Mike Jordan

Member-

Posts

537 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Mike Jordan

-

From the album: Deck Lights

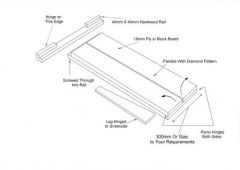

Traditional diamond pattern painted on top surface of folding table. (Open width of table 600mm) -

Hi If you look on the Waterways World website and put my name into the search box you should be able to find the article and download it for a small fee. Best of luck with the project. Mike.

-

From the album: Deck Lights

A simple to make chest in plywood with hardwood corners. Suitable for painting in any style -

From the album: Deck Lights

A ready hung door in a frame ready to be transported to the boat for fitting in a ready cut hole. -

From the album: Deck Lights

A high level storage unit using the ready hung door system. After the carcass has been constructed the frame is made with a rebated outer edge to fit into a hole cut in the carcass. -

My boat usage has always been much as yours appears to be, I find that for the first 36 hours or so after turning on the gas boiler, moisture is driven off from all the soft furnishings and internal woodwork, this condenses on the coldest area which is usually the metal window frames. The only cure I have found is to wipe up the water and both heat and ventilate until the problem subsides as things dry out. The problem will be much worse if towels and wet clothing are dried inside the boat, my solution to the drying problem was to install a heated cupboard with a 100mm computer fan drawing air from inside the boat, through the cupboard, and out through a roof vent. The fan was consuming a fraction of an amp and was left running 24/7 while the boat was in use. I am convinced it was a great help. If your boat has any water in the cabin bilges the problem will be much worse with the condensation constantly cycling round. Cooking with gas has an obvious impact on moisture levels, adequate ventilation being the only counter measure. Short of running a dehumidifier in the boat between trips ( not something I would suggest you do) I don't know of any cure for the initial drying out stage, boats live in a moist atmosphere and running a ventilator may keep it fresh but will not make it drier.

-

Ive now had a look on the gallery and find that the pics I thought were there are not! (just a touch of senility on my part I think) If you care to look on the Waterways World site there is an article on internal doors in the April 2010 issue that can be downloaded for a small fee.

-

I agree that louvre doors are not much use for the heads or the shower area. Most of the internal doors I have made in the past have had 22mm thick stiles and rails in solid hardwood with a 9mm thick veneered panel/panels. The angled doors to fit the sloping sides of the boat can be a brute to measure but are easy enough to make. My normal practice with square ended doors, is make a rebated frame and hang the door in it in the workshop before taking the assembly to the boat for fitting. This method allows you to do the internal bulkheads and furnishings and just leave holes for the ready hung doors and frames to be made and fitted in one go. Shaped doors used to block off a corridor are most easily fitted if you include a partial bulkhead a few inches wide to take some of the shape out of the boat side, its much better to fit the door against the partial bulkhead rather than into a rebate. It also means any swelling or shrinking of the timber in changing seasons wont jam the door in place. Try a look at my picture gallery, you may find some usefull ideas. Mike.

-

I suggest that you go for a table that can be moved to where its wanted rather than use the desmo legs which tie you to one spot and can't be used on deck or off the boat. I have plans for two types if you are a capable woodworker, one that folds to the wall with a stowed thickness of about 65mm but needs about 1.3M of wall length. And a drop leaf without the spread feet which is much more flexible to stow and make in different sizes. The easiest to make is the type shown in odana's post above, you only need a hinged top and a folding leg. If you look in my photo gallery there may be something of use. If you look on the Waterways World site and put my name into the author search it should provide more tables with plans you can download for a small fee. Mike.

-

Hi You are quite right, I failed to read carefully and also missed the clues in the photos. Your solution is similar to one I have seen where a hardwood dog box was made to fit over an existing Houdini hatch to keep it a little warmer in the winter. It was only a partial success but better looking than the 200mm slab of polystyrene and a purpose made cover used on top of a Houdini by some live aboard friends in an attempt to sort the drips. Some of the Dutch barge shells sold for self fit out come with a steel box similar to yours but without the inner hatch. Those I have met with these are sick of condensation long before the job is finished, and sometimes resort to replacing the steel hatch with a double glazed timber one. An expensive solution for a problem which is very predictable. Mike.

-

The quality of the fabrication is obviously very good, I like the appearance and also the handle on each end of the box to assist in lifting it off. The down side to the job is the need to line every bit of the internal steelwork to stop condensation forming on the inside faces. I suggest that anyone considering this type of hatch should first talk to others who have used their boats with steel hatches or Houdini type roof lights through at least one winter. The truth is that they are a nightmare! I have wasted a lot of time down the years trying to persuade new boaters who want to "lie in bed and see the stars" to talk to other boaters before having a hole cut in the roof. I have also spent many hours (and made a living) from making internal glazed shutters and sliding inner hatches in attempts to solve the problems caused by these type of hatches. They are great for ventilation over the galley and in hot weather but near useless in a boat occupied during cold weather. Hardwood boxes are much better from the insulation angle and in all instances double glazing with toughened and laminated glass is a must! I think this post will be unpopular with some so don't take my word for it, talk to someone who has had one through a winter.

-

If you are doing serious work you need a corded saw. I suggest the De Walt 331K and some of the hollow ground blades for wood cutting (Bosch T 308B) Cost will be about £130.00 but worth every penny in my experience. The battery powered tool will be worthless when the battery is shot whereas the corded tool will work reliably for years and not stop you half way through a sheet! Cheap and nasty tools only make a fit out harder to do, in the illustration even the blade seems to be the wrong way round in the battery tool. The easy way is hard work why make it worse?

-

The foam and polystyrene are normally very flammable and I can't see the plasterboard doing any good. The July 2014 issue of WW has an article on an inexpensive sound reduction method, it can be downloaded from the WW site.

-

Improvements that you value and enjoy may the exact opposite to the next person and even reduce the value. The suggestion about taking it to London can be very true! A boat can often be sold for more in the south than in the midlands. I think its better to use it and look after it, rather than spend boating time and cash on revamping a satisfactory boat and probably narrowing its appeal.

-

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

Insulation around the windows

Mike Jordan replied to Phil1884's topic in Boat Building & Maintenance

Is it possible to make a frame for the inside of the window which is rebated over the internal linings and comes into contact with the inner face of the alloy frame? If the frames are made in one piece its then possible to fill the space between the timber battens and the alloy frames with rock wool. The bats used by builders for cavity wall insulation are fairly stiff and shouldnt sag over time. The more of the alloy frame you cover up the better since this will always be a condensation area. Mike. -

I think that a narrow boat version will be difficult because of the inward slope of the topsides as already mentioned. A wide beam owner may may be able to fit one on a bulkhead. The suggestion has come up before and a claim was made that the studybed people were going to make one for a narrow boat. I have plans for two types of desk, one that folds down beneath the gunwhale and some very rough sketches for a version that folds down from the topsides and makes a desk you stand to use.neither of these is any use if you want to fold the desk without clearing everything away. If you find an answer, or have a study bed in use on a narrow boat please let me know. A stand up version has no appeal for me but it would solve the problem of what to do with that huge chair shown on the company video Mike.

-

A hospital silencer is both expensive and usually large in size, its sole purpose is to reduce the noise coming from the exhaust pipe. The lions share of the noise from the engine comes from the surfaces of the engine itself, the diesel clatter is much louder than the exhaust note. Having spent money on the problem, its not uncommon for the boater to claim a great improvement when all that's been achieved is a reduction in exhaust noise rather than any real improvement in the diesel rattle and clatter.

-

There is a cheap and effective method of reducing the noise in an article in the July 2014 edition of Waterways World. You can look at it in the back issues and download it for a small sum. There is no better cure for vibration than and adequate weight of flywheel, flexible mounts, and a flexible drive shaft. That means a thrust bearing and two flexible couplings not just one. Most inland boat builders still go for the cheapest method of rigid mountings and rigid shaft, any competent boater can do a better job for limited cost, every penny will be worth it when you are boating in near silence. My objective is to be able to hear the water emerging from beneath the counter over the sound of the engine. Above all, don't let anyone sell you a hospital silencer!

-

I had a similar experience some years back with a new shell built from best quality german made steel. A very small leak came from the centre of a roof plate with had been blasted and epoxy primed, only the windows and doors having been fitted. On grinding away the paint in a small area I found that a ball shaped piece of some sort of slag ( 4mm Dia) had been rolled into the plate presumably during the making process. I was able to drill out the marble shaped piece and weld up the hole. Only ever seen this once, but as mentioned above it could have been in the keel plate. Mike.

-

What to use on exterior wood (hatches)

Mike Jordan replied to Odana's topic in Boat Building & Maintenance

I would also advocate the use of the thinned exterior varnish, the only difference being that I prefer to thin 50/50 with white spirit for the first coat. Many exterior pieces of joinery on narrow boats don't have proper " weathered" top edges, no surface should be left flat to retain rainwater but should have a minimum slope of 9 degrees to encourage water to run off. This problem is evident even on some of the top priced boats. You say that the hatches and doors are decayed, does this mean that you are making new ones? If so this would be an ideal time to consider changing the material used. I would suggest that you look at the idea of using Iroko as your replacement timber. A swift google of the name will tell you all you need to know about the material much quicker than my two typing fingers can. It costs the same as most other hardwoods, its very oily in nature ( so much so that epoxy resin glues are used for joints) and has all the advantages of teak but without the staggering cost. I made some garden furniture with it in 1996 and its still standing on my soggy lawn today with no sign of deterioration. Best of luck with the project. Mike. -

From the album: Deck Lights

A table which folds down and opens out for use. Diamond pattern is painted on the underside of the folding leaves to display through the glass when stowed upright. -

From the album: Deck Lights

A folding table fitted to the cratch board and showing a diamond pattern to the front through the glazing when folded. -

Please Share Your Bunk Beds With Me!

Mike Jordan replied to cheshire~rose's topic in Boat Building & Maintenance

If you look on my photo gallery, I have just uploaded two pics of the three function berth (only two will upload) The photo of the twin bunks shows a timber stop fastened to the bulkhead to halt the back rest at the desired angle. Mike. -

From the album: Deck Lights

Bottom berth extended to form a double