Mike Jordan

Member-

Posts

537 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Mike Jordan

-

Making a draining deck for crusier

Mike Jordan replied to OllyO's topic in Boat Building & Maintenance

Hi Bullfrog I'm delighted to hear that you got a good result. The cost of 70 pounds for the bits looks like a bargain when you look at the cost of the special foam slabs. You seem to have used the same method of getting air for the engine as well - try it and see! Mike -

Making a draining deck for crusier

Mike Jordan replied to OllyO's topic in Boat Building & Maintenance

Hi Olly When you look at the article you will see that most of the sound absorbing materials are expensive for not a lot of effect unless the decks are sealed down tight. The engine needs to breath so ventilation is a must at some point.If the engine can draw air from under the cabin thats great but if you are putting in air vents they need to be as small as possible and ideally be sound trapped to prevent the rattle of the diesel escaping. The cost of sealing the boards with foam strip is very cheap but hinging and providing locks hold the boards down takes time, effort, and a few pounds. If you hinge the boards as suggested the gas struts become a must to keep you safe. Any materials used as sound absorbers need to be fire proof and that tends to put up the price. The sound levels on the boat shown in the article were hugely reduced by just the few strips of self adhesive foam shown. Mike. -

Making a draining deck for crusier

Mike Jordan replied to OllyO's topic in Boat Building & Maintenance

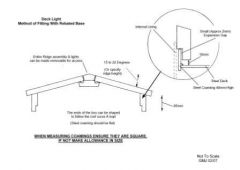

Hi Olly Since you have the ability to weld I suggest that you use the method shown in the attached photos. Many cruiser sterns are fitted with self draining decks in this way. The drains can either be pipes as shown or simply run the channels through the back of the boat or sideways if it has an integral fuel tank. Some prefer to use chanel rather than angle but the system is the same. There is an article with my name on it in the July 2014 edition of waterways World which shows how to keep the noise down at minimal cost, you can download it from the website for a modest cost. Best of luck with the project. Mike. -

Please be very carefull!! It is possible to make panels of 3mm thick glass reinforced resin layed up on a sheet of thin plastic sheeting supplied for the purpose. these are then taped together at the corners with glass fibre tape and resin to make a tank any shape you want. The resin you use for this is VERY CRITICAL It must be of a special kind suitable for contact with potable water. Failure to get the right stuff will lead to serious illness. Not sure of the chemistry involved but its something to do with styrene and partial bonding of the components of the resin mix. I suggest that you have a look instead at the idea of building in one or more of the type of plastic barrels/tubs used in the food and chemical industries and frequently recycled as water butts. last time I bought a couple they were £15.00 each for a 45gallon size Again make absolutely certain that the material is suitable for your intended use. Best of luck with the project. Mike

-

Angles of pipes in Gravity feed system.

Mike Jordan replied to Gavin Brunton's topic in Boat Building & Maintenance

Providing that the pipes have enough slope to allow any air in the pipes to be vented at the highest point (In this case I assume the radiator) the system should be fine. Mike. -

This may be caused by the pressure relief valve from the calorifier lifting momentarily as the pump reaches maximum pressure. The pressure relief valve prevents damage to the calorifier caused by the expansion of the contents when heated, they normally vent a small amount of water overside as the water is heated. If this is the case it could be cured by lowering the output pressure of the pump a little. mike The photo shows a pair of relief valves being fitted to a vertical calorifier, only one is fitted in most cases.

-

Hi Neil Are these framed and panelled doors or just panels of veneered ply let into folded steel surrounds? Mike.

-

Hi Dave I will PM you with information Mike

-

The fastest method I know is to use Liberon Brass & Copper Cleaner. Its and acid solution that wipes off the tarnish without effort, you then just need to polish up with brasso or similar. The 500ml costs £10.75 from Axminster Power Tools. Code No 810071 Mike.

-

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

English ash was the material used on the Morris Traveller, its used for vehicle body building, the shafts of carts and carriages, and the outer rims of wooden wheels. Its rated as tough and flexible as well as durable for outside use. American ash is widely sold in this country but its only suitable for inside use and is nothing like as durable as the European variety. Spruce is a low quality softwood used for things like fencing and carcass work, roofing etc. I agree that its cheap, but of poor appearance and with a short life. Mike.

-

I have known of complaints about paint reportedly not adhering to the timber but also been told that paint bonds better than it will to other woods! I can't recall painting any so can't be certain which is true if either are. I always feel that the varnish sits on the surface rather than soaking into the timber at all I am certain from my own experience that the oil content slows down the drying time of varnish and also the curing time of silicone sealants. Mike.

-

It's given me a smile as well! It's one of the oldest terms for a woodworker, supposed to have come from HM Dockyards. You might find a useful photo or two of cratch boards in my gallery. Mike.

-

Julian- Thanks for that, always nice to get a pat on the back. Stig- It wasn't until I Iooked at your profile that I realised the amateur description was a poor choice of words, no offence intended. Mike.

-

If you are keen to use home grown hardwood then Oak or Ash would be suitable and durable. If you want a timber which thrives on neglect and will last twenty years at least without rotting, then I would recommend that you google the timber Iroko. This is an oily timber like teak but without the huge cost, most comes from Africa and it has been a popular boat building timber for many years. Its two main drawbacks for amateur use are that it has interlocking grain which can make it difficult to work, and the fact that its initial colour when newly cut is a sort of banana yellow which changes to a mid or dark brown over a few weeks of exposure to light. Normal woodworking adhesives are of little use with it because of the oily nature, epoxy resin is advised for best results, polyurethane glues also claim to be suitable. I have some iroko garden furniture which has been standing on my lawn since 1996, still no signs of rot. Best of luck with the project. Mike

-

From the album: Dog box Vents

A simple manifold connects twin pressure relief valves. Using two costs very little and reduces the chances of a sticking valve damaging the cylinder by excess pressure. -

Daniel A domestic cylinder is fed from a tank in the house room which in turn is topped up by a ball valve rather than mains pressure. The pressure applied is measured from the top surface of the water in the roof tank to the bottom of the cylinder. Most cylinders are situated on the first floor and, as already mentioned only have to stand the pressure of two or three metres of head. The grade three ones are good for up 14.5 metres of head approx., not enough for a water pump and the pressure of thermal expansion. Dave I have no idea how to post a picture from the gallery. But if you are logged in I think clicking on my avatar will show it up. If that fails you just send me a PM and I will see if I can find the original photo to email to you. Mike.

-

In my experience the grade 1 domestic cylinders are not normally on the shelf and are available in a limited range of sizes. my system is to contact Newark Copper Cylinder co who will make one to your height & diameter needs either vertical or horizontal for very little more money. My hobby horse is the fitting of twin PRVs to reduce the chances of over pressurising your cylinder. There is a photo in my gallery. Mike.

-

If the board is really made of teak (not very likely because of the extreme cost) or has been given numerous coats of oil, the varnish will tend to sit on the surface rather than soak into the timber and get a grip. I normally recommend that new timber is given a coat of exterior varnish thinned 50% with white spirit to allow it to soak into the surface before coating with full strength varnish. If the oil content is causing your problem, you may have better luck with a cellulose based sealer. These do seem to get a better grip on oil contaminated surfaces, the only other resort being to carry on using an oil finish which will need doing every year but is at least quick and easy to do. Mike.

-

From the album: Deck Lights

Flat screen TV with bookcase surround. -

From the album: Deck Lights

Pivoting bracket allows TV viewing from many angles. -

From the album: Deck Lights

Table folds down and opens for use.