-

Posts

1,246 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Eeyore

-

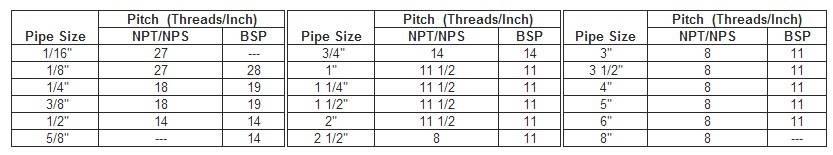

Are you sure that the engine is taped at 1/8" BSP-Parallel?

-

Any use? Thread form and angles vary as already said. The other common instance of “incompatibility” are parallel plastic threads on domestic water pumps labeled 1/2” NPT; which happily accept 1/2” brass BSP fittings.

-

Hot water circuit off engine to radiators and calorifier

Eeyore replied to Emilyandrose's topic in Build Blogs

Some basics, if you need them. Unusual to find an expansion tank on domestic hot water system, but see @Tony Brooks comments. Most engines cooling systems have some form of integral header/expansion, usually part of the exhaust manifold. Additional header/expansion capacity is however very common as it helps with the additional expansion when you have a large coolant capacity. Radiator and calorifier coil (effectively another radiator sitting inside the calorifier tank) are plumbed into the engines primary cooling system (same as car heaters); and subject to pressure as dictated by the pressure (radiator) cap. Opinions vary, but using any "push fit" plastic plumbing on systems subject to pressure from the engine cooling system can create a weak point. -

Maybe something like this would help. https://www.amazon.co.uk/flip-switch/s?k=flip+switch

-

I briefly owned two Brompton clones branded as “Merc”, allegedly illegally imported from Taiwan. Very much a “BSO”, and recycled.

-

Not another oil thread , general service questions ...

Eeyore replied to T_i_m's topic in Boat Building & Maintenance

Its worth noting that the Kubota 03 series engines use an oil filter with a 3/4" unified thread, and definitely not the M20 thread used on the smaller 05 series. Some cross reference resources get this wrong. Also the threaded part of the filter casing should be flat or slightly convex; but never concave as the treads will barely reach the fitting on the engine. I've had a concave filter come off in less than one turn during a service; and there are plenty of stories of M20 filters blowing off into the bilge, quickly followed by the contents of the sump. -

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

Presumably a Blue Sea 9009BSS aka Kraus & Naimer A211 ? So there is a long cable running from the appliance inlet at one end of the cabin to a rotary switch and IT at the other end. Which would need a protection device somewhere near the inlet because it exceeds the length specified in some regulation or another. I've got a head full of Christmas, so someone else will know 🥳

-

The parts list is certainly a little confusing. My experience is that the 1.4kw starter is suitable for the lpw2, lpws2 and lpw3. The 2kw starter being suitable for the lpws3, lpw4 and lpws4. i once lent my spare lpw3 stater to someone with a lpws3 engine; didn’t start at all well. Had it tested when it was returned, it was fine; just not up to the job.

-

Happy is a difficult concept for someone called Eeyore; but yes it mostly feels like my tail has been pinned on in the right place 🥹

-

The HS2 situation remains fluid at Great Haywood marina. The original HS2 plans could be overlaid onto the OS map to show the northern third of the marina disappearing under the base of the HS2 embankment; an interpretation denied by marina management. The revised HS2 plan saw the embankment replaced by a longer viaduct; so no significant loss to the marina. Recently HS2 said it was ok for the marina to have the fenced off area back; but then came back within a day or two to say the marina couldn’t have it back!! I’m still a little surprised by the response received by @robtheplod, a bit more “straight talking” than I’ve experienced to date.

-

Welcome to the "anything but standard" world of narrowboats; the stop cable works opposite to yours on the vast majority of similarly equiped boats!

-

They're a bit of a "Marmite" setup, some very polarised views out there in internet land. I have one as a second/backup sim in my phone. Their access to the EE network is via an arrangement with Now Telecom, its self a virtual network operator on the EE network. Very interesting reading @IanD comments about band allocation, explains why the coverage is "spotty" at best.

-

The railways used Bostik on similar sized hoses fitted to the 1950s built railcars. Done primarily to reduce leakage, and a pain in the a**e to change.

-

The drawing seems generally ok apart from the top righthand corner. Separate isolation of the cabin batteries is a bit unusual. An X-Alt external controller is fitted to the alternator; the split charge relay (simply labeled "relay" on the diagram) appears to be controlled by the X-Alt. 230v ac (at least originally) is from a Red-line rotary converter. You may find that this has been replaced at some point by an electronic inverter. The wiring will doubtless require some age related maintenance/renewal.

-

The relays inside the box occasionally require wiggling/pushing back into their sockets.

-

A little advice for next time: The camera fitted on most phones is not only useful for posting photos of your lunch on social media, it can also be used to take photos of things before you take them apart! The spark might just be the normal reaction of an inverter being reconnected whilst still switched on? It being perfectly normal for there to be a (single) bond between battery negative and the hull.

-

Completely different series of Kubota base engine, but I suppose they're both green and burn diesel 😎

-

Could someone point me in the direction of the "bleed nuts" on the injectors? I'm inclined to think that the "engineer" who penned the report is just covering his ar*e, just like a surveyor really.

-

Constant beep and light illuminated - IM4LB33 Isuzu

Eeyore replied to ElsaRose's topic in Boat Building & Maintenance

The one in the photo is the other side of the engine, probably a coolant drain. -

Ahh, so they no longer bring the beer up from the cellar in a jug? 6X doesn’t travel well, can be crystal clear and still taste like Bass 🤮

-

These are one of the few "designed for 12v" plug and socket designs out there. Fairly robust, and good current carrying capacity. I wonder if anyone has used them on a boat? https://www.durite.co.uk/durite-shop/quality-core-components/equipment-and-accessories/trailer-connectors/caravan-12v/3-pin-socket-and-plug-din-9680.html

-

We definitely need photos in order to make any sense of the situation as described; as the two mounts you mention are different in just about every way possible.