agg221

Member-

Posts

845 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by agg221

-

Could it be K&A? One of the former turf-sided locks? I have a vague recollection of having seen Larssen piling there but that would have been 30 years ago. Alec

-

I would say it is a fuel/air mix problem, running too rich. That means either too much fuel or too little air. Can you add a photo of it is on the lowest setting on on the Toby? That should give a clue as to which of these is the issue, from the size of the flame. Alec

-

Assuming you have an iPhone, the quickest way I have found is to open the picture on your phone, then screenshot it (hold the power button and press the button on the front once). Save the photo of the photo, use 'edit' (top right) and the crop function to remove everything you don't want shown and you should have a suitable resolution image to post. Alec (no, I am not that tech savvy, but I have 14yr old daughter who showed me how to do this...)

-

Because if a boat that you like is on the market for £70k, and it sells to someone else, then you can be confident that it was a viable current market price for it. However, this is largely useless information as all you learn is what it was worth to someone else. In the end, you have to decide what a boat is worth to you. Alec

-

The problem is, the only way to find out what a particular boat is worth is to see what someone else paid for it... Practically speaking, if you happen not to want something which matches the current fashion in length, layout and interior decor then it will probably sell more slowly. That applies both when buying and when selling. It's not about the wrong price, just about finding the right buyer from a smaller pool. Alec

-

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

What would happen if you extended the overhang on the worktop? They are being custom made anyway, so if you widen the worktop to increase the overhang at the front it may improve both the look and the strength. When I did my (land based) kitchen I did this to fit a large butler sink and it hasn't caused any problems in 7+ years. Alec

-

I don't know the person who manages those moorings, but I do know that the CRT person who manages another set of moorings has a very pragmatic view. Ultimately, it will be noticed if you are always aboard, so one way of tackling this is to ring the contact number for the mooring you are interested in and ask to speak to whoever manages them, and clarify whether there are any limits on how much time you might spend aboard. They can answer this question without breaking any rules - unlike if you ask 'can I live aboard'? which has the official answer of 'no'. In my (limited) experience, CRT is well aware of people living aboard at moorings which are not technically residential, and doesn't have a problem with it. It has a problem with people who try to break the rules on CCing and who act in an entitled or disruptive fashion. There are so many of these, and they are so far ahead on the list of issues to deal with, that someone quietly going about their business and paying their way is really not going to be a priority for decades (if it ever is). Alec

-

where to get my hydraulic system serviced??

agg221 replied to crosser's topic in Boat Building & Maintenance

Do you know who supplied the system? If it was ARS or uses the same parts they use then they do offer a mobile service. I did enquire about having mine serviced by them, which they are happy to do, but given the symptoms I described they advised that I didn't call them out, and talked me through how to do it instead (and sent me a free copy of the manual). I am therefore sort of not a customer, but for the best of reasons. Alec -

I agree, and suspect the lack of application was mostly a function of quality/price. A J2 on high compression heads would be functionally no different to a 2DM/DM2/JP2, but it's rather like the difference between installing a Ford engine or a Rolls Royce engine - you would generally expect the Rolls Royce engine to be better engineered, run more smoothly and reliably and be all round nicer to have, but at a price that generally isn't viable. If my life was dependent on a single engine when fishing in the Atlantic I would buy the best I could afford; for a canal boat which could just be towed home, I would economise. Alec

-

One question I have wondered about - are you able to run it hard enough to avoid bore glazing? The J2 in ours is definitely worked hard. When we first got it, it smoked badly (blue) but with repeated hard work we have now got a clean exhaust up to most revs. I could of course strip it down and rebuild it, which would solve the problem, but it seems to be doing a decent enough job of sorting itself out. I can see how a 70' boat could make use of 44hp but I have sometimes idly wondered whether you can make 66hp work hard enough on canals to avoid the problem? Alec

-

Kelvin did not appear to envisage this being a question that would be asked when these engines were being manufactured. The general reckoning is that the Kelvins were too expensive for that application. The only original installation I am aware of during the period of manufacture was in Joel and that was a Kelvin Ricardo petrol/paraffin twin. In practical terms, I would take it that the primary bearers on which the engine sits should always be transverse, but that the lower stiffness of the flat baseplate in a narrowboat would require additional stiffening - probably using attachment to the sides and extending fore and aft to spread the load. I am sure if you looked at a Northwich Trader you would find a good solution, since excessive vibration does not appear to be something that owners report. Alec

-

It's a valid point that the K2 is twice the hp of most other vintage twins, and that the installation requirements need to take that into account, but Graham's comments weren't that specific. All slow running twins will cause vibration, make battery charging a bit more complex and need a big prop, hence deep draft. They are also all (with the possible exception of Gardners) relatively simple and easy to set up and maintain, hence my comment that in terms of living with an installed traditional engine there isn't much difference between them (assuming they are properly installed in the first place, which whilst different in the detail would be a common requirement for any engine). One point of genuine difference with the K is that as originally specified it did exclusively use 24V starting whereas 12V or 24V were optional on most other engines. However, there are many Kelvin Js, Lister JPs and Gardner LWs with the same basic BS5 starter motor, some using 12V and some 24V, so 24V charging/starting has established solutions, although as Graham points out, if that has been addressed with 24V electrics throughout it is a bit less convenient. It is perfectly possible to charge 24V one side, 12V the other side on a split charge system (a friend's boat has this) but personally I prefer mechanics to electrics so will switch mine to a 12V system throughout. I would hazard a fairly educated guess that high CCA batteries were not available when Ks were being manufactured and that actually you could start one on 12V if you fitted a suitable battery and cables, but they might be rather heavy! Btw, the recommended installation for all Kelvins, right down to the 7hp E2 petrol/paraffin, is a transverse engine bed. I quote the Kelvin Ricardo Petrol/Paraffin service manual: *75. ENGINE FOUNDATION.— All Kelvin models are designed to rest on two transverse bearers (longitudinal bearers are not suitable). The bearers must be of hardwood and should rest direct on the planking clear of ribs. In boats having only steam-bent ribs the bearers must run up the bilge to the height of the flywheel centre, but in boats with grown frames the bearers may be straight on the upper surface. The bearers should be fastened from outside with brass screws and drawn hard down to the keel with a proper brass screw bolt which should be tightened once a year as the wood shrinks. 8 levelling washers were supplied with the engine. One at least should be below each foot to prevent it sinking into the wood. Alec

-

Hexagon Boat with Nana Engine and Hydraulic Drive … any good

agg221 replied to Didne's topic in New to Boating?

For reference, I have found ARS very helpful, in that they have provided me with information and advice -not- to spend money. Very much appreciative of their responsiveness as a 'not yet' customer. One piece of advice I got given was to replace long hydraulic hoses with a short hose and a length of steel pipe. It helps with cooling, requires less wrestling in and out of place and when the hose eventually needs replacing it is much more portable. Because the steel pipe (proper hydraulic pipe) is oil filled it can only corrode from the outside, so if that is painted up there is effectively no degradation. I will probably do this when my hoses eventually need replacing, but at 20yrs old there is still no sign of deterioration so they may well be good for many years yet. Alec -

Graham has direct experience of the K but most of his comments apply to pretty much any vintage engine running in an engine room. Similar comments would apply to our J2. We draw 3'1" and have made it to the end of the Llangollen feeder so draft hasn't yet proved to be too much of a problem (although the occasional bit of hauling over the shallows was needed up the feeder, but that is nominally limited to 2'3"). I have managed to deal with a lot of the annoyance of the vibration which happens at certain RPM. Some of it is about finding the thing that rattles and fixing it down harder, but our whole cabin roof vibrated at certain revs. Having noticed that a friend's boat with a Gardner 2LW and a wooden cabin did not vibrate at all, I have started adding wooden 'cabin frames' internally which have a huge effect on damping the vibration. These are glued in with a high strength polyurethane construction adhesive which gives excellent bond strength and a bit of toughness. If what you are looking at is a Northwich Trader I wouldn't have too many concerns - the boat is basically designed and built around the engine. Alec

-

Apologies for the delay - strange forum error kicked me off and asked me to respond to a verification email, but it wouldn't send one! This now seems to be resolved - link is here: http://www.sky-net.org.uk/kelvin/equipment/ee/index.html Alec

-

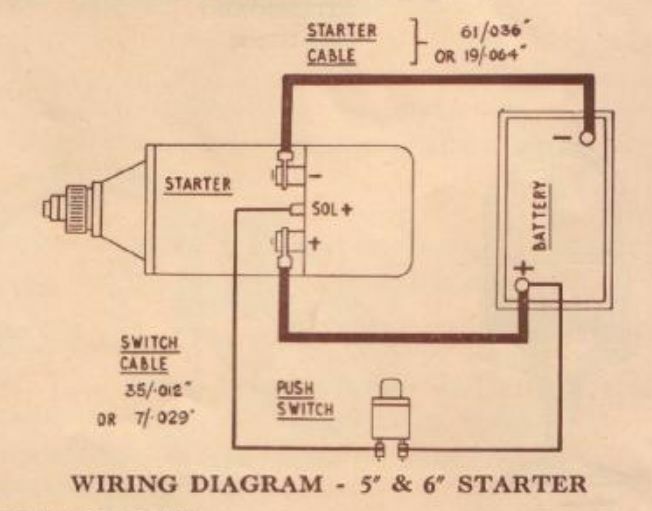

That would make sense - it also gives the correct specification for wiring up your solenoid! Alec

-

I found an online copy of the starter motor installation specification for Kelvins. It isn't part of the normal manual - it is part of the specific electrical equipment manual. It includes wire dimensions - not quite sure how to interpret the numbers but if the second part is a cross-section in square inches and the two options are for 24V and 12V then it would make sense that the larger dimension is for a 12V system. If so, 0.064 square inches is 41mm2, which seems reasonable. Alec

-

Thanks everyone! Replacing the pinion is a job for the weekend (assuming the floodwaters aren’t blocking the path to the shed). I will let you know how it goes. The main reason this information is so useful is to confirm that there is nothing lurking in there like a compression spring or retaining grub screw which can cause no end of problems if you don’t know about it in advance. Alec

-

Hexagon Boat with Nana Engine and Hydraulic Drive … any good

agg221 replied to Didne's topic in New to Boating?

We have a hydraulic drive on Oates. In addition to the comments made above (which I agree with) there are a few more things that are useful to know. If the engine, pump and motor are well matched, it is a long-lived and reliable drive system. The hoses are expensive but are not exposed to the UV and flexing that they would be in, say, an excavator so they too are very long-lived. They also give a warning sign that they are about to fail by bulging. The only requirement is to keep the filter clean and change the hydraulic oil from time to time (do find out what the right specification is). The oil is cheap. There are two types of pump. One is forwards/off/reverse so feels like a gearbox, the other has a variable angle plate (swash plate). The latter is infinitely adjustable which is nice if you have it but not essential. It's a more expensive system to buy than a simple prop shaft, but if done properly and looked after it should see you/the boat out. Ours was installed by the previous owners c.2003 and has been around the whole system and is still going fine. Do check that there is a header tank, that it has a level gauge and that there are no obvious leaks as sorting them out is a pain. It's easy to test if the set-up is right, just take the boat for a spin and check that it picks up properly and does not feel excessively laboured or slow for the engine revs. Listen out for the slight whine (inevitable) but check it has not got very loud, which would indicate a problem. Try forwards and reverse (btw, although you could probably wear it faster eventually by going from forward to reverse at high revs, it is a lot more tolerant to this than a mechanical gearbox is). Having run it, check the oil temperature and see whether it has an oil cooler or not. Some (inc. ours) don't ever get hot enough to need one if the pipe run is reasonably long and it runs against the hull. Would I only have a hydraulic drive? No. Would I take out a perfectly decent prop drive to fit a hydraulic drive? No. Would it put me off buying a boat if it had one fitted? No - I would be quite happy to have another. Alec -

Thanks for that - the picture certainly helps, and it doesn't have any problematic springs to go flying across the workshop! Just to clarify on the first picture, is there any relevance to parts 54 and 55 being shown? E.g. do they need to be removed prior to starting to remove the split pin and nut? Thanks Alec

-

Thanks - that sounds a lot easier than I had feared. I was anticipating springs buried in there... It will be a replacement starter motor anyway, changing from 24V to 12V, so I will have to set up the clearance regardless. To be honest, when I re-fitted the motor which is currently on I eyeballed it and it has worked fine. I could take a more structured approach and use a drill bit this time. Alec

-

I'm OK in that regard. I have a couple of spare bronze pinions, one NOS from a company in Manchester and the other advertised on Facebook for a Gardner U6 starter motor but conveniently they are the same part. I haven't worked out how to take it apart and change the pinion yet though, that joy is yet to come... Alec

-

Thanks - that's exactly the information I needed. It also ties in with previous thoughts above. Alec