-

Posts

557 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Quattrodave

-

Isuzu 55 Marine Engine Coolant Emptying...

Quattrodave replied to Quattrodave's topic in Boat Building & Maintenance

Thank you, I've had a look and yes there does seem to be a bit of a trend! This one has a temp guage the reads accurately, holding about 65 degrees all day long.... Yes, I've seen this before. Had the waterpump refurbished with new impeller, seals and bearings! Ooooh interesting! Where did you source the parts from? Is there anyway of telling if I got a modified head gasket or not? Ah, so they ARE stretch bolts, I did suspect they were...! -

Ha! Go you, jammy bugger, I bet your over the moon!!

-

Isuzu 55 Marine Engine Coolant Emptying...

Quattrodave replied to Quattrodave's topic in Boat Building & Maintenance

Thanks guys, Tony: hmmm good thought, might be difficult to seal everything, what sort of pressures would i need to test to? Yes manual specified a sequence first torque setting, second torque setting & final 90 degree. Now here is where its gets a little sketchy, we didn't use new head bolts... The reasoning, genuine suppliers had the top end gasket sets but not head bolts, they we're available to order from Isuzu. The suppliers had them listed as 'head bolts' not 'stretch head bolts' they them selves were surprised at this and couldn't tell me if they were actually stretch bolts or not, they concluded they were not stretch bolts. The last reason was they were asking £28 per bolt!! With a 6 week lead time!!!!! I didn't see any sign of a liner protrusion, unless it's been machined off many years previous. Tracey: yes previous one defiantly did, I do hope this one does too.... -

Isuzu 55 Marine Engine Coolant Emptying...

Quattrodave replied to Quattrodave's topic in Boat Building & Maintenance

The saga continues.... It's done the headgasket again, well I assume it done the headgasket, I have exactly the same symptoms as before huge amounts of air bubbling out of the coolant cap... I'll be taking the head off again in a week or so but any reason it would have failed again so soon?? Genuine gasket set used, head was skimmed, manual removal and tightening sequence follows to the letter, everything was cleaned, checked and double checked on assembly. One thing that's playing on my mind, the manual never mentioned re-torqing the head bolts after x amount of time... many years ago I was taught to torque head bolts, get engine hot, let it cool then re-torque... problem is I can’t remember how you re-torque. Just test the torque on each one, slacken and re-torque, or loosen by a quarter turn and re-torque...?? -

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

Nearly all victron units have programmable outputs. Program the output go high when the charger goes into float (batteries charged) this can then switch a large relay to turn your dump load on.... Edit: I was just looking for the setting on a Smart Solar Controller so I could screen shot it.... I can't find it... I'm now wondering if its available on the Smart Solar Controllers.....

-

If you fit a dual voltage (12v & 240v) immersion element could you use the 12v immersion as an MPPT dump load?

-

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

I'd be careful there, if AI can already create 'deep fakes' i wonder what it can do in say 10 years...

-

I was expecting much bigger and many more panels.... You can easily get 3kw of solar on a wide beam.

-

The only pub I can think of is the fish and duck on the junction of rhe old west & the cam...? IIRC there's a campsite near Stretham Old Engine...?

-

Where abouts in the UK are you located? I take it you'd prefer to be able to go in and talk to the engineers as opposed just post it off to one and try and explain it by phone?

-

Have you managed to find a replacement for the, I'm guessing, rubber center part. If so I'd take ut to a decent engineer, I see no reason why they couldn't weld on new lugs / pegs or what ever you want to call them...

-

Yeah, that's a fair figure...

-

I'm in the process of a major refurb, full wiring, plumbing, walls, floor, windows, ceiling, engine & gearbox. I thought it would take me 2 years to do properly so far it's been 4... but we did have lockdown in the middle of it. I've been working on it nearly every weekend... and I recon I have another year till its done.... The big problems I've encountered are working space, deliveries not turning up on time and the really annoying way that plans morph and change as you go on... Costs.... well don't even go there, everything marine is expensive, marine plywood, marine paints, stainless screws, stainless p clips, stainless pipe clamps, adhesives & sealants, tinned cable, fuseboards, breakers, chargers, batteries, water pumps, bilge pumps, fixtures & fittings, fridges, cookers, tools & more tools.... the list is endless.... If you want to do it yourself fair play but bare in mind you're taking on the job of every trade! I'm not trying to pit you off just want you to know what you're getting in to... The sense of achievement at the end it's awesome, when some one says 'oh wow that looks great where did you get it / who did it? You can reply 'Me, I made it...'

-

Isuzu 55 Marine Engine Coolant Emptying...

Quattrodave replied to Quattrodave's topic in Boat Building & Maintenance

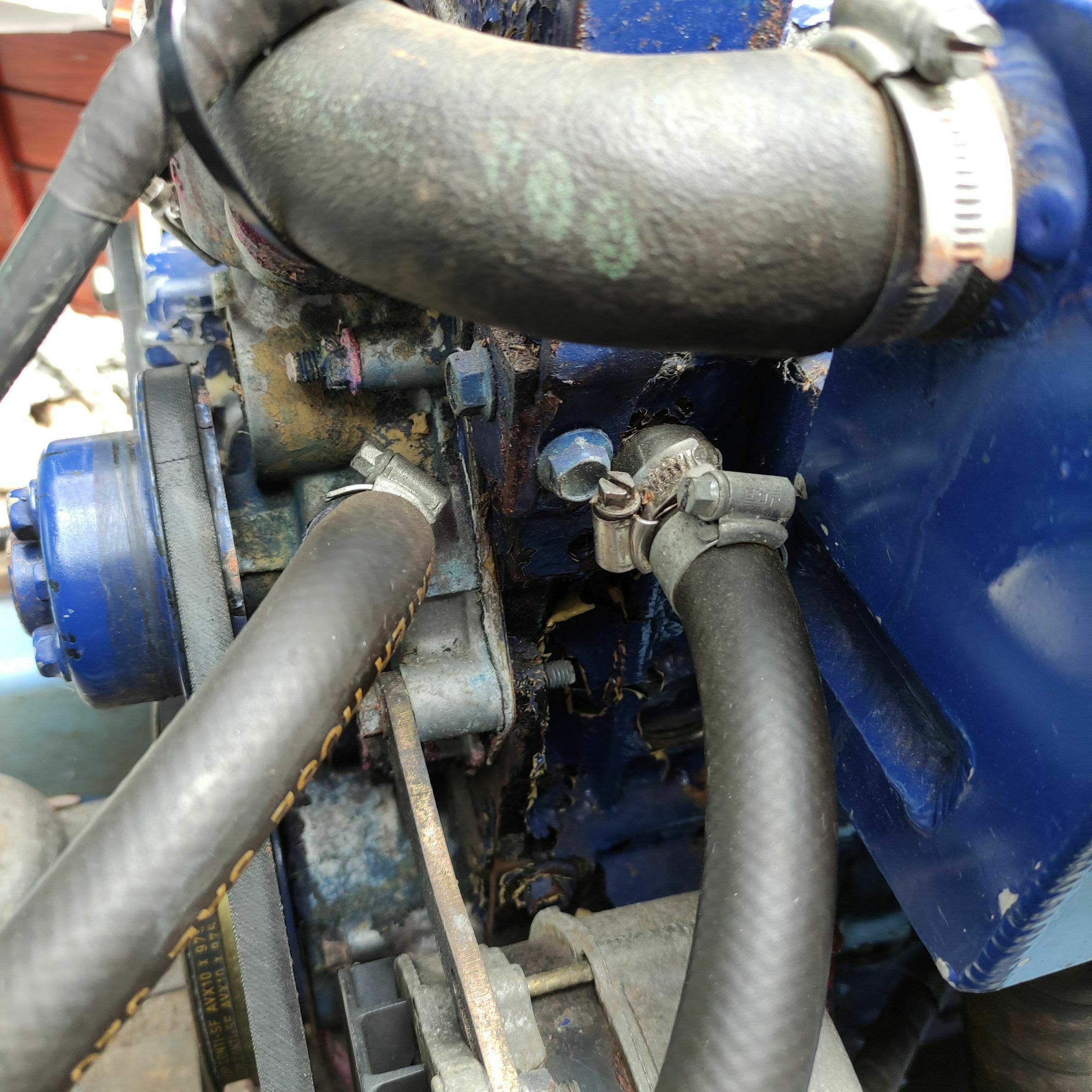

Just to clarify, it's not a Jabsco type pump with a rubber impeller, it's the factory engine coolant pump. The calorifier is connected (as far as I can tell from the manual) to where the heater matrix would be which is not skin tank side of the thermostat. Image curtesy of blackrose but engine in question is exactly the same, photo is much better than mine: Tony, what do you say that, not arguing or disagreeing, just intrigued? Thanks -

I don't doubt you, but that doesn't seem fair... what if I'd purchased a doer-upper spent a number of years completely refitting, surely the boat would be worth vastly more that the original price... or have I mis-understood?

-

Isuzu 55 Marine Engine Coolant Emptying...

Quattrodave replied to Quattrodave's topic in Boat Building & Maintenance

Perfect, thank you!! -

Isuzu 55 Marine Engine Coolant Emptying...

Quattrodave replied to Quattrodave's topic in Boat Building & Maintenance

Good shout, TBH I'm very tempted to remove it and send it off for refurb anyway... New bearings and seals won't hurt... -

Isuzu 55 Marine Engine Coolant Emptying...

Quattrodave replied to Quattrodave's topic in Boat Building & Maintenance

UPDATE: After far too much time I've eventually got round to doing some work on this engine. I was pretty sure the had gasket had gone and the coolant was being pressurised by one ot more cylinders. I cut the bottom out of a large fizzy drink bottle and wedged the bottle neck into the engine coolant filler neck, basically to act as a bug funnel. Topped this up with water and started the engine.... wow, massive bubble just kept coming up through the make shift funnel and it would not bleed or slow down.... Now convinced the head gasket was faulty I ordered all the parts up to do the job. Removed the head, actually not a bad job, nice engine to work on. Ah ha!!! A few areas of the headgasket didn't look in great condition, sent the head off to be skimmed, apparently wasn't far out at all. Cleaned everything up & re assembled the engine as per workshop manual. Engine started pretty much first time, was rather pleased with my self and packed up for the night. The next day I used the make shift funnel again to bleed the coolant system, muchmuch better this time, no air continually bubbling through it! Engine running to temperature with no issues, bled the calorifier, no apparent issues, engine still running fine.... just can't get any hot water.... Sooooo after a bit of head scratching and a fair amount of testing the coolant pump only seems to be pushing water through the calorifier when engine is over 1200 rpm... Even then its an unsteady trickle... Have I got a lazy coolant pump... could a lazy coolant pump have caused the head gasket to fail...??? Thanks Dave. Edit: If anyone has got an isuzu 55 with a calorifier, would you be good enough to take a pic of the take off and return engine side please, thanks. -

Thermostat for cocooned engine air extraction

Quattrodave replied to CanalRetentive's topic in Boat Building & Maintenance

The engine it's self can endure well over 90 degrees c, what can everything else in the cocoon endure? If it was me I think I'd be aiming for 65 to 70 degrees, I'd also be careful of the temp switch hysteresis else it would be cycling the fan on and off. Most cars that I've seen with after run cooling fans also have electric coolant pumps to circulate the engine coolant whilst running the fan. Can you not use some sort of 'chimney' and make use of convection to cool the engine cocoon? -

Yes, I have one, they work well but as Alan said they need installing properly on a boat. I threw all the ancillaries out, keeping the main heater and installed with parts that were fit for purpose & passed BSS. Total cos just under £500. Oh and I also used an 'Afterburner' controller.... if you're in IT you'll like the 'Afterburner'...

-

Is this cheap enough? https://www.ebay.co.uk/itm/284833053610?hash=item42515f7baa:g:9xIAAOSwQBtikhb4 Plug in fuel, pull and away you go... if it runs well I'd keep as a spare. You could even fit a drop bracket (I assume it hasn't already got one).... Edit: Even cheaper one.... https://www.ebay.co.uk/itm/134120829171?hash=item1f3a3970f3:g:w9EAAOSwC1ZicDKh

-

A lack of punctuation makes it a little difficult to workout exactly what you're after. Are you after a free outboard, advice on what outboard to get or advice on where to get an outboard? Edit: Also, how far along this project are you? Commercial insurance, commercial river licence & commercial safety certificate all sorted? Not wishing to sound harsh but if someone was to donate an outboard, quite feasibility a good few thousand quids worth, I assume they'd want to know the project was taking shape and not just a whim....

-

Outboard engine stalls when putting into gear.

Quattrodave replied to Dockeroo's topic in Boat Building & Maintenance

When in neutral, can you turn the prop by hand...? Cancel that, I've just re read the above post....