Tessy

Member-

Posts

51 -

Joined

-

Last visited

Profile Information

-

Gender

Male

Recent Profile Visitors

1,005 profile views

Tessy's Achievements

Engager (3/12)

0

Reputation

-

Those of you who have experience with washing machines onboard... I know that some have disconnected the heating element and plumbed a hot supply directly to the machine via a mixer valve. I have done this, but I have not disconnected the heater as the machine has a cold wash button that I press to ensure the machine doesn’t use it anyway. however I now have a fault popping on the screen that is to do with the element. I want to try disconnecting the element completely as I don’t use it and it has an annoying 2 second activation that it does anyway before registering it is a cold wash. when disconnecting, is it as simple as pulling off all wires and blanking them off?

-

I have just taken off my 120A alternator put back my older, weaker A127. For some reason, I'm getting no warning light turning on when I connect to the smaller spade connector (and so no charging upon start). However I have noticed that I DO get warning light turing on when I touch the wire to the case / earth. I haven't used this alternator in a long while, is it buggered? No problems when I reconnect the newer one with the warning light cable going to D+. In case you are wondering, I need to put on the old alterator to make a long trip as I still haven't put on the double engine pulley that I need for the more powerful alternator. The 10mm belt holds up when idle charging but snaps once on the move as too powerful!

-

I recently changed my starter battery thinking it was causing my start issues but it wasn’t. Until today the situation deteriorated to the point I was getting just a click with no turning over, UNLESS I had the starter on charge above 14.5. Realising it still did this even after battery replacement, I tried giving the solenoid/ starter motor a few taps with a hammer prior to starting and this works. Presumably this means the piston is engaging (Clicking) but not rotating as it’s stuck? If that’s the case then why would the higher voltage work? After a few starts it now starts every time, but I doubt this will last. Ultimately I want to know what causes this, and weather or not the issue can be fixed without replacement? Engine is bmc 1.8

-

advice needed on water filter position and plumbing

Tessy replied to Tessy's topic in Boat Equipment

I shower with the hot tap and will catch the spare water from it while i'm waiting for it to get hot and pass this through the propur for drinking later, and don't like the idea of sediment building up in the hot tank. I'm happy to replace the filter every few months rather than every six if thats the only reason not to -

I have a 10 inch filter under my sink that filters water after it exits my domestic pump. However the water tees off to the hot water tank before it goes to the filter. Therefore only the cold taps in kitchen, bathroom and shower are filtered. The filter is physically 40cm or so higher up than the pump and the tee off. I want to move the tee from before the filter to after it, so that ALL my water goes through it. Will this cause other issues? I'm not sure why it would have been set up like this by previous owner. Maybe they took the view that filter was only needed for drinking water but seems silly to me not to filter hot water too. Currently I have a new 5 micron carbon block filter in there, and flow seems perfectly fine. I put all my drinking water through an additional propur gravity fed filter system.

-

Expansion vessel or accumulator (leaky PRV)

Tessy replied to Tessy's topic in Boat Building & Maintenance

Can confirm that there is NO NRV between tank and calorifier. The tank is set to 15psi (pump cut in). Does this mean that it is being used as an expansion vessel when the water is hot? If so I'll need to change this PRV. New one hasn't come with any gasket of any kind, how does one typically ensure a good deal to the calorifier? As you can see from the pic, old one might need insulation dug away first. Never done this before. -

In the process of trying to figure out weather or not I have a faulty PRV on the top of my calorifier, I have realised that my expansion vessel is actually installed on the cold side before water enters the calorifier. Am I right in thinking that this makes the tank an accumulator, rather than an expansion tank for hot water? Would setting the correct pressure on this vessel make it a hot water expansion vessel, even though its on the cold side? Basically I'm trying to see if I can stop the PRV from kicking out perfectly good hot water, which it has been doing too much of lately. I have a new PRV ready to fit, but I'm not actually sure it is broken. I find my installation odd, is it not common to have a vessel fitted on the hot side?

-

I wouldn't mind touching up the waterline of the hull. I've read that anti-corrosion paints for the hull have been developed in recent years that can be applied under water! Is there any truth to this?

-

I have just purchased this dual fuel generator: https://www.championpowerequipment.co.uk/products/Champion-Inverter-Generators/Champion-20000-Watt-Inverter-Generator-Dual-Fuel-82001i-E-DF I have tried to start it for the first time using LPG only. It will not start. I have noticed that, although the LPG gas bottle is full, nothing comes out of the other end of the hose (the generator end) when it is not clicked into the generator. I do not think that the hose mechanism is sophisticated enough to prevent the flow of gas when not connected to the unit. I suppose the two regulators on the hose do not prevent this either? Am I right in thinking the hose is somehow blocked? Any help is much appreciated! Pictures of hose attached.

-

Hi there, Please can anyone familiar with the Plastimo flexible water tanks explain to me how on earth I remove the inner bladder from the outer cover? The unit seems stiched except for one small corner, it came with no manual, there is nothing online, nothing on their site except the words "easily removable inner bladder". I am forced to conclude that I am being a bit thick since it doesn't seem to have been an issue for literally anyone else, but in any case can somebody assist me!?

-

Leaky fuel lines on CAV and lift pump... sealant?

Tessy replied to Tessy's topic in Boat Building & Maintenance

Hi all, I have fitted the 5/16 union on leaky pipe with dowty and is fine now. The pipe was crushed and there was a mangled brass olive at the end of the break pipe joint instead of a flared pipe! Cut the end off and fitted new union instead. now I’m interested in all the talk of webasto having its own filter. Basically there is a second filter on the engine, and this first unit with the webasto outlet used to be a sediment catcher until someone turned it into a filter as well to protect the webasto. I have a blanked off tee out of the tank that I could fit a separate webasto filter to. Why would this be necessary and how would the webasto suck fuel when off? the only remaining leak is inlet to lift pump which I’m sure has the same issue as fuel filter, as the same awful boat yard installed it (I sued them over engine install previously). I’m guessing I can fix with the same type UNF adapter? I may just replace the lift pump while I’m at it as it doesn’t seem to work very well when bleeding! -

Leaky fuel lines on CAV and lift pump... sealant?

Tessy replied to Tessy's topic in Boat Building & Maintenance

Hi all, I'm just now understanding that the leaking old union is a break pipe fitting in which presumably the pipe has been flared or shaped to form an olive at the end. So if this is the case how can it be crushed by a separate brass olive? Are they gotten with separate olives too? -

Leaky fuel lines on CAV and lift pump... sealant?

Tessy replied to Tessy's topic in Boat Building & Maintenance

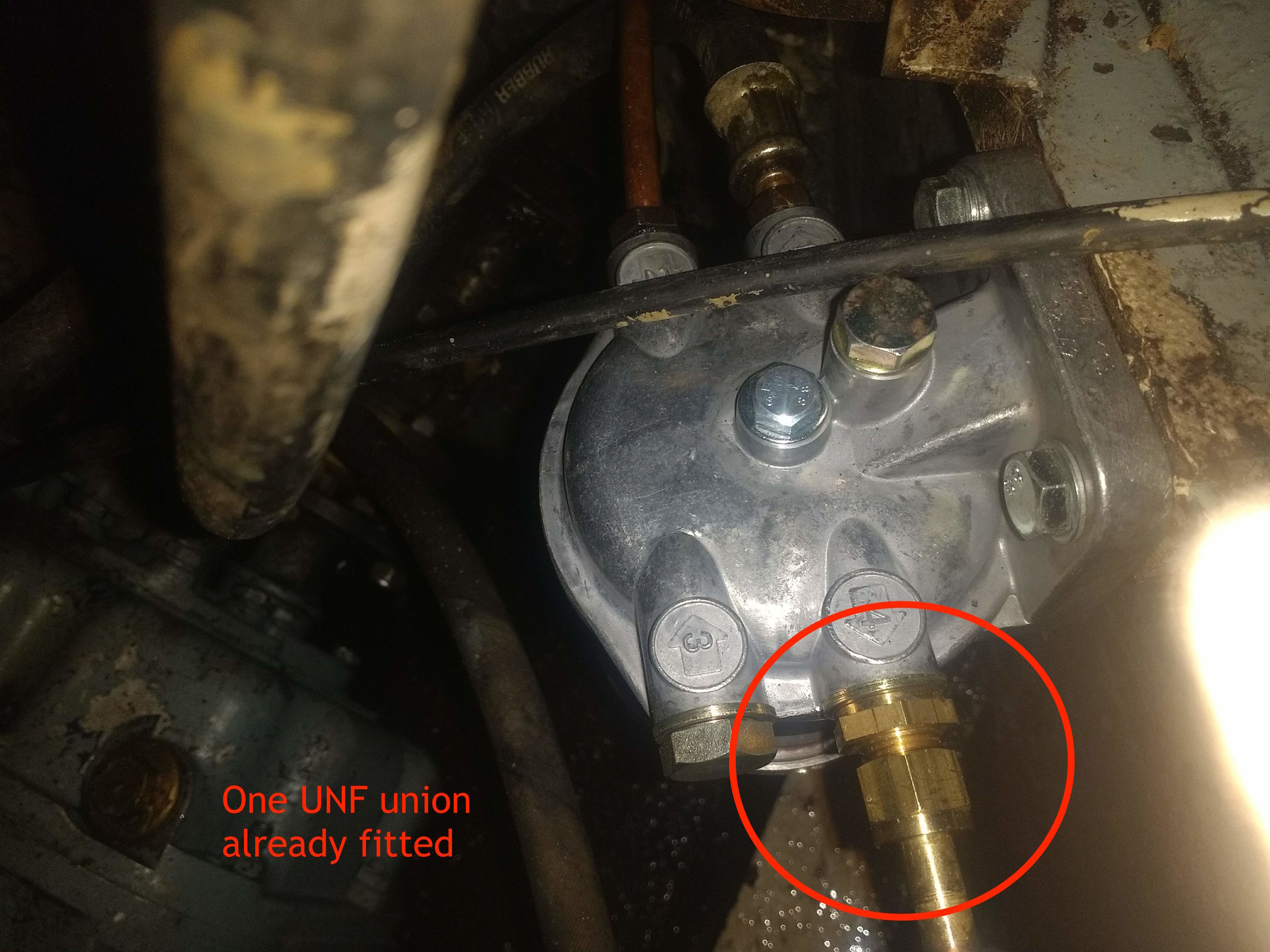

Here are a few pictures to clarify. One pic of the new UNF union I want to use. One pic of this type union already installed on one side of the unit, and another pic of 8mm leaky inlet using old union. I want to replace this old union with new type but it is for 5/16 pipe, not 8mm like is there. -

Leaky fuel lines on CAV and lift pump... sealant?

Tessy replied to Tessy's topic in Boat Building & Maintenance

Tony, what I have is 8mm copper pipe for main fuel line. I need to connect it to the CAV which has UNF thread. however the union bolt I have for it is made for 5/16 pipe, not 8mm. Since this is slightly smaller, I am concerned that the 8mm pipe will not fit through the hole in the compression nut. Now, I do have some 8mm union bolts too, but these have BSP threads. I am guessing that I can't just use the compression nut from the latter on the former? An easier thing to try is to leave the existing union on the pipe, remove it to change the olive and pop some loctite 577 on the thread entering the CAV, but my concern is that if this doesnt work I will be left with a CAV that is gummed up with loctite. -

Leaky fuel lines on CAV and lift pump... sealant?

Tessy replied to Tessy's topic in Boat Building & Maintenance

Thanks! Can you explain the difference between BSP and UNF threads? The unit is UNF. I have a new UNF union for it but the compression end of it is 5/16 while the pipe itself is 8mm!! I do have 8mm compression unions too, but their threads are BSP! What can I do here? Perhaps use the UNF union with the nut and olive from the 8mm one so the pipe fits??