-

Posts

21 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Santa Cruz, CA USA

-

Occupation

Engineer

-

Boat Name

Steadfast

-

Boat Location

Santa Cruz Harbor

Recent Profile Visitors

646 profile views

Julian Xavier's Achievements

Explorer (2/12)

0

Reputation

-

Thanks, that explains it.

-

Got another opportunity to get down to the boat. I don't suspect the timing chain but I did want to remove and clean the timing chain cover regardless due to the large amount of rust and grime that I just couldn't get to easily. Used an impact gun to get that nut off of the crank pulley mine happened to be 1-5/16" FYI. Here are some images and a video of the timing chain, the tensioner seems like it's got a lighter spring than I expected however being on the slack side I'm not sure it matters. For my motorcycle I usually measure chain wear as the distance pin to pin. I'll have a look in the manual to see if there is a spec but if someone already has the figure or another method for checking I would appreciate the assist. I turned the motor over until the pips lined up, seems close enough to me. Thoughts? https://photos.app.goo.gl/YQymfJM63G8owv336 I'm taking the pulleys and the timing chain cover to sand blast them, replace the oil seal and gasket ect. I plan on scraping the rust and old gasket off the motor. All of the bolts are getting replaced, they all seemed pretty tired and corroded. On a different note, does anyone happen to know what the threads/fittings are for the injector pipes? Are they 1/4 bsp or some other designation?

-

I struggled with that, eventually I did find the specs for resistance and pressure/temp range. Ultimately I just ordered new senders and gages as matched sets. The temperature guage came as a complete kit whereas the Seastar oil temp guage called for a type C sensor (0-80 psi 240-33ohms) so I found the appropriate sender and purchased it separately. It proved difficult for me to find an oil guage sold with a sender. It's a problem I've run into frequently with this motor. Auto parts vendors always want to know vehicle specifics to source parts. Give them specs and measurements... good luck. I've had some luck with parts such as the alternator providing info on vehicles such as the 74 MG MGB that were fitted with the BMC 1.5 Petrol motor.

-

Ah! I'll have to look him up. I live in Boulder Creek not too far away we were evacuated during the fires, I hope your cousins home was left intact. COVID restrictions put a bit of a damper on meeting new folks at the moment. And to your point, yes the climate is very moderate here, another reason why the starting issues trouble me. I am hoping that the timing truly takes care of it. though to get more adjustment out of the injection pump it looks as though it would require bending the injector pipes. Another option would be to increase the speed of the starter. Very subjective but it sounds like it's turning over just fine as is. Earlier the state of the battery cables was asked after, they are all brand new. I bought brand new 4/0 wires, short as possible and made all of the connections myself with solder in the terminal ends. I could have gone heavier on the wire gage but I seriously doubt that's my limiting factor. It's an option to bump up the starter voltage but I am weary of destroying the starter output gear. All that said I made my adjustment earlier in the week and had to wait for a cool motor to see if the starting has improved. Might get back out to the boat this afternoon.

-

Hopefully unrelated but my oil pressure gage stopped reading somewhere along the line, I suspect it was just the sender (when I measured it it came out to 153kohms with the engine off). I've ordered a replacement and shut the engine off, I don't like running it without being able to keep an eye on the oil pressure. The new sender is on it's way with a 1/8NPT thread, anyone happen to know what the threads are in the motor? It looks to be 1/4NPT or 1/4BSP. While I was at it I ordered a new temp gage and sender, it bothers me that even after running in gear for up to an hour the temp generally hangs out around 120-140F. The 82C thermostat is on its way as well, it is currently fitted with the 72C, though I wouldn't expect this to make a difference after a sufficient amount of run time.

-

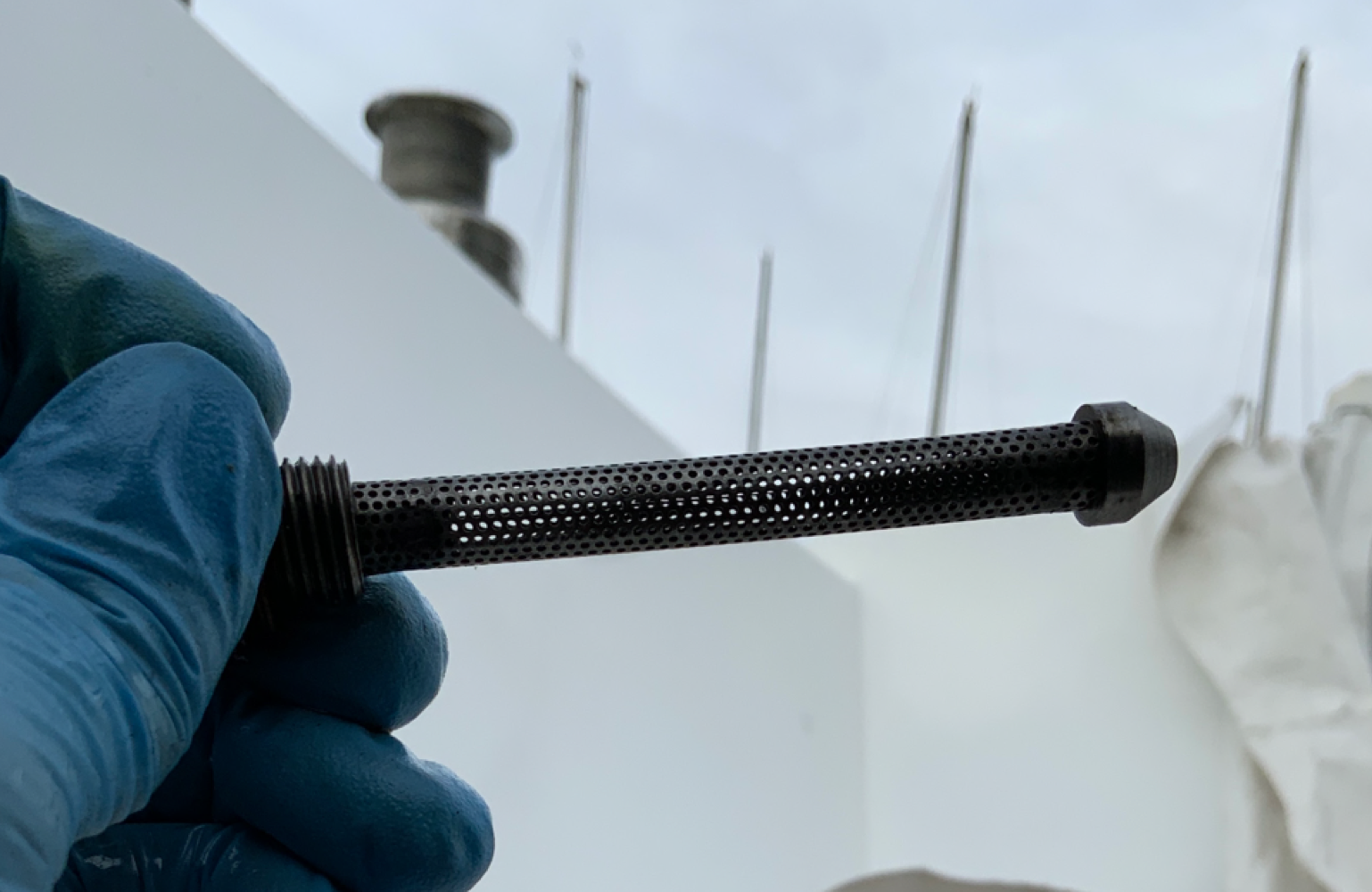

Tony, yes I checked both. The strainer had a couple of Small splinters I could not identify. They could have been metal or portions of gasket or even carbon. The second component seemed clean but I noticed a of bit resistance while reinstalling it.

-

The fuel is likely two years old, however I do add Stabil diesel treatment to it every 6 months. That said I can swap out for fresh diesel to see if it makes a difference. I have used starting fluid (with ether) and that works like a charm, but I would like to find a different solution as so many people caution against it, plus It seems to me it shouldn't need it with the compression I'm getting.

-

It seems like this motor will be in great condition once I figure out the timing or whatever else is causing me issues on cold starts. I'm looking forward to getting it squared away so I can clean up and paint the motor.

-

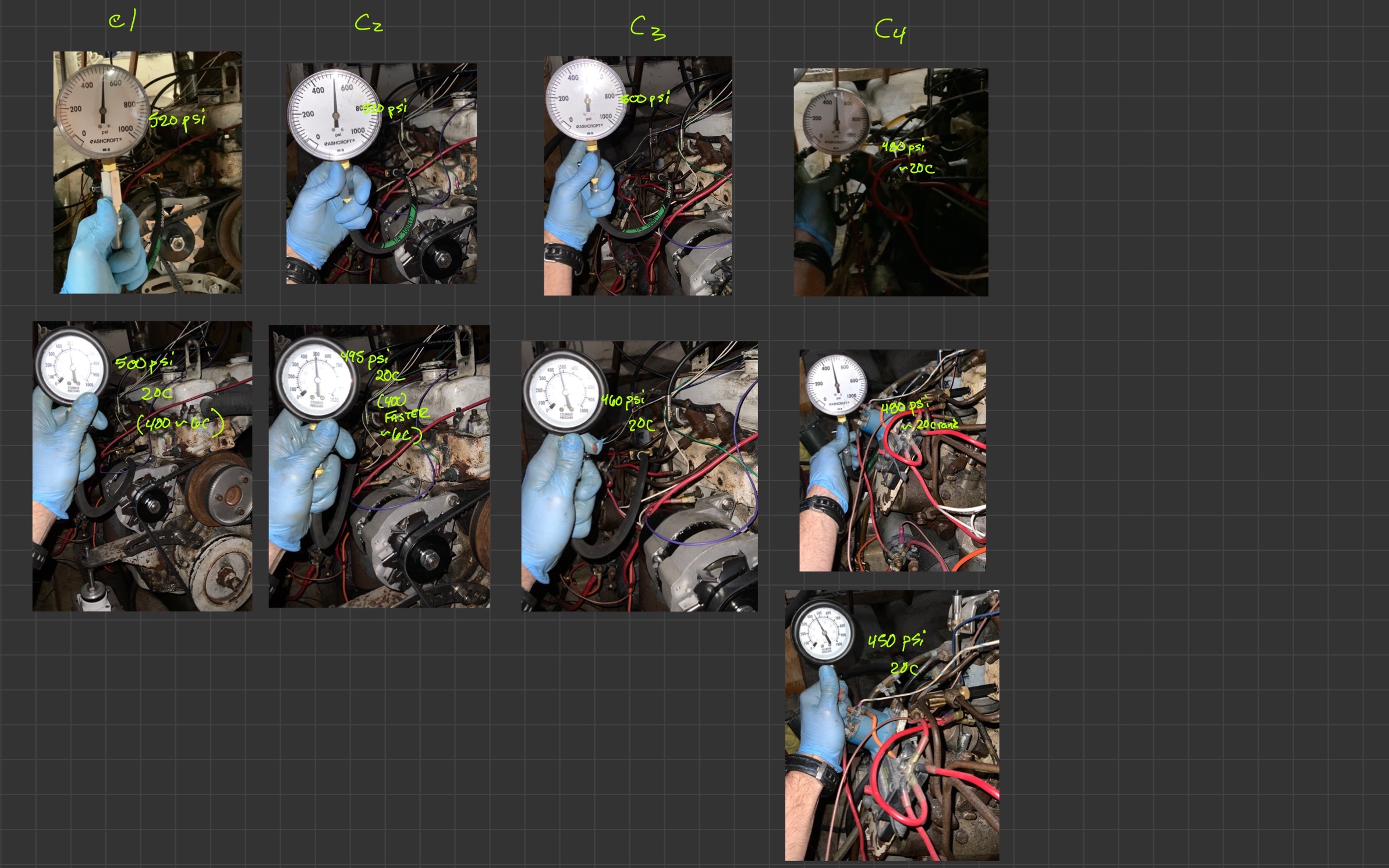

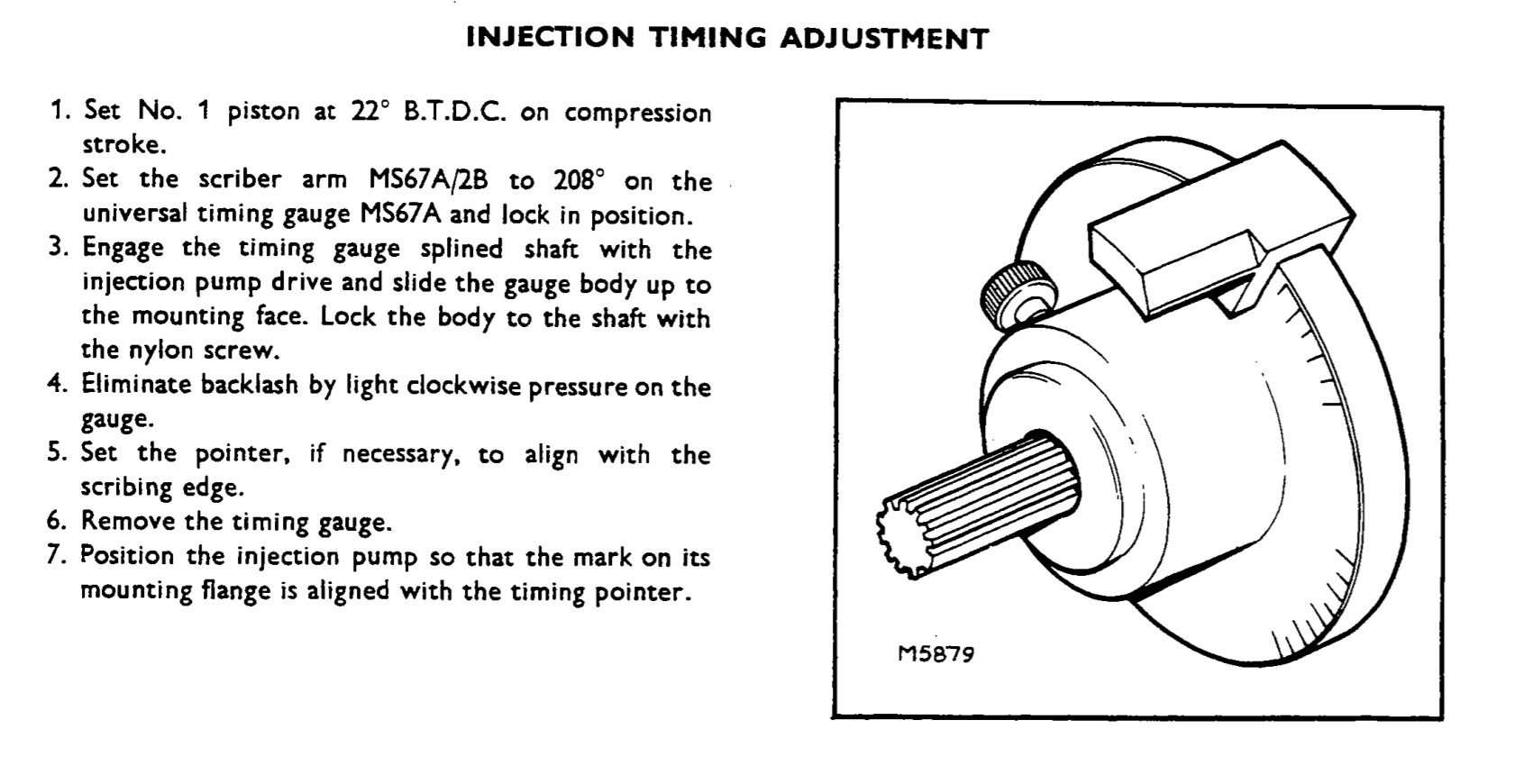

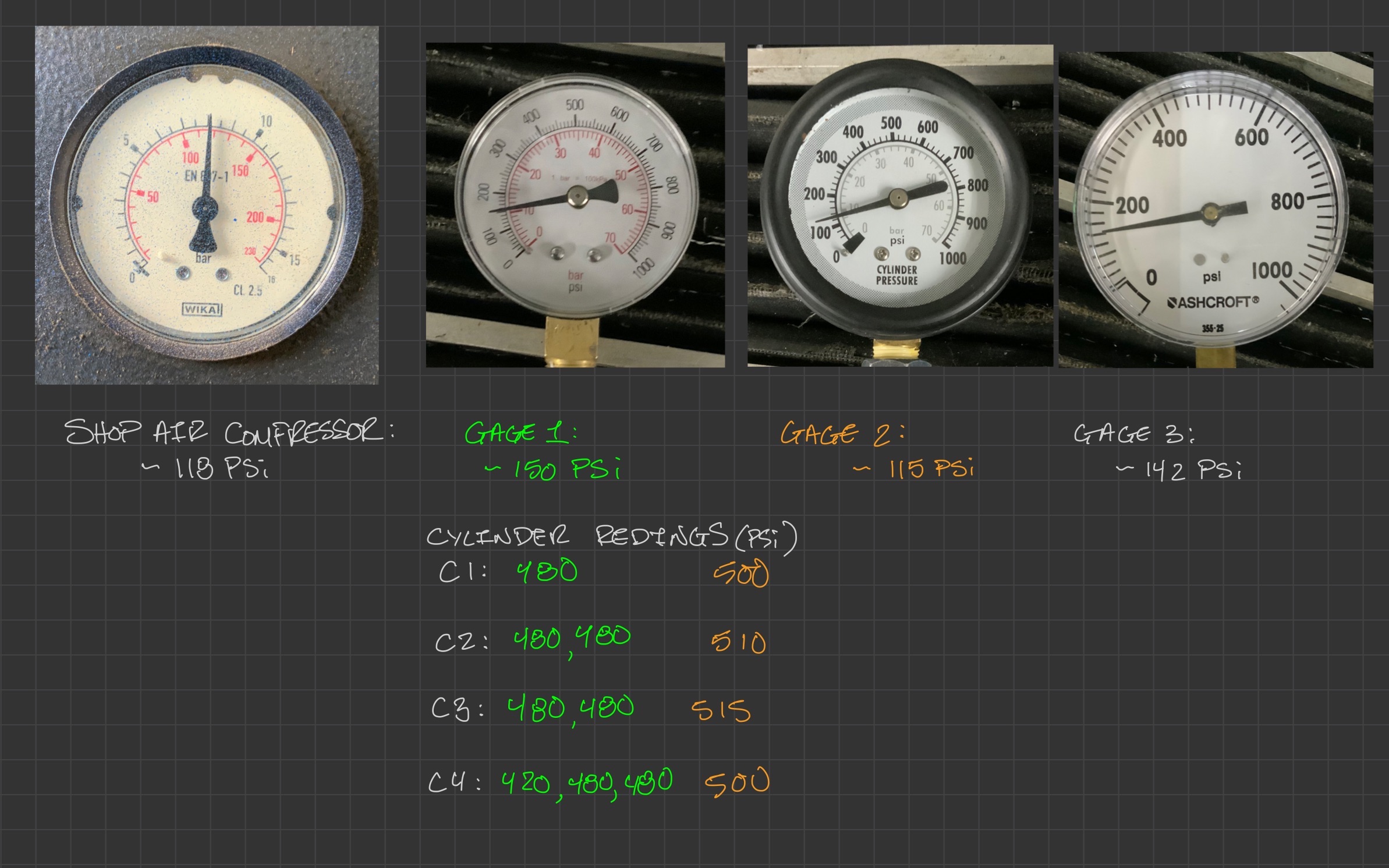

That's excellent Rob! What did you use to establish the proper angle between the master spline and the timing notch that you have on the outer disc? I see in the manual some mention of 208 deg but really not sure what that means. 208 degrees from the master spline? Also according to the figures discussed for the compression it seems that my engine is doing just fine on that front. I really have no idea how the mechanic I called previously could have come up with values as low as 220psi when this is what I read: Anyhow, I checked the oil strainer to the skew, seemed clean and clear. I ran the compression test above. The motor still had a hard start but once she runs that's it, I will have to have a friend along next time I cannot see the exhaust smoke from inside the engine compartment. Whilst running I rotated the injection pump (CW seemed to slow the revs, CCW sped them up). Ultimately I rotated the pump very slightly CCW and it seems to run faster for the given throttle input and perhaps smoother, very hard to tell though, the whole boat experiences significant vibration while the motors running and I'm not sure how much is normal for this motor. Next time I get out to the boat will be the real test. I will try to start cold (with the glow plugs), and see how it goes. If this still doesn't improve the starting I'm going to try changing the battery cables out to series and go for 24v on the starter, see if the extra oomf starts it up or burns my starter out, hoping for the former. It could be that the extra juice would get her going quicker, might be better for the motor than the endless cranking have had to do in the past.

-

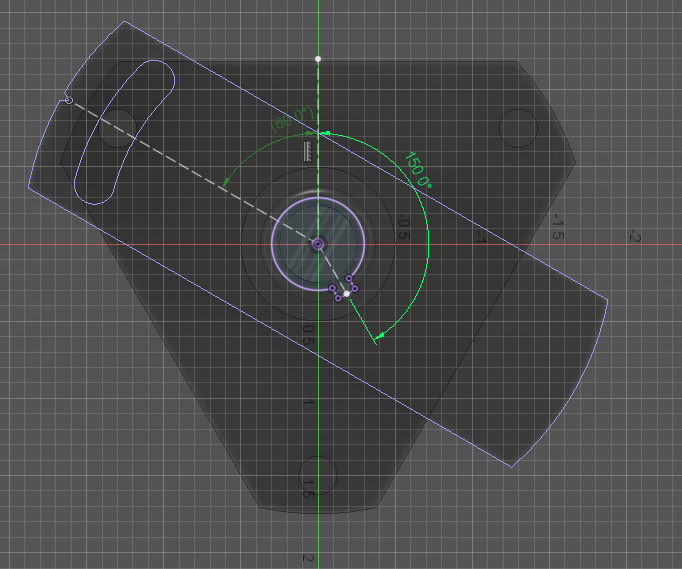

This is what I have come up with based on the information in the manual, though I'm not certain about the placement of the notch. I'd be interested in making these for anyone that could benefit from the use of them, not looking to make a profit. Best case scenario these may be candidates for 3D printing, in which case I could simply make the file available, no shipping necessary.

-

Ok, I think I'll still try making one of those, unless this was the timing tool that you mentioned members might be interested in? Or is there yet another...

-

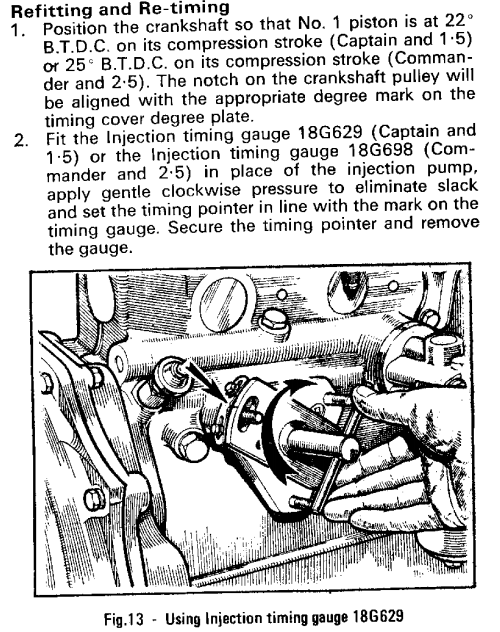

I've been doing a bit of digging trying to figure out the injection pump timing tool but I still haven't figured out what all the geometry would need to be. Has anyone already puzzled this out? Looks to me like perhaps this is another tool for establishing the master spline at 5 O'clock. If that's the case, and all that needs doing for a notch to be made opposite the master spline I should be able to make one. Anyone able to weigh in on the alignment of that notch? Also came across this Tempest version of the BMC 1.5 manual, seems like it has a lot of great info, additional drawings as well. https://drive.google.com/file/d/1_nglPfi5gnKQ_w9qtlc_gwAGM-NilaIn/view?usp=sharing

-

I have not but after all the information I'm getting here I'm pre pairing my tools in order to try all of these approaches. check the timing chain/tensioner, pressurize and listen for leaks, pull the skew gear + strainer. It will be a bit before I can make it to the boat but I’ll post my results.

-

Bizzard I have an adapter that should work. I will bring the compressor & give it a go with the leak down test. However I was able to test the gages at my shop today. The results suggest that if anything I have ~ 500 psi + on each cylinder. If accurate I doubt I have issues with rings or valves. Is 500 psi problematic? Could excess carbon buildup be responsible for that large of a reading?

-

I will do all the above, feel and visually inspect for wear. If I can figure out the necessary details to make one of those timing gages I would happily make one for my own use and make them available. I would probably just turn the shaft down and only worry about making the master spline (the large tooth) I believe but do not know that the valves are in good order, last I had them out they looked decent in terms of pitting etc. and I lapped them in by hand. I performed the valve clearance adjustment last week before the compression test (0.015") and triple checked them to be sure. I might ask my mechanic to come down and perform another compression test before I take the head off, but if it still comes back high (480 psi +) If low: I'll remove the head inspect the valves, maybe replace them or have them ground, seats cut, etc. inspect the cylinder wall for wear if high: I don't really know what to do here, pull the head anyways and check what's going on, clean out carbon if excess buildup is present count my blessings and leave well enough alone, try to address the cold start issues with the injectors and pump timing alone.