-

Posts

79 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Maudesmaster

-

Prop is brand new boat has only been in water 3 weeks changing gearbox not an option no fouling engine revs are very responsive

-

Hi i need recommendations for new prop size I have a 62’ narrow boat with a Gardner 3LW and PRM 500 2:1 reduction gear box and 24” between Skeg and uxter I have a 21” 18 pitch propeller which is very slow on the forward uptake and full revs only gives me walking speed ( little legs wife on tow path ) in locks I have to use full revs to stop boat hitting gates I am going to order a new prop rather than having existing prop reworked

-

Thank you all drilled and stainless roll pin 6mm X 36mm same as nut AF

-

I have a bronze 19” prop on a narrow boat stainless steel shaft from 3LW That came with Brass nut and brass washer How do you all lock the nut I am thinking of changing nut only to a Stainless steel Nyloc nut any reason as to why not thank you

-

Weak link for button fender?

Maudesmaster replied to Jim Riley's topic in Boat Building & Maintenance

Wasn’t going to use ty wraps just saying about a bag I bought from toolstation and the cure for them snapping -

Weak link for button fender?

Maudesmaster replied to Jim Riley's topic in Boat Building & Maintenance

Thank you for this bought a bag of ties from toolstation and they were snapping off before fully tightened I will try the boiling method as desperate and used a few or would have returned them -

Linking Eberspächer and exhaust heat exchange

Maudesmaster replied to Maudesmaster's topic in Gardner

I do have 2 120 amp alternators running off 70mm pulleys to a 14” crank pulley 1 of which I may change to a lesser one for starter batteries It’s a big learning curve however I would never take on a total fit out again 10 hour days and sleepless nights thank you all for your input will let you know how it’s all gone in September when hoping to launch Maud of the marshes -

Linking Eberspächer and exhaust heat exchange

Maudesmaster replied to Maudesmaster's topic in Gardner

Thank you for all replies feeling a bit sad now I do have the bowman header tank on the cooling system which was all a bit of a mish mash as as the engine came from a fishing boat I had to buy a new thermostat housing and re route the pipe work so if all goes t!ts up I can re route through the heat exchanger on the bowman header tank, what would have been great if bowman made them for the Gardner would have been a manifold heat exchanger perhaps -

Linking Eberspächer and exhaust heat exchange

Maudesmaster replied to Maudesmaster's topic in Gardner

Thank you for replies The boat has not been floated as yet, when I first installed and ran the engine with skin tanks full the pipe work to and from skin tanks after 1 hour running the was only luke warm whereas the exhaust was very hot My thinking was to try this idea out using only a small can with the flanges welded around the exhaust so water did not boil or cool the exhaust gasses too much I can modify the exhaust at a later date Can I tee into the pipe work so that when engine is running it heats the radiators -

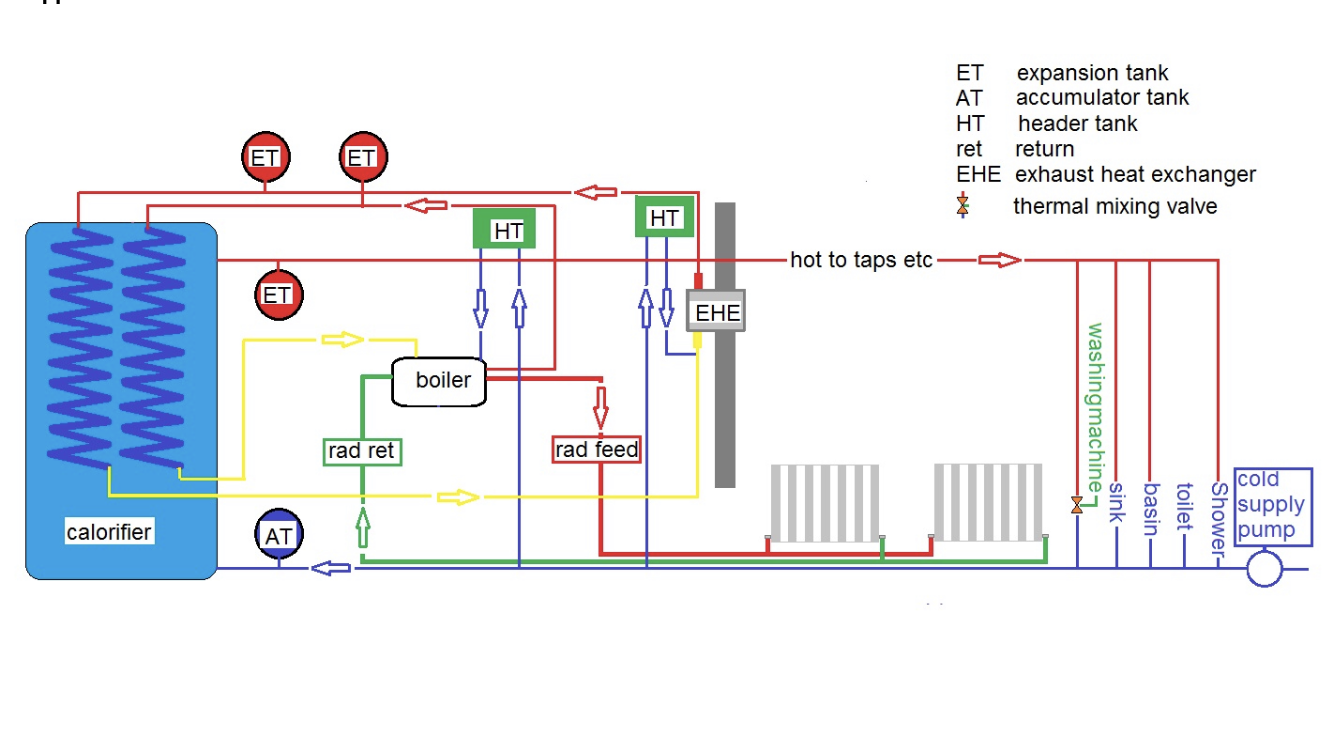

I will be heating boat and water via Eberspächer hydronic 5 to 5 radiators and 1 coil in calorifier but would also like to heat via an exhaust heat exchanger I have fabricated on the Gardner 3LW which will go to second coil in calorifier How can I link the Heat exchanger and Eberspächer to heat the Radiators and hot water

-

Thank you all there will be no joints and a gate valve both ends fusible head fire valves Toolstaion less than a fiver ?

-

Thank you all there will be no joints and a gate valve both ends

-

Does the BSS allow a 10 mm diesel feed copper tube to run alongside the heating pipes left of the two plastic pipes and right of the upstand in photograph clipped every 12” or so

-

Great thank you guys the shaft is 1 5/8” so about right then with everything else was a bit of a shock when fitting prop plenty of room behind prop for folding chairs etc Richard

-

On fitting Propeller to through shaft there is a gap between front of prop tapered face and aft face of through tube to stern gland of about 1 1/2” This is mid engined so shaft from Gear box to through shaft is bespoke and cannot be altered I can recut key way in shaft and chop off end So how much gab would be about correct between shaft and through tube Also would a flexible coupling be advisable between shafts thank you in advance Richard

-

Thank you all very much for your input Crowther marine were unable to recommend a prop due to limitation on swing Other company's were vague also As Daves is tried and tested although all criteria were not as my build I think I will go for the 21x19 Now has any one got one kicking around it their shed thinking T Norris as supplier as fairly local Thank you all again

-

Sorry for late reply I have been working away Thank you for your input it seems I have a lot to research ie 3 or 4 blade change gearbox (which is new) as I said before prop manufacturers seem a bit vague and 1 wouldn't advise at all Richard

-

Hi although not a Gardner question I would like to find out proper size for a new build 62' with 3LW AND 2:1 reduction box Distance between uxter plate and tiller Skeg is 24" I have had e mails from various companies who all seem a bit vague some would not advise at all, nearest being T Norris who advise either 22 X 16 or 20 X 17 or 18 i would really like to get this right first time so looking to you good folk for your experience Thank you Richard

-

I am fitting out a new build 62' with a 3 LW The top of the Skin tanks are about 4" below the centrifuge pump After around 1/2 hour running 3/400 rpm the pipe work from pump around block and head up to Borman header tank are warm Skin tanks feed and draw are cold Any thoughts on this thanks in advance

-

Gardner Engines and Beginners - Advice Please

Maudesmaster replied to Jim Batty's topic in General Boating

I replaced my CAV 24 volt starter with a 12 volt unit from /startermotoralternator.com but keeping the 24 volt very good company excellent service -

I have a 3LW The original air intake was alumiminiun and had snapped halfway down I fabricated a new one in stainless I don't know how to post photos on here but it looks nice

-

Steamraiser2 All these calculations went way over my head and could not measure fly wheel anyway I went to Gardner marine in Canterbury and they let me count the teeth on a new one You were correct 175 teeth Thank you

-

Thank you Steve I think so it has a pin like detector on the business end I don't know how to put pictures on here it's a Murphy Magnetic Tachometer Sender 76mm x 5/8-18 UNF A.S.A.P Part No. 708855 Richard

-

I have the hole drilled and tapped 5/8 to 5/8" UNF and ordered the sender so would like to go down that road Thank you though This is my first owned boat as been one of them there hirers for the last few years because we had a time share thingy We are hoping to be CCers come next summer when all fitted out Regards Rich

-

Thank you all very helpful The 12 and 24 volt starter both 11 teeth the 24 volt used to skip there was an O ring between the shouldered plate I assume is for lining up tooth to tooth as the hole the motor fits through is not central When I took the 24 volt starter out half of the pinion was scuffed and inner half clean. measuring in to ring gear from plate and measuring pinion depth there was about 13mm difference so removed 8 mm O ring now catches every time I need to know teeth number for magnetic RPM sender