p6rob

-

Posts

671 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by p6rob

-

-

Hi,

As part of refitting my boat, I'm removing the unused pump out tank. Before my ownership, the boat had a dump though toilet which had long since been removed and the porta potti sat on top of the tank with a plate over the dump through hole.

I've now discovered the tank is about 1/3 full of at least six year old bodily fluids and is a bit too heavy to maneuvre without risking spillage.

If I reconnected the pipes, would it pump out successfully or will the hole where the toilet should be cause an issue? In my head, pump outs require vacuum to work but now I'm wondering if it's just a suction pump pulling the liquids up but then how do they cope with solids.

The tank sits low in the boat, so not sure how I could successfully siphon it into portable containers for elsan disposal.

Also, if anyone wants a stainless steel dump through tank there's one available very soon, currently in Cambrian Wharf with or without existing contents. ?

Thanks in advance

Rob

-

I'm guessing I've missed some excitement! The floor still isn't sorted that's for sure. I've got all the boards and joists but it's been an experience cutting to fit, finding the board wouldn't fit through the door. Taking it back to my mother's to cut, returning again finding it would fit through the door but needed a bit more shaving off, etc. Replacing the floor without removing the side panels is proving to be an endurance feat with at least a few more weeks to complete.

Rob

-

6 minutes ago, Bee said:

Your local fencing or roofing supplies place might be worth a try. Those bits screwed to the bearers? I wonder if they fitted over the steel cross members in the boat?

It's a job to tell and unfortunately those are the most rotten joists and literally fall apart when you touch them but from what I can make out, the extra bits are the full height of the joist.

6 minutes ago, BilgePump said:Could those bits on either side have been added as doubling once the original bearers started to rot and there was give in the floor?

I don't think so. The amount of work that would have gone into fitting them at that stage wouldn't have made any sense.

-

3 minutes ago, BilgePump said:

Good luck with that. Just come off the phone to my local timber yard. Can't get a delivery before Tuesday and needs to be over £300 at the moment (normally £100). Not complaining, they've only just reopened, running with skeleton staff, the world and his dog want materials and it's Bank Holiday weekend which I'd forgotten about.

It has been proving quite difficult. The most frustrating thing is my boat is in Lapworth, right by Curtiss' timber yard and pass it everyday going to work. I can see the stuff I want, neatly stacked at the side of the road but they are shut. Realistically, I can just wait a bit longer to order the wood and spend longer cleaning, prepping and painting the metal.

-

Thanks for the replies.

There were four reasons for the standing water. A long term leak from the hose to the bathroom sink taps, which I fixed when I bought the boat six or seven years ago. The shower tray having a crack, which will be replaced as part of the refit, the pipework to the carolifier, which I'm not convinced is fully cured at the moment but as it'll all need to be disconnected to fit the new floor, will be. Oh and a partial sinking when the base plate had a hole in it, that one has definitely been fixed!

I'm attempting to buy the wooden joists today.

Rob

-

I'm stripping out the interior of my boat to replace rotten floors and joists. The joists are 75mm x75mm what type of wood should I use? Are fence posts adequate? Also on some of the transverse beams it looks like 12mm x 75mm pieces had been screwed to both sides, why would that would be? Would it be better to get 100x75mm posts to replace them?

The boat has had a lot of standing water in the cabin bilge for some time, so a few of the joists have been squidgy enough to pull apart by hand. It's a job that I've been wanting to do for a couple of years but a frozen shoulder has prevented it until now.

Thanks in advance.

Rob

-

Thanks. I suspect I'll just keep replacing the batteries every couple of years until li-ion controllers become affordable but might take these ones into work and use their fancy charger to see if that perks them up a bit first.

The isn't much electrical stuff in use. If all the lights are on they draw under 3 amps and the lights might be on for six hours per day in winter, The water pumps run for about 15 minutes a day in total. Phone charges overnight but the internet dongle is always plugged in.

On the rare occasions I use the TV, the engine tends to be running, same with vacuum.

Only really use the laptop on its battery.

The diesel heater gets used about 30 times a year when the weather is chilly but not worth having the stove going.

Fridge and water heater are both gas.

-

Sorry. It's a battery question.

Since moving on the boat about 6 years ago, I've had to replace the batteries every two years. Up until the last set, I always bought sealed maintenance free lead acid as I didn't think I'd be regimented enough to keep an eye on acid levels, two of the three batteries are difficult to peer into the filler holes.

Getting on for two years ago, I thought I might be better at maintenance, so bought 3X 110 batteries. Initially I was fairly good at checking the levels but as they never needed topping, that soon slipped to 3 or 4 months between checks. Yesterday I checked them for the first time in probably six months and they still don't need any water adding.

They have however lost a bit of power. This isn't a major issue as I don't really consume much, the lights are LED, I occasionally run a vacuum from the generator but the engine is usually running at the same time.

Whenever I've fitted new batteries the Smart Gauge tends to show 13.2 volts at rest and after about two years this drops to about 12.8v. What I've noticed is at night, when there's no solar the diesel heater won't start because of low voltage. When it's doing it's start up sequence the Smart Gauge shows volts are around 12.3v. The heater is not a marine one, so I understand why it won't run. When the batteries are tired if it's a bit nippy but not worth getting the stove going, I'll run the engine while the heater starts up to keep the volts high enough. Once the startup has completed, the engine gets turned off and the heater will run for several hours quite happily.

Getting to the point.

During winter I charge the batteries from the engine at about 1200rpm for an hour or two every few nights and about six hours at the weekend.

During the sunny season, the two solar panels do the charging through an outback mmpt controller.

Is there a setting I should change to make the charging more aggressive and if so, with proper maintenance, would that make the batteries last longer than two years?

I don't necessarily think replacing batteries every two years is bad but when I hear of people getting 5+ years, Having never had to top up these batteries makes me wonder what they do differently.

Cheers

Rob

-

I've use these people a few times. Easy to find what you want and stuff arrives quickly.

Rob

-

13 hours ago, David Schweizer said:

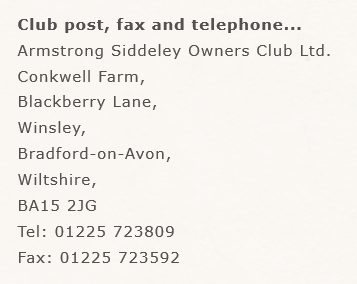

Thanks David, I didn't realise you were so close to the stores. I visit there fairly regularly and have spent many hours trawling through boxes of random bits in the hope of finding a few missing parts.

13 hours ago, David Mack said:Is this a diesel engine?

No. It's a 5.0 straight six petrol. This banjo is for the automatic chassis lubrication though, so not engine related.

Rob

-

2 minutes ago, dmr said:

Surely once the connector becomes double ended it has lost the crucial attribute that makes it a Banjo?

...............Dave

Maybe that's why I'm struggling to locate one. Using the wrong name... parallel brass hydraulic union perhaps?

-

1 hour ago, canalboat said:

I saw a beautiful Armstrong Siddeley saloon car yesterday at the Bicester Scramble. I love the sphinx mascot.

I had hoped to get there yesterday but didn't make it in the end. Was the Siddeley KMP 700 or CXT 150, by any chance?

Rob

-

Thanks, I'll follow up the leads. I had a price to get one made but it was going to be a few hundred quid. The annoying thing is, when dad bought the car it was on it. but in the past 23 years it's gone missing and with him no longer being around to ask, it's been like looking for a needle in a haystack. I've found most of the missing bits and know from previous experience that as soon as I spent a few hundred replacing it, it'll turn up within a week. This has already happened a few times.

Rob

-

Hi,

Some of you may know I've been rebuilding a 1937 Armstrong Siddeley Siddeley Special car. It's back on the road now but I've not been able to find an inline double banjo union for the central chassis lubrication system. I think the threads are BSP P. I know it's not a boat but a few of you have good engineering contacts. Has anyone any idea where I might find one of these? I've been trawling autojumbles for the last four years with no success.

Rob

.

-

-

On 13/12/2019 at 20:18, Richard T said:

Time to do a tot up of who might be attending:

Richard and Mrs T

TRackman and Mrs Trackman

Jan and Dave

BSP and Tree Monkey

Chris and Lise

The Moomins

Alan and Kath F

Big Col

Ray T

Dr and Mrs Bob

Have I missed anyone? Theres not as many as last year. Matty and Kathy? John and Rene? Ally and Marc?

I'll go into the pub and enquire about food one evening next week.

I've just booked the hotel, so, unless something bad happens like last year, I'll be there.

Rob

-

1

1

-

-

As well as Apollo Duck, one of the best places to start looking at lots of boats is Whilton Marina. Their website has lots of boats to browse, so you've got an idea before you get there, once there you can get the keys to three boats at a time and they'll leave you to look around. That's a good way to get an idea of what's on offer and more importantly what aspects of a boat appeal, eg stern type, layout, round or square windows. Whether you buy from there or not is up to you.

-

OAT antifreeze is not compatible with yellow metals, so, if there's any brass or copper in the system, you should really stick to Glycol. That being said, before I knew it was bad, I used OAT and hadn't noticed any bad effects after three years, I did however change to glycol.

Euro Car Parts, GSF and any motor factors that sell to trade will stock antifreeze in 20 or 25 litre drums.

As for removing the old stuff, catch as much as possible, undo the bottom hose and drain into your bilge, then mop it up is one option. You should disable your bilge pump first though.

Buy a vacuum pump like a Pela 6000 and hope you can get the probe deep enough.

Depending on the age of your boat, the bleed valve might be an imperial size, scrape the surrounding paint off and try heat and a correct sized spanner, probably 5/8af, before resorting to stilsons.

-

1

1

-

-

Having a car in Central Birmingham is becoming a liability. Most of the 'free' parking has become residents only Monday - Saturday.

As far as I know Sherborne Wharf doesn't have any parking now, although it was expensive when I moored there, it included parking, so worked out cheaper in the long run. Now when I moor in Brum, I tend to park overnight by the Flapper and leave the car at my mom's at weekends and use the train.

If you can commute via public transport, there's Copt Heath Wharf, and Knowle Hall Wharf, both near Knowle, Nearest train station is Dorridge which would get you to Solihull and Birmingham.

-

22 minutes ago, tree monkey said:

I might have mentioned before quite how lovely she is but what makes her a special, what was added over the normal none special model?

Thanks, Alan. The Siddeley Special was a model made between about 1934 and 1938. I think they were supposed to show off the companies advanced engineering, or On the car there's no mention of Armstrong, all the badges being Siddeley Special, or S6, so maybe it was because JD Siddeley was retiring, he would have been about 65 when the model launched. Most of the bodywork is aluminium as is the engine block, head and con rods. It's got hydraulic valves, which I think was quite advanced for the time. It was basically the biggest, most expensive model in the line-up at the time costing about as much as a 4 bed house in London. The other models were all known by their RAC HP rating, eg 12HP, 14HP, 16HP and 17HP. The Siddeley Special 5.0 litre engine, was RAC rated at 30HP, which is roughly 110BHP.

About 253 were made but being made of aluminium, quite a few got donated and scrapped for the war effort. Worldwide there's about 22 extant about half of those are roadworthy.

My dad bought this one in 1997 and although he didn't make much progress with it before he died in 2015, he was always dreaming of the day he could drive it. I promised him I'd get it back on the road and have spent the last four years restoring it. At about 1:43 in this video you can see what it looked like six months into the restoration. Maurice Smith, RIP, helped with panel beating the wings and it's been a feature of the club's stand at Stoneleigh and NEC restoration shows for the last few years.

-

11 hours ago, roland elsdon said:

Dont follow my advice... just drove a tesla yesterday totally underwhelming. Now looking for a 1937 car to match boat. I think up grading is over rated.

I have almost the perfect thing to match your boat, a 1937 Armstrong Siddeley, Siddeley Special. Just returned to the road after being laid up since 1966ish. A heater and power steering would be a welcome upgrade though.

-

1

1

-

-

11 hours ago, Kelbs said:

Thanks for that Rob.

I finished work late today and am knackered so didn't give bleeding the unit a go, however I gave it a token start up while it was going through the start up and I could hear the water pump going I gave the hot water flow pipe a wiggle around, in between the Webasto and the bulkhead, trying to move anything along. There were several big clunks which happened. I'm not really sure how best to describe it but the pipe moved when the clunk happened and it sounded like something was having trouble passing through the pipe.

Is this possibly air inside the Webasto trying to get out/restricting the water flow? It felt as though it was on the flow pipe (hot water leaving the unit).

Beau

Hi,

Sorry no idea, could be but it's unlikely to affect the running at this stage. Assuming there's a decent amount of coolant in the system, I'd get it running first then worry about the water flow side.

-

If you're only getting a little bit of smoke and the unit isn't starting up, it's far more likely to be a lack of fuel than a lack of volts.

If you've got fuel but not enough volts there will be clouds of white smoke.

If the unit runs for about three minutes and stops it's usually because of a failure to ignite caused by one of the above.

If it fires up but cuts out after about 10-15 minutes it's overheating because the coolant isn't circulating.

Have an empty jar or receptacle handy before this bit.

Check you've got fuel by disconnecting the fuel pipe from the fuel pump inlet and suck on it. If you get a decent mouthful of diesel, there's no air leaks on the supply side.

Once you get that far, reattach the fuel pump inlet pipe disconnect the fuel inlet at the webasto and start the webasto while sucking on the pipe from pump to webasto.

It should spit fuel with each click of the pump, again of you get a decent spit of fuel, there's no air leak on the fuel supply so reattach it to the Webasto.

Now with the pipes firmly reattached, restart the webasto. On my Eberspacher it takes about 4 attempts from this stage to get enough fuel up to fire. You should find the fuel vapour clouds increase each attempt until it eventually runs.

If you get to this stage and it still doesn't run, there's an electrical issue or, because of previous attempts, the unit might have locked out and need resetting (you'll get an error on the display in that case). On my Eberspacher, this is done on the controller, I don't know about Webasto.

I hope this helps.

Rob

-

When single handing in narrow locks I tend to let my 40' boat float, untied, while I set the next lock in the flight but I do keep an eye on what's happening. To date most of the problems I've had with locks have been with crew involved.

How does a pump out work?

in Boat Building & Maintenance

Posted

Thanks everyone.

Mind back at ease now. I do have a wet and dry vac but not one I want to chuck, however, there does seem to be quite a few on ebay to choose from, around the price of a pump out, so that could well be a viable alternative.

Rob