-

Posts

667 -

Joined

-

Last visited

Giant's Achievements

Proficient (7/12)

55

Reputation

-

Treating black rust on the inside of a heavily pitted bilge.

Giant replied to DHutch's topic in Boat Building & Maintenance

It wouldn't be impossible to get it blasted. You'd need to put up some plastic sheeting around the rest of the area, wrap up that propshaft, remove anything that can be got out of the way, and shovel out & hoover up all the grit when finished. If you can get good epoxy onto freshly blasted steel and follow it up with a couple more coats you will never have to worry about it again, it will outlive you. The epoxy works its way into all the microscopic nooks and crannies of the rough surface. The result is an astoundingly strong bond, you're basically making a thin layer of composite. You'll never get the paint off except by abrading it away. Alternatively, do the same thing you did before but without the Vactan. By the time you've got to a surface that's been needled and gone over with a wire wheel, you shouldn't need a rust converter. Anything you have to put on and rinse off at that stage is probably just going to worsen adhesion of the epoxy. The Clarke needlegun isn't bad, but for pitted areas it's often necessary to take the needle attachment off it and use the single-point chisel that comes with it instead. It's much better at knocking those last bits of black magnetite out of the bottoms of all the pits. The needles can often fail to get right in there, since too much of the available force is hitting the surrounding areas instead. For an area that gets wet, it's crucial that you get right down to sound metal in every pit, or there's bound to be water trapped between layers at the bottom of them. -

Tonic required. Send in your photos of what is nice on the waterways now.

Giant replied to DandV's topic in General Boating

-

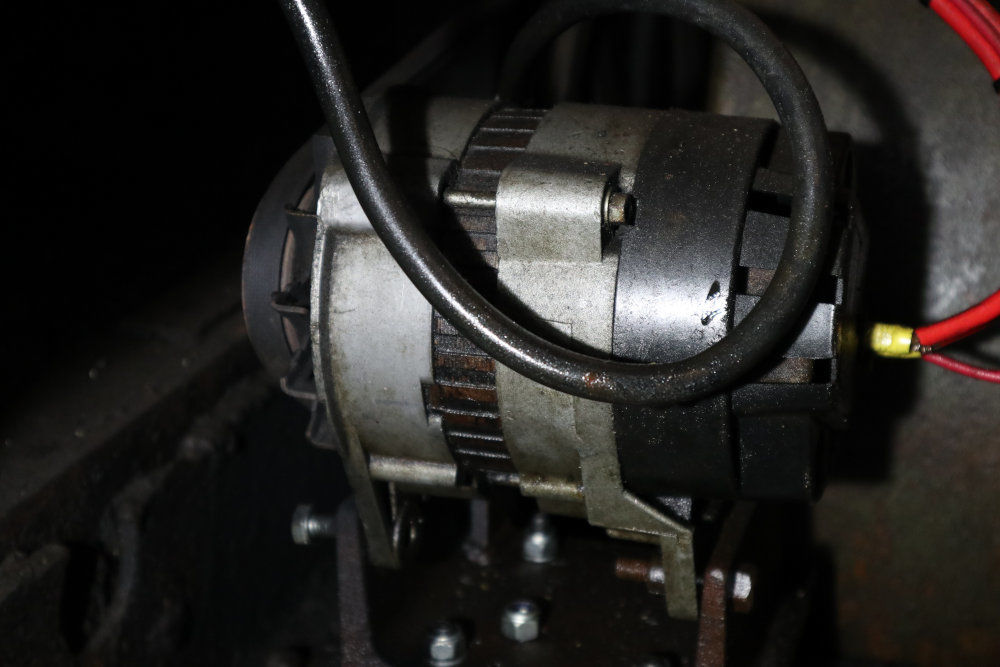

Our alternator has failed. No markings on it. Design looks like a Lucas ACR but the back cover doesn't exactly match any of the variants of that I'm seeing online. We very badly need to be back underway on Thursday with a working alternator, so I want to find a drop-in replacement for this by the end of tomorrow. We're tied up at Gravesend. There is a Euro Car Parts here but they don't seem to deal in anything that old. I can travel tomorrow to anywhere in or near London to pick one up. Next day delivery could work in theory (we have an address nearby), but has been very unreliable lately so would want to be very sure the supplier could get it done. Any ideas? Photos: Symptoms: Was working fine when we left, 13.8V at idle and 14.4V with some revs on. At some point I noticed the battery voltage dropping, went below and found the alternator light on despite plenty of revs. Battery and field coil connections are fine. There's about 2.3V between negative and the field coil terminal regardless of revs (rest of the battery voltage is dropped in the bulb). The belt had got a bit loose so suspected that, but have now tightened it and no improvement. No squeaking. Diagnosis: My understanding is that this means either the brushes or some of the diodes have gone. Fixable but given time constraints we want to just swap it out. Installation: 16" pulley on the front of a JP3 driving a 2.5" pulley on the alternator, so ~7700rpm at full revs (1200rpm engine). V-belt with "A" section. Turns clockwise looking from the pulley end.

-

What is your latest purchase, bargain, 'must have gadget' ?

Giant replied to Alan de Enfield's topic in General Boating

Thanks. Our freeboard is about the same so I'll keep an eye out for the 9 step version. -

What is your latest purchase, bargain, 'must have gadget' ?

Giant replied to Alan de Enfield's topic in General Boating

I like the look of those ladders at the start of the thread, hadn't seen that design before - will have to keep an eye out on ebay for them. @Alan de Enfield or @magnetman, how far apart are the steps on yours? I want to work out how many steps we'd need to get. -

Today's mystery, however, is in the exhaust manifold that came off engine #2. We'd like to use this one, because the troublesome joint to the silencer is in much better shape. But while having a look through the channels in it yesterday, I found this inside the exhaust - a bent rod around 3-4mm in diameter. I could just about reach each end of it with a finger, through the forward two exhaust ports: At first I thought it was just lodged in by being bent around the corner, and tried to free it, but eventually I realised that both ends were free, and that all I was doing was bending it around a point in the middle where it was welded to the casting - here, you can see where the weld is and where I've dislodged the carbon either side by bending it: So it seems like this is a brass brazing/welding rod that's been used to fix a hole at that spot, and then left in there. For context, it's positioned like this (in green) within the manifold, with the weld (circled) seeming like it's on the edge of that round feature on the side of the casting. It seems like that round feature is at the end of a boss, that shows up as a ridge across the exhaust channel. But it doesn't seem to be a tube that connects to the water side of the manifold, and it would make no sense to have a tube across there - the water flows along the manifold below and to the side of the exhaust channel. So why was it necessary to weld up at this point? Any ideas what's gone on here?

-

Well, I suppose we should start updating this thread again. The bottom end & gearbox of engine #2 have been with @RLWP and @Mrs Tawny Owl for a while now getting a complete strip down & rebuild. The crank has been reground, reinstalled on new main bearings and everything is looking very shiny. Sometime soon, we will be taking the boat into to drydock, and while we're there we'll have engine #1 craned out through the deck, and the newly rebuilt bottom end of engine #2 installed in its place, after taking the opportunity to strip the area under it back to bare metal and repaint. Then we'll be rebuilding the top end onto that, with a mix of parts from engines #1 and #2. There's a complicating factor with the reduction boxes, because the one from engine #2 was water damaged and unusable, and it's not possible to remove & strip down the installed one until we have the engine out. So we're going to need to get that apart, deal with any issues and get some paint on it before reinstalling. We're hoping there's not too much wrong there - it runs smoothly, and looks to be in reasonable condition on the inside as seen by an endoscope down the dipstick hole. Meanwhile, we've been getting engine #1 as ready as we can for its final voyage, swapping in some top end parts from #2 that are in better shape, and installing some new bits, all of which will then get transferred to the newly rebuilt bottom end.

-

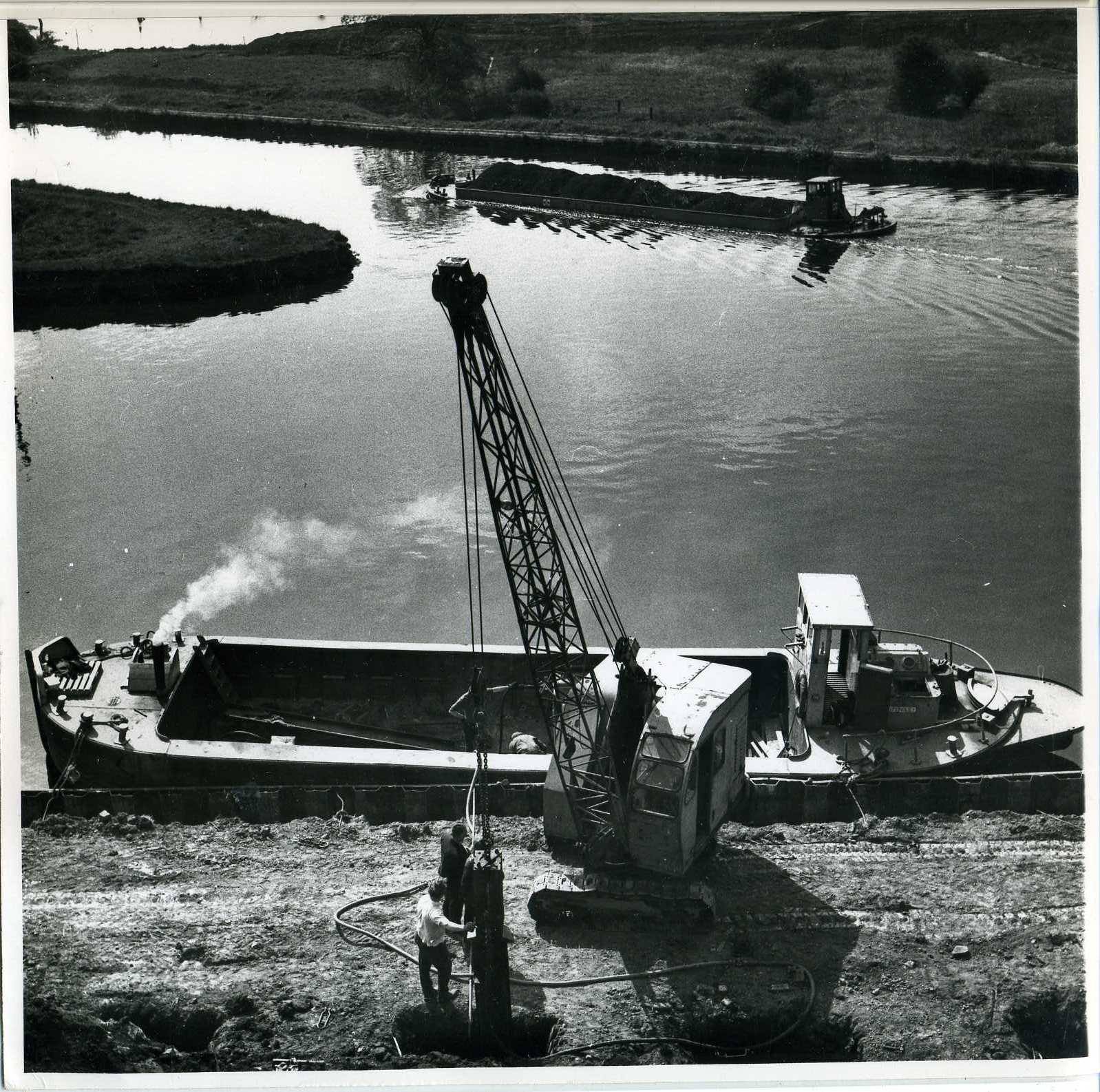

She was the last built of a set of four, her sister ships are Barnsley, Haddlesey, and Knottingley. All were dumb barges originally, Knottingley and Stanley were motorised later. I think this is her in British Waterways colours - it's a still from 3:41 into this amateur film in the BFI archive from 1960. This might be her too, or one of her sisters: This is her sister ship Knottingley from a recent ad: Look for a Facebook group called "Barges tugs and workboats on Humber" and ask around on there, it's a treasure trove.

-

Looking good Simon. Need to find some more time for our JP3M project...

-

Seat bumpers for a 1948 Baby Blakes Lavatory

Giant replied to Kingdom Isambard Brunel's topic in Boat Equipment

If I had the original in my hand I could give you a rough guess what it is. The proper tool to measure is a durometer, but a useful rough guide to Shore A hardness is: 20 = Rubber Band 40 = Pencil Eraser 60 = Car Tire Tread 70 = Running Shoe Sole 80 = Leather Belt 100 = Shopping Cart Wheel I would go for 85, given that you'll be putting your weight on them when you sit on the seat and presumably they're not that big. Think about a running shoe sole being 70, and you spread your weight across the whole foot on that.- 22 replies

-

Seat bumpers for a 1948 Baby Blakes Lavatory

Giant replied to Kingdom Isambard Brunel's topic in Boat Equipment

Yeah, a 3D print in Ninjaflex or similar rubbery filament is another option, but I'd hesitate to use a 3D print in this application since the surface will be rough and somewhat porous, which makes it hard to keep clean. And with the flexible filaments you can't really smooth the print with sanding or with solvent vapour in the same way as you can with solid plastic.- 22 replies

-

Seat bumpers for a 1948 Baby Blakes Lavatory

Giant replied to Kingdom Isambard Brunel's topic in Boat Equipment

If you have an original one as a reference - even if in poor condition - then it's possible to cast a mould from it, clean it up, and use a two-part liquid casting rubber to make new ones. I do a bit of this sort of process for making prototypes of plastic parts etc.- 22 replies