rgriffiths

Member-

Posts

248 -

Joined

-

Last visited

Profile Information

-

Gender

Male

Recent Profile Visitors

3,328 profile views

rgriffiths's Achievements

Collaborator (5/12)

13

Reputation

-

Beta 43 (v1903) Heat exchanger - oil cooler

rgriffiths replied to rgriffiths's topic in Boat Building & Maintenance

Thanks both - can't thank you enough. Fantastic help and much appreciated. So I guess if I pull it apart it would be the O ring seals, maybe just the pipe in/out end, that may need attending to. Will report back tomorrow after some fiddling about. -

Beta 43 (v1903) Heat exchanger - oil cooler

rgriffiths replied to rgriffiths's topic in Boat Building & Maintenance

Thanks Tony. Swapping it for a newer setup would be great - suggested by Beta too - but we are trying keep costs down for now. If it is a case of replacing some seals then I would prefer to do that at the moment. Just wondering what is going on inside that metal box. Beta didn't have any diagrams, and I can't find any online. Is it likely that there are some perished seals in there that could be easily replaced? -

rgriffiths started following Engine noise , Beta 43 (v1903) Heat exchanger - oil cooler , Gearbox removal and 1 other

-

Beta 43 (v1903) Heat exchanger - oil cooler

rgriffiths posted a topic in Boat Building & Maintenance

I have a Beta Marine 43 with a heat exchanger that seems to have a problem with oil from the gear box and water from the heat exchanger getting mixed. The oil in the gearbox is contaminated with water and there is also oil in the heat exchanger. I was told that seals can go around the oil cooler system, but before start taking it apart I was wondering if anyone had any pointers/tips. -

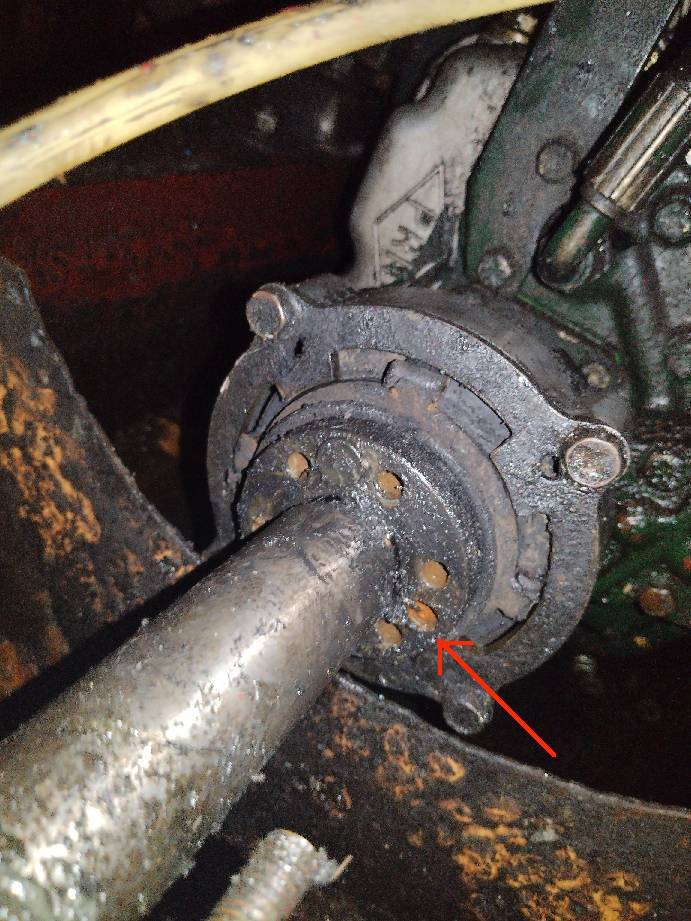

Thanks all. The 10mm bolt tip did the trick. Popped off very easily and managed to get the drive plate off. It was in a bad way and definitely needs to be replaced.

-

Ah I get you now. Yes that is what I was trying to do. It was releasing it from the shaft I was struggling with. Thanks again.

-

1 Good idea 2 Even if the coupling is unbolted from the gearbox flange it won't go 3 Tempting Thanks Ah - that makes sense. I will investigate - thanks.

-

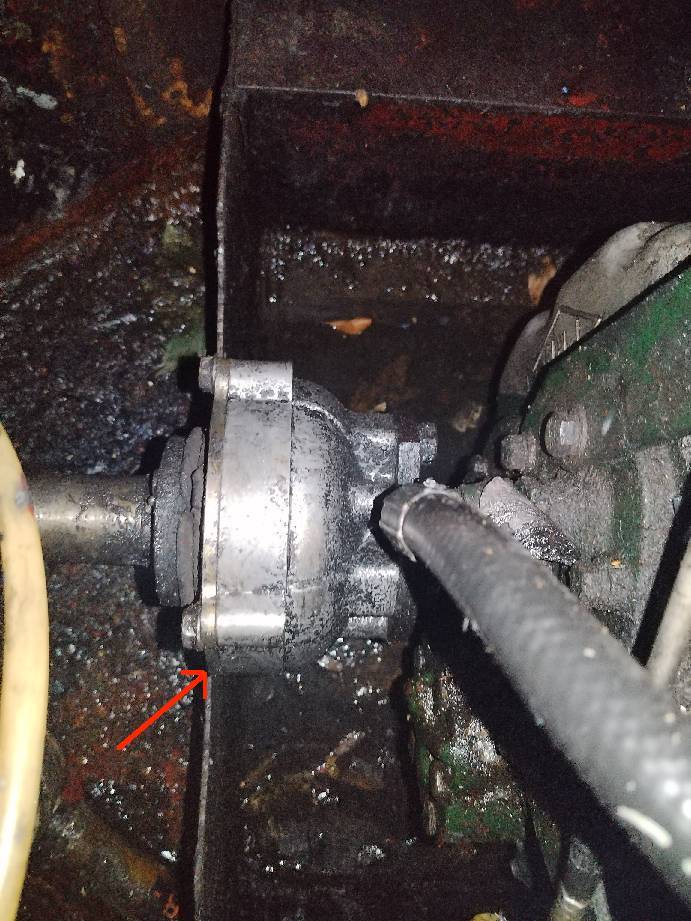

I am trying to change the drive plate on an engine but I am struggling to remove the gearbox. The gearbox moves back a short way but the bottom of the coupling hits the engine drip tray. I have undone the bolts (pic3) but the prop and coupling do not come apart. Any ideas? I could cut the drip tray down a cm or two but would rather avoid having to do that.

-

I have a leaky drain plug issue, the same as this problem here: https://www.canalworld.net/forums/index.php?/topic/44259-perkins-mc42-water-drain-tap/ Mine has sheared off when I tried to remove it. I have chipped away at the old one and the centre of it has come away easily, but it has left the outer threaded part still in the block, very difficult shift. I have tried various tools such as a scribe to pick at the metal but not really getting anywhere. Any tips, or is it just a case of more chipping away? I have considered getting a tap but I am not sure of the thread size. Any thoughts? Perkins replacement part number: 198736120 DRAIN TAP

-

Yes, inspected the rocker arms and all look fine. It certainly sounds like it is coming from this area. The head was taken off and fully checked over by specialists (pressure test, valves etc) but it's possible they may have missed something with the rocker arms. Will do some more investigation along with Alan's long screwdriver stethoscope idea. I have stood on it and no change.

-

Thanks all. Yes - that's the one. Tick, tick, tick, tick..... Definitely sounds like it is top end, and is not a mount. When I got the injectors checked, I was told there was signs of water in one of them. They said I might need to get the pump checked. Could water in a fuel pump make such a noise?

-

I have a Beta marine engine 1998, the Kabota 1505 type. Runs fine but I have this tapping/knocking noise that I can't diagnose. http://sndup.net/d2tb I have had the head off, injectors checked, tappets set to 0.010 inch. All fine. I can hear the tap as the engine turns over too, before it fires up. Before I go down the route of pulling the whole thing out and stripping, or possibly replacing it., I wondered if anyone here might have some bright ideas.

-

For anyone interested this is what happened : Got it out, welded up and good as new I hope. Found the drive plate was broken too so changed it at the same time. Thanks for all the help and advice.

-

That's kind of you. We are in London though. Just out of interest does anyone know what the material is most likely to be? It looks like aluminium but might it be cast iron?

-

Thanks all. Sadly the one on ebay is not the same and I am not sure will fit. I will have a trawl around to see if I can find one. Failing that I think a weld plus extra strengthening as you suggest Tony.

-

Again thanks. I was about to ask the same question ... where from? While I suspect it must be, does it have to be like for like or are there alternatives that might work? I can't seem to find anything on the net that looks like it.