-

Posts

360 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Steve56

-

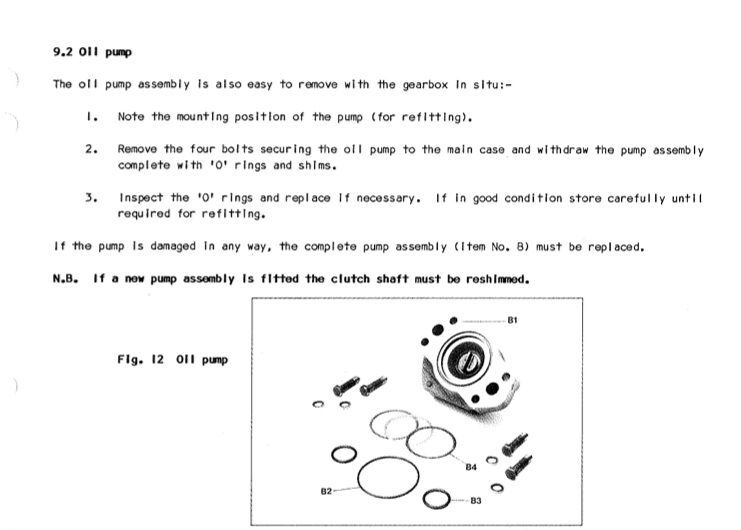

The oil pump can simply be removed with the gearbox in situ. When replacing just be sure to put it back on the same way. There are no gaskets, but rubber o rings to seal. These will be re usable although you should check the condition. They can be held in place on the pump with a little grease. Also be careful not to lose any of the shims from the end of the shaft.

-

The owner of that business sold the business a few years ago when he retired. The boats and business were sold to Saul Junction Marina. The boats were repainted and carried the Saul Junction Marina logo. The operation carried on as normal. Whether they are still in operation I couldn't say as I have been away from the area for at least 3 years.

-

There have been a number of hire companies on the G&S. Many years ago there was Glevum boats that ran for a good number of years quite successfully. When the owner sold up the boats moved to the Black Shed at Slimbridge who unfortunately let the boats go downhill and in the end the business just fizzled out. In later years another company started up. That was Gloucester Narrowboats. Again that ran successfully for a number of years until the owner retired. The boats were sold to Saul Junction Marina who were operating them as hire boats. All of these businesses were using small boats doing day hire. Both Glevum and Gloucester Narrowboats also operated a larger boat which was used for 3-4 day hire. Both of these companies restricted use to the G&S only. The main reasons for that were not wanting to let inexperienced hirers through Gloucester lock onto the Severn. Also if there is a breakdown or any other problems on the Severn it can be a nightmare getting to the boat. As I say both of these businesses were quite successful in what they did.

-

Air Filter for a Lister 3 Diesel Engine

Steve56 replied to C.Mamczak's topic in Boat Building & Maintenance

The Elements for an ST engine, assuming you have the original casing are either 366-06227 which is a paper element, or 366-06741 which is a foam element used on marine engines. The foam element was more a thing on sea going boats as the wet would not do much for the paper element. The 366-07188 which has been suggested, will not fit. That is the element for the Alpha housing and is thicker than the ST elements. -

Diglis river lock, the largest and deepest in England?

Steve56 replied to doratheexplorer's topic in General Boating

I think you will find that is the limit of navigation (end of CRT waters) not the source. -

Aftermarket Beta Marine injectors

Steve56 replied to Charlielamus's topic in Boat Building & Maintenance

As you say they sit on a copper washer. There is also a heat shield below the injector nozzle. Both these should be replaced when changing an injector. -

Centreflex CM-160 Coupling

Steve56 replied to Unicorn Stampede's topic in Boat Building & Maintenance

Well spotted. That'll teach me not to post to fast, and without checking the spellchecker. -

Centreflex CM-160 Coupling

Steve56 replied to Unicorn Stampede's topic in Boat Building & Maintenance

If it were me I think I would helicopter the coupling threads and then fit studs using a high strength locktite. -

Beta 38 (BV1505) stop solenoid replacement

Steve56 replied to Pete Morrison's topic in Boat Building & Maintenance

Ther are probably different solenoids available. Energise to stop for marine engines, and energise to run for industrial applications. -

It was built with the Ailsa Craig engine.

-

That is quite correct. I know the guy who built it but won't put his name up here. It was built using all the Northwich Trader templates, but if I remember correctly Phil insisted on a few small changes so it didn't look identical.

-

The thermostat will just be the normal type. As I mentioned earlier a lot of these would have left the factory with a 50 degree stat. So worth checking out. It can be replaced with a 74 degree stat assuming it is keel cooled.

-

As said the spring and ball acts as a bypass. This is needed because the jabsco pump is a positive displacement pump so you don't want to stop the water flow and also you need to keep a water flow to the water cooled exhaust. The way it should work is that the barrels and heads and water manifold hold the water until it reaches the thermostat temperature. The thermostat then opens and allows the hot water to mix with the water flowing through the bypass and out of the engine. So when the engine is running the water in the water manifold should reach thermostat temperature. As these engines were primarily made as raw water cooled engines running in salt water they would have been fitted with a 50°C thermostat to ensure the salt wasn't boiled out of the water. Obviously running as a keel cooled you can safely use a higher temperature thermostat.

-

Lister 3 Cylinder Air Cooled Diesel Engine

Steve56 replied to C.Mamczak's topic in Boat Building & Maintenance

Most of the marine engines did not use the self bleed system. I've come across it a few times on industrial engines. I think you would have to order as an extra when placing the engine order. -

Lister 3 Cylinder Air Cooled Diesel Engine

Steve56 replied to C.Mamczak's topic in Boat Building & Maintenance

Have you removed the fuel pump housing door and bled your injection pumps. -

Yanmar 1GM10 won't start - injector or pump?

Steve56 replied to cheesegas's topic in Boat Building & Maintenance

Could it then be a fault with your delivery valve. I have had this a few times in the past where a faulty delivery valve allows air to be forced back through the injector and back to the pump. -

Again it's how the engine evolved over time the earlier engines were cable stop. It was only later that they went over to fitting a solenoid to allow for engine stop using the keyswitch. It was a case of one of the engine manufacturers started doing it and everyone else followed suit. A backward step in my opinion as I would prefer to keep things simple.

-

You are quite right in what you say Tony. Originally the engine was fitted with Lucas Marine insulated alternator and starter motor. Then a relay was used to put a negative connection onto the engine casing to allow the heater plugs to work. Then slightly later Lucas stopped producing the insulated starter to suit the engine. So Lister used a 4ST solenoid to switch the negative onto the casing to allow for starting and heater plug operation. All the guage senders, and switches were two pole so when engine was running they all had there own negative with no connection to the engine block. This carried on for a while until Lister reverted to a more normal earth return system. Over the years many of these engines have been altered (bodged) in various ways by people with little understanding of how things work. Whether any of this has any bearing on the OP's problem, but I thought it may throw a little light for whoever is trying to sort it out. Can confirm by the photos that the engine is the LPWS3.

-

Don't know if it has any bearing on the problem, but a lot of the early Alpha marine engines were built as insulated earth engines as opposed to earth return. The engine you have there is definitely an early model.

-

If I remember correctly that should be a square section rubber joint that fits into the fuel pump housing. When fitted it will sit slightly proud of the housing to give the seal when the housing is clamped down. Should not need any sealant on the face. As Tony Brooks says speak to MES. Sure they will sort for you.

-

As far as I am aware it was only the TS engine that was used as a marine engine from Lister Petter. They did not use the TR or TX. Not to say that the later two models were not marinised by other companies or individuals.

- 1 reply

-

- 1

-

-

Sounds correct. Years ago all bridge and lock keepers would have done the VHF course, and have a licence. I guess now that CRT are trying to save money, and also with the reliance on volunteer's they don't bother doing this anymore. So what they are saying is correct. If you don't have a licence you can listen to the radio, but are committing an offence if you transmit over it.

-

Officially when you approach a lock on the Severn, or a Bridge on the G&S canal you should be given a flashing light to show that the lock or bridge keeper has spotted you. Although in saying that the way things are now it probably doesn't happen that often.

-

In my opinion you should not try and align an engine with a flex coupling in place. You need to work with two solid faces, then install coupling after alignment is good.

-

The engine is not raw water cooled, it will be heat exchanger cooled. The heat exchanger is mounted just below the exhaust manifold, and there will be a raw water pump fitted on the forward end cover. Looking at the photo and just wondering what that pipe fitted to your thermostat housing is for. If that is going to a header tank then in my opinion it is in totally the wrong place.