-

Posts

1,249 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by PeterF

-

I have seen several reports on the Victron Community where an MPPT has failed and passed solar panel voltage through to the lithium.battery. With FET based BMS the over voltage can fail the FETs closed allowing overcharging of the cells. A LiFePO4 incident had swollen cells, obviously ruined but not leaking or burning. An NMC incident resulted in the batteries catching fire. I am sure I have posted the LiFePO4 incident on here before.

-

We have just travelled from the T&M to Lymm and on to the breach. There were surveyors with a theodolite and reflector pole working between the breach and Little Bollington winding hole. I have no idea if this was some prep work for the repair or just monitoring the stability of the remaining embankment. It was quite surreal winding knowing that all that is there to keep you afloat are 2 fabric dams. I suppose it is better than 1 dam. As an aside had an excellent meal at "Eighteen the Cross" in Lymm, albeit a bit pricey. We often stop at Dunham Massey and visit the Axe and Cleaver, not to be for a while.

-

And the time we turned up below the lower lock to find several boats in a queue below the lock, the lock full, no boats in sight above the lock and were told they were waiting for a boat to come from the other direction to save water.

-

I should have said Hesford Marine are on the Great Haywood side of the breach.

-

Hesford Marine on the Bridgewater are 2-3 miles from the breach and have a crane. Not sure about any marinas the other side with their own lifting facilities. http://hesfordmarine.com/

-

The first time your prop sucks up a load of grit in the shallows it will clean off 99% of known weed.

-

If they still sell sewing, tapestry and cross stitch kits then my wife will do her bit towards keeping them going.

-

You need to set the tacho calibration, my alternator has 12 poles, the default setting is 2 which is silly. Try 12 poles if you do not have a value for your model then that will divide the rpm by 6. Then you can fine tune the pulley ratio or try a different number of poles.

-

Good news. Glad to help, there is a lot to get right on these.

-

TekDek or other deck covering systems?

PeterF replied to TandC's topic in Boat Building & Maintenance

Had it fitted on a new boat, just over 4 years old now, light grey Flexiteak rather than Tek-Dek. Holding up well, no signs of blistering, does get a bit dirty but scrubs up OK. You can give it an occasional sand if required. The thing I like the most is its non slip nature in the wet. -

The chap who fitted the cover strips on our boat mentioned diluted washing up liquid to help ease it in.

-

I have no idea if the CAN BUS output on the Drift Pro could communicate directly with the Zeus and provide battery temperature via that route. They quote that it can communicate with Victron, if so a GX device should get the battery temperature and I know that the WS500 can get the battery temperature from the GX device via CAN. Without reliable battery temperature to stop the Zeus charging before the battery shuts itself down, your alternator could become a cyclotron generating a self sustaining black hole and suck your boat through the event horizon.

-

Generators hanging off the stern of NB's?

PeterF replied to T_i_m's topic in Boat Building & Maintenance

You also raised the question about propane and 3 way fridges, boats are a hole in the water that is sealed at the bottom and sides. Any heavier than air flammable gas or vapour (LPG, petrol, methanol ( just a bit jeavier) etc.) will just collect in the bottom of the boat until it ignites. This is a fundamental difference to vehicles and caravans and needs to be understood. This is why you should not decant petrol on board, keep petrol or LPG where it can accumulate, not use portable LPG appliances on board, only use LPG equipment with flame failure detection etc. -

Go to Waterside Moorings website, the CRT mooring page and download the standard t&c, nothing shall be placed on your mooring without permission, pretty clear cut and standard. Some sites come with permission for a small lock up cupboard. As to enforcement if you do erect something without permission, that is another issue.

-

It can be made to pick it up from Teltonika routers, large thread on the old Victron community if you know about scripts modbus TCP etc. I don't know anything about this, I have a RUT X11 with gps, which gives good coordinates to my phone, the Cerbo has a Globalsat USB GPS connected. https://communityarchive.victronenergy.com/questions/17470/venus-gx-to-pull-gps-coordinates-from-onboard-rout.html

-

Beware, if you have purchased a SmartShunt for the alternator then you do not want to connect this to the Cerbo because then you will have the alternator current measured twice, once by the SmartShunt and once by the WS500 connected to the SmartShunt. This will cause all sorts of problems with the Cerbo. That is why I linked specifically to the dumb shunt.

-

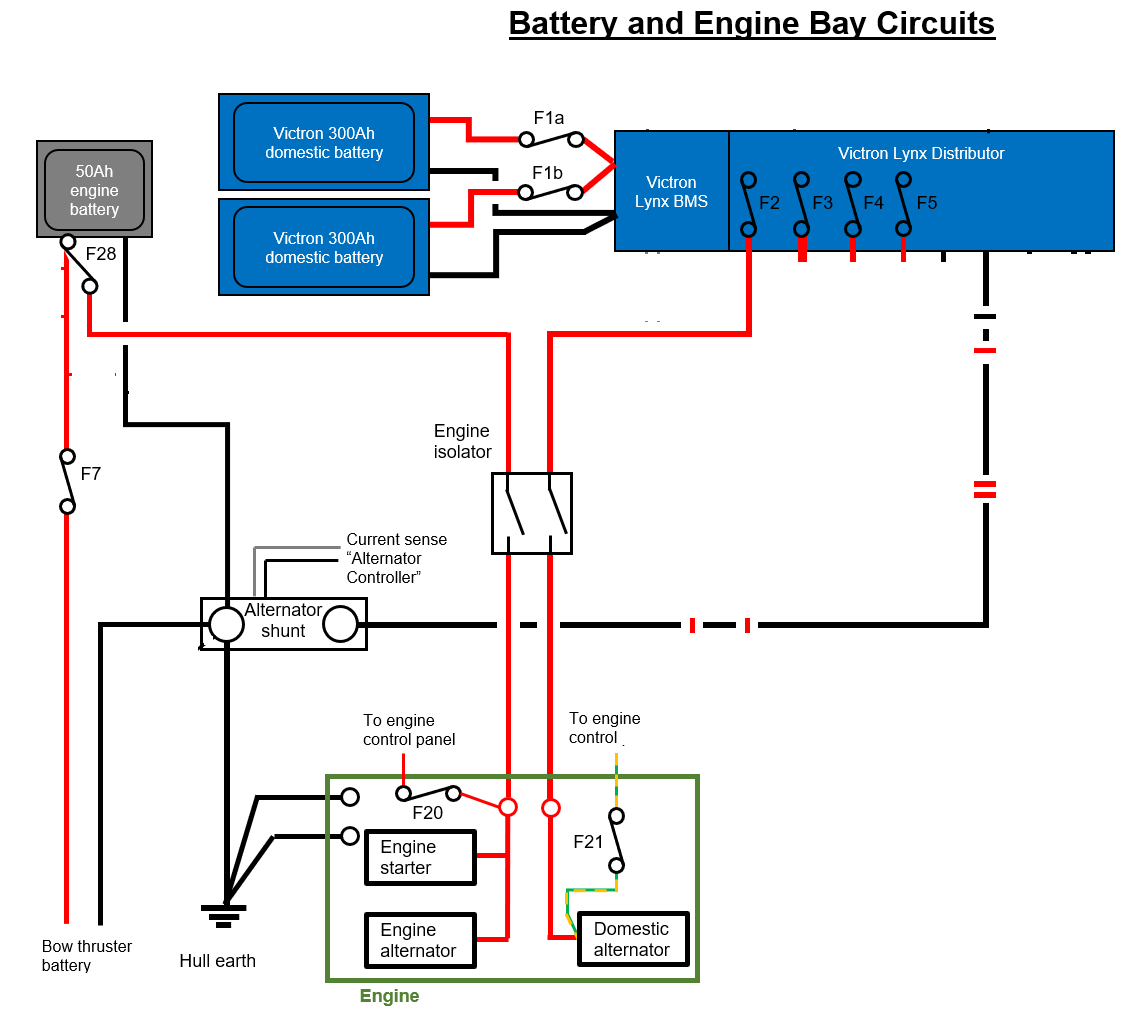

if you would like to know what the alternator is doing then yes you can fit one. You only need a dumb shunt, I purchased Victron part number SHU500050100 link below. Victron dumb shunt SHU500050100 If you can fit it in the negative that is great as it does not need insulating and the sense wires do not need fusing, I managed on my set up. If it has to go into the positive then it needs to go into an insulated box or cover and the sense wires need 1A fuses. Then the changes to the settings covered above will be needed. I ran for a while with AGM non managed batteries with the WS500 picking up the battery current from my BMV702 via the Cerbo using the Victron SmartShunt in the CAN protocol mentioned above. Now I have swapped to BMS managed Victron batteries I still get the battery current via the Cerbo from the BMS, it works just as well as directly measuring the current so no problem losing that input and having the shunt at alternator. One advantage if you have the alternator shunt is that you can set the alternator max current, say you have a 100A alternator and find the current gets limited to 70A by the temperature control, then you can set the max current at 65A and it will control to this. I have my Iskra 175A unit set to max 120A in the WS500 settings. You can then also use DVCC if you wish but I am not 100% sure if it would do anything with non managed batteries. Here is my wiring diagram with alternator shunt in the negative, both alternators 12V, you will need to work yours out.

-

OK excellent news. Regarding your points 1. Cerbo GX data. Earlier you said you had an alternator box, so comms were good, presume this remains the same but you have no current measurement data. To get the alternator current you need a shunt to measure the alternator current, bit your description did not include one. You need another dumb shunt to measure the alternator current and connect the WS500 shunt wires to this and swap the shunt setting from battery to alternator. Then you need to tell the WS500 to use the SmartShunt. The setting "Alternative CAN / BMS protocol" must be set to Victron SmartShunt. 2. You have a negative DC load which is a charging current. Because the Cerbo can not see the alternator current it assigns any unmeasured charge current to the generic DC system. This is normal behaviour. Unless you have a shunt to measure the alternator current this is how it will work. 3. Increase the WS500 setting "number of alternator poles" and/or pulley diameters until the readings match. You can divide the indicated rpm by the actual rpm to give you the factor for correcting the number of poles or pulley diameters. When fitted with an alternator shunt you will see

-

The 14.4 / 13.6V is fine for SLA. If the re bulk voltage offset is 0.4V, a dip below 13.2V will restart a charge cycle so any time you use the bow thruster essentially. Leave it in adaptive absorption.

-

ABYC (American Boat and Yacht Council) wiring rules state the main fuse should be within 7" of the battery terminal, but I am not sure about "not within the battery box".

-

Yes, that is the output battery. It populates defaults for the absorption voltage etc. Input battery is all dealt with under engine shutdown detection.

-

As far as I knew Mahle had stopped selling the dumb brush holder, perhaps Beta bought up lots of them. Pre Covid you could buy a new regulator on ebsy relatively cheaply and cut off the regulator. That option no longer appears available. Soldering hidden under woven glass sleeving. Used lead free solder per Nick's advice.

-

WS500 user here, works a treat but it is a complex thing to set up. Is your BMV712 monitoring the battery. Does the battery communicate with the Cerbo, is DVCC controlling. If the BMV712 is monitoring the battery is this receiving this by the WS500 via CAN settings. Is the WS500 shunt wiring connected to a shunt. Do you have a battery temperature sensor or are you getting this from the Cerbo. You will not see any charging information on the Cerbo because to see that you need a dumb shunt on the alternator to report the alternator amps. You should still see field, rpm, alternator temperature etc by clicking on the alternator box to get to the devices menu. As the alternator box appears you have the CAN cables working. RPM being registered is key. You can also monitor on the app when it is running. You could post the content of the text settings file here, this can be exported from the app and emailed to yourself. There is a good Facebook group WS500 Facebook group Some potential issues have already been listed, here are more, brushes vs harness polarity rpm not being registered not seeing any battery current if relying on the Cerbo wrong shunt setting no temperature from the battery Settings for required readings not matching with installed readings Feature in wire not set correctly so this is shutting the device down. More info on WS500 set up re shunts and the text settings file and I will have a look.

-

It is really hard estimating anything from those auto ranged charts on the phone app.

-

From the numbers on the screen you mentioned 2% tail and it looked like about 8A so 400Ah, but as Tony says it was just estimated rather than exact.