-

Posts

23,321 -

Joined

-

Last visited

-

Days Won

119

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by nicknorman

-

-

If the decline was gradual, I’d say limescale on the calorifier heater pipes. The trouble is that it will be on the outside of the pipes, on the potable hot water side, not inside from the coolant circulation. So descaling is a bit tricky as you have to pour nasty chemicals into the hot water supply. Lots and lots of rinsing out required!

If the calorifier has an electric immersion heater element, you could undo this which allows you to look inside at the state of the heating coil pipes and see if there is a lot of limescale.

-

8 hours ago, IanD said:

Nick's repeatedly-stated position is that because his particular LFP cells don't need top balancing, it's not needed.

The position of multiple LFP battery/BMS suppliers is that top balancing is recommended (or required...) because there's no way of knowing whether a set of cells need it or not without trying it, and some (many? most?) do -- so the safe option is to do it. And if you don't, it's likely to invalidate any battery lifetime guarantee -- it definitely does in some cases e.g. BYD.

Given their experience with large numbers of LFP systems as opposed to one DIY setup, I prefer to follow their advice. Others are free to make their own minds up... 😉

Having seen the data you recently posted I can see why you are taking the line you do. But if that is typical data from your setup, that is abnormal and points to something horribly wrong with your system. Obviously you are in denial about it at the moment but you will find out eventually. And when you do I’m sure you will keep quiet about it.As to using emotive words like “safe” and “invalidate … guarantee”, if a battery really is out of top balance, this is not unsafe nor going to invalidate a guarantee, this is scaremongering. All it means is that the capacity of the battery is temporarily reduced. No damage is accrued and the situation is entirely reversible. Not a scary situation.

7 minutes ago, GUMPY said:

Well as we’ve said voltage differences at 75% SoC are not relevant to anything. Obviously “out of balance” is not a binary thing. I’d say out of balance becomes significant if the BMS protection kicks in due to one cell going overvoltage at the chosen charge voltage. So the higher the charge voltage and therefore the more determination to cram as much charge into the battery as possible, the more important it is to have the cells well balanced. -

1 hour ago, Gybe Ho said:

A technical point of order, not that it matters, I thought passive balancing used resistors and active balancing was more hitech.

Yes. Passive balancing uses resistors to dump energy from the higher cells. Active balancing redistributes the energy from the higher cells to the lower ones. But is more complicated and expensive.Since good quality well set up cells don’t really go out of top balance(!), boat type systems generally use passive balancing. The main advantage of active balancing is if you want to maximise the capacity of the battery, ie have it top balanced AND bottom balanced, so you can fully discharge it. During discharge, energy is shunted from the cells with slightly higher capacity, to those with lower capacity, so that as the SoC approaches zero the cells are at similar voltages and ideally all hit the minimum of 2.5v simultaneously. During charge the reverse happens so the cells top out at the same time.

-

1

1

-

-

Yes a battery can suddenly die. Lead debris builds up at the bottom of the battery and eventually reaches the plates, where it shorts out. This takes a cell out and the other cells discharge through it.

So probably just one battery is to blame, and you can possibly tell because it might be warm. But if the batteries are the same age, the other ones won’t be far behind and the best option is to replace the lot, and 7 years is a good life.

It won’t be an unexpected heavy drain by something - if it were, the SoC meter would show a low SoC. But you said it still showed 99%.

-

1 hour ago, 1st ade said:

Much as it pains me to agree with Gybe Ho - I'd argue that going into a state where the system could Top Balance but doesn't, counts as Top Balancing?

I disagree, top balancing occurs when … the system is top balancing (by turning on the balancing resistors etc).

I could drive my car, I have the keys in my pocket and the car is a few feet away and it has petrol. So I am in a state where I could drive it. But I am not driving it. Just as well as I’ve had a gin and tonic!

There are two issues at play, the need to top balance and the need to charge to 100% ish to synchronise an Ah counting battery SoC meter. The latter is necessary reasonably frequently, every few weeks depending on how accurate you need the SoC indication to be. That is why the system is placed in a condition where the system COULD top balance. But it doesn’t, because it doesn’t need to.

6 hours ago, blackrose said:Update:

I've just fitted a nice new alternator and I think the issue is resolved.

The highest buffer battery voltage I now see with no load on the battery is now about 14.47v measured on the multimeter which I think is ok. The Orion B2B charger only gives voltage to 1 decimal place on the Victron app and that says 14.4v max.

That maximum voltage is observed when engine revs are lowest at idling which would make sense wouldn't it, because current from the alternator is lowest?

Jolly good.4 hours ago, IanD said:

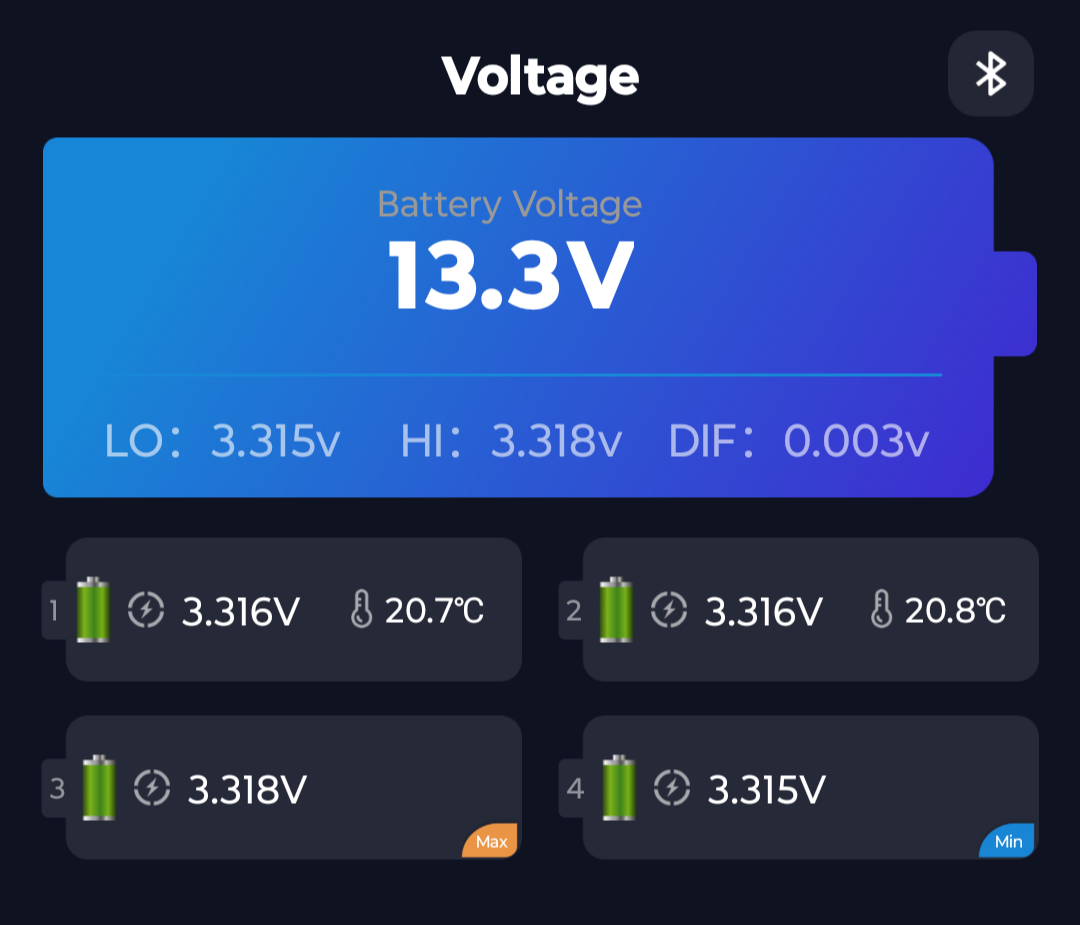

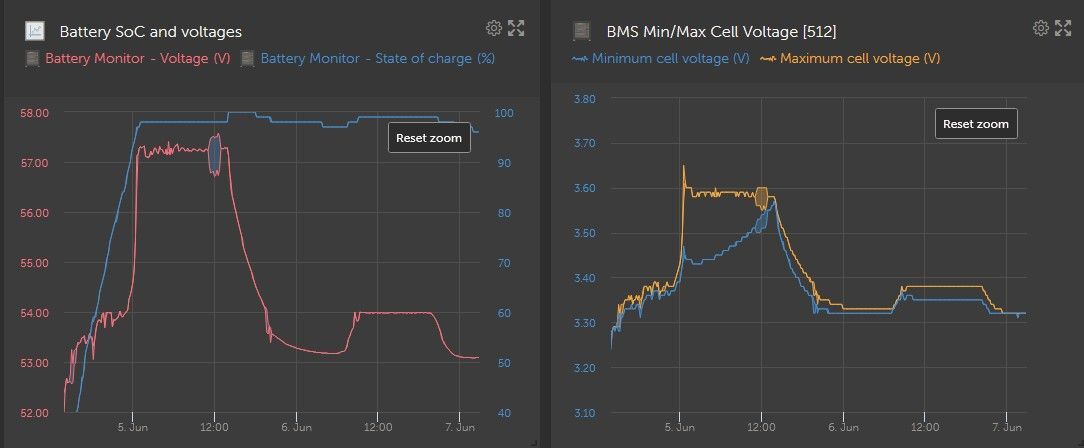

Jeez one cell at about 3.44v and one at 3.65v. And 1/2 a day to rebalance. That is terrible. How long since the last balance?Something is wrong with your system. Do you have some tap off part of the battery to run something at say 12v? If not I would be worried.

-

51 minutes ago, missingtheboat said:

but the post points to lots of data sources, is this not evidence? As I mentioned earlier, a quick google appears to support the idea that cell balancing is a normal requirement (see https://www.victronenergy.com/media/pg/Lithium_Battery_Smart/en/appendix.html#UUID-bd5c63a2-ff2f-7d25-896b-182910e8dad5)

A suggestion...why not, rather than making continual demands on other to cite evidence, present some evidence that supports your assertions? - or at least offer a critique of something like the evidence presented in the link above.

Wouldn't this be the more efficient route to get to the bottom of all this?

My evidence is based on my own data - that my cells don’t go out of balance. I did ask IanD several times for similar data ie how often/how much/if at all his cells go out of balance, but no response, just repeating the mantra. This leads me to believe that his cells don’t go out of balance either. It’s true that some manufacturers mention the need, but manufactures (who don’t actually make any cells) say lots of things, some of which are valid and some are not.

As an example, some manufacturers’ literature thinks Peukert is important for Ah-counting SoC meters, others think it is not relevant.

So in order to refute my supposition I’d need actual data, not something written by a manufacturer’s technical author, someone who has probably never used a Li battery and is writing out of an abundance of caution.

-

1

1

-

-

3 minutes ago, Davidgabriel said:

Yeah. Sorry about the bare leg. Trying to get sunshine when I can😀

Seriously, I think one of the issues is the melting point of lead-tin solder, which is about 180C. An alternator can get quite hot in places and obviously one doesn’t want the solder to melt! I noticed that the Iskra regulator chip leads were spot welded, to avoid the risk of melting solder. Lead-free solder has a higher melting point and thus is preferable.

-

2 hours ago, IanD said:

especially when they present data that shows he's wrong. Which of course is impossible in his mind...

If only you had presented any data. Such a shame you didn’t.2 hours ago, IanD said:Having just seen the quoted post from @nicknorman -- OK, here's some data sources for you, go and look at them.

Victron's requirements for LFP absorption/charging to 100% SoC can be found in the manuals (available online), as can those for BYD, as can those for REC-BMS, as can those for various EV manufacturers -- which can also be found in exotic places like YouTube videos, if you can degrade yourself by watching them. The limits for Victron Quattro/Multiplus when acting as charge controllers can be seen when you're setting up the unit using VEConfig -- if you've got one you can do the same, if you haven't you can't. There's also lots of information in places like the Victron community forum.

No I'm not going to spend time digging all these out again and snapshotting them and providing them for you, go and spend your own time doing that like I did -- just be warned, it'll take some time, especially if you don't read a couple of hundred pages per hour.

Every single one of them recommends regular charging to 100% SoC -- typically every couple of weeks -- to make sure the cells stay balanced, and to reset SoC counters to 100%.

Nobody -- including me -- is saying that all cells go out of balance and disaster will strike if you don't do this, because it won't be *needed* in all systems. But it's universally recommended because some systems *will* need it to keep the cells balanced, given production variations in cell performance. Nothing to do with bad design or manufacture or not being "decent", it's just how LFP cells/batteries work.

I've also sent my logged data and spoken to Ricky at Finesse about this (since he uses VRM in fleet mode to remotely monitor the LFP banks on all the boats Finesse has ever built) and he says that in his experience cells needing balancing after multiple charge/discharge cycles over a couple of weeks is not unusual, some boats need it more than others (all built using the same Winston cells and REC-BMS) but the BMS just deals with it when a "charge to 100%" cycle comes round -- as I found. That's based on perhaps 20 hybrid boats built using the same components, as opposed to your one.

Since you've monitored your cells over some time and found that they don't need balancing, you don't need to do it if you don't want to -- unless they change as they age. That would also apply to others *if* they've also done regular balancing cycles/charge to 100% and confirmed that there is no imbalance -- but this does mean going up to 100% SoC to be certain of this, sitting below 95% is useless. You got lucky in not needing balancing, and so might they -- or not...

But you saying that this can be general advice to all boaters "with decent LFP batteries" is *not* safe, which is why all the suppliers recommend regular charging to 100% SoC.

If you disagree, it's up to *you* to provide references to show this (i.e. from reputable suppliers who say that this isn't needed) -- which doesn't mean quoting them word for word, links to reputable sources is enough. I keep saying "reputable" because there's an awful lot of misinformation out there -- as a rule of thumb, if getting it wrong would cost them a lot of money because they've got a lot of real products out there, they're probably reputable -- like the sources I referred to.

But having seen your continued name-calling in the quotes, I'm now going to carry on ignoring you until you decide you can discuss things in a grown-up insult-free manner. Which could mean a long wait given the history of "discussions" between us... 😞

Long post, lots of opinion, no evidence. Same same.Although you are conflating balancing, with synchronising Ah-counting SoC meters. But then again, since you have said that your own SoC meter only drifts 1% a week, you did provide evidence that synchronising SoC meters is only required every several weeks. On which we agree😍

-

I was going to say kneet, but that might be inappropriate.

-

1 minute ago, noddyboater said:

Has anyone passed Streethay Wharf lately and seen the knackered Dawncraft with it's adjacent boat size pile of crap on the towpath, including a lovely homemade sign saying "SLOW DOWN CUN#?

I'm not entirely sure someone bending the rules as such can expect a sedate, tick over pass by. Or can they?

No. Carry on. And if there are complaints, reverse back and do it again. Although Caution, a nutter in a Dawncraft is probably faster than any narrowboat!

-

6 hours ago, IanD said:

Go and do some searching. There was a thread on diesel engine governors where I got the wrong end of the stick and was rightly corrected, another one on gearboxes, and I've changed my mind given new information on several other things -- for example I originally thought a parallel hybrid was better then series, but after some things I hadn't thought about were pointed out to me I changed that view. I'm sure it annoys the hell out of some people that this doesn't happen very often, because I try and do some in-depth research into a subject and get things right before posting -- and when I don't is when I get things wrong, and I'm happy to hold my hands up to this... 🙂

Because that's how science and engineering works, changing your mind when new facts appear, and I'm always willing to have a civilised discussion with people who disagree with me because it's not always clear who is right or wrong. Facts should always win over opinion, though some people don't seem to agree with this...

What I really don't like is people who when challenged about what they've said/written use bluster and personal attacks and insults to try and divert attention from the fact that they were wrong, it's the behaviour of Donald Trump -- and Nick has resorted to this multiple times whenever I've challenged what he says, every time I unblock him he starts another argument and then resorts to ad hominem attacks, usually until I give up and block him again to stop a flame war which he won't do. Again, go and do some searching, I can think of at least half a dozen times this has happened -- and it p*sses me off, because this is supposed to be a discussion forum, not a name-calling one... 😞

Which is a pity because he does actually know his stuff, but seems congenitally incapable of ever admitting he was wrong, even when it's shown that he is... 😞

That's not quite true, the simple Victron assistants (which run on the Multiplus/Quattro, not the Cerbo) can't use SoC as such if you're using an external BMS as the master charge controller, they can only use voltage. I don't know if this is the case using the Multiplus/Quattro and a SmartShunt to control charging but I suspect it is, the assistant trigger conditions include various things but not SoC.

Pretty much any complex control is possible using Node Red (running on the Cerbo) but I haven't tried this yet.

But don't forget that SoC is a calculated value based on various other things, including voltage... 😉

The advice from Victron (and other BMS manufacturers) is that it's not a good idea to use SoC itself to start/terminate charging because it's a calculated parameter which can have errors, which can get bigger with time (SoC drift) if a balancing/SoC reset charge to 100% SoC hasn't been done -- and with some BMS (e.g. Fogstar) the SoC errors accumulating over time can be quite large. Depending on the direction of drift, this could lead to terminating charge early (too low a voltage) or late (too high a voltage), both of which are bad for different reasons.

I've had a long discussion with Victron (and Finesse) about this, specifically trying to get the Quattro solar/wind priority to work properly with the external BMS -- there's a conflict because the solar/wind priority mode only uses voltage levels to decide what to do, it can't use the SoC from the BMS. So what happens sometimes is that the Quattro tries to do a "charge to 100% SoC" but the BMS is holding the CVL at the float level (54V), so the Quattro never thinks it's succeeded and stays in "charging to 100%" mode indefinitely. I've tried reducing the "absorption voltage" for the Quattro to 53.9V but this still doesn't always work.

Using SoC is not as simple as it first seems... 😞

The reason why I do sometimes resort to criticising you personally, is because it is your habit to make long posts spouting a whole lot of stuff without presenting any actual evidence. And when presented with someone who has personal experience of an issue, you discount that and continue to spout the same imagined stuff and provide no supporting evidence. You think people should believe it just because you say it. And even when people do agree with you, you still crave arguing with them. This is unreasonable and irrational behaviour and I don’t have a method to deal with it other than making comments like “neuro diverse”. That surely is better than “fantasist liar” isn’t it?

-

2

2

-

-

The cheapo (at the time) cells I bought direct from china were very well packed.

-

5 minutes ago, IanD said:

I have happily admitted it when the facts have shown I was wrong, because that's how science/engineering works -- there's no shame being wrong, it's how you learn.

But only when the facts show it, not when somebody else shouts more loudly or resorts to ad hominem attacks or starts throwing insults, which is what Nick does when confronted -- and why I'm now ignoring his posts.

We are saying the same thing about one of the issues under discussion (that voltage difference at lower SoC doesn't give any useful information about cell balance). We're disagreeing strongly about the other one, where Nick keeps saying that regular cell balancing isn't needed because his particular DIY setup doesn't need it -- which disagrees with the recommendations from pretty much the rest of the LFP world, meaning reputable battery/BMS/LFP charger suppliers with *far* more experience and knowledge than he has -- or me, which is why I follow their advice... 😉

You have presented no facts or evidence. You have only presented your opinion as if it were fact. I realise that in your world, your opinion IS fact. But not for the rest of us.

41 minutes ago, blackrose said:But doesn't that also apply to the Orion B2B charger? I was switching that manually too. I didn't know it could be automated. How is that done? It has no SoC function.

Maybe it depends on exactly which model you have, but they mostly seem to have a link wire that allows remote turning on and off. The little green link wire bottom left in this pic:

The two connections allow for various schemes for remote on/off:

The slight problem being that you can’t connect the BMV relay to both the MPPT and the B2B, because they work at different voltage levels. So you would need another low power relay to operate them both, that relay being operated by the BMV relay.

-

2 minutes ago, blackrose said:

Going back to my alternator issue, I don't suppose it would make any difference if instead of disabling charging on the Orion B2B I switched off charging on the Fogstar BMS?

I don't think it would be any different, either way charging to the lithiums is switched off.

I'm away from the boat for a couple of nights otherwise I'd just try it now.

Yes you could do that. But it makes it all rather manual and one day you will forget to turn it back on again and then wonder why the lights go out. Or lose your phone and be unable to turn it back on again. Humans are unreliable hence IMO it’s better to automate it.

2 hours ago, Gybe Ho said:No you were fatally torpedoed below the water line when @IanD demolished the credibility of your scaremongering interpretation of the report that you claimed confirmed LIPO batteries should not be routinely charged up to 100%.

I do not think the sides in this debate are far apart because your position has shifted.

We can conclude:

- There is no harm in routinely charging LIPO up to 100% providing a daily excess of solar generation does not pin batteries at 100%

- A conservative MPPT charge config is a good idea in summer months to prevent 100% soc pinning.

- As daily solar begins to falls short of consumption a higher voltage charge profile is needed to push the batteries towards 100% whenever solar has a good day.

- You will experience less cell imbalance because your 3P4S battery bank will average out cell discrepancies within each 3P block.

- Hell will freeze over before you accept the world-view that cell balancing near 100% is a good idea.

- @blackrose should be able to limit the output of his B2B using a replica of the rely rule technique that works for the MPPT.

- Life would be simpler for all if Victron upped their game and supported Cerbo to MPPT and Orion XS logical on/off control via canbus. Relays are so 1999.

Funnily enough I seem to still be floating. As usual IanD made a statement that you sucked up as truth, without providing any evidence. I did look again for the research paper but couldn’t find it, so whether IanD’s recollection is accurate is unknown at this time. But since your bromance is firmly established, obviously you won’t be interested in the facts.

1. You have no evidence for this. I disagree. Although the harm is modest, it is still harm.

2. A better idea is to stop charging at a specified SoC

3. Obviously

4. You have no evidence for this. I do have a Fogstar battery in the caravan (4S configuration), last time I took it to 100% (several months after the previous time) balancing was not invoked.

5. Not a cogent comment. Do you mean that cell balancing is required routinely (I disagree). Or that you can only balance when very close to 100% (I agree).

6. Careless typo which renders the point indecipherable. But if you mean relay, then yes but another relay would be needed.

7. Easier for you. Not an issue for me.

8. Just remind us how many leisure lithium battery installations you have experience of?

-

1

1

-

57 minutes ago, IanD said:

There are two discussions going on; we agree on the one you keep banging on about, and I'm not arguing with it, and never have been.

The one we disagree with is the one you keep ignoring, presumably because you now realise that what you said is wrong. But I'm sure you'll never admit that... 😉

I'm sure everyone is bored to death with this, because it's sadly predictable that as sure as eggs is eggs, within a day of me daring to contradict something you wrote you resort to insults and character assassination to try and start a flame war, presumably so you can deflect the blame and hide the fact that what you said was wrong.

I've lost count of how many times this has happened on multiple subjects, it usually results in me putting you on ignore until things have calmed down. So, bye bye yet again... 😞

Oh good, that means I won! But I know that you will still be reading!

So read that you once again have failed to provide any evidence to back up your conjecture, and are using sulking as a vehicle to cover that up.

-

2 minutes ago, IanD said:

Like I said, leave out the digs and insults, it's getting tedious... 😞

Try reading what I wrote -- what I'm arguing about is your statement that "decent LFP batteries don't need regular balancing" which is simply wrong for all the reasons I explained, and backed up by pretty much the entire industry except you.

Trying to divert attention away from this still won't make you right about this particular matter... 😉

What you repeatedly wrote is that voltage differences at lower states of charge are no indication of being top balanced. I have agreed with you several times. I don't understand why you need to keep pretending that I disagree with you. It's rather weird.

There is a second part to my earlier post now, addressing your conjecture.

-

4 hours ago, IanD said:

But unless they do this, statements like "I don't need to do balancing because my cells match to within a few mV at normal SoC (<90%)" are dangerous -- they might be true (like for you), or this might lead to gradually increasing imbalance (and perhaps cell degradation/damage, depending on how good the BMS is at preventing this) which they won't spot until it becomes large.

...

I'd say that was fairly conclusive proof that any cell imbalance does not show up except close to 100% SoC, and (small) voltage differences below 95% SoC do not give any information about cell balancing.

I am left wondering what sort of neuro-divergence it is that causes you to continue to argue against me when I have repeatedly said that I agree with you. It is quite weird! I guess you just like to argue even when there is nothing to argue about. Whatever floats your boat I guess, and glad to be of service.

4 hours ago, IanD said:What I said is that to allow for things like manufacturing variations in cells, all the reputable LFP suppliers/manufacturers recommend regular charging to 100% SoC to balance any cells which *might* be out of balance and to reset SoC counters. This applies to EV manufacturers (millions of units?), off-grid charger/BMS/battery suppliers like BYD (second-biggest worldwide supplier), Victron (tens of thousands of units), REC-BMS (thousands of units), all the way down to boatbuilders like Finesse or Ortomarine (tens of units). In some cases the guarantee is invalidated if this is not done (BYD, Victron?) and logging/remote monitoring is used to check this (BYD, Victron, Finesse...), in others the maximum programmable interval between such charges is limited (28 days for Victron IIRC).

I'd hope that with your engineering background you'd be well aware that you can't draw any valid conclusion about performance/lifetime/reliability from one sample (your boat), which is why any tests on such things before they're certified as fit for purpose requires testing on a large number of units. Because it's not acceptable to have a significant number of failures, and the number required is derived from statistics -- IIRC it's something like 77 for electronic assemblies undergoing lifetime tests, which we have to do on a regular basis.

So the fact that *on your boat* you find balancing your one-off DIY setup is not needed is not at all surprising, this is likely to be the case for quite a lot of boats -- but it's unsafe to then say that this means *nobody* needs to follow the regular balancing routine, because theirs may well be one of the boats that needs it -- and there's nothing wrong with this, no fault or reliability problem, just the luck of the draw on cells, even "Grade A".

Of course if they do what you do and find that after multiple balancing cycles over a year or more they never find any imbalance, *then* they can do what you do and not bother. Always assuming that this doesn't change as the cells age, of course... 😉

...

Which is exactly why all the suppliers referred to above recommend/enforce regular balancing cycles, because they don't want to see warranty claims if this isn't done, and all these statistical/reliability subtleties are beyond the understanding of many customers... 😉

This is conjecture, you again have provided no evidence except repetition of your conjecture.

There are of course manufacturing differences in cells, and this results in minor variations in capacity. Which is why a battery needs its cells to be top balanced. However they will only go out of balance if there are variations in charge efficiency. They will not go out of top balance if there are variations in capacity. As we know Li cells have a very high charge efficiency, pretty close to 100%. And it is pretty hard to see how this can change because the current flowing across the electrodes arises only from the migration of the Li ions. There is no sneaky alternative path for current and Li ions don't suddenly disappear or appear. Unlike lead acid, where the conversion of water into O2 and H2 results in a lower and variable charge efficiency.

As I said before, if a boater finds that their Li battery is in need of regular balancing, something is wrong. Repeated balancing just masks a developing problem. I know this because it is exactly what happened to me.

One thing you haven't shown us in all your swathes of data, is just how much and how often your own cells need balancing and by how many Ah. I suspect you will find that the answer is, they don't. Please show actual data, not just repeats of your mantra.

-

13 minutes ago, Gybe Ho said:

There is absolutely no evidence of that. There is however overwhelming evidence it is broadly accepted that lithium cells will go out of balance over a period of time and some form of balancing circuity and BMS balancing regime is required.

I am now more convinced my earlier observation that this forum has a cultural aversion to charging lithium's to 100%, is true. This whole debate is essentially sustained by an establish group-think belief system that fully charging lithium batteries is best avoided.

Please provide this overwhelming evidence. Otherwise everyone will (correctly) think you are making it up.

Well, to be more precise, I’m sure Li cells do eventually go out of balance as they age differentially, and since you haven’t defined what you mean by “a period of time” your comment has no actual meaning.

-

2 minutes ago, IanD said:

I'm sure that intelligent CWDF posters are capable of deciding who is more likely to be correct, you or all those BMS/battery/EV manufacturers who disagree with you... 😉

Even though everyone on here knows you have intimate knowledge of these systems since you designed them all, perhaps you could provide evidence from all those battery manufacturers who say out that their Li batteries seem to go out balance quite quickly and need to be balanced every couple of weeks? Rather than just saying it and thus hoping that makes it true?

No I thought not.

-

7 hours ago, IanD said:

It's funny that you seem to be the only person claiming that LFP cells never need balancing -- based on your experience of 1 DIY bank! -- when BMS and cell manufacturers with experience of thousands of LFP banks (REC-BMS, Victron, BYD...) as well as the newer EV manufacturers (with experience of millions now...) all recommend regular (every 2-4 weeks typically) charging to 100% SoC and then stopping charging when balanced to maximise battery life, balance cells, and reset SoC counters, in the presence of inevitable cell variations in production.

And it's them I'm taking my strategy from (together with recommended settings for the Winston cells), which agree with observations of *my* battery -- which works just fine including fortnightly balancing, but thank you for your concern... 😉

Unlike you I don't have any banks of cells wired in parallel which can become imbalanced, I have 16 700Ah cells connected in series by dual flexible 1000A busbars (on dual terminals), so it's guaranteed that the same current flows through all of them, amd the BMS active balancer works with each cell.

The cell imbalance varies hardly at all regardless of load current as the plots show, so I'm sure it's not bad wiring causing the voltage differences since this would cause drops to vary with current. You can carry on sniping (with wrong information...) if you want, it won't change the actual facts -- which as I said, are different to those for your setup... 😉

As you said earlier, individual cell voltages don't always track each other especially above 3.45V/cell and the curves can cross over, which is why it's useless to conclude that the cells are balanced just because there's a small voltage difference at lower SoC -- as the curves I showed demonstrate.

Anyone on CWDF (or elsewhere) concluding that "my LFP cells don't need balancing because there's very little cell mismatch at <90% SoC) is labouring under a misapprehension, no matter how many of them think this... 🙂

Perhaps you could mention the people on here who find their Li batteries need routine balancing? I can’t think of any. But of course you should introduce us to your imaginary friends, it’s only polite.If you took your thumb off the transmit button and read what I wrote instead of imagining what I might have written, you would notice that I agreed with you that cell voltage mismatch (or match) at anything less than very close to maximum cell voltage (3.6 or 3.65v) is meaningless. The only relevant thing is that all the cells approach 3.65v at very much the same time with minimal difference.

But once this is set up, a decent system will not need much further attention. If a series string of Li cells is routinely going out of balance, something is wrong even if you are in denial. -

3 minutes ago, MtB said:

Thanks.

Its probably time I figured out how an alternator works! But curiously I've always had other things I'd rather do

It’s actually quite interesting because the basic physics is about rate of change of magnetic field creating a VOLTAGE, not a current. And in order for anything to happen, the voltage swing on the stator has to exceed the battery voltage plus 2x diode voltage drop before ANY current can flow out of the alternator. So even with zero output, it still needs perhaps more field current than you might think to make the stator voltage swing up to the 12.7v + 0.7v + 0.7v (zero output, but keeping the W terminal working). I’d need to check again but I think my system shows about 0.25A field current for zero output, (eg when it drops into float mode and residual battery voltage is higher than regulated voltage) out of a maximum of 4A for full output. ie the first 6% or so of field current doesn’t produce any output, it just keeps the W terminal etc ticking over. So I can see no excuse for an alternator going over-voltage under no load, unless there is a fault.11 minutes ago, Tony Brooks said:But I have seen that at least some do, and cars, vans and trucks only have one battery so in the vast majority of vehicles other equipment is always drawing some current, even if it is only the engine electrics. For the cost of the parts, I think it is worth trying to load the battery and see what happens.

But surely on most boats with dual alternators (and there are a lot of those these days) the starter alternator is not supplying any significant current several hours after start. Ok perhaps there is a very small current to run the gauges on the panel, but this can’t be much, and some boats don’t have gauges.

In OP’s case the high voltage seems to occur pretty much straight away, when the battery is surely taking a bit of current. So I would either suspect a fault somewhere, or as you say a regulator that is set rather high.

-

1

1

-

-

1 minute ago, MtB said:

What if the load is absolutely zero?

Then the regulator should shut the field current down to near zero and regulate the voltage at the specified value. This can cause a 9 diode machine to glow the warning light and/or lose the W signal, but it doesn’t cause an over-voltage in a correctly functioning alternator.-

1

1

-

-

2 hours ago, IanD said:

What you mean is -- in your case, with your particular cells and BMS, you don't see any imbalance. That's a sample size of 1.

Saying that this means all decent LFP batteries in narrowboats behave like this is about as credible as Peter making similar assertions that "him and his mates" can be extrapolated to the country as a whole... 😉

My experience with different cells and BMS (Winston 700Ah and REC-BMS -- which I'm confident most would describe as "a decent Li battery" -- is not quite the same as yours. But I'm always careful to say that my results apply to my particular setup, and not to everyone else's -- again, sample size is 1.

What they do show is that you can't conclude whether cells are balanced or not *unless* you take them up the voltage knee, which in my case means above 3.45V/cell (13.8V, or 55.2V for me). Since "normal" daily charging stops at 54V in my case, the only way any imbalance shows up is during "absorption" charges, normally these run every couple of weeks when plugged into shoreline or running from solar -- and if the boat hasn't been out cruising, there's little imbalance.

Other people may have similar experiences to yours or mine, there's no way of knowing or predicting which... 😉

Everyone on here who has experience of Li batteries says they don’t go out of balance, except you. Perhaps your system is not as fabulous as you hope, and there is some defect that is causing the problem? It seems hard to believe that cell imbalance occurs randomly amongst the cells, I would be fairly confident that it was always the same bank of cells that gets low or high, compared to the others. This would point to some defect in the cells or wiring - you might remember that I had a problem with cells suddenly seeming to go out of balance, it was a bad internal connection in one of the cells that I was able to remedy. So I my experience, cells going out of balance is an indication that something is not quite right. -

2 hours ago, Tony Brooks said:

I think the problem is that you are trying to operate the alternator way outside its design criteria.

I don’t understand why you say this. The alternator is connected to a battery, which sometimes has a load on it but other times doesn’t. I can’t see any difference between that and a starter battery which initially is slightly discharged from starting, but after several hours of running is fully charged and not taking any current (or any more current than OP’s buffer battery).A correctly functioning alternator should not allow the voltage to rise above the regulated voltage just because the load is very slight.

Leisure battery replacing, probably?!

in Boat Building & Maintenance

Posted

Shouldn’t be a big deal. For the solar, it’s best to cover or disconnect the panels so that the sequence of reconnection is first to connect the solar controller to the batteries, then connect or illuminate the panels. It may well not matter but for some controllers it does matter!

For the inverter the only thing to bear in mind is that they have big capacitors on the 12v input, and when the batteries are disconnected these will slowly discharge. So when you reconnect the new ones, the capacitors will recharge instantly (even if the inverter is switched off) and this pulls a very brief but very high current, likely to cause an alarming spark. So grit your teeth and be ready for it!