RS_Pete

Member-

Posts

30 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Bath

-

Occupation

Engineer

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

RS_Pete's Achievements

Explorer (2/12)

1

Reputation

-

Should they ever surface I would love to see them for the same reason. (if your storage is anything like ours!.....😬) That would be fantastic, thanks.

-

To be honest I would be happy with anything if it showed something... Methods of copying have changed dramatically over the years and often something got lost. Digitization is not without issues either going by the number of DVD, CD's, files, photos etc I have that no longer seem accessible. Re-drawing would have been the only option originally I suspect and certainly one of the best for refreshing fading and decaying documents. It is shame that with his passing Canal history seems to have lost a great archivist. While it is a shame that the small Woolwich drawings were not it would still be great to see a copy if available anywhere...

-

Yes it is, bloody slowly, too slowly!🤣 That was Sara my wife. We'll get there hopefully.

-

If you are able to scan them Id love to get hold of a set as our boat was once a Star Class butty. Considering how old the original drawings would be I cant say I'm surprised that they would be poor quality, especially if they have been copied several times already! I was intrigued that there was something in one of the early CAD? packages being used by schools that the thread seemed to think was based on the originals. If you do find them and are willing to scan do let me know Id really love to see them and maybe purchase a copy? Many thanks

-

RS_Pete started following Rudderstock bearing question (as in does mine have one?) and Narrow Boat Plan

-

A great shame to have come across this thread so late. Do any of the drawings of the H&W "Star Class" exist anywhere? I would have loved to see the CAD drawings but anything really showing layout and detail would have been of interest. Intrigued that the drawings were part of a School CAD software package.... Anyway if anyone has anything or could point me towards I would appreciate it if only to see how mine may have looked once upon a time!

-

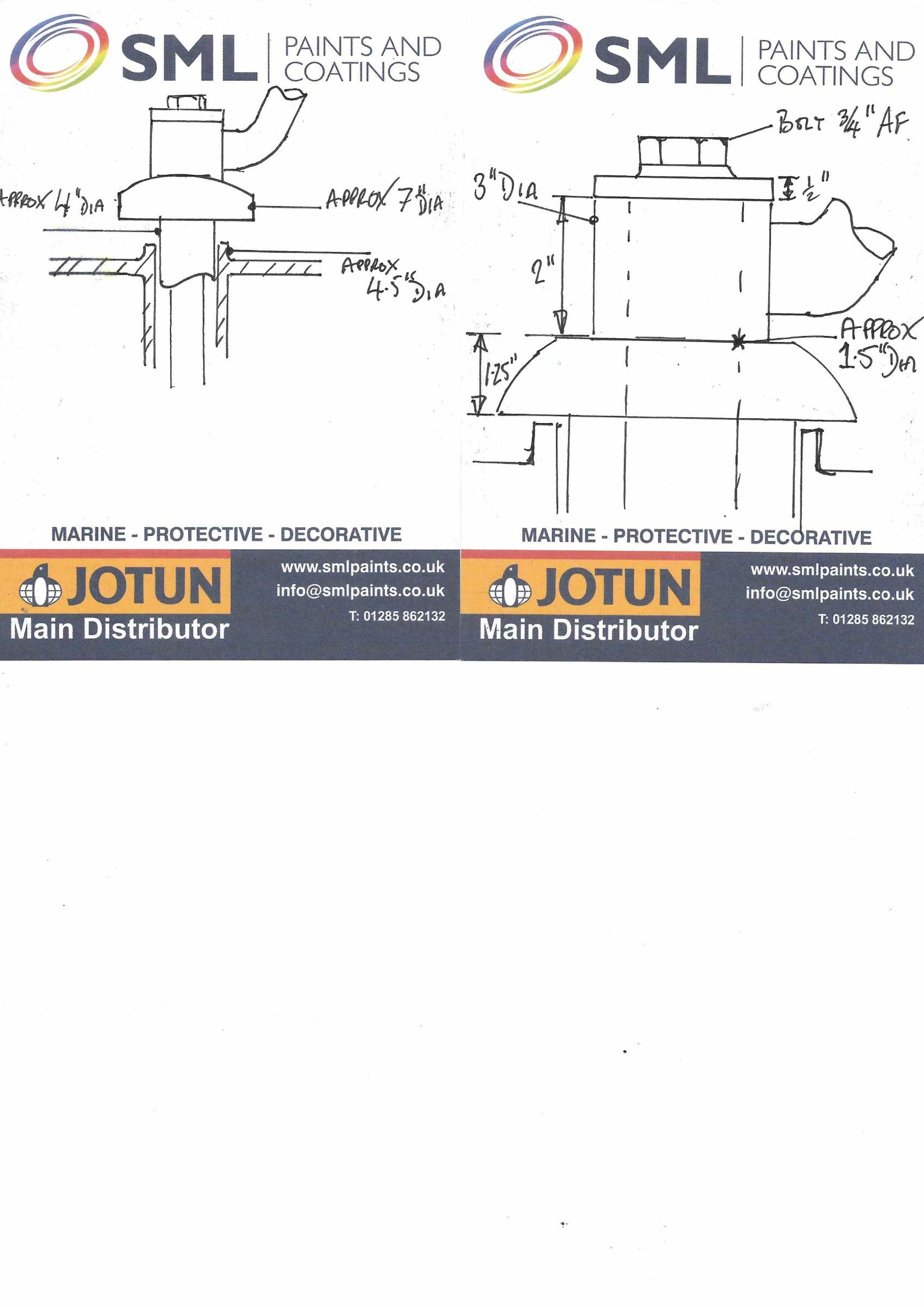

Looking for some advice regarding the rudder stock support / bearing on my narrowboat. This has never felt smooth since we brought her and I felt I should investigate further. The boat, or at least the rear was built sometime in the 60’s. Looking at this it appears different from others I have seen that have a bearing block mounted on the rear supporting the top of the rudderstock. I had thought originally that the “mushroom” cap was a simple pressed or spun steel cover for weatherproofing sitting over a bearing (and that may well be its purpose.) However, this is a solid steel machined piece with a parallel steel section below it sitting in the top of the rudderstock tube. The fit of the parallel section in the rudderstock tube is loose or sloppy, allowing movement at the tiller end radially in all directions of approximately 6mm With a pry bar the whole lot can be lifted at least 25mm (1”) and the parallel bar slides up and down in the tube freely. The tiller and rudderstock can be, with a pry bar again, be lifted through the mushroom and parallel section by a similar amount. Can anyone throw any light on how this is supposed to work? I am wary of trying to dismantle at present without a greater understanding as I am concerned as to how willing the parts will be to separate. I don’t want to end up in a situation where it can’t be reassembled easily… However, it will need addressing at some point in the not too distant future.

-

Thanks Jim, I'd love to see a picture of this if one is available. I love some of the ingenuity that can be found out there, not just in the boating community, and often find myself disappearing down an internet rabbit hole for hours when looking at what can be done. The small home movement have a lot to answer for!

-

RS_Pete started following 60ft narrow boat hull with wooden cabin

-

Oh I've been poking with a sharp thing.....?I have stripped the inner cladding back to gain access to the first 6 metres or so. Due to the over cladding with metal on the outside access is difficult there though the cladding doesn't appear to have been the full length and is only on the vertical surfaces where applied. Definitely worse where clad though that may mean its older.... The starboard side is, oddly, in far worse condition than the port side, both appearing to be constructed at the same time using the same materials. The roof is worse at the bow and the stern leading me to think that it has been subject to patchwork repairs before. I also don't think there is sufficient framing giving support to the roof and sides... So I will tackle the first 5metres and then the next and then the next and presumably return to the beginning to fix anything I got wrong the first time..... And repeat?

-

Indeed. And truthfully I don't see an easy or economic option open to me. At least with a "repair and make good" option it can be done piecemeal... unlike a steel top which will be done all at once as a one off but at unknown cost.. assuming there is anyone out there willing to do it. I have the skill sets to do either myself, though experienced guidance is always a bonus. I just lack facilities and £££'s currently. So it looks like timber/ ply replacement and repairs. All advice most welcome though?

-

Part of the problem I have is, I think, caused by the previous owners attempts to protect the roof actually acting as a catchtank for water trapping it under poorly fitted tarps. Properly fitted as that centre section appears to be in the photo on Bargus may be the way forward while repairs are ongoing. Looks like replacement of outer panels and any other rotten wood with marine ply sealed with two pack epoxy will be the starting point. Fingers crossed

-

The current top appears to have this done, at least in part. The existing construction, which is 18mm plywood has been repaired previously and is faced with sheet metal and then covered in a cloth painted with a bitumen paint (and yes that looks as bad as it sounds…), is somewhat sad and tired with sections needing replacing. Unfortunately I have no idea when it was done and it may have been applied over existing damaged wood, or has actually trapped moisture in as the current panelling is pretty rotten in places.

-

Especially as it's a few years since I did any....?

-

Well I have had a reply from Martin. Unfortunately due to Covid and its restrictions he needs to focus on his current business orders and is unable to help with this. I suspect his will not be the only boatyard in this position at present so it may be the repair option is the only option..... (Of course there's always that cheap welder and some tinsnips on FB marketplace....?) Hmmm....3 sheets approx 1.5 metres by 15 metres on the BMW might prove interesting....

-

That stripout shouldn't take too long! The boat was effectively a blank canvas so fitout is effectively a little way off at the moment. Really need to decide where the rapidly diminishing budget is best spent and order of attack. My preference is for steel for the longevity and maintenance point of view, though I have to admit a perverse fondness for the wooden top... I have sent an enquiry to Martin. I expect it'll be a few days before I hear back with it being a holiday weekend however when I do will report back on here. Just have to figure out the best course of action...and route to Southam from the west end of the K&A...

-

Hi Tracy, Thanks for the fast response! Do you remember if this was a welded construction or was it steel panels screwed to the existing structure? I suspect if it was Southam it may have been Kedian Engineering?