CompairHolman

Member-

Posts

269 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by CompairHolman

-

You're right , looking in close up its some kind of sealant. Surface rust like this doesn't need sand blasting that would be way over the top, you just need a wire wheel in a grinder . ( never use wire wheels without eye protection ) I have restored plenty of stoves over the years.

-

Must have belonged to Stevie Wonder going by the weld on the collar of the flue.

-

Any movement is taken up by the rope seal between the glass and the door.

-

If you replace the glass holding clips screws with stainless steel ones from the start they will never seize and you can replace the glass in a few minutes with just a screwdriver.

-

Cracked glass won't make any difference to how your stove burns, your stove has a two inch hole above the glass and CO doesn't come out of that does it ? The tiny leak from the crack will suck in air as the stove is negative pressure inside, whatever extra air it leaks in will be adjusted for by the air controls. The only safety issue is if the glass is broken parts of it could fall out, the Squirrel glass is held in by a clip at each corner. If you take the glass to a glass supplier they will cut you a piece of high temperature glass while you wait for about £7.

-

It would not be difficult to have an engine start cut off switch on the weed hatch lid.

-

"Off-Grid, Solar-Powered, Zero-Battery Refrigerator"

CompairHolman replied to a topic in Boat Equipment

In the region of £8 / 10 per square ft. You have to factor in the cost of the fuel you save recharging your batteries to run a badly insulated fridge over the long term. Like investing in solar panels. Well if you want a seriously insulated fridge you would need to go up to 120+ mm of PU foam and that's not practical on a boat. -

"Off-Grid, Solar-Powered, Zero-Battery Refrigerator"

CompairHolman replied to a topic in Boat Equipment

https://youtu.be/1h8-OdkGflc -

"Off-Grid, Solar-Powered, Zero-Battery Refrigerator"

CompairHolman replied to a topic in Boat Equipment

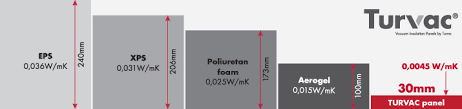

Like I posted in another thread, vacuum panel insulation is becoming affordable and a top loading cabinet with this is the only practical way you can get the highest efficiency, plus you can use a 12 v Danfoss compressor and eliminate the inverter power loss. A freezer may have thicker insulation but its still no where near the maximum, which is 120 mm with PU foam, a vacuum panel will achieve the same with 20 mm. As far as I've read , this level of insulation could get you down to 25% of the power consumption of a normal fridge cabinet. -

It would be better all round if they made everything from steel except the doors and top plate then it would bring the cost down as well as making them airtight and easily weld repairable.

-

The smaller you want the fridge / cool box the more they are going to cut back on the insulation and the more power it will draw. The only way around that is vacuum panel insulation.

-

My first boat was a Les Allen and that had a weed hatch that came up to the stern deck, so impossible to sink.

-

You can get cool boxes for free , they are used in chilled food packaging, fishmongers throw away loads of them. You buy them for peanuts anyway.

-

We always have a box of catering UHT individual milk pots in the larder for emergencies , we never run out of milk, ever. We order them from eBay in boxes of 120 and collect at the nearest Argos store. Don't buy the discounted ones though , they are short dated and taste of the plastic pots.

-

Potential cooling solutions in hot weather .

CompairHolman replied to CompairHolman's topic in Boat Building & Maintenance

The wind scoop that is used on sea going boats has never transfered to the inland waterways, maybe it could be use full , it would need to rotate into the wind though for a stationary moored boat. -

Yes this law applies but only when you reach the point of maximum practical insulation, with PU foam as you go thicker the gain in insulation decreases , at around 120 /150 mm it becomes too much wasted space for the small gain in insulation, vacuum panels don't need to be massively thick to achieve the same insulation values. Any fridge design with high efficiency in mind would be top opening.

-

The standard boat fridge is constantly battling against the poor level of insulation in the cabinet which is made to fit in a small space rather than minimal power use, and with being in a bigger insulated box ( your cabin ) that you are also trying to heat at the same time as trying to cool the fridge. Once vacuum panel insulation becomes affordable ( 20 times more efficient than PU foam , 38 times Rock wool ) then there could be a properly insulated fridge come on the market which would not require 120+ mm of foam to achieve maximum insulation. Its probably affordable now if you factor in the long term cost of generating the power to run a standard badly insulated fridge. Probably around £100 extra cost for the average boat fridge.

-

Potential cooling solutions in hot weather .

CompairHolman replied to CompairHolman's topic in Boat Building & Maintenance

You're right, my experiments were put on the back burner since we moved to a mooring 200 m from a pub. -

Cool boxes work on thermoelectric cooling principle and it requires a lot more energy than a compressor fridge, its beyond science at the moment to make a low power drain cool box.

-

I've come up three potential solutions to cooling boat cabins in this hot weather. What do you think ? 1. Air conditioning. The side of my cabin facing the sun is around 50 deg C today but the bottom plate is around 20 deg C, this led me to an experiment with a desk fan and some cardboard ducting feeding the fan with the air from under the floor, the theory seems to work and got a noticeably cool output from the fan. Developing it further would mean having an area of the bottom plate welded with fins as heat exchangers and ducting the cabin air through it. For a new boat being built the ballast could be arranged in a pattern to allow air flow through it, the ballast acting as a cold store ? 2. Evaporation cooling. A solar powered pump and a drip feed hose on the roof that keeps the whole area wet with canal water, I tried this with a mains water hose and it does work, the problems are that raw canal water blocks small pumps and the boat would develop a coating of silt which would need regular cleaning. 3. Water cooled air con. A solar powered pumped closed circuit , a coil lying at the bottom of the canal and one in the cabin with a fan behind it should get 20 deg C cool air flow from the fan. Not one I've tested yet. I'm still looking for a suitable 12 v pump with a low flow rate and quiet operation.

-

You started with an incorrect proposition that blacking paint needs to be thick. What matters is the bond to the steel, which is why there exists a Bitumen primer which is a thinner version of the paint designed to flow into all the pores of the steel. Thinning the first coat with white spirit and preparing a very dry surface gets the best results.

-

12 v USB charging hub ?

CompairHolman replied to CompairHolman's topic in Boat Building & Maintenance

I said £10 because that's what I reckon I could make one for. I have everything I need to build one already except the ports . -

12 v USB charging hub ?

CompairHolman replied to CompairHolman's topic in Boat Building & Maintenance

That's a good option I didn't find. Thanks. -

I'm looking for a bank of at least 6 USB charging ports in a single neat wall or desk mounted unit powered from 12 v, some or all 2 amp rated. I can construct the enclosure or panel if I need to. I don't have the means to micro solder USB ports though. Total cost must be less than £10. Anyone got any ideas ?

.jpeg.807eac79688e8dfa9515b665aa1e14a8.jpeg)

.jpeg.2de34f0e1864fc0cf3e371f03a44854c.jpeg)