-

Posts

1,153 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Eeyore

-

Engineering officer: How long will it take? Tiffy: About 2 hours. Engineering officer: You've got 10 minutes before we sink. Tiffy: Ok, I know a bodge that'll work, if I can get hold of a sanding block in the next 10 minutes. Beyond that I'll be sticking to established engineering methods; "v" belt drives have been around for about 100 years, so we must have been doing something right all this time.

-

Are you a belt retailer looking to improve his sales figures?

-

I have retained the original 50amp ND alternator on my Mitsubishi, very difficult to keep in line when adjusting the belt. Often see other engines where the front face of the boss on the engine worn to a taper; no hope of alignment once that happens. Thorneycroft and Barrus had the right idea and bolted a fabricated mount to the pto flanges.

-

A thick steel washer under the head of the through bolt will also help stabilise things. The legs on the alternator are thick enough in their normal use, but a bit on the thin size for this type of arrangement, hence the note on leaving the through bolt fairly tight during belt adjustment. You don't want to be trying to pull the alternator back into line using the through bolt after tensioning the belt.

-

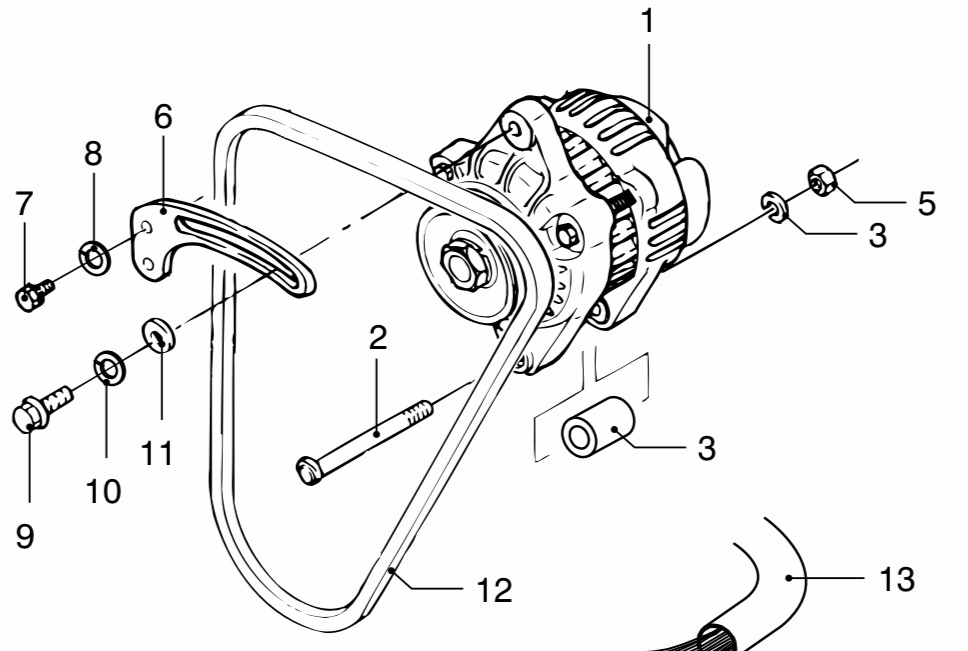

Have a look at this extract from the Vetus parts manual for their Mitsubishi engine range. The front leg of the alternator is clamped directly to the front of the mounting lug on the engine by the action of the sliding bush in the rear leg acting on the spacer (3). The front leg is clamped to the engine, and the rear leg is supported by the sliding bush. The bush is roughly the shape and size of a cotton reel, and needs to be long enough to prevent the sliding bush from falling out of the rear mounting leg when the bolt is tightened. The alignment must be adjusted after the alternator is in position, adding or removing washers from behind the pulley. When tensioning the belt you need to leave the through (2) bolt just loose enough to move (with some effort) the alternator, minimising the chances of the alternator twisting on the mounting.

-

I'm curious, did you source an A127 with the same single bolt (pivot) mounting; or is this an improvised mounting using the far more common two bolt mounting A127? The question is of course to do with the belt and pulley alignment. A second, less common issue can caused by running a very tight belt on the usual two piece pressed metal pulley. The pulley can flex and widen whilst running and cause accelerated wear. One piece machined pulleys are available.

-

I refer you back to my previous post regarding the pump impeller, which if stationary doesn't allow water to flow through it, unless it's very worn or missing a vane or two. By all means close the valve, but please, please put a notice next to the ignition switch!!! Missing vanes usually find there way into the end of the gearbox heat exchanger before the smaller parts migrate into the main heat exchanger within the exhaust manifold, so you'll need to remove a few pipes to check for bits.

-

Possibly related to your previous post about overheating, so maybe a head gasket. Did it hydraulic to a stop whilst running, very bad; or did it simply refuse to turn over when you came to start it? The brass pump that you removed for access to the belts has a rubber impeller inside. The rubber impeller is a consumable item, and as such should be renewed annually, this is the manufacturers recommendation. You didn't come back to the forum to update on the overheating issue, were you able to restore the raw water supply?

-

And an apology to whoever fitted it, the wiring isn't elegant, but at least it addresses the bodge committed by the manufacturer.

-

Is there a drain due to the warning lamp driver on some alternators with separate ignition feeds?

-

Manual http://www.canaline-engines.co.uk/wp-content/uploads/2019/04/Canaline-Operators-Handbook-CE-Version-3870T.pdf.pdf Interesting to see that the aux/domestic alternator is sensed from the start battery, hence the short black wire to sort that.

-

The small black wire is a bodge to replace the feed from the domestic battery. A common arrangement is to have an ignition controlled relay to switch this feed from the domestic battery. Have a look in the spiral binding for the remains of the original cable, and look behind the control panel to see if there is a relay in there. There are often extra wires alongside the multiway loom plug to accommodate this.

-

Do bigger fleas have lessser fleas?

Eeyore replied to Man 'o Kent's topic in National/Russell Newbery

So chaps, why does the engine motor over when only the terminals of the r/h solenoid are shorted? Seems as though something else is providing a negative for the starter? My Canalstar used the armour on the fuel lines when someone’s size 11 broke the main negative lead! Perhaps the negative solenoid has been bypassed unintentionally by some earlier work. Need to look for a large cable from battery negative to the body of the engine, and it might be close to the alternator. It’s not uncommon for the negative from an insulated return alternator to be found connected to the mounting of a non insulated (standard) alternator. -

A lot of the dead ones I encounter are very early versions with a big power transistor (2N3055?). Seems a shame not to repair them. The modern Prestolite ones have those tiny surface mounted components, so not a viable repair option without specialist kit. I’ll have a go at drawing it from the tracks on the pcb.

-

At last a use for that old 24 volt Heart Interface combi, just need a a few lamps; I nearly forgot I had it! Do any of the CAV manuals have the circuit diagram of the regulator? I can only find the generic ones online.

-

I'm confused, you asked about "breathing" but these are pictures of the exhaust and not the breather system.

-

I'm fine with the connection details, these are configured to run without warning lamps, and fitted to 1950s diesel railcars. The circuit diagram and volt drop figure for the shunts have proved very elusive! Current supply of shunts appear to be the 80 amp types, which have been "tuned" by drilling away some material as in one of the attached images. The two images show differing instals for 60amp alternators on different vehicles. I certainly had you in mind when I posted this. Do you know if the unventilated versions of the AC 203 were used in other applications?

-

Not strictly boat related, but can someone provide a circuit diagram for this type of CAV regulator. It is used with a 460 control board, and the M1 and M2 terminals use the volt drop across a shunt to current limit the alternator. Shunts are available for 60 and 80 amp unventilated versions of the AC203 alternators, each producing the same volt drop at their rated current, but I also don't know what that volt drop is. Any help would be appreciated.

-

Water cooled engines from page 110 in the first one.

-

Petter ACW2, spares from Lister Petter dealers.

-

These can be fitted into the consumer unit or a suitable DIN rail fitted enclosure. https://hager.com/uk/products/h/him402-modular-change-over-switch-4x20a?q=changeover switch

-

That looks the same as the ones used on some Lister engines.

-

Reasonable journey times for stations from London out as far as Reading going towards Bristol. About 2 hours each way from local stations, down to about an hour on direct services from Reading. Budget about £100 per day for "walk up" return fares. Reading and as far out as Bedwyn going towards Bristol. 2 1/2 hours each way (average), travel via Reading. Budget about £100 per day for "walk up" return fares. Bedwyn to Bradford on Avon/Trowbridge. Catch the bus to swindon for a train service? Devizes is probably the only place this works. About 45 min on the train, plus time on bus. Budget (for train fare) about £20 per day for "walk up" return fares. Bus fare n/k. Bradford on Avon/Trowbridge going towards Bristol. About 45 min each way from Trowbridge. Budget about £15 per day for "walk up" return fares. Very limited service from Freshford and Avoncliff. Nearly all travel by train requires a seat reservation at the moment, although this is often managed by quota control where a percentage of seats are available for customers who purchase on the day. Avoid anything that involves Cross Country Trains for the short leg of the journey between Bristol Temple Meads and Bristol Parkway; its often more expensive; and their trains have much lower capacity, leading to over crowding.

-

Looks and sounds ok. I think the starter may be staying in a bit too long, or perhaps you need to release the key a little earlier?

-

You might be able to use a switch and contact cleaner spray, if theres a gap to spray it into. I got lucky with mine for a similar fault.