Split Pin

Member-

Posts

243 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Split Pin

-

The head gasket on LW's is a 12 thou stainless steel shim which seals the combustion chambers, so the flatter the head is the better, the water ways are sealed with "o" rings. LW's have a tendency to weep oil from the push rod side of the joint as the contact surface is only about 3/8" wide, a light smear of jointing compound helps in eliminating the oil leakage. I have surface ground both 2&3 cylinder heads without any problem, if you decide to get your skimmed find someone that can surface grind it rather than fly cutting on a milling machine as this removes more material and leaves a rougher surface finish. The shims that you cannot find are generally unavailable, they are used between the block and crankcase to get the piston height within the specified range. Steven

-

Lock 3 Wolverhampton 21

-

Any hope of finding this engine's history/number?

Split Pin replied to bigoltubosteel's topic in Gardner

Yes that is where you may find a date. The E4934 is a casting ref number. The other position is on the back of the crankcase as per the picture in this case the engine build was tested in May 1952 -

Any hope of finding this engine's history/number?

Split Pin replied to bigoltubosteel's topic in Gardner

Kromhout built engines under licence from Gardner's as far as I can ascertain the first engine was a 4LW serial number 6970 delivered in September 1933. Gardner's had previously licenced a little end design from Kromhout for use in the "T" series engines. So there was some previous collaboration between the two companies. I think that Kromhout purchased some raw castings as part of the agreement, then finished machining them in house, Kromhout did have ideas of their own and did use their own versions of things like injectors. They also used metric fasteners, in some cases they had Whitworth hexagon sizes. In 1935 Gardner's licenced 50 3LW's between engine numbers 7391 and 7758. So that is the range of number that you need to find to confirm it as a 1935 build. Another place that you may find a number or date is the flat surface above the starter motor mounting, or on the back face of the crankcase, usually only visible when the engine is stripped. Gardner's stamped the crankcase with its test date which is usually a little bit before the delivery date. Kromhout built engines usually have "Kromhout" aluminium covers on the cylinder head although they could easily have been lost/changed for Gardner ones. As regards the sump Gardner's listed 3 different sumps for the 3LW they all look to have the same capacity of 3 Gallons. Neither your boat name of engine appear in the GEF membership list so it looks as if the previous owners were never members. If you can find another number I may be able to find more information if it is a Kromhout built engine. For comparison a Kromhout 3LS which utilised a LW block on an L2 type of crankcase, one of the variations that were produced. Steven -

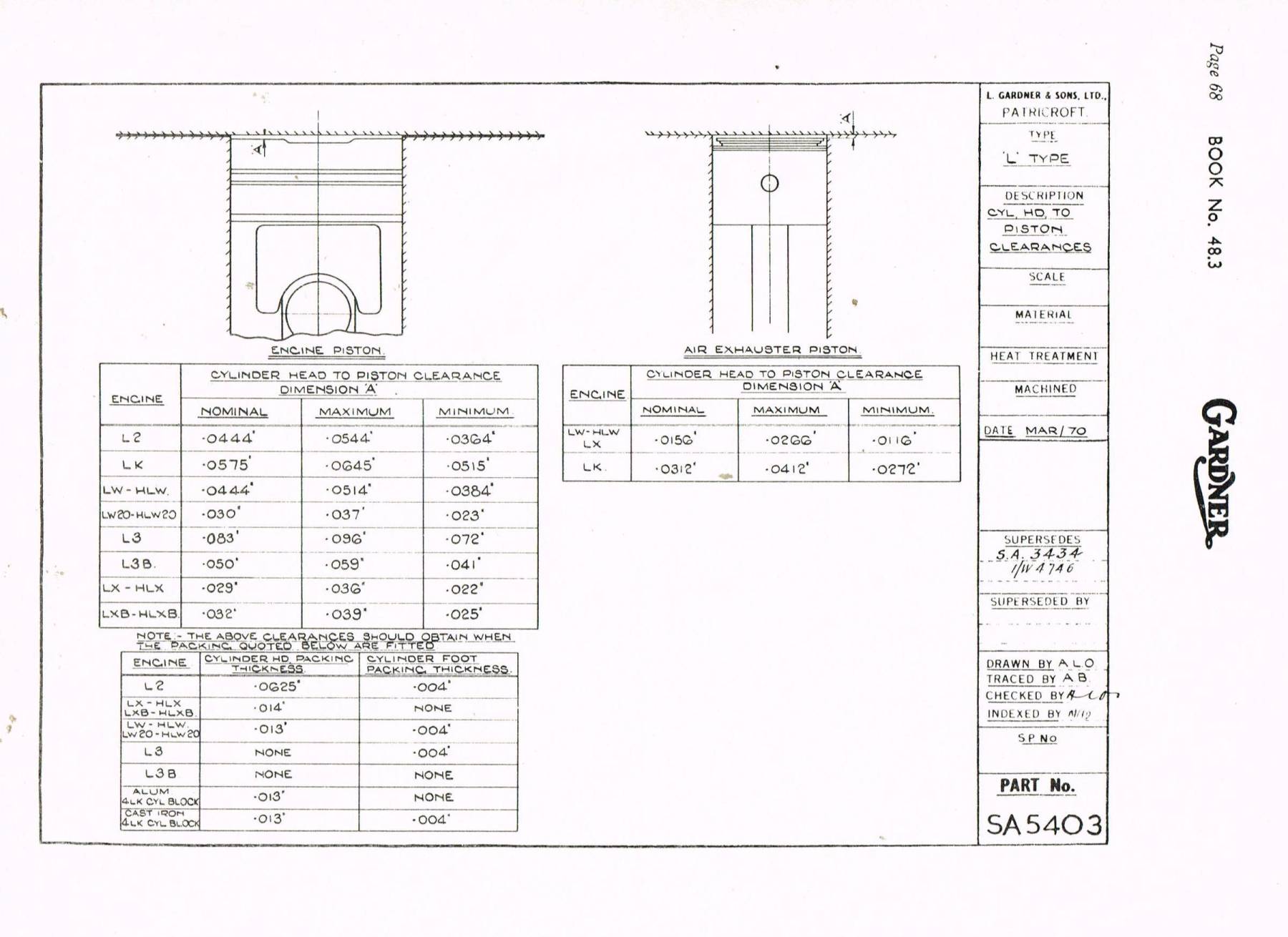

Chris's copy of the clearances is an old version, they were revised giving slightly more compression. Skimming the top of the pistons is not recommended, you would need to recut the valve pockets as well. Due to the shape of the skirt they generally cannot be held in a standard 3 Jaw lathe chuck. (Extra long jaws are required). Far better to make a paper/card gasket for the bottom of the block to compensate. As john.K says you will probably be able to remove the block manually but to refit you need to be able to lower it in increments to get each piston back into the bore. one ring compressor clamp will do the job. Keeping the piston square to the bore and getting the rings to enter needs more than one pair of hands !!! Best of luck.

-

The seals very rarely fail, I have used them more than once without any problem. The head gasket is a 12 thou stainless steel shim which is fairly non compressible. liners should be level with the top of the block. It may be that the head wasn't tightened down correctly. It may be possible to just replace the head gasket and seals, but in the long run it will probably fail again unless the head and block are skimmed.

-

There is a banjo on the other end of the pipe. That is what he is looking for so that he can make up a new pipe

-

Search Stafford Vehicle components Fuel pump supplies you will find a variety of sizes Steven

-

0-2-4-6 BA Combination Spanners are shown here https://www.drapertools.com/hand-tools/spanners/ba-spanners/ Relying on the spanner size to identify a bolt size can be misleading, 10years ago Tim Leech was trying to ascertain the correct fixing for the two parts of the pump body As I had a spare pump and the means to check the bolt, it turned out to be a 1BA bolt with a 2BA size Head It is not uncommon to find non standard combinations of shank and head size OD is 0.207" pitch measured with thread gauges is 28 tpi 1BA is 0.2087" OD and 28.2 tpi As the pumps were British made I would have expected it to be to a British Standard of its Time Having said that the head size is 0.321" AF which corresponds to 2BA. So using 2BA bolts wouldn't look out of place, neither would M5 as the head is pretty much the same size, (0.315") There are other anomalies with the pump top itself the inlet fuel union bolt is M18, if the holes are drilled for the fuel stock locking plates they are M8 the nuts on the stud are 5/16 Whit and if I remember correctly the rack bushes are M20, The Injector pipe nuts at the pump end are M14 despite the fact that they have a 3/8" Whit Spanner Hexagon

-

The tightest bridge is probably Whittington Horse Bridge, doesn't help that its not square to the canal so has to be steered through.

-

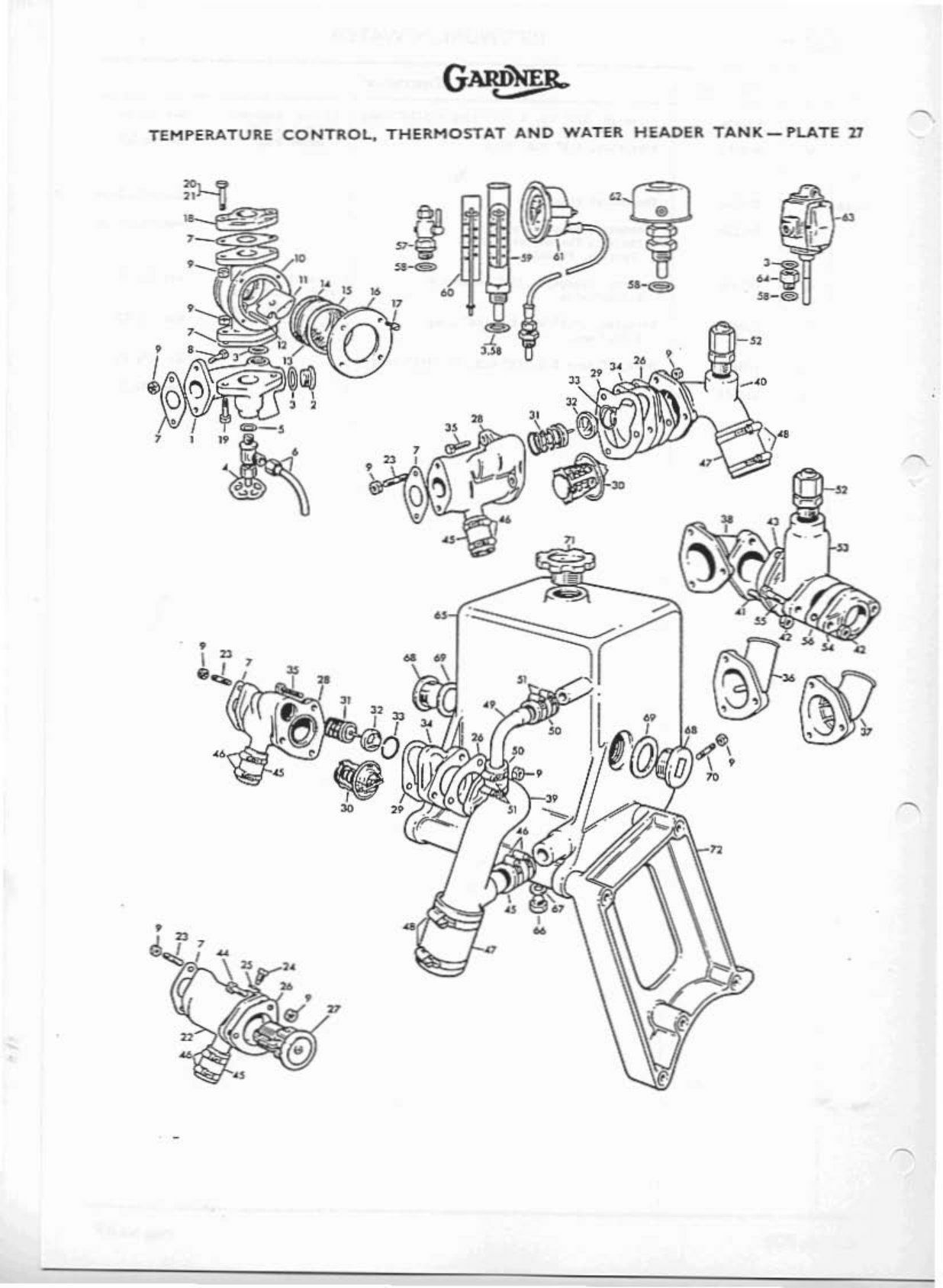

That is the later twin thermostat type, so the one I linked to is the correct type. Are you looking for one that is a different temperature to the one that you have in? This is the correct type https://gardnerspares.com/product/74-degree-thermostat-drop-in-unit/ It says its for LXB but the housing that you have was used on both the LW,LX and LXB

-

It depends upon what type of thermostat housing that is fitted, if it is a a single type then unless it has been modified then it has a different type of thermostat with the bypass cut off as a sliding vane attached to the outside (No 27). They are larger in diameter than the twin housing which uses a smaller one (no 30) more commonly found in older vehicles (2" dia from memory.) The later type https://gardnerspares.com/product/74-degree-thermostat-drop-in-unit/

-

It does help when you have lived in the area for a good few years, another image taken by the late Alan T Smith M.B.E at the 1962 Rally, the yellow pontoon conversion was our family boat. so I had a bit of ahead start.

-

Foster & Rastricks Iron Works, home to the Argenoria, now the site of Lion Heath Centre housed in part of the old building An earlier image

-

Most likely Bob Derricott as he owned Seaford at that time, a picture would allow confirmation.

-

As I remember the estates department was in the same building maybe before it became the shop, I remember visiting there probably with my father for something in the 60's or early 70's Steven The George is one half of the Dudley Canal Trusts replica of the double ended Gorsty Hill Tunnel tug that was built for use on the tunnel trips, it wasn't successful so was converted to two separate boats I think by Dave Harris the other half being William, both still in current use.

-

Alfred Matty's Yard at Deepfields, Coseley

-

Make sure that the rack is returning properly, if you leave the stop lever in the stop position after stopping the engine there is a good chance the rack will stick, especially if it has a low tension return spring fitted to lower the tick over. It is pretty much impossible for the fuel gallery in the fuel pump to empty to a point where the engine will not start, unless there has been a catastrophic failure within the pump body. They will run on the fuel in the pipe from the filter for about 60 seconds. Are you using the cold start?

-

Prior to its restoration the Stourbridge Canal had some fixed windlasses on (lock 9) the upper double lock which is next to what was a canal company house, so probably housed a lock keeper. They were single start paddle gear so were fairly heavy in comparison to modern reduction gearing.

-

The bridge number appears to be 01 or Q1, I only have a photograph to work with. It is a brass plaque It is one in a friends late husbands collection which her sons are mounting on a board for her as a memory. I have asked if there is anything on the back. I will add any further information which comes to light. I find it odd that there is no date or organisation on it. Steven

-

-

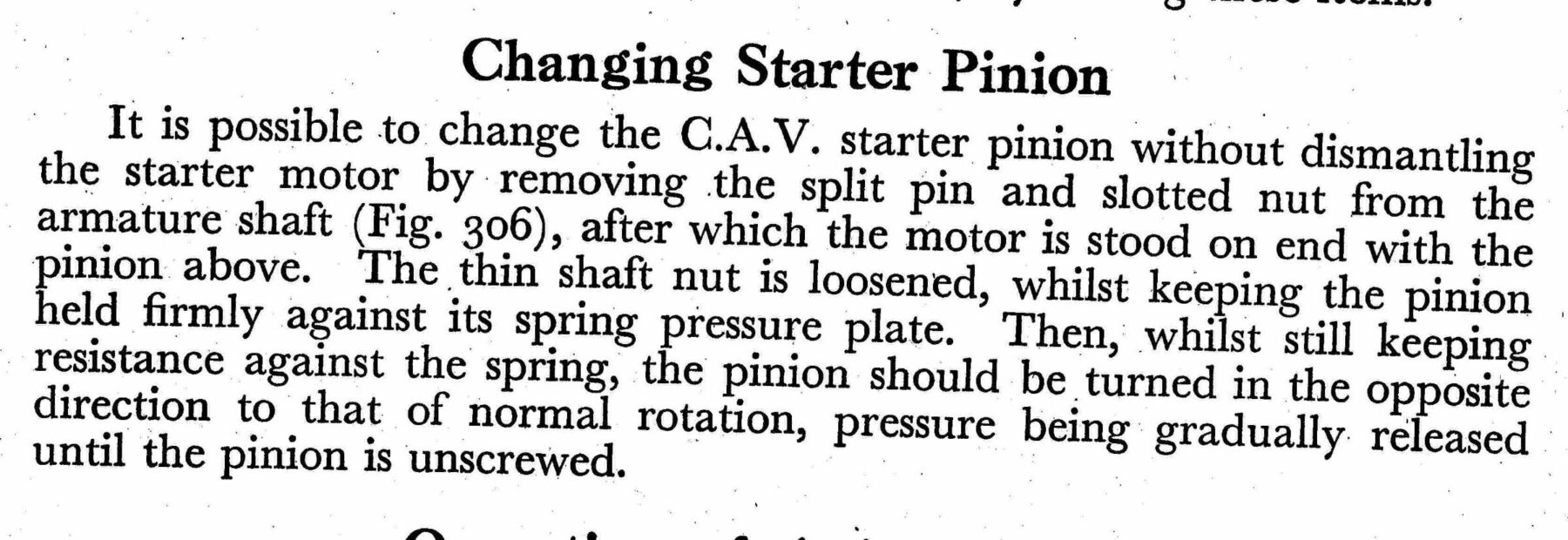

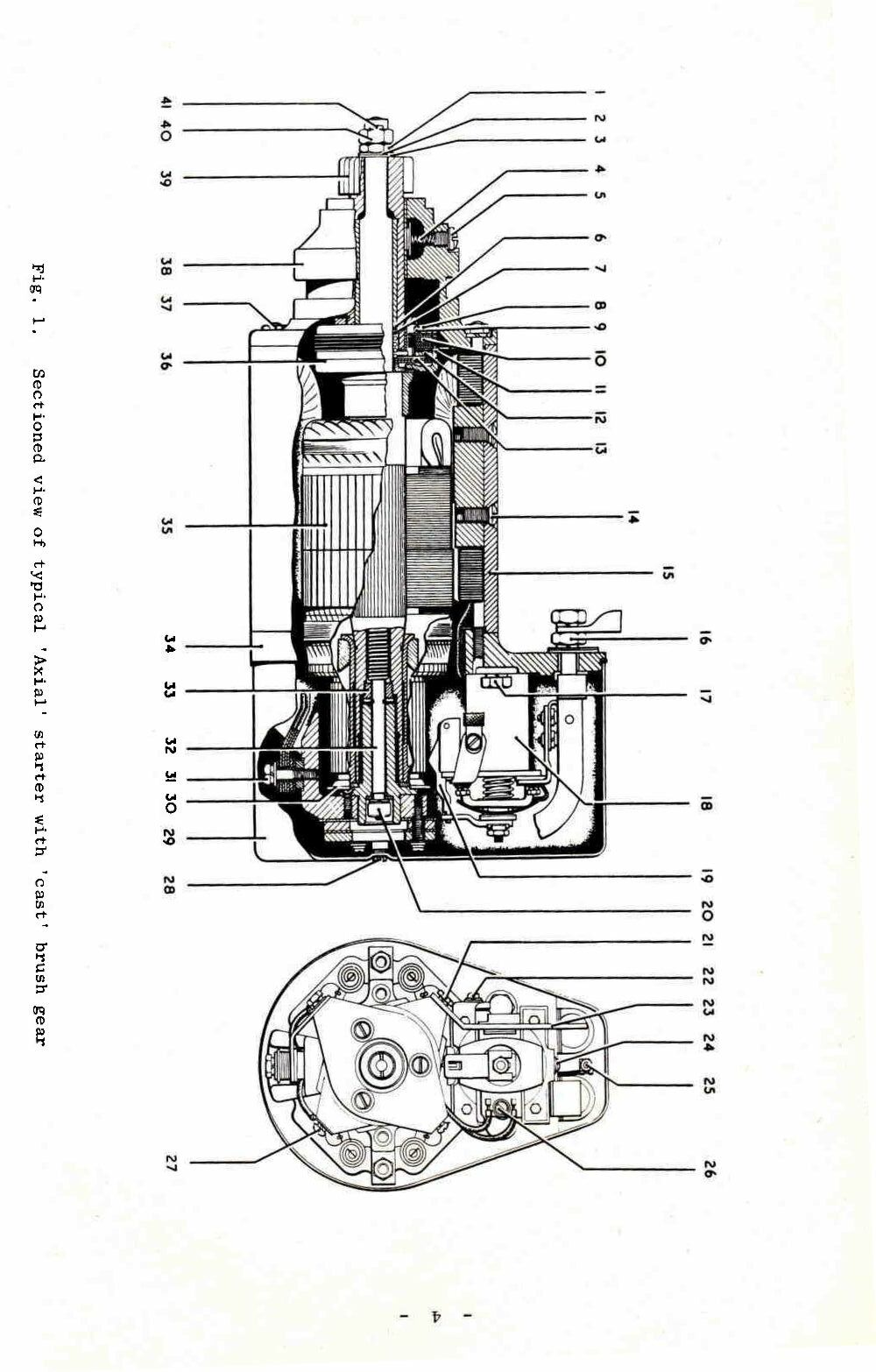

I would agree that it looks like a spring and oil pad but there is an oil cup shown behind it. Non of the ones that I have dismantled have had a spring just a short screw to allow oil to added, so it can possibly be ignored. I have dug out the book from which the picture was taken and there is no mention of the need to remove the items. Text from the book.

-

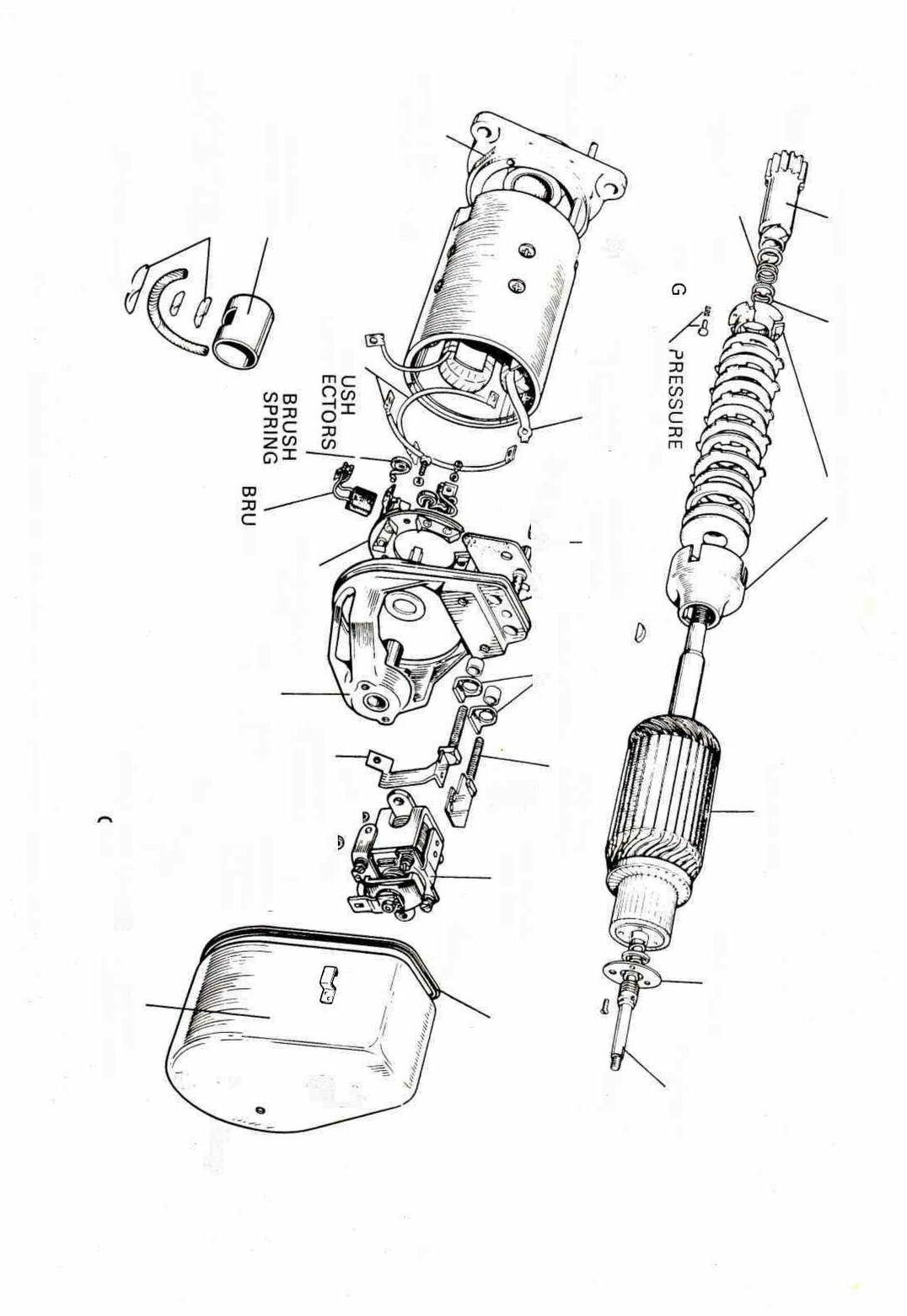

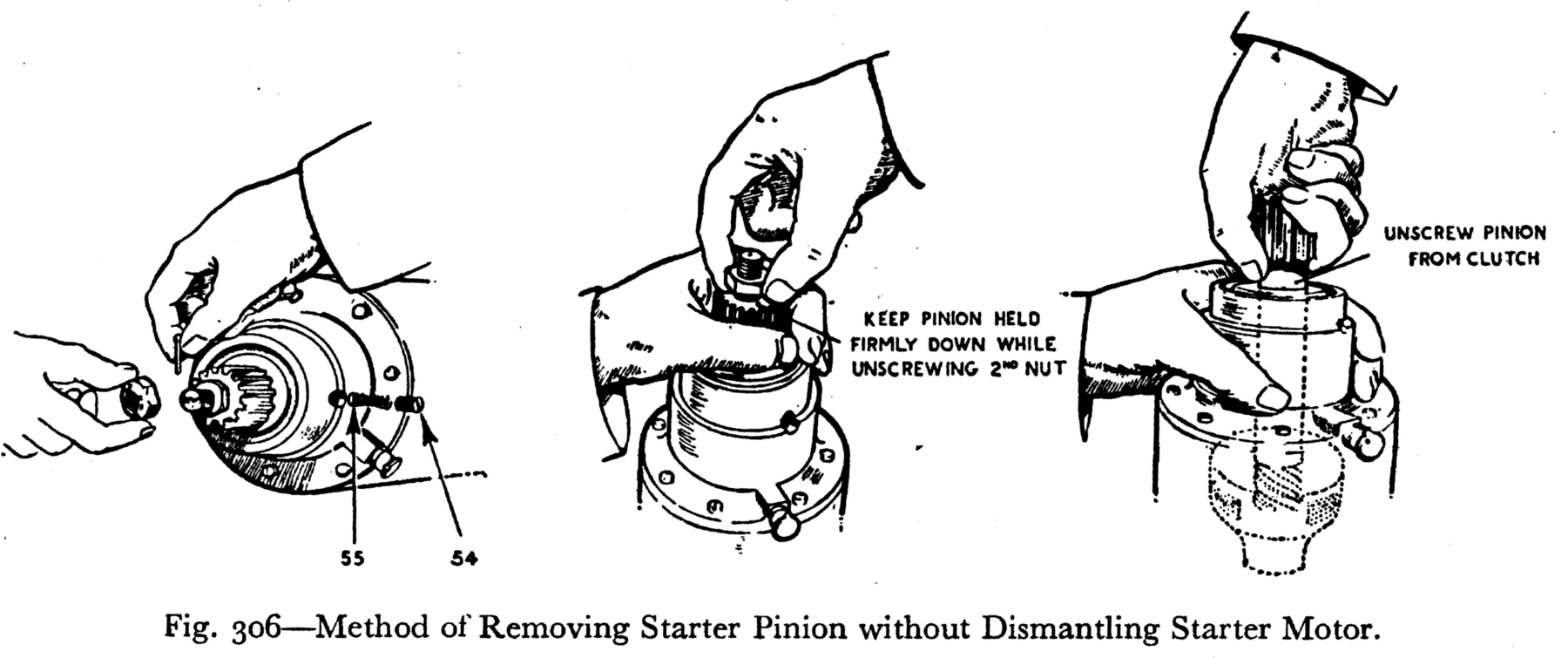

They are manufactured with both insulated return and case return, and they both have the two terminals. i have dismantled a number of these units an have never encountered those items, but if they are there then I would suggest that they need to be removed before removing the pinion. The illustration is from a book published in the early 1950's so may be applicable to units manufactured in the 1940's. Another couple of pictures that may help

-

A picture makes it easier to explain. Best to stand the starter upright so that the clutch plates remain in position. The pinion should be 1/8 inch away from the ring gear when set correctly