Batainte

-

Posts

59 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Batainte

-

-

On 12/01/2021 at 11:29, Bee said:

Many different experiences and methods and no two quite the same. Bee is panelled in proper t&g, lengthways on the roof and vertical on the sides. Below the gunnel it is proper plank tapered and forced into shape merging with proper plank floorboards. (Bee is shaped like a tapered barrel so never again!) I sprayfoamed the shell myself so in places it is brilliant, in other places it is pretty rubbish. No vapour barrier and no problems at all but we don't live on through the winter. I would not use proper t&g as it shrinks, swells and moves all over the place. Painting the back of panelling is a must or it will cup . priming is not enough, it needs to be just as good both sides I would be very tempted to try that greenish stuff in the picture above.

Would you be able to suggest which type of paint (just any regular oil based with undercoat/ primer) any particular brands?

-

On 12/01/2021 at 14:41, dave moore said:

The late Trevor Ward, a superb craftsman who worked at Norton Canes used to add 5 coats of varnish to the back of any lining timber, 7 coats to the visible face. The boards looked almost like glass! Those were the days!

Would you know would be the product he used? Trying to navigate the seas of materials and brands nowadays is rather overwhelming

-

On 13/01/2021 at 11:04, David Schweizer said:

Several people have referred to T&G timber, when what they may mean is Matchboard, which is a decorative variation of T&G, with champhered edges, designed to throw the light and consequently help to hide summer shrinkage. If ordering from a stockist, it is important to state which you actually need, or you may end up with floorboards. Below are two photos which illustrate the difference

T&G board Matchboard

Thats super helpful, thanks for this suggestion. Was actually considering to use hardwood pieces for the ceiling.

Firstly would line the ceiling with sealed (oil based undercoat preferably with 2+ layers) 9mm marine ply and then screwing+ gluing T&G hardwood pieces lengthways. Wondering how this might work?On 12/01/2021 at 12:39, David Mack said:If you use real wood T&G, paint or varnish the front face, including the whole of the tongue, in your chosen finish, and then after fixing just touch up or do one final coat. That way you won't see a different colour in the gaps between the boards when they shrink in dry weather.

Actually was experiencing this when refitting another boat a year ago- the grooves had to continuously repainted due to timber "movement" as it swells and shrinks. Best is to do it right the first time (even if it takes extra time)

On 13/01/2021 at 11:46, Tracy D'arth said:I had to strip and refit 2 boats that were less than two years old. Water resistant green MDF was used for linings and furniture, the whole lot fell apart due to damp and lack of suitable adhesives for MDF.

I like OSB, hate chipboard and MDF, yes, I know some is waterproof but I still reckon its not for boat building.

We all have our foibles.

Wondering what would you use for the furniture (kitchen cabinets, wardrobe) instead of water resistant MDF? Surely OSB wouldnt be good enough for carcases?

-

-

20 hours ago, ditchcrawler said:

I used waterproof MDF for my ceiling some 20 years ago and would rate it much higher than WPB ply. Some of that old 20 year old stuff is still kicking around the yard and is as sound as the day it was bought. I wouldn't use it for walls due to the lack of strength, even screwing a picture to the wall, the other down side as mentioned is working with it when cutting and machining .

Thats interesting as several people have advised against MDF due to possibilities of absorbing moisture, bulging and warping over a period of several years. Did you treat it in any way with some special products (varnish, sealant, PVA?) before installing?

19 hours ago, BEngo said:If it is sprayfoamed there is no need for an extra vapour barrier. Buy a tin or two of No Nonsense foam from Screwfix and use it to touch up any damage to the spray foam. Gun grade is easiest, but you have to buy the gun so if there us not much needed the ordinary upside down can variety is fine.

60mm of foam sounds like plenty of insulation effect too.

N

Thats what the sprayfoam people mentioned- apparently 50mm is more than enough for domestic use. Had to check the thickness and in some places it was even 80mm thick.

19 hours ago, ditchcrawler said:I bought a hull tat was sprayfoamed and it was crap, like a coat of paint in places. Luckily for me the hull builder backed me up and the company who did the job came all the way to Suffolk and resprayed it. They wanted to send me half a dozen cans to start with, it was only because the hull builder told them they wouldn't get any more work they came and fixed it. The end result was I had a lot of trimming back to do.

Thats a true boat builder, its always good to know there are still people in this business who care for their customers.

-

Awesome tips, thanks for the advice.

In regards to moisture barrier- was really contemplating about this, it is a sailaway and has a 60mm closed cell sprayfoam insulation throughout with extra thickness sprayed in other parts.

Spoke with the company who sprayfoamed and they advised that with 50mm insultaion it should sufficient and since it is closed cell, then apparently no vapour barrier would be needed. Their comment was that at this stage its not worth spending extra several £100's to improve something by a 2-4%.

Obviously a seller is a seller, but the end user is just tangled in infinite product sales pitches- so no personal opinion on this matter, except for their confidence and "expertise".

Whats your take on this?

-

Hello all, been working on fitting out the interior of the boat and was wondering whether anyone has done this job in past? Its a widebeam 70x12Would you have a good advice about different materials for ceiling/ wall panels? What thickness would be optimal? Are there special products to use that would help in reducing condensation/ moisture passing through the panels in/ out of cabin?If I was to use regular or moisture resistant mdf (or plywood?) panels what thickness should I go for as there are 6/9/12 mm options? Was after a T&G effect ceiling panels.Thanks in advance.

-

Hi all,

as per the title, intending to install all the necessary lighting as required by the Collision Regulations (COLREG) on a 70 x 12 widebeam.

If understood correctly from article found on waterways.org.uk there are 4 lights which are required to be compliant with this regulation:

- White masthead light (Installed on bulkhead at the stern/front of boat above the door or a raised mast)

- Red port sidelight (Left side closer to the stern front)

- Green starboard side light (Right side closer to the stern front)

- White stern light (external section of stern)

In addition to the above

- Tunnel Light (Installed on bulkhead at the stern/front of boat above the door)

- Horn (On the roof closer to the stern)

In particular, have questions about respective installation requirements i.e. positioning, location, distancing, heights, wiring etc.

Does there exist a step by step guide or easily digestible content (a youtube video?) on these specifics?

Would anyone perhaps know of good online stores selling the lights, what would be things to look out for, any reliable brands perhaps?

Any help or pointers in this direction will be much appreciated.

-

Below is a more detailed explanation with pictures in case this might be of interest.. or anyone encountering similar problems in future.

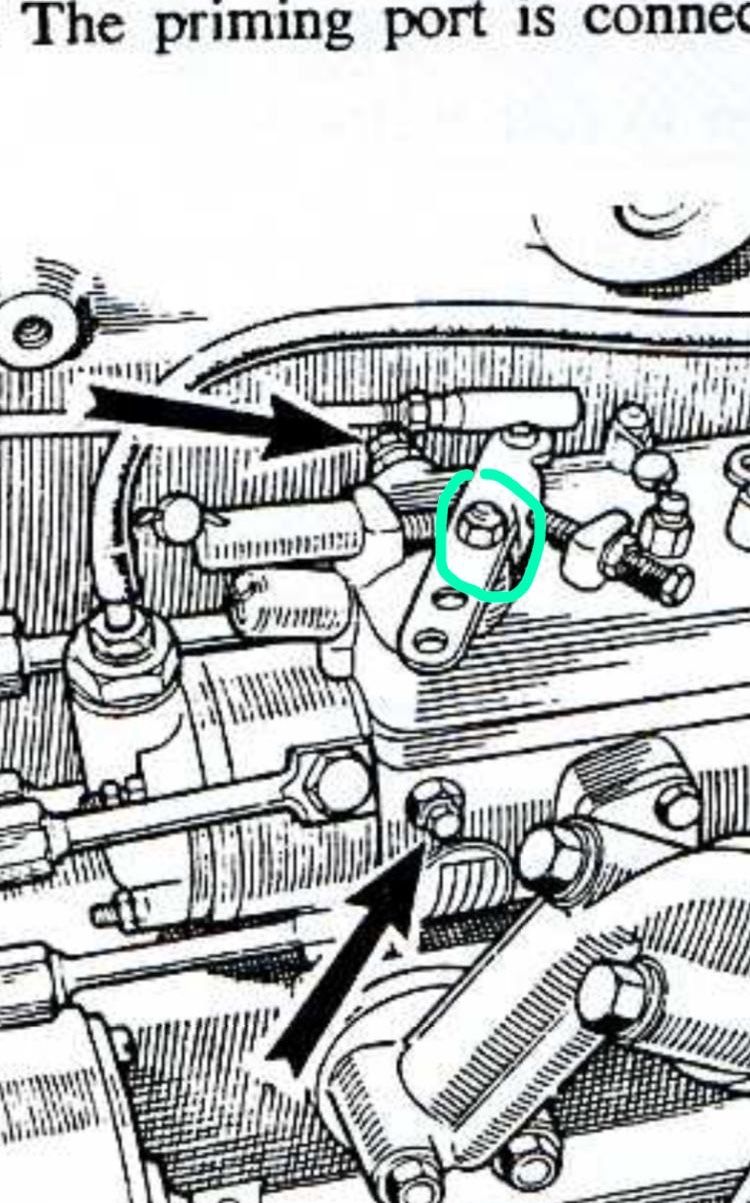

The circled nut below required some fastening

Due to not having enough tightness the circled bit was loose and the "Governor spring"couldnt actually do its job properly.

-

Hi all, apologies for delay in response as real life took over.

Nevertheless, the above mentioned issue was identified and eventually resolved. It was a bit of a headache to try and figure this one out and was discovered by chance after randomly tightening and checking for any bits which might be loose.

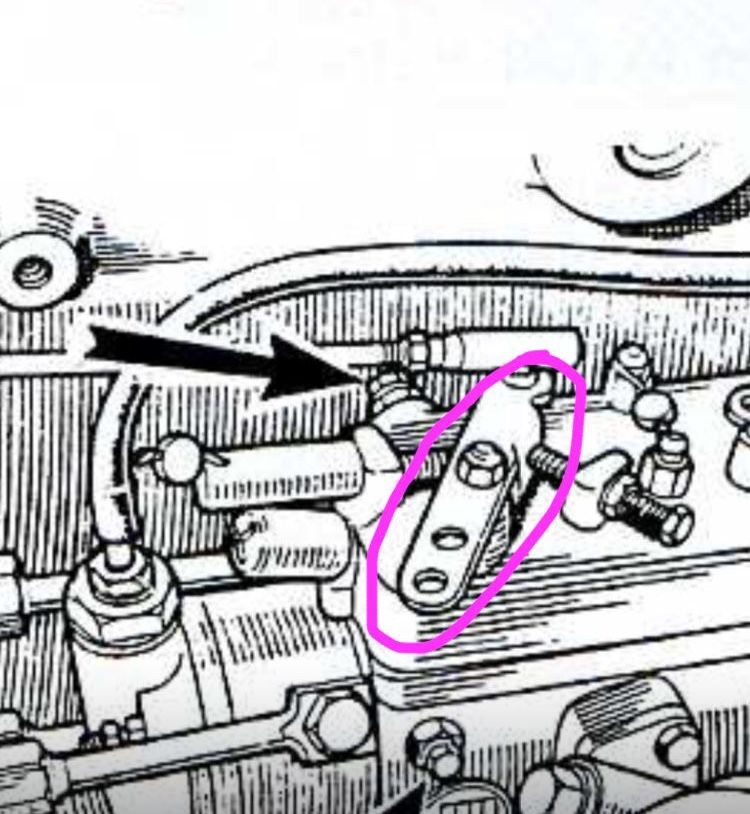

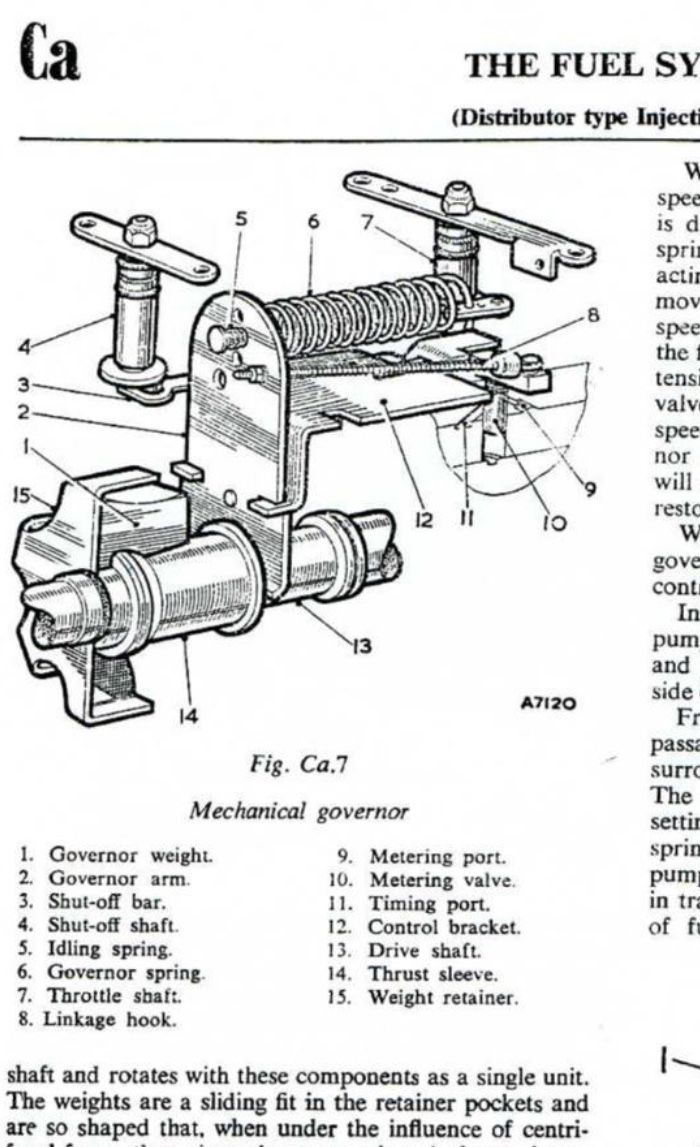

What happened was that "Throttle Shaft" (no.7 from the diagram below) was rather loose and the holding screw required some tightening, as a result the "Governor Spring" (No.6) could gain more resistance and aid in allowing the fuel to reach the injector. Probably due to engine vibration this part became loose over the time, therefore the flow got disrupted.

Hope this helps anyone who might search on the forum for similar troubleshooting.

-

On 29/06/2020 at 21:39, WotEver said:

So what did he say?

So, after a long and exhausting 2 weeks - due weather conditions - mostly rain put all job in setback, (as our canopy been damaged and no cover when working on the engine bay), our mechanic managed to do full service on the engine, changing filters, bleeding fuel system - and all the other service related duties!

But....

Engine won't start anymore. It seems that lifts pump is getting fuel to top filter and fuel gets to injector pump, but after injector pump fuel is not coming out, maybe only a little drip, so no fuel gets to engine. No pressure at all in injectors. We are in contact with some old legend mechanics who has striped apart every engine- apart of Apollo 13. If it comes removing injector pump and sending to engineers to look at it - so be it.

If it comes removing injector pump and sending to engineers to look at it - so be it.

Maybe you have any ideas what could be the issue or maybe there could be some McGyver fix!?

On 30/06/2020 at 15:23, TheBiscuits said:I've just moored up at the wharf if your mechanic didn't turn up yesterday. Let me know if you want me to take a look.

Maybe you have some idea or advice to share?

We got to get it up and running!

-

Been on the lookout for a decent Silent Portable Generator (price vs. quality) and so far havent found anything that i could relate to budgetwise.

After having touched on this topic, people mostly on the forums stand by a variety of manufacturers such as (high to low cost):

1- Honda,

2- Hyundai,

3- Yamaha,

4- chinese makes on the lower end of market.For the latter it obviously reflects on quality over a period of time.

Albeit not in the range of low to medium budget, the general consensus is that all the glory is taken by Honda- youd get what you pay for and the

equipment would last a lifetime.

Followed by Yamaha as a cheaper cousin of Honda.. its reminiscent of choosing the second or third cheapest drink at the bar- cant go wrong, but cant go

full potential either.

Yamaha's older models apparently have proven to have a good reputation over the years by its users, however it appears they havent kept up

with their quality nowadays.Since it would be more convenient to have it as a back up, rather than switching engine on when battery bank goes low during the evening hours etc.. Initially was intending to purchase a budget diesel/petrol powered portable silent generator to power all appliances on the boat (when necessary i.e. "flat batteries"). However considering the investment it only makes sense paying a little extra and paying only once, rather than ending up with two/ three budget low end units which have have to be replaced every other year or so.

Based on gathered intel and basic requirements, would anyone be able to comment in regards to this matter?

1. Required power output for generator in range of 3 - 3.5kw.

2. Perhaps anyone has had experience, and could share some wisdom on German manufactured MIL SILENT 8500W generator? Are they reliable?

3. Does anyone use Hyndai HY3200SEi or any other Hyndai generators? Would like to stay on the safe side by ordering the 2nd/3rd cheapest drink...

4. What could be your best recommendations for a reasonably priced and decent silent generator?

Ta'

-

Thanks everyone for your advice and suggestions. Did some tinkering around and realised it would be better to arrange someone with more experience to take a look.

Initially suspected some air intake issues as perhaps the engine doesnt have enough "gasp" in order to function properly- but this being a speculation coming from a newbie...

A mechanic is taking a look later today, once he gives his final verdict, will update on here in case anyone else has a similar problem in future.

-

4 hours ago, Alan de Enfield said:

Is this in a narrowboat ?

Yes it is, 37 feet!

-

@TheBiscuits boat is parked in Burscough!

19 hours ago, Arthur Marshall said:Mine (Lister) wouldn't start without revs on, obviously in neutral. And stopped in neutral. I just speeded up the idle screw till it didn't, and now it keeps going happily. Can't reall help till we know what the engine is.

It is BMC 2,5l diesel 4 cylinders! Maybe you know location of idle screw as can’t find it!

-

Hi all,

as per the title- the engine doesnt start when in neutral (only if its in either gears- forward or reverse).

Same goes when switching from reverse to forward or vice versa- as it needs to pass through neutral, once that is being executed the engine just stops and needs to be restarted again.

Anyone has had such an experience in past? Would this be filter issues- been theorizing that if this would be the case, it would lack air intake therefore the engine shuts down completely. Alternatively, perhaps some gear- box issues?

Would anyone advice on attempting to resolve this via DIY route or better to search for a professional. If so, would anyone know where to begin the search around Lancashire area?

Thanks all

-

Thanks all for advice

-

Thanks all for advice

-

Thanks everyone for your suggestions/ tips and tricks.

This was very helpful (especially the string theory @bizzard nice and creative solution, makes quite a lot of sense).

Will inspect these options further.

Cheerio

-

Awesome, thanks everyone for your time and wealth of information (didnt budget this in, so thanks @Wide boat man )

Understandably there is much more time needed to prepare for this journey as its not something one should just "wing it".

Cheerio

-

Hi all,

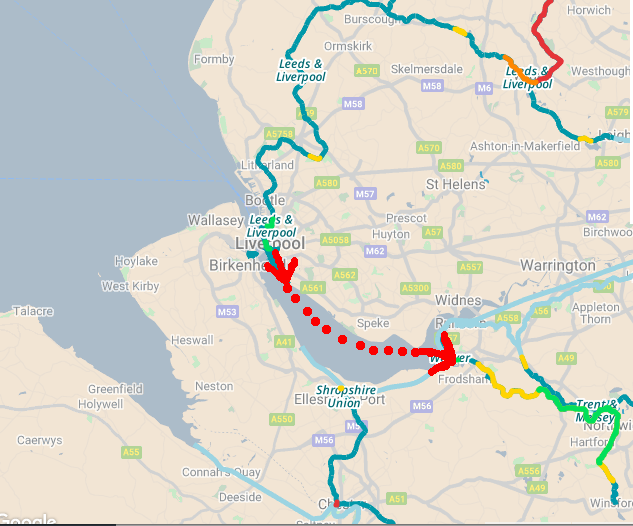

Contemplating about crossing with 38ft Narrowboat from Liverpool& Leeds canal via Manchester Ship (River Mersey) into Weaver Canal and enter through Marsh Lock.

Given the fact that this is a river with tidal changes and potentially strong currents, would this be a good idea or sounds more like an overly ambition adventure?

Has anyone done this, if so any comments suggestions or criticism is very welcome.

Thanks in advance

-

Been on a renovation project for quite a while and wall linings are going up, but ofcourse since the boat's steelwork expands and contracts due to outside weather its near impossible to use a regular "Screwfix" product which is mean for onshore homes. For this reason would anyone have a pointer toward a quality type/ brand of deocrators caulk to be used for sealing in between the lining panels? Preferably something flexible enough to remain in place between the linings (if such a thing exists at all).

Uploaded the photos below to show how the panels have moved apart even though when screwed them in place they were sitting flush against each other + its visible where the filler has been applied prior to expansion.

Any advice would be welcome. Thanks

-

Knowledge, feedback, insights and opinions shared on every post are definitely worth considering, thanks to everyone for your take on this.

Agreed that this is rather ambitious, however have watched a few videos of other boaters installing their own underfloor heating systems (some also did pour screed all over), although at a time it appeared attractive, it could be interesting to find out their feedback about this and how it served in longer term....

-

Thanks everyone for the wealth of advice.

All has been taken on board and by the looks of it the whole interior will require a rewire (oh never ending joys of boat refit and amendments).

Any pointers where youd be getting your cables from to fit for this? Bought the above mentioned 0.75mm wire loom at "Yess Electrics", after having explained to the sales staff that this would be used on a 12v boat project... although now it seems that perhaps their knowledge is limited to domestic electrics. And this being rather specific requirement (voltage drops, engine bay heat resistence, etc..) would prefer to use more specified supplier.

What type of stove?

in Boat Building & Maintenance

Posted

Wood burner stove question...

Intending to install this on a 70x12 widebeam, would anyone know how many kWh's, what type (solid, multi-fuel, central heating stove...) of stoves would be suitable for this space?

Any pointers for good brands and aesthetically appealing units would be much appreciated.