gregich

Member-

Posts

25 -

Joined

-

Last visited

Profile Information

-

Gender

Male

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

gregich's Achievements

Explorer (2/12)

0

Reputation

-

gregich started following Lister Petter AVA2 missing Gearbox and Morals on the Waterway

-

Not so, working class women went into pubs but usually accompanied by a man. Some pubs had segrated areas like a 'snug' or the lounge. Middle class women did not though.

-

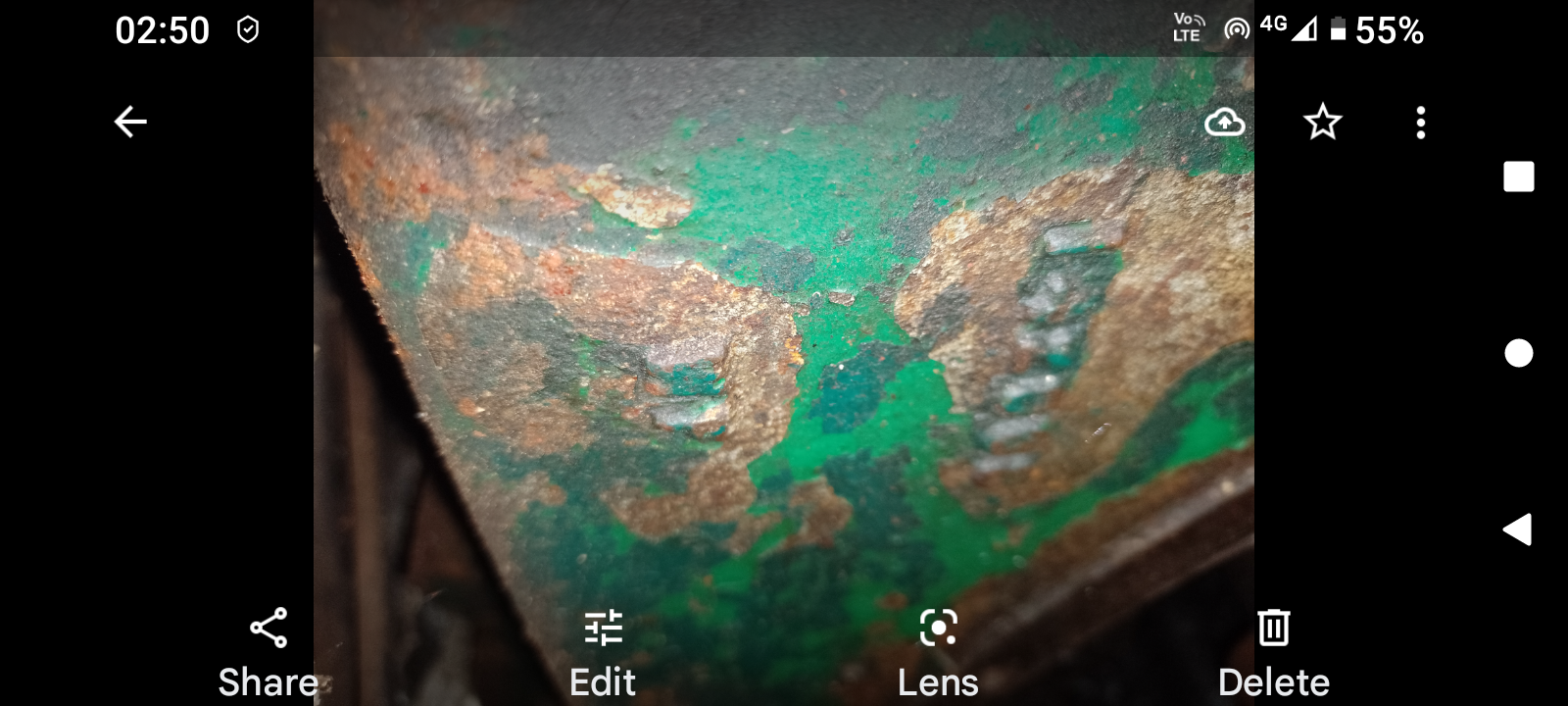

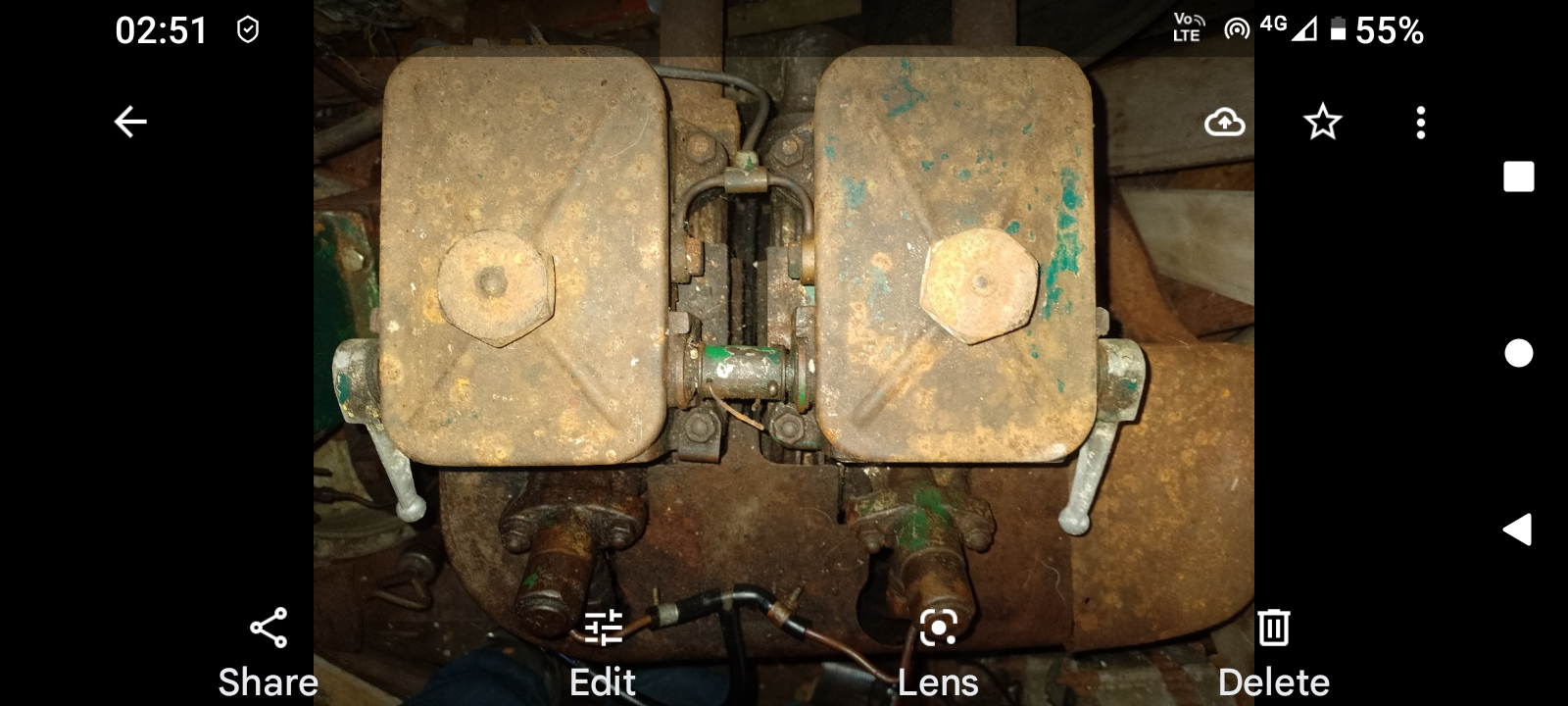

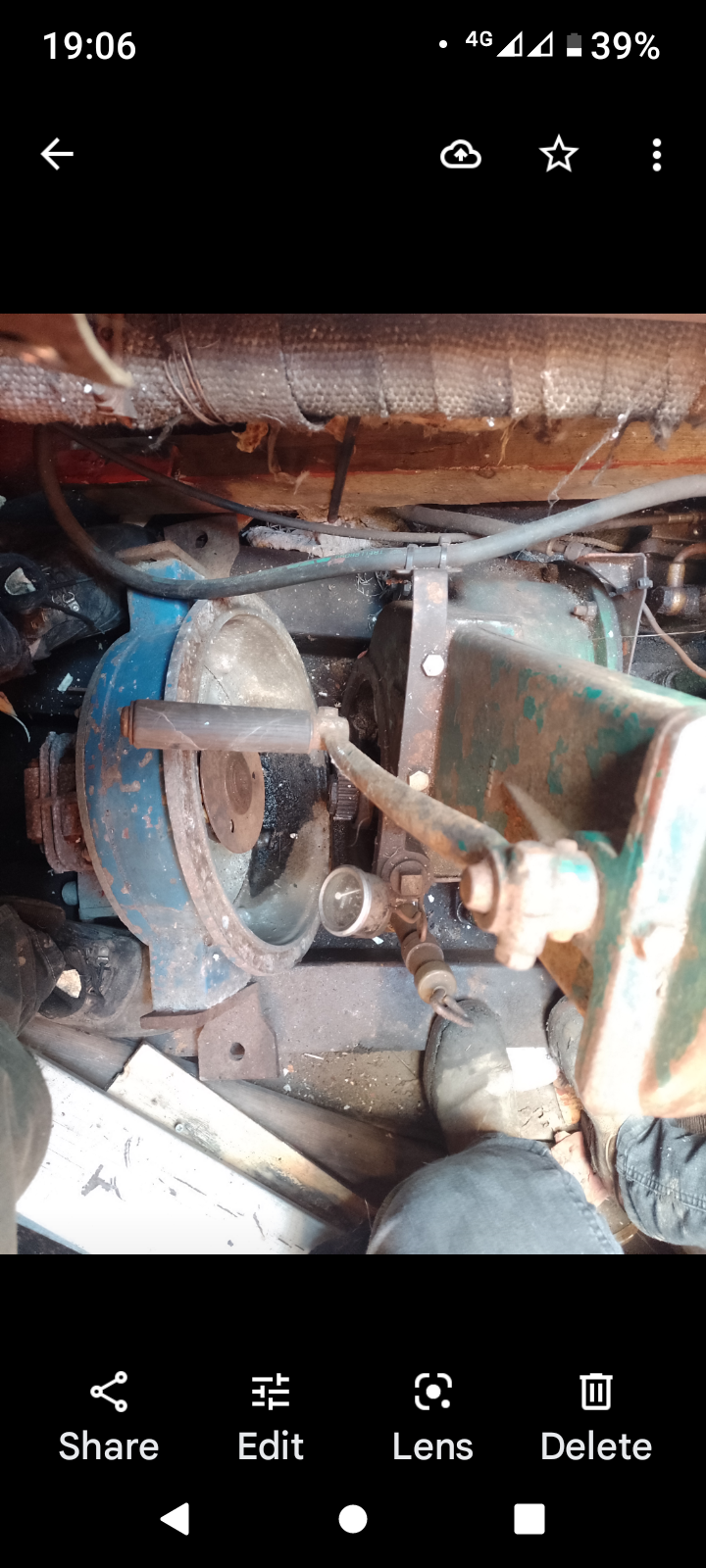

It's took a while to get more pics due to it not being my boat but here they are. There's an offer of a Isuzu engine with gearbox but I thought I'd check out getting right gearbox first as this seemed easier to me on paper. The reality seems anything but atm. More pics that might help

- 25 replies

-

- ava2

- lister petter

-

(and 2 more)

Tagged with:

-

If i was to move the gearbox out the way and get some better pics, would you be able to tell what gearbox it was or wasn't or would it take detailed measurements etc. Any more monetary mistakes might just sap the energy out of this effort to put things right as my friend has lived without it for 2/3 years now. Maybe if i took a template of the housing face before purchasing and a close up pic of the 'gear' wheel. I have very little knowledge of gearboxes and the nuanced differences although i'd feel confident fitting one so long as i was sure it was the right gearbox as i'v done this with my BMC 1.5.. I'll have a look over the weekend..

- 25 replies

-

- ava2

- lister petter

-

(and 2 more)

Tagged with:

-

Hi Richard, sounds promising, how would I be able to confirm this is a PH2? Thanks Alec, I'll see what happens with Richard and get back to you when iv determined if the engine is indeed a PH2. It's been a couple of years so I'm tidying up an old mess tbh. Obviously that was my first question. Probably sold on by the conman. That would be my normal recourse but it's not my call so my hands are tied.

- 25 replies

-

- ava2

- lister petter

-

(and 2 more)

Tagged with:

-

Indeed, i was warned off doing it to my SR2 on a previous thread. The AV owner has already been ripped off nearly £300 plus the gearbox so money would be an issue too. She'll need a slice of luck to find the right gearbox by the looks of things.

- 25 replies

-

- ava2

- lister petter

-

(and 2 more)

Tagged with:

-

Thanks. She has a manual for the engine but not sure if that will mention the gearbox but i'll get her to dig it out. Where is he based?

- 25 replies

-

- ava2

- lister petter

-

(and 2 more)

Tagged with:

-

- 25 replies

-

- ava2

- lister petter

-

(and 2 more)

Tagged with:

-

Hi all, my friend has a Lister Petter AVA2 engine in her narrowboat but no gearbox. She doesn't know what type of gearbox it was as it was taken for repair but basically stolen along with a her money. Can anybody help with some info on the type of gearbox used with AVA2 engines or even better have a servicable one for sale?

- 25 replies

-

- ava2

- lister petter

-

(and 2 more)

Tagged with:

-

That's already in there so wouldn't need to change it, just the connection to the rest of the linkage.

-

It's not a minor problem, i wouldn't entertain the idea if it was. It's like driving a tank at a the winding hole and i hope to sell it in the next year or two so want it sorted beforehand.

-

Sounds similar to my set up. Could i replace the bar with some 25mm box section maybe 2 or 3mil thick?

-

The main lever coming off the gearbox shaft is a 30mm diameter solid steel bar stretching about 700mm, I'm pretty sure it doesn't need to be that robust :). You could chuck a hand grenade in there and it would still be intact. I'll try and take some pictures and see if some clever bod can't give me some pointers to improve the set up.

-

Genius 🙄 No machine shop here unfortunately, I will look into the LH150.

-

It's always been the same and has very little use really.

-

Sounds complicated although not beyond me and possibly quite expensive. It might be easier to redesign the leverage operating the gearbox. It's made from very heavy thick steel. I'm fairly sure it doesn't need to be that built to that spec to function properly.