Man 'o Kent

Member-

Posts

198 -

Joined

-

Last visited

Profile Information

-

Gender

Male

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Man 'o Kent's Achievements

Collaborator (5/12)

66

Reputation

-

Do bigger fleas have lessser fleas?

Man 'o Kent replied to Man 'o Kent's topic in National/Russell Newbery

A final update on this topic. Sadly terminal illness prevented me from further visits to the boat so the rescue people were called in. They found for us someone who had owned a Russell Newbery and in a couple of hours he had sorted out a dirty fuel supply including a previously missed shut off valve that was well clogged up. Sadly I do not have the name of the man that quickly and so efficiently sorted out the problem so this is the best accolade I can give him. Once the RN got a sniff of decent fuel it was "donking" away like nothing had ever happened. -

How long does it take the engine to heat water?

Man 'o Kent replied to Blob Fish's topic in New to Boating?

Ball park figure, an engine produces 1/3 useful power from the energy content of the fuel it uses, another 1/3 goes straight up the exhaust and the remaining 1/3 goes into the cooling system and general radiated losses. Even at tickover speeds that means there is quite a lot of energy in the cooling system so the next question is how is the cooling system organized? Is there any means of dirverting all the coolant from the engine to the calorifier until the temperatures are more or less equal or does the coolant get circulated via the calorifier and skin tank all the time? -

Do bigger fleas have lessser fleas?

Man 'o Kent replied to Man 'o Kent's topic in National/Russell Newbery

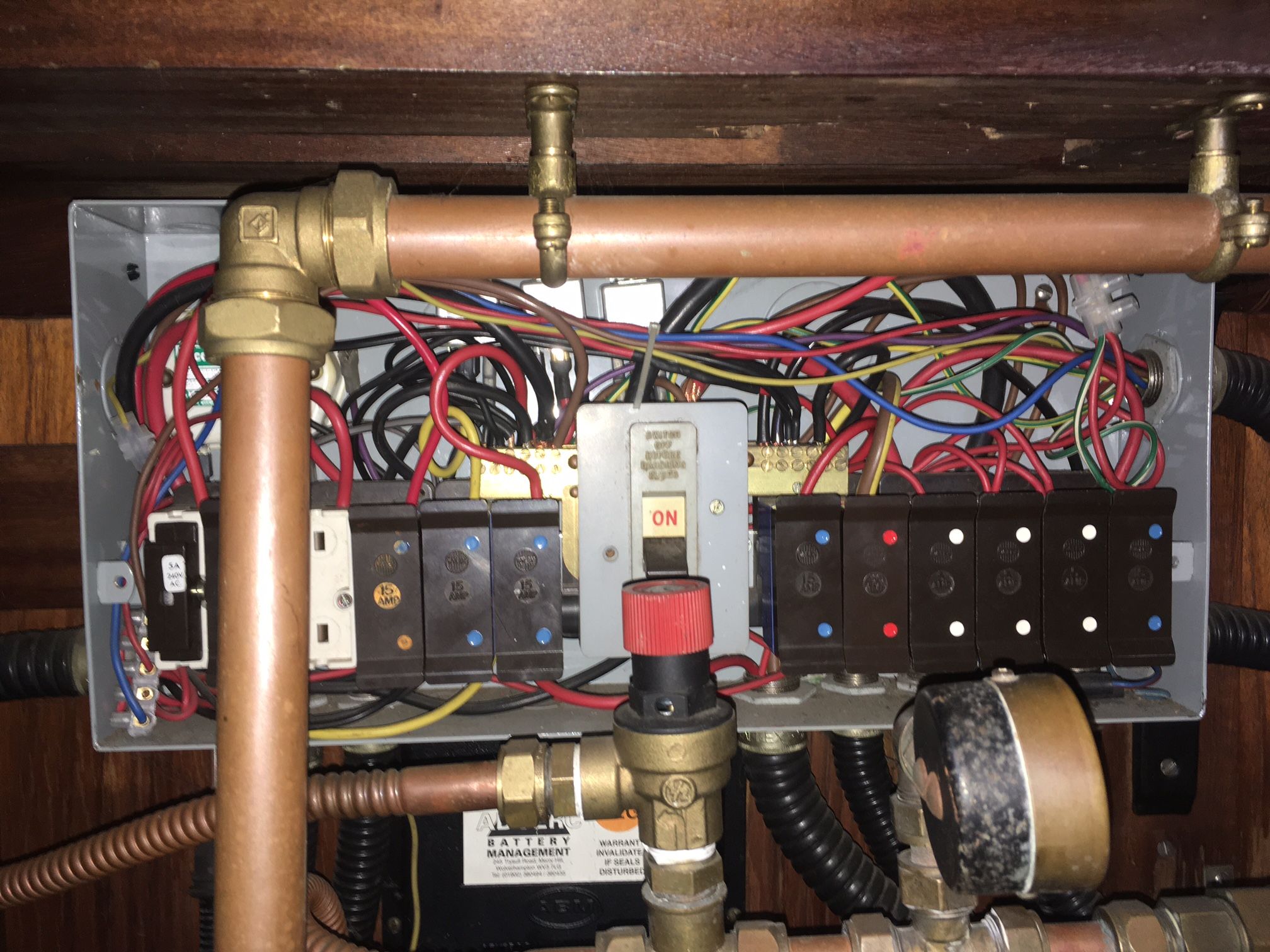

So often people do not round off a request for help, my only excuse for not posting erlier is a serious health problem. So here is the outcome, it turned out to be one of the "extra" solenoids but It took five different suppliers to provide four replacements that were unlikely to work. Fifty plus years in the enngineering game count for naught, it was my daughter that ran down the right one, don't ask me how, she is a b****y Arts Graduate . . . And just to rub it in she correctly fitted the new one herself and has spun the engine over on the starter. I did start to trace the wiring in the hope of getting my head around the what and why of it but the the starter attery positive found its way, (see below) into this before going anyway near the solenoids. At this point I blanched and gave up! -

Fitting Electric start to DM2: Advice please.

Man 'o Kent replied to DRP's topic in National/Russell Newbery

I've got two or three starter motors taken off lorry sized six cylinder engines that were used for research so the starters are all but new if it helps. That flywheel weighs in at about 300lbs. Not a weight to be taken lightly . . . Don't ask how I know but it involves an old Standard 10 saloon and a trip to Southampton.. Given the cost, not unreasonable given the amount of work for what is effectively a one-off, for a purpose made ring gear it might be worth hunting for something a tad bigger and having an adaptor ring made. -

To a goose a signal of dominance is a low extended head and neck posture. The lower the more dominant,. If threatened a human can extend an arm low to the ground fingers extended, little finger and thumb tucked underneath. A purposeful advance with some hissing for effect will usually convince the bird that it has better things to do elsewhere. Remember, birds are fragile, hollow bones, it is nearly all bluster, handbags a dawn stuff, the risk of real injury is too great to risk a real stand up fight. Of course as with humans there is always the odd psycho . . . ]

-

Not quite, I know one that did 270 miles and over 200 locks. She was getting quite good at it by the end!

-

Leisure batteries - advice on what to buy

Man 'o Kent replied to cairanvanrooyen's topic in Build Blogs

For what it's worth I've been using Lincon Batteries of Southend-on-sea, Essex for over fifty years in cars, yachts and narrowboats without a single failure or complaint. .A very helpful business that will advise and make up a battery to match your requirements. Usual disclaimer, no interest other than a satisified customer. -

Integral water tank with fibreglass

Man 'o Kent replied to Benny's topic in Boat Building & Maintenance

An added point to consider: Repairing GRP under these conditions would be an almost impossible nightmare, at the very least you would need a supply of small chimney sweeps to clean it out but I hardly think the Reverend Charles Kingsley would approve. It will be all but impossible to get a new GRP lining into that space that is entirely waterproof, GRP is to some extent hydroscopic even when laid up in perfect conditions. You really do not want to have to go inside that tank! Here is where grit blasting, ideally Zinc spraying and then an Irathane coating would be a permant solution without the need for anyone to go inside the tank. -

Integral water tank with fibreglass

Man 'o Kent replied to Benny's topic in Boat Building & Maintenance

Many years ago I had cause to investigated a product under the trade name Irathane, (in truth for quite a different purpose), but I was impressed and in my dotage it has occurred to me that it might just do the business on water tanks. It comes in various formulations some specifically intended for domestic water. It is mainly a two pack spray-on material but if memory serves can also be brush applied. In a perfect world the inside of the water tank would be grit blasted down to bare metal and then ideally Zinc sprayed followed by a coating of a suitable grade of Irathane. Clearly the subject would need further investigation but does offer an alternative long term solution. -

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

If, and it is a big if, I can find my silly little camers would photographs of the cam shafts out of my, believed to be a 1936 build National engine, be of any help?

-

Thank you GBBS for that! Interesting that, it would seem then that this is not the boat's original engine.

-

Never had a sister, Hitler saw to that, but blokes I know that do seem to regard them as scary creatures so yours should be well placed to keep the ghosts of them designers in their place! Matthew Boulton: Was it not he that in a letter extolled the virtues of a certain Mr Stephenson who "could finish his engine cylinders to the thickness of a thin shilling."?

-

The toolmaker in me sometimes had cause to think that draftsmen/designers were the Spawn of the Devil! In this case I am inclined to think you may be right about the pawls being stuck in the run position as things in there do have, (being kind), a patina of surface rust and general grubbiness. The Devil's Spawn reference applies here because the cover plates, (pt.31 on billybobbooth's drawing), are instead of being placed facing aft where they could be accessed and removed are tucked away facing for'ard and inaccessible short of gearbox removal and complete stripping of the starter assembly. The only possibility for the present is a bit of judicious "old skool" application of the Manchester screwdriver to free things up.

-

Do bigger fleas have lessser fleas?

Man 'o Kent replied to Man 'o Kent's topic in National/Russell Newbery

It is a matter of serendipity that this image exists at all because it is a "fail". DIY colour printing kits were pretty new back then and this was one we didn't get right. I'm sure the "good" ones still exist somewhere in a dark archive. The image is shown in false colours, the negatives, used for the droplet counting, were 35mm black and white film. The false colours represent variations in density and were used only for presentation purposes. It is interesting to note that the rendering is sensitive enough to pick up variations in air density in the swirling air shown in green. The bottom quarter is why this one was a reject.