-

Posts

71 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by kiwiSteve

-

All the scrubbing and blasting and more scrubbing must have been worth it.... oil after 3.5hrs running....

-

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

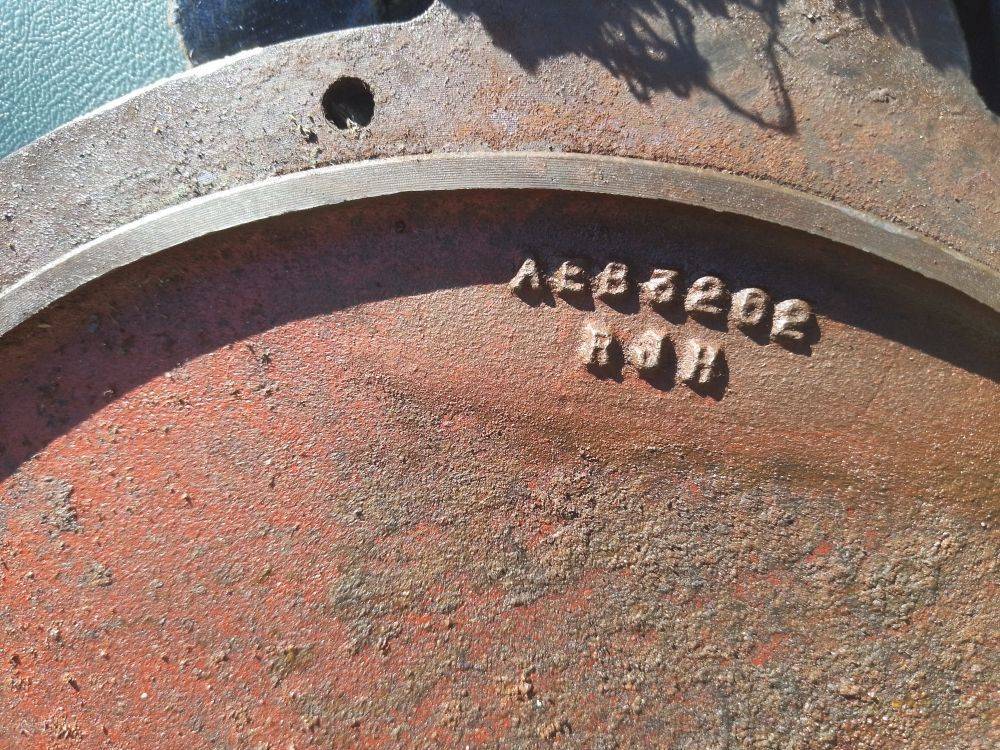

yeah this is the spare that is here at home I dismantled it for a practise run... had to build a puller and stuff. I thought I might recon this plate then just exchange them on the boat... I'll have a search for that thanks Tony the pinion my be as bad or worser on the other engine and need it... -

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

Yes.. the pump sits on a cam and pumps oil onto the planetary gear which then runs to the bottom of the box where its picked up by the pump again rather than spinning through oil.. looks like one of those endless threads on the inside of the pinion that carries the lube theres no cooling on the reverse box and I guess the oil passes to the end runs back down the box and a lot of the heat in the oil would be lost to the cast iron housing then pools in the bottom ready to go round again -

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

finally got a puller sorted and slipped off the rear bearing, oil pump cam and adapter plate... big rubber seal on the back of the main bearing.. I'm guessing the oil pump is pushing oil through the bearing seal and its pooling in the bottom of the bell housing and being picked up by the teeth on the fly wheel and spraying up top of the bell housing and running down the front at the join.... -

BMC 2.2 modern(ish) replacement ideas...

kiwiSteve replied to Quattrodave's topic in Boat Building & Maintenance

Ive just been through this whole scenario.. dont be fooled an engine change is like a snowball the problems just get bigger as you roll... weight, horsepower, bed length, gearbox rotation, prop size, drive shaft length, reduction, modern wiring loom, slip fees more costs, etc, etc... mate its a nightmare then you find something nasty that will need sorting before you can get it all finished... even more fees and hidden expense... Stick with what you have or you would be better selling and buying what you want already sorted... trust me..... a bloke i know set out to change his engine he already owned the engine he was going to use and he still ended up spending $13,000.00 NZD (6339.38 GBP) and ended up selling to pay the bill... Bugger! of coarse if you know a mate of a mate that can sort it cheap and do the job ok then good on ya, give it a go... I'll pray for you -

what about fitting a bladder... cheaper than chasing dry rot from your fresh water leak...

-

ok, that makes sense now i think about it, theres got to be some sort of flow just to keep things going in the right direction...

-

oh ok... you are probably right... "trying to find a solution to a problem that doesn't exist."... But when the thermostat is shut when the engine is cold there is no water movement through the manifold until the thermostat opens @88 degrees... I guess the water in the manifold wont boil while its waiting to heat up and the thermostat to open so no worries then...(even though theres not a lot of water in there) I was worried that, that small amount may heat up quicker than the engine, boil and turn to steam and the pressure might pop a hole in the manifold or something nasty... anyway just a thought...

-

Sailing the seas of Confusing Portable Generators

kiwiSteve replied to Batainte's topic in Boat Equipment

Hi... Ive had 2 of the Honda Eu20i gennys.. 1 has 5700hrs on it and the back up has over 7000hrs... incredible eh... My son is a Honda mechanic and he recommended them to me over 15 years ago as I need portable energy for my business I just had a new carburetor and valve grind done to the 5700hr one as it was running a little rich,,.. Both still start on the second pull.. -

You know how you come up with brilliant ideas that may or may not turn out to be so brilliant after all... When I set up my BMC marine engine i was worried using a closed cooling system might lead to cooling water trapped in the manifold boiling and causing a fuss, so as I had a few parts lying round and came up with this bright idea... just wondering what people think of the theory if boiling to steam is possible inside the manifold water jacket of the closed circuit cooling system or will the thermostat open before any problem...

-

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

... Ive just remembered the box was changed from my original engine so the box has been changed and by a mechanic who possibly damaged the seal as he put it back together (I found out from his boss that he was an experienced truck mechanic but new to marine engines... Bugger ) it was so long ago now (a couple of years or a bit more) I forgot. Thats why I didnt want to mess with it to much as I don't understand the planetary gear thing very well and dont know anyone that does.... He charged so much it led me to believe it must have been a really difficult and specialist job.. -

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

-

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

once I sus out just whats actually happening... this might be an option,, (I just want to go fishing ffs... lol) I have a second box here at home so can do some practise runs on dismantling with out having to drive the 70km to the boat every day and one box has the bolts already changed so I will do the same.. great idea thanks -

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

yes I see... so if it could have previously had EP in the reversing box that had leaked through the intermediate plate seal and now the new SAE20 that is leaking through has caused the the old oil to flow confusing the new leak with the smell of the EP... it is still that thick slippery stinky oil that the ep usually is in the bilge though.. exactly the same consistency and look as what overflowed from the bung Right... on with sorting the intermediate plate seal... thanks Tony Man I hope I have your luck.. and yes I have been a little out front on this one as it was only a couple of hours running before I noticed it.. so true.. I'm lucky you fellers put up with me thats for sure.. maybe someone else will gain from my posts if there is still anyone that needs this olde information left.. I know we have covered the subjects pretty deeply so the infos good -

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

and that would still only be the SAE20... although it would be hard for me to tell if it was a mix of darker EP from the reduction and the SAE20 by the time it is in the bilge so maybe both seals have a problem... why not... every other thing has been a battle I tell you this thing will be the death of me... at least some body is going to get a really good boat out of all this i suppose 😇 -

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

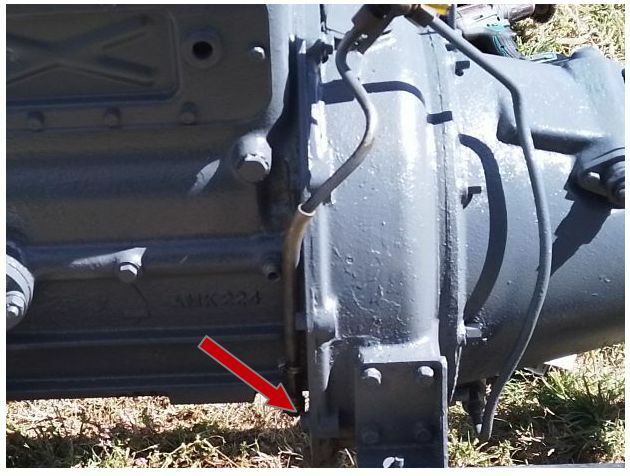

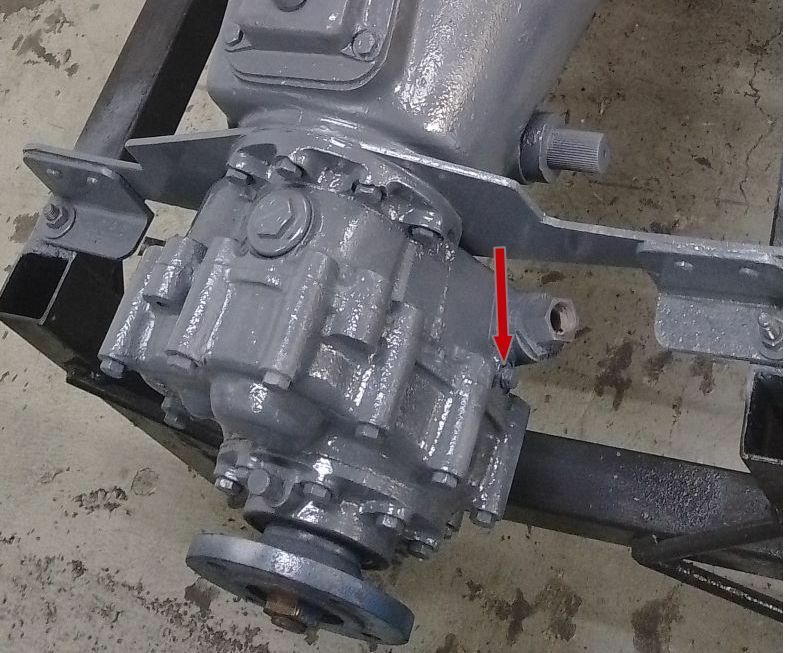

Yeah managed to get it started the other day... didnt remove the gearbox as I couldnt get hold of a set of mains or caps just checked the end float and put it back together.. an inframe rebuild i think its called or something like that... Ive got receipts for a box service done about 160hrs ago so I thought it would be fine... (and yet just another dumb move... if your rebuilding... check and clean, check and clean ) (Just a tight ass KIWI I guess 😋) yes to the arrow and when you watch its got a bit of a trickle going on, but as i said it was over filled and maybe theres some kind of relief system that has caused it It dripped a bit of this when I ran it up on its stand after the rebuild from the same place and I thought then it must just be from an old leak so spent 30mins with the break clean and water blaster trying to clean the bell housing out (bit of a laugh now i think of it).. anyway the main problem of water in the oil seems to be fixed and she run up beautifully its on 3hrs now... -

BMC gearbox.. and the fun continues...

kiwiSteve replied to kiwiSteve's topic in Boat Building & Maintenance

thanks for your help Tony... I thought the same as theres an EP smell in the reversing box bung... but the oil in the box is clean SAE20 and the oil flowing down my pristine bilges is dark EP the same as the oil that overflowed from the overflow bung... its got me stuffed mate... -

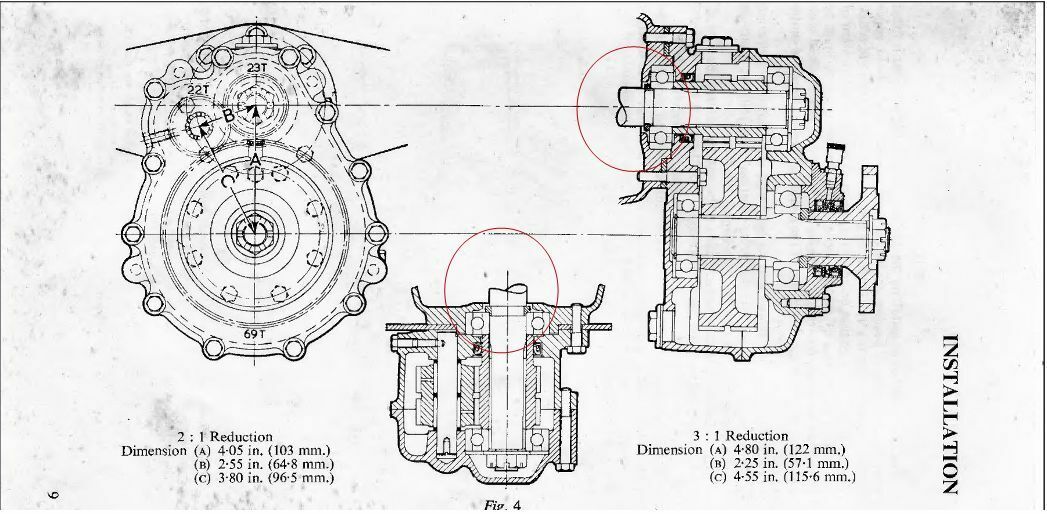

Hi Guys and the fun continues.... I have a BMC B type marine gearbox with a 2:1 reduction gearbox and a bad seal leak the oil is leaking quite badly and is coming from where the gearbox bell housing joins the engine it all seems a bit odd but its definitely the reduction as its leaking an EP oil and the main reversing box runs on SAE20 I'm picking its the shaft seal where the reversing box connects to the reduction has anyone or does anyone know or have any suggestions on how to change this seal... ? at one stage the reduction oil level was running overfull and when I opened the filler level overflow bung about 500mil of oil ran out so i was hoping the reduction may find a level and stop leaking but then discovered there's a seal on the shaft so knowing my luck it will need to be replaced

-

yeah good spotting... it was 34c in the shade on the day I set her up and couldnt be bothered walking a couple of hundred yards to the chandlers to score a few more so robbed a few from here and there just to get her up and running for now, but your right I must get on to some replacements...thanks for the reminder...

-

-

thanks mate... and for your help along the way...

-

Videos are so good at seeing wee problems you mite otherwise miss... you can see a tiny little drip of diesel appear under the bleed screw on the injector pump I would have missed that for days probably...

-

Ok... Ive been giving this a bit more thought... you do make a very valid point... so as Ive upgraded to a 3/4" fynspray pump @ 50LPM there should be ample water pressure to split off enough cold water to send down a 1/2" water pipe to cool the reduction gear and out via another outlet on the header pipe to sea... with the back pressure on the HX I probably won't even need a tap to dictate the flow. Well that gives me even more options to choose from... should be back up and running in a couple of days, now theres just the 50hrs run in time @ 1200 rpm... just as well we are not in to much of a hurry then eh.. Thanks for your help guys 😉 👍