-

Posts

8,598 -

Joined

-

Last visited

-

Days Won

39

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Chris Pink

-

Was that an intermittent picking up problem?

-

I've seen worse me Old Son, much much worse. (to your first post, excuse the pun) To this one, link +ve to -ve to make two pairs in series join the two top +ve and the two bottom -ve then run your supply cables one from each battery I would always use 8mm studs where fitted (as I say I've never seen them added in as you describe). There's only connection to make = more reliable and I've seen some well dodgy clamp terminals done with any old bolt. And when they get old they tend to ride up the post making it difficult to tighten them down properly. Though you are right, as with all connections, they need making right with proper washers and well crimped terminals.

-

does that answer your concerns, Bizzard? in the case of 4 batteries like this I would much prefer to make the linking straps on the 8mm terminals, it will make a much sounder mechanical connection. Well it must be said that a favourite forum sport is gathering into a pack to beat an incompetent engineer ;-)

-

Question for numax but I would be surprised if they got CE marking if they weren't up to full load. 8mm rings are standard fitment and in my opinion much better than those quaint clamp terminals. More rubbish. I don't think you should trust this engineer. re: spats, I don't see any on this thread, there is slight discussion about whether the 8mm terminals on a numax battery are capable of full oads but that's a normal basis for discussion. btw these batteries have a 3 year warranty.

-

That is absolute crap. The 8mm terminals are perfectly capable of carrying all loads. T105 pattern traction battery have no others.

-

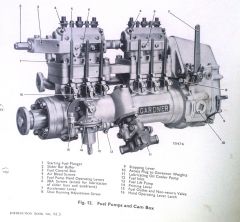

I did put this down to not having been used for a while. Mine is not particularly slight, although it doesn't run away with itself. I kinda figure it all linked as in my non-engineering way it all seems to be 'sticky governor' and lubrication is probably the key. The 2BA screw instruction is in my 6LX manual. But the pump is different to mine. There's a hole showing on this diagram that has a screw in it on mine that is just a hole in this. I have oiled through the screw, as I say, in the top of the fuel control box and hopefully that's done the trick. I have a plethora of information about 6LX which I am beginning to feel is pretty useless to my 4LW. I have an instruction manual for the 4LW what I could really do with is the parts list. (and, of course, the workshop manual to give to my imaginary engineer)

-

From the album: Chris Pink

-

Going Round In Circles, Learning Curve Too Great. . .

Chris Pink replied to Wassat's topic in Boat Equipment

The issue with those is not accuracy it's that you have to pass the whole current through them which involves taking the alternator (etc) up to the panel and down again, and they usually have 5mm ring terminals. FIne in the days of 35A alternators (ish) but absolutely useless in a system like the OPs (always assuming you can find a 300A version) Obsolete. -

Going Round In Circles, Learning Curve Too Great. . .

Chris Pink replied to Wassat's topic in Boat Equipment

Is that one of the clippy ones or one like a Fluke 322? -

I removed the screw top left (it's actually behind the protusion in the casting that you can see. It had a pin on the end of the screw (about 5/8" long all told) and squirted dollop oil in and oiled the rack at the other end, touch wood, it's been behaving today. But again boating had taken priority so I'm not 100% sure. Though I had a couple of hours at lunchtime while a family overturned their cruiser on the cill (mur de chute) of a staircase just outside Carcassonne. I wish the British canals were run by VNF. They were brilliant. I can't get a good purchase on the screw bottom right without taking an engine cover out so I left that.

-

And to what George says (no drivel there), rock it a good 'un and it will come off. My favourite trick (once the bow is over the other side your stern gunwale will be nearer the bank) is one foot on the gunwale one on the bank and push the handrail, there's very few boats won't come off that way. Just make sure you keep your weight on the gunwale. If that doesn't work, get your gangplank on end and use it as a lever under the counter (obviously using the 8" width not the bendy way). Stick it into the bottom and push it outward against the counter bottom. If neither of those work, you're not trying hard enough or you need a crane. I've never failed to shift a boat, much more than 4" out of the water with a combination of the last two posts.

-

Going Round In Circles, Learning Curve Too Great. . .

Chris Pink replied to Wassat's topic in Boat Equipment

No. As far as I know. There wouldn't they are inaccurate and only give and indication of current activity, ie charging or not and this information can be found in other ways. If you're going to install something the a shunt ammeter is the way to go, why would anyone manuifacture anything else? The only reason for a clamp ammeter is to obviate breaking connections, if you are going to install something this is irrelevant. -

1. Yes, but you should have been aware of some way of disconnecting your charging system so a domestic (or starter) battery fault didn't disable your boat. 2. It's possible that the connection system exacerbated this issue, read smartgauge,co.uk on battery connections but it could equally have been a random failure. 3. yes 4. yes but was not the main cause. you don't need to replace the good batteries. Only the duff ones. I would suggest taking the covers off (sealed doesn't always mean sealed) and checking water levels. The little windows are useless - ignore. This is simply the condition of one cell.

-

The others do what a smartgauge can't The smartguage does what you'd otherwise have to use knowledge and experience for. It's not an either/or really. But if you wanted one I'd recommend any of the Victron / NASA type and a bit of research will tell you all your need to know. If you get an ammeter (Ebay stylee) get a voltmeter too. And make sure it can be powered off the source your are measuring, not all can. Smiley Pete's usually up to speed on these. Hang on a minute...... OOOOOOYYYYYY! (he'll be along soon)

-

I'm with Dean. Hold off. They really aren't that useful on narrow boat or wide beam. Occasionally they are but for £900 you'll go a long way without it. Better of getting a long shaft and learning how to use it. That will serve in the long run. You've got the tube. If it turns out you can't cope without it then fit one later, maybe at your first docking. And buy yourself some training, it's confidence you need, not a bow thruster.

-

Introduction Of Quiet Zones On The K&a.......a Good Idea?

Chris Pink replied to louca Inglese's topic in General Boating

It's a great idea and I'm so glad it seems to be working. Mind it is the quiet season anyway, not so much need for electric and lots of solar. If it works over the winter it will have passed the real test. I am going to be the first portable quiet zone. -

Going Round In Circles, Learning Curve Too Great. . .

Chris Pink replied to Wassat's topic in Boat Equipment

Why? It's not that difficult to install a shunt and then it's accurate. Your Outback will be giving quite a lot of information. I think you need education rather than a gadget (except perhaps Robbie from Lost in Space). Do you have no metering at all with this lot which is quite a sophisticated set up? Where are you based? Whereas a power audit would be a useful exercise my dear petite chatte, it's not going to be that useful in this case. It's going to be relatively easy to find out how much is being used (and how much is going in) Question to the OP; Is your solar keeping up? How many amp hours per day do you get? (the Outback will tell you) If the answer to the first is yes, then the second is your usage (the Outback will stop once the batteries are full) -

That's the way most people lock who just want to get through the lock. It's no great deal, get in gates shut, paddles open, job done. What you are missing is that for Dave Mayall this is an opportunity for him to show his importance and authority. He doesn't get much chance, poor chap. While he's in the lock nobody can do anything about it so he's going to take his time ad sod everyone else.

-

SImilar but different. I assume steve's post means the two nuts arrowed. If so does the whole cold start mechanism come away too without removing anything else? It's one whole casting. Theres also two slot head screws (arrowed top left and bottom right) the bottom right looks like it might match Steve's description. Sorry about the quality of the picture, there's not much light in there.

-

From the album: Chris Pink

-

Sounds like sticky something then. So Steve's idea is a good un. I haven't identified the quadrant cover yet. There is a cover behind the priming levers (Steve's fuel pump levers?) I was about to post a picture but then I thought I might as well take the 3 3/16" screws out and have a look for anything quadrant like. I haven't managed to appoint an engineer yet, whenever I show them the crew's quarters and tell them the pay, they laugh for some reason and leave.

-

I think, I might be wrong, this is the same Dave Mayall that calls me arrogant. You have to laugh. I haven't in many a year encountered (I am happy not to able to say 'met') someone with such little self-awareness as mayalld.

-

That your word of the week then Pete?

-

Look Alan, Les Flics (as Lady M will forever be to me) has said 'stop swearing' Although that's a new one on me, 14th Century English?

-

Boat BSC examiner, near Peak forest canal

Chris Pink replied to Frankieboy's topic in Boat Building & Maintenance

Maybe you would be so good as to point me to where I have done that? All I can see in your pompous and over-weaning post #18 is a directive not to use someone for the crime of breaching the Mayall protocol for posting (are you one the new moderators then Dave?) and inappropriately using letters after his name (allegedly). I simply point out that your negation of his talents is contradicted by a far more authoritative source than you. Much like your opinion of my professional skills.