Search the Community

Showing results for tags 'gearbox'.

-

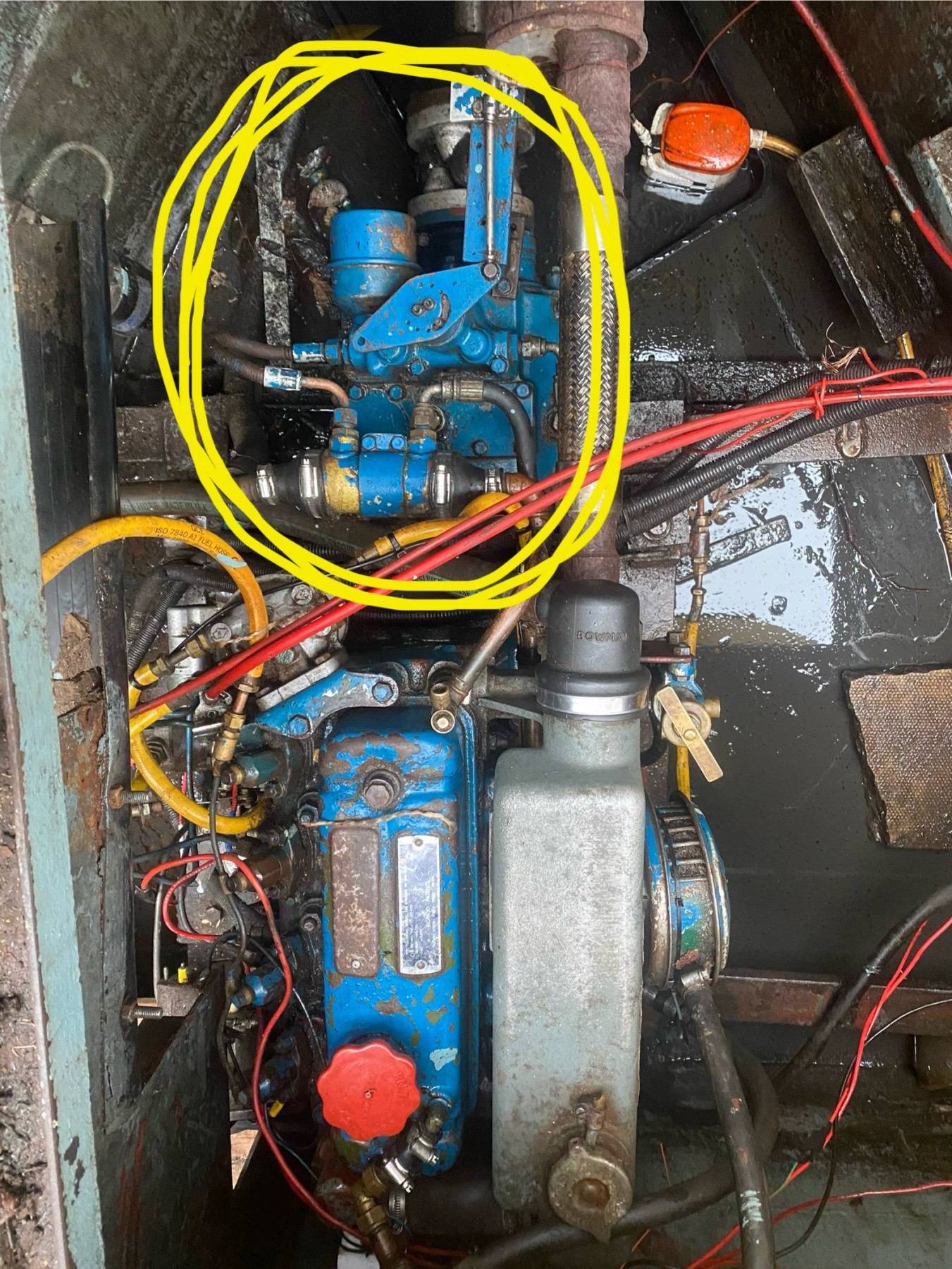

Hello this is my first post here, I was driving my boat the other day and I lost the reverse gear, I took a look at it and noticed this part highlighted no longer moved into reverse when the throttle was pulled back into reverse. Any help? Please ignore all the oil in the bilge I had an oil spill from the engine a few days ago which is all sorted now just need to clean up

-

Hello I got some 15w 40 oil for my BMC 1.5 and was wondering if this is the best option for it and what quantity to put into once fully drained? If so does anyone recommend a certain brand and where to get it cheap? Also asking about the best oil for the gearbox? Appreciate all suggestions! Thank you 🙃 all the best Goldilocks

-

Any body had a parsons gearbox lacking oil presure failing to go into forward gear

-

Could anyone identify this gear box please. It's attached to a BMC 1.5 with polar heat exchanger. The gear is slipping on high revs and I have been told there is a clutch tensioner but not so sure. Any help would be much appreciated.

-

Hi all. Today I have taken my narrowboat out for the first time in a year. I'm currently moored on the canal and am stranded. Today when on the water there was some loud clunks when shifting into gear. The boat then stuck in gear and I ended up crashing into a lock. Traumatic experience... I have just discovered I have no oil in the PRM 120D2 gearbox. Can anyone advise my next step to fixing this issue please? Is it as simple as adding more oil? Many thanks, Jason

-

I have just had my gearbox and drive plate replaced with a like for like Technodrive TMC60-P coupled to Vetus M4.15. Its on a SeaOtter. I did consider a PRM150 but unfortunately it wouldn't fit my boat. A downside of having to change a gearbox in a SeaOtter is that you have to lift it out of the water due to the PSS seal that is used. I have taken the boat from Reading to Newbury this last weekend (15hrs) which is its first outing since the fitting and the gears engage OK and I also appear to have adequate thrust but the gearbox has a terrible rattle like some one shaking a handful of bolts in a tin can. A noise I didn't have before and it occurs both in forward and reverse. oddly enough with the engine board lifted and engine exposed you can barely hear it but with the boards down it transmits and is amplified through the tiller. Any thoughts? I'd like to understand some of the possible causes before I get the engineer who fitted it back (River Canal Rescue).

- 4 replies

-

- gearbox

- gearbox noise

-

(and 1 more)

Tagged with:

-

Wot it says in the title... Start engine, into gear and nothing - for about 5 seconds and then the prop starts churning properly. It happened when we set off from the mooring on our last cruise but then all was good for the rest of the cruise. Gearbox PRM120D transmission fluid about 1-2cm above mark on dipstick.. difficult to tell as is clear fluid! Got OH to observe driveshaft and it is THIS which starts to turn really slowly at first and then suddenly speeds up, so i may be wrong but don't suspect the prop.. v difficult to access weedhatch! Help? (Beta 38 engine btw....)

-

5I'm currently cruising the K&A when without warning or any noise I have lost reverse gear. I have searched technical manuals and have deduced that it is a conical clutch system. I have disconnected my drive cable and tested it for movement. The cable operates freely. I carried out the following check with the cable disconnected. With the engine running I operated the gearbox lever by hand. It engages fwd drive ok, however on full movement into reverse the propshaft is barely turning. Is there any adjustment I can carry out which would enable reverse to engage correctly without affecting fwd drive? Any advice and help would be grately received

-

We have a Canaline 38 with a PRM 120 gearbox. If we wanted to change it out for a PRM 150 is the fit the same or will I need a new flywheel cover/endplate and modify the prop shaft etc. I read it will also need an oil cooler does this use raw canal water or is it plumbed in to the engine cooling water.

-

Hi recent issue, I believe the output shaft seal has gone on me. I was playing with the morse controller without the engine running and when I fired it up this began to leak. its behind the control plate, how can I take this apart and replace the seal, I really need to do it myself as I am out of money. But worried I may lose something. any help will be great. Okay so I should scrap the above, how to keep the ball bearing and spring in place, when I undo the nut where the control lever lives ? IMG_1644.mp4 IMG_1681.MOV

-

Hi any advice as to specs to look for much appreciated , thanks and sorry If i have been bombarding you with lots of questions the pressure is on to get this right, as I know you’ll understand.

- 17 replies

-

A friend has a hard to pinpoint oil leak from his PRM150. I too have a PRM150, but mine is rather lovely and wouldn't dream of doing such a thing to me, it's doting owner. His is quite young, though it's long out of warranty due to sitting on the builders shelf so PRM are understandably not rushing to be responsible. It seems seems likely to be a seal as he says he has no signs of damage, but what are the common sources of said leaks and, prempting the results of the better informed search, which of the issues can be resolved with the gearbox in situ? Thanks in anticipation.

-

I have the above gearbox fitted to my Lamborghini engine. The gearbox has a single nut holding the coupling on the drive shaft which when coupled to the the prop shaft is inside the two couplings. Problem is the nut keeps undoing itself and the drive shaft parts when I put in reverse leaving mm email with no drive at all forward or backwards. I have to take it apart every home it happens , tighten the nut, put lcktite on a bed burr the ends but to no avail. After a while it comes apart again as the nut had loosened and fell off. What can I do to stop this happening?

-

Hi all, When family and friends are steering the boat they are often clunk from forward straight into reverse without knowing. Although I advise that when the handle on the gear rod is in neutral, it is inline with the hatch front, as there is no resistance often they forget. I wondered if I could add a shim or block to the rod and attach a metal flap to the ceiling so there is some resistance at the neutral point. Anyone done this and any nifty ideas or suggestions? (other than steering the boat myself) Tom

-

Hi. I have a norwegian displacemeant / semi displacemeant Tresfjord 26 boat and im thinking about chancing the propeller. 8m long (waterline is 7.4m) and 2.8m wide, draft is 1m. Boat weights 2500kg fully loaded. Beta engine is rated 43hp @2800rpm, prm 150 gearbox is 1:2,09. It says on beta's website that the right propeller for beta 43 with gearbox ratio of 1:2 is a three blade 18x12. Would a 3 blade 18x13 propeller be over pitched? What kind of propellers do people have with this same engine and gearbox setup and what is the achiavable max engine rpm. I dont want a propeller that is oversized and i wont be able to reach 2800rpm My current propeller is a vetus 3 blade 16x14 and im getting maximum of 3000rpm and at cruising speed my propeller slip is 40% Regards Henri

-

Dear all, I have a beta marine 38, with a PRM delta gearbox (no input shaft spline wear) driven by an R & D 'extra dampening' drive plate. Coupled via a double-cardan/constant velocity joint (from a london taxi propshaft), through a plumber's block to the stern bearing. When engaged in gear, at tick-over (wound down to 550rpm), there is a distinct 'clonk-clonk-clonk' coming from the region of the gearbox. At higher engine speeds, this noise seems to go away, although that could just be the engine drowning it out. The shaft/cv join moves freely (with the force expected to drive a prop in water) by hand in both directions. The engine is angled down slightly on its mounts (adjustable screw-nut ones) so that the double-cardan input is slightly off-set. My question is - should I worry about this? I have no nylon coupling between the gearbox and the prop/cv-join input shaft, so is this likely to just be 'clonky plumbers block'? Should I raise the tick-over? It was wound down when the engine control lever insisted on increasing the rpm prior to engaging gear - there is now a correct control lever. I think the rated tickover is 750rpm. I will increase it. Many thanks, Patrick Vale (cross-posted to http://www.waterwaysworld.com/questions.cgi) Which seems to have replaced the title - should read 'Drive train clonking in gear'.

- 5 replies

-

- beta marine

- clonk

- (and 8 more)