-

Posts

6,509 -

Joined

-

Last visited

-

Days Won

2

NB Alnwick last won the day on October 27 2024

NB Alnwick had the most liked content!

About NB Alnwick

- Birthday 22/02/1947

Contact Methods

-

Website URL

http://www.grahamoliver.com/

Profile Information

-

Gender

Undisclosed

-

Location

Cropredy, Oxford Canal

-

Interests

Folk music, boats, trains, and almost anything vintage . . .

-

Occupation

None

-

Boat Name

Alnwick (pronounced 'Annick')

-

Boat Location

Usually moored at Cropredy

Recent Profile Visitors

NB Alnwick's Achievements

Veteran II (12/12)

510

Reputation

-

Morsø Squirrel 1410 repairs?

NB Alnwick replied to NB Alnwick's topic in Boat Building & Maintenance

. . . but it wasn't easy: We started by scrapping the butchered back plate which had also cracked from the corner of one of the two holes that had been roughly hacked out with an angle grinder when the original back boiler was installed long before our ownership. This was replaced with a new backplate, and we are grateful to the technical experts at the Morsø UK office in Rugby who provided the drawings and advice, to enable us to drill the new backplate correctly to take a new stainless steel back boiler. As previously described, one of the securing lugs on the front plate was broken, so we fashioned a substitute from a piece of 75mm x 75mm x 6mm thick stainless steel angle purchased from eBay. This was secured to the front plate with three M5 socket head stainless steel machine screws and fire cement. For final assembly we used M6 stainless steel studs, thick washers and nuts (supplied by ACCU who we have found to be a most useful resource) and about eight metres of stove rope! The images below illustrate our replacement of the broken lug. -

Morsø Squirrel 1410 repairs?

NB Alnwick replied to NB Alnwick's topic in Boat Building & Maintenance

-

Morsø Squirrel 1410 repairs?

NB Alnwick replied to NB Alnwick's topic in Boat Building & Maintenance

Well, the good news is that we managed to get the stove out of the boat and it is now completely dismantled. With the exception of the previously butchered back plate and the leaking back boiler, all parts are re-usable and the rebuilding work will start soon. We learned a few lessons with the dismantling: Firstly, the bolts are M6 - elsewhere in this site as well as on YouTube it has been suggested they might be M8 or M10. Perhaps due to confusion with the spanner/socket size as opposed to the thread size - a 6mm threaded bolt usually has a 10mm hexagon. Anyway, we will probably replace the bolts with stainless steel studs and brass manifold nuts. A few of bolts were relatively easy to undo using a 10mm socket on a long extension but others just wouldn't budge. We tried shearing the head off one of the bolts with a cold chisel but we only managed to bend it - breaking the cast lug in the process! Lesson learned - if the bolt won’t budge, remove the head with an angle grinder - taking care not to damage the cast iron! That worked and, as someone previously mentioned, once dismantled, the remains of the bolt (which gets red hot when the head is ground off) was easily unscrewed with mole-grips. The broken lug was a disappointment but we are in the process of having a simple repair bracket manufactured. -

Morsø Squirrel 1410 repairs?

NB Alnwick replied to NB Alnwick's topic in Boat Building & Maintenance

All good news - thanks for the replies . . . -

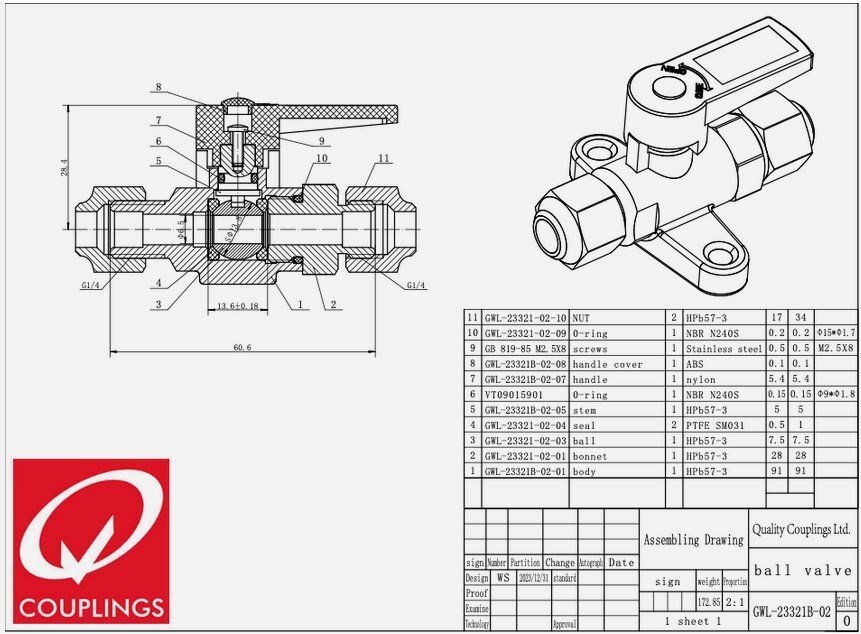

This is the valve that I referred to in my post of September 22 above. I did contact Bullfinch and their reply was that they no longer supply 3/8" gas valves and the ones they did once supply were not manufactured by them. The valve that was made by Quality Couplings was sold as a replacement for the Bullfinch valves but our BSS inspector was clearly concerned about the product.

-

Morsø Squirrel 1410 repairs?

NB Alnwick replied to NB Alnwick's topic in Boat Building & Maintenance

Yes the original back boiler in ours is cast iron - the failure is near the bottom and could have been the result of corrosion from the outside perhaps as a result of a casting flaw - anyway, it doesn't matter - it is now in the skip. Our stove is now out of the boat and in our garage - that was some achievement! We will completely dismantle it before planning what to do next. Scanning the Internet, it would appear that there is an abundance of stainless back boilers but the cast backplates (we are likely to need a new one) are harder to find and the ones pre-drilled for a boiler are no longer available. If anyone has recently adapted one of the undrilled back plates we would be pleased to hear of your experience. -

Morsø Squirrel 1410 repairs?

NB Alnwick replied to NB Alnwick's topic in Boat Building & Maintenance

Thanks for the offer Mike - but the one you now have doesn't have a back boiler - and that is likely to be the only part that I need! I should have realised that the back boiler was the most likely component to fail after the door glass and mild steel flue. It was always going to happen and my only regret is the timing of the failure. Best Wishes, Graham -

Morsø Squirrel 1410 repairs?

NB Alnwick replied to NB Alnwick's topic in Boat Building & Maintenance

Our Morsø Squirrel was installed in 1998 and was used more or less continually throughout every winter until we moved the boat to Cropredy Marina four years ago. The previous owners (1998 to 2004) also lived aboard. After 2022 we used it less often but we often stayed on the boat or cruised during the colder months so it has lasted for 27 years with no more attention other than changing the glass and rope in the door and a couple of flue changes. We keep a spare door for the anticipated occasion when the glass might crack or break at a time when the fire is alight. Thankfully this has only happened once. We have drained and refilled the central heating system (hardly a system - one large radiator in the living quarter and two small ones - one serving the shower/lavatory room and one in the bed 'ole) a couple of times and have been using Morris Ankorsol anti-corrosion inhibitor since 2007. The point is that the stove has more than earned its keep and now deserves a proper overhaul. Our only regret is that we didn't take the stove out and overhaul it earlier in the year when it was warm and dry and we couldn't go anywhere! Perhaps the lesson learned is that it would be sensible to give these stoves a thorough overhaul and replace the back boiler every 20 to 25 years! -

Morsø Squirrel 1410 repairs?

NB Alnwick replied to NB Alnwick's topic in Boat Building & Maintenance

Ours was very badly corroded and is probably glass lined. The image below is close up of what we found when the fire decided to extiguish itself! We have added an arrow to highlight the hole! As can be seen, we had been burning a mix of wood and coal. -

Getting back on track and referring to the image in the first post, we have an identical shut-off valve in the supply line to our new cooker. It was manufactured by Quality Couplings of High Wycombe and is sold by several trusted chandlers - the images below show a close up of the valve and what we believe is the manufacturer's drawing. Our BSS inspector expressed some concern with the design of this component even though it was gas-tight and functioned properly. As a result the inspector is carrying out further research to confirm that it is compliant with EN331 etc. We wondered if anyone else may have used similar valves and experienced problems.

-

Barely two months after we decided to dispose of the spare Squirrel 1410 that we had kept in store (just in case) for at least ten years, the back boiler of the Squirrel installed on our boat has started to leak and has put the fire out! We no longer live aboard and the fire hadn't been lit for many months - this happened when we were staying on the boat last weekend after deciding to light the fire due to a forecast of cold weather. The stove that we kept as a spare didn't have a back boiler so would not have been useful as a source of this particular spare part. Nevertheless, we are now faced with the prospect of replacing the corroded back boiler and possibly rebuilding the whole stove. We have made a start by draining the radiators and connecting pipes, removing the damp ash and squirting releasing agent onto the two connections on the backplate but we would be pleased to welcome advice from those with experience of having undertaken similar work. We are wondering what the best course of action would be: Attempt to remove/replace the corroded back boiler with the stove in-situ, or, Completely disconnect and dismantle the stove so that it can be reassembled with a new back boiler and any other new parts as necessary? We look forward to receiving any useful comments.

-

I have used 'Heldite' on fuel and coolant joints and it has never let me down - it states that it is suitable for gas too.

-

Perhaps we ahould also have a "Roll of Honour" to remember those who once contributed to these great forums but are no longer with us?

-

Oh Dear. Electric DayDream over (Gayton Boat Fire)

NB Alnwick replied to Russ T's topic in General Boating

Well said! And so glad that we can now endorse mod posts with a greeney!