Binkie's Grandson

Member-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Binkie's Grandson

-

Or better still, does anyone own a Bob Bush can that they'd like to sell to me

-

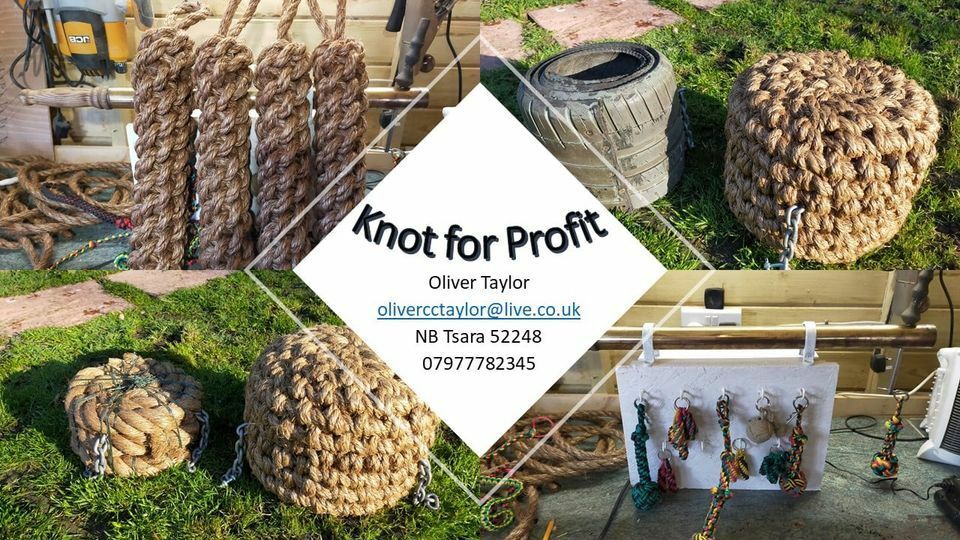

I make fenders and have made long buttons up to 22" long, but I generally wouldn't recommend anything longer than 18". For the cores, I use a combination of old tyre treads wound up tightly and coiled 1.5" diameter rope; for the longest ones I have even connected two tyre cores together. However, these long buttons do risk drooping over time or buckling under a heavy impact, and they just look silly (IMHO). You really only need about 3-4" of protection longer than the rudder and you are better off with a combination of tipcats and buttons for two main reasons; the button can easily be pulled out of the way if you are in a tight lock or winding hole; and the button also takes the majority of the wear and tear, so can be replaced at relatively low cost. Your particular setup seems to have only two fixing points, but you have added a third chain wrapped around the tiller bearing, which is far from ideal as this risks damaging your bearing or even the rudderstock. You may have another central point below the fender, which long buttons often utilise, but for the reasons given above, this does make it difficult to move the fender quickly, when needed. In the long-term, you might want to consider having two additional points welded on so that you can fit a combination of tipcat(s) and a button (A temporary fix could be achieved by adding two pieces of flat bar drilled at each end, with an eyelet at one end and bolted down with the same bolts for the tiller bearing, but I would only recommend this temporarily as any forces on the bearing that it is not designed for could be a problem). As you will see from the various photos sent by others, the tipcat(s) fit to the wider points and the button chains run over the top to two narrower points; if you do decide to weld on some additional points, the wider points should be about 26" apart and the narrow about 12" apart. When I make tipcats, they are typically each 7" thick, combined with a simple button of similar dimensions or the more decorative Barlow button option about 11", so you can work out what you need to protect your rudder. However, if you want fewer tipcats, these can be made thicker to suit. https://www.facebook.com/KnotforProfitFenders/

-

Bob (my uncle) died some time ago and sadly Elizabeth, his wife, last year. My cousins did a clear out of their loft, but I'm not sure if there was any archives left.

-

What makes you think this was Bob's work? He was my uncle and I'd love to know how to recognise his work

-

I can re-cover that for you, with whatever natural or man-made fibre rope you want https://www.facebook.com/KnotforProfitFenders. I often use old tyre treads to make the cores for long buttons and they'll probably outlast most boats; they can be re-covered many times and they don't suffer from fender droop. However, it's not so easy to make the core shapes for U-fenders, V-buttons and tipcats with tyre treads, so I stick to the traditional manila rope cores for these.

-

Thanks for the shout out, Hudds Lad. The link gives a good idea of what I do and, like Tradline, don't expect anything straight off the shelf, as they are all made to order. Currently my lead time is about 6-8 weeks, so if you can live with that, get in touch.

-

My Perkins 3.152 was previously used as a standby generator and the guy who fitted out the boat in the early '90s told me the Borg Warner Velvet Drive came from a forklift truck

-

I shared the exact same idea with CRT myself

-

"Medium" length stern button

Binkie's Grandson replied to IanD's topic in Boat Building & Maintenance

I have messaged you -

"Medium" length stern button

Binkie's Grandson replied to IanD's topic in Boat Building & Maintenance

https://www.facebook.com/KnotforProfitFenders -

"Medium" length stern button

Binkie's Grandson replied to IanD's topic in Boat Building & Maintenance

Your boat setup has four fixing points for a tipcat and button, which I can make for you (Knot for Profit Fenders). The advantage of this arrangement is that it breaks in half if you ever get stuck in a tight lock or winding hole, by simply lifting up the button. It also means the button takes the majority of the daily wear and can be replaced without changing the tipcat. And it looks so much better than a droopy long fender. I can also make this for you if you want; I use old car tyres as the core to avoid the droop, it should be 3-4" longer than your rudder. -

The IWA seem to be going through CEOs like the Tories through Prime Ministers. What's going on?

-

Is there a traditional method, rope material and/or knot for securing fenders to the boat? I am thinking particularly how the fender chains are extended to the fixing points in the photo.

-

I just saw a terrapin above bridge No55 above Hatton flight. It was clinging to a branch in the water as I went past, but had swim off before I could get a photo. Can anyone corroborate my sighting as my family don't believe me (Not after the 4ft swimming grass snake I saw on the K&A).

-

40+ when it is cold. It takes about 15-20 minutes to get up to normal temperature, and pressures are still good at cruising and idle; the drop off seems to happen after an hour or so of cruising, although no perceptible change on the temperature gauge.

- 25 replies

-

- perkins 3.152

- oil pressure gauge

-

(and 1 more)

Tagged with:

-

I may be clutching at straws, but could the fact that it is a newly rebuilt engine (~100 hours), running tight, be generating more friction and heat in the oil, so it loses its viscosity after a run. There is some improvement after a period at idle, presumably because the oil has a chance to cool, although the temp gauge doesn't show any increase on the normal 75C operating temperature. When it was rebuilt the oil pump was replaced (at least according to the invoice!).

- 25 replies

-

- perkins 3.152

- oil pressure gauge

-

(and 1 more)

Tagged with:

-

Yes, I bought them as a package together

- 25 replies

-

- perkins 3.152

- oil pressure gauge

-

(and 1 more)

Tagged with:

-

We ran the boat through Chester yesterday. The new gauge and sender definitely give a damped fluctuation of the needle, however the same drop (and more) in pressure is still concerning me. At cold start it indicates 50 psi, falling to 40 psi when warmed up and running at normal cruise. After an hour of running at this speed it has dropped slightly, but when in idle/tickover the pressure fluctuates between 0-5 psi. It suggests there may be some heat build-up in the oil, so it losses its viscosity, whilst the coolant is staying constant at 75C.

- 25 replies

-

- perkins 3.152

- oil pressure gauge

-

(and 1 more)

Tagged with:

-

I replaced the sender and gauge this weekend and, although the engine has not had a full run up to temperature, the needle doesn't seem to be bouncing around like it was before.

- 25 replies

-

- perkins 3.152

- oil pressure gauge

-

(and 1 more)

Tagged with:

-

Memories from Richardf59 (From TractorByNet): Hi I remember the issue we had with the Perkins - it was a really stressful time as we had initially had the engine replaced with a like for like Kelvin P4 which proved to be worse than the old one (bought å–ªefurbished from Marine Power Services? and then having made the big decision to get rid of it - the Perkins was a nightmare to get right. We never did get to the bottom of it, but they took it away and rebuilt it again - I always reckoned that they put the wrong size bearings in it initially. I always found Canalworld a good place to ask questions like this. Wildly varying oil pressure sounds like a blockage somewhere or a pick up issue in the sump, maybe an oil pump issue. Once fixed, mine never ran less than 45psi The boat is sold now (nb Marcellus), but the Perkins was a great engine - although I never really got the exhaust running clean! All the best with it. Cheers Richardf59 I have the same experience with our engine not running clean; before and after the rebuild it tends to smoke more than most.

- 25 replies

-

- 1

-

-

- perkins 3.152

- oil pressure gauge

-

(and 1 more)

Tagged with:

-

I'm not so concerned about the drop in pressure over a long day, although I wonder whether changing to a different oil might help (currently 15W40), but the wild variation of the gauge, particularly after an engine rebuild when the oil pump and PRV were supposedly replaced, does seem strange. The bouncing needle of the gauge was common before the rebuild at idle, but usually stabilised at mid-revs and rock solid at faster speeds. Now the situation is constant 20psi pressures at idle (although I have my doubts this is a true reading), fluctuations at mid-revs, with some improvement at higher revs; the same pressure sender and gauge were installed before and after the rebuild (soon to be changed).

- 25 replies

-

- perkins 3.152

- oil pressure gauge

-

(and 1 more)

Tagged with:

-

I came across this post on TractorByNet and I have a remarkably similar problem: I wonder whether Richardf59 ever solved his issue satisfactorily. I have a D3.152 dating back to pre-1992 (the age of the boat), which I can only guess was taken from an MF135 tractor or generator and marinised for installation into a narrowboat. We have had it for two years without much problem, except for some clogged fuel filters, but broke down in March this year and we had to have the engine removed and rebuilt after finding one piston was oval in the cylinder; all bearings, liners and pistons replaced, and new oil pump fitted. In fact the engine had to come out twice, because during the first re-installation something metallic smashed up the crown of one of the new pistons. Anyway, when we finally had everything back in order she ran beautifully; from cold the idling oil pressure was about 40-50 psi. However, I have found that an hour or so after getting up to temperature (75 C, constant) the oil pressure gauge can fluctuate rapidly from 10-60 psi, even at normal cruising speeds, often mimicking the tone of the engine (revs fluctuating?), and to maintain good pressure we have to push the revs up higher than normal. At idle and tick-over the pressure reads a constant 20 psi, but I am concerned that this could also be bottoming out on the gauge range and simply a reading error. The sensor and gauge are electric, so I shall be swapping with a new one and also testing with a hydraulic pressure gauge next week. At normal cruise speeds on some long days (6-8 hours running) the oil pressure fluctuates around 30 psi and above, so the engineer who rebuilt it says it is within normal operating parameters, but this doesn't fill me with confidence for the long term. I use a 15W40 oil and changed the oil and filters after 50 hours after re-installation, which made no difference. I have no rev counter, just gauges for temperature, oil pressure and battery charge. Any thoughts/suggestions welcome.

- 25 replies

-

- perkins 3.152

- oil pressure gauge

-

(and 1 more)

Tagged with:

-

Further cooling problems Perkins D3.152

Binkie's Grandson replied to buggsy's topic in Boat Building & Maintenance

The narrowboat is on the Llangollen canal, is keel cooled with a skin tank and has a gearbox oil cooler. -

Further cooling problems Perkins D3.152

Binkie's Grandson replied to buggsy's topic in Boat Building & Maintenance

No steam, as I said it is running at or just above 210 on the gauge, so you could be right that the sender is not matched, but looking at some US and European resistance curves a false reading of 210 could be a true reading of 170, which is still hot compared to the 125-150 range specified for Perkins marine diesels or D3.152. Am I reading these wrong or is there some other reason that you would get double or half? -

Further cooling problems Perkins D3.152

Binkie's Grandson replied to buggsy's topic in Boat Building & Maintenance

I have a few similar queries related mainly to overheating of a Perkins 3.152 engine, but with a number of other issues (possibly related), which I would be very grateful for any assistance. I have a 1992 Gary Gorton 53' narrowboat with a Perkins 3.152 engine, which I have had for 12 months, but that's about as far as the engine identification goes; the only serial number on the engine block is 22128R, which is in the right location, but bears no resemblance to Perkins standard IDs, so I can only assume that it is a reconditioned engine, possibly a marinised D3.152. The engine had been unused for ~2 yrs, but was serviced when I bought it, including overhaul of the injectors and injector pump. The fuel in the tank was also 2+ years' old and we have suffered repeated diesel bug clogging of the mesh inside the fuel lift pump; the fuel has been dosed with Marine 16 and I have become adept at quickly cleaning out the lift pump and restarting the engine. We have only been using the boat at weekends and apart from the diesel bug issue, it seemed to be running well, temperature on the gauge was ~150-160°F, as far as I can recall. However, when the temp gauge stopped working I found that the sender unit was broken (it was a bodge job using a smaller unit, cross threaded into a reducer into the engine block). When I replaced it with a Perkins sender unit, everything seemed to be back to normal, but very soon the engine started overheating (running above 210°F on the gauge). The skin tank inlet appeared to remain cold, so I removed the thermostat, which meant a very slow warm up, but the engine eventually ran at ~150-160°F on the gauge, but the calorifier didn't heat the domestic water to anything more than tepid. The old thermostat was marked 74 on the cylinder, so I have just purchased the only 74°C thermostat that I could find to fit the engine (Apologies for the change in temperature units). When I fitted this stat it partially improved the situation; in idle, the engine got up to temperature faster (~150°F on the temp gauge) and the domestic water temperature was much warmer, although still not what I would describe as hot, but when travelling the engine temp was close to the red zone (210°F). There is no oil/emulsion in the coolant, no bubbles or pressure/overflowing in the header tank, although a very slow leak from the hose into the water pump (or possibly from the water pump itself) needs half a cup of coolant to be topped up each day. As far as I am aware the engine is the original that was in the boat when she was built, so I would assume the skin tank is correctly sized, but I will get some measurements and check the actual temperature of the coolant with a thermometer, next time I am on the boat, but what is the definitive operating temperature? The Perkins Marine manual suggests that a marine 3.152 engine should operate at 125-150°F (52-65°C), but this engine is marinised and, even before I noticed a problem, was running above this with a 74°C thermostat that appears to be a rarity (most Perkins stats are rated at 82°C). Could there also be a restriction in one of the coolant lines or an imbalance of flows from the water pump between the engine and calorifier, or perhaps a problem with the water pump itself? Could the old/infected diesel be causing a higher than normal operating temperature or could an overdose of Marine 16 be an issue (I dosed it and then found out that the marina had also added some)? On the issue of diesel bug clogging the lift pump screen, I was considering adding a filter before the lift pump, which would be more accessible for cleaning, but I am concerned that whoever fitted the current 2-bolt pump may have done this as another bodge job and it is not entirely suitable for the engine. I can’t be sure of the original spec for the lift pump, but it would appear that the engine block has 4 stud bolt holes, but the current lift pump only uses the top two. As well as the clogging problem, the manual priming arm on the lift pump has little or no travel, even when turning the engine to a lower point on the crank, so it doesn’t feel very effective for manually pumping fuel through the fuel system. Having said all that, it does appear to run the engine. All thoughts welcome.