same happen to me when I first started painting my boat. -

I DIY epoxied my boat last year (well, the important parts anyway) without gritblasting using a rotary blaster mounted in a drill. This was over 12 months ago and it all appears to be still intact including the entire waterline which only survived a few months when using normal bitumen.

-

Changing the oil in my Borg Warner Velvet Drive and thought I'd have a go at cleaning the oil strainer located in the coolant return connection. However , removing the cooler hose return connection, the drain assembly came out but couldn't find any sign of the strainer so assume this is located further in. In the manual it states you have to reach into the opening with a suitable tool but fails to mention what this tool is. I made up a piece of wire with a hook at the end hopeing this would pull it out but to no avail. I assume if it's been in there a while it won't shift easy anyway. I suppose there is the prospect of the strainer not being present of course. So what have other people used to get the strainer out and how easy was it?

-

Deck drains - height above water

Bloomsberry replied to Neil2's topic in Boat Building & Maintenance

After getting messed about between surveyor and boatyard a couple of years ago when trying to get a survey for fully comp insurance I've decided to sod them all and go 3rd party. Now I don't have to comply with some of the barmy rules associated with getting fully comp insurance like the deck drain rule. Do you think my boat is in imminent danger of sinking with a couple on 6mm holes drilled in the side of deck drains ? The distance to waterline is probably about 7 inches, maybe more. I don't anticipate any issues with the 6mm holes in the deck drains. -

Deck drains - height above water

Bloomsberry replied to Neil2's topic in Boat Building & Maintenance

My deck drains were welded up when I bought my boat and large pools of water used to accumulate as a consequence. I was going to fit an auto bilge pump to take it away but in the end I just drilled a couple of 6mm holes either side to provide drainage. I suppose the deck drains are welded up to prevent water ingress when in choppy waters or if taking on water? if taking on water the water will go to the back end of the boat bringing this end down so not sure how this would effect the bow. In choppy waters there's going to be very little water ingress through small 6mm drainage holes so am happy about leaving this as is. -

Ok, I did a small mix of 954 yesterday and applied it on top of an area of bitumen on the hull which is currently in sound condition. I tested it today and it does appear to have adhered very well, I've used sharp chissel to try and peel the 954 off and all I've managed to achieve is to scar the 954 surface instead. In no instance did the 954 part from the bitumen. Points to take into account are 1) Area treated was above the waterline, applied by brush 2) Test was only done 24 hours after application 3) Only one coat used, I assume others will create a more durable surface. So maybe taking the hull back to bare metal isn't required if the bitumen is in good condition. Only other thought is that would it be able to withstand being pressure washed when next taken out of the water.

-

I only applied 954 to prepared steel so have no idea if it is compatible to bitumn. I still have some 954 left over so can try a small mix and apply this to an existing bitumen covered area of the hull.

-

I used interzone 954 for my boat last year after getting some dissappointing results with normal bitumen. I didn't coat it over any existing blacking but prepped the surface back to metal to try and get the best adhesion. 12 months later and the interzone is still intact and is not showing any signs of deteriation. Just to add that the prep was very time consuming and I only had 3 days so concentrated on the vunerable areas ie. waterline, welding seams and pitted areas.I slapped on old bitumen on other areas I didn't get time to prep. I'm having the boat back out of the water next year to check on the condition of the interzone and include other areas if existing areas are still intact.

-

"is always" above water level or "should be" above water level ? Wouldn't the trim of the boat effect this also ie. if it's been overplated, water tank at the bow empty etc. but then again probably not by that much more if the bottom of the tank is close to the waterline anyway. But like you say , if the diesel level in the tank is always maintained above the water level then there should be no water leaking in.

-

If diesel is leaking out then surely canal water will be entering the fuel tank. If this builds to a certain level then this is going to go to the engine (when running) which isn't going to do it much good. It may be a good idea to syphon the tank bottom to make sure there isn't a build up of canal water in there. If the water tank is at the bow then try filling this up to maximum which will raise the back end up, maybe enough to get to the leak

-

I did an experimental DIY epoxy job on my boat last year, preped it using a rotary blaster tool in a drill and used international interzone as the epoxy. Prepping took a very long time but I stuck at it and managed to do the waterline, welding seems and pitted areas in 3 days. A year later and it all appears to be in place. The boat is coming out next year to check on the blacking and treat other areas that I hadn't had time for previously.