-

Posts

496 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by OptedOut

-

-

Probably the best option if the costs are mounting. Best of luck.

-

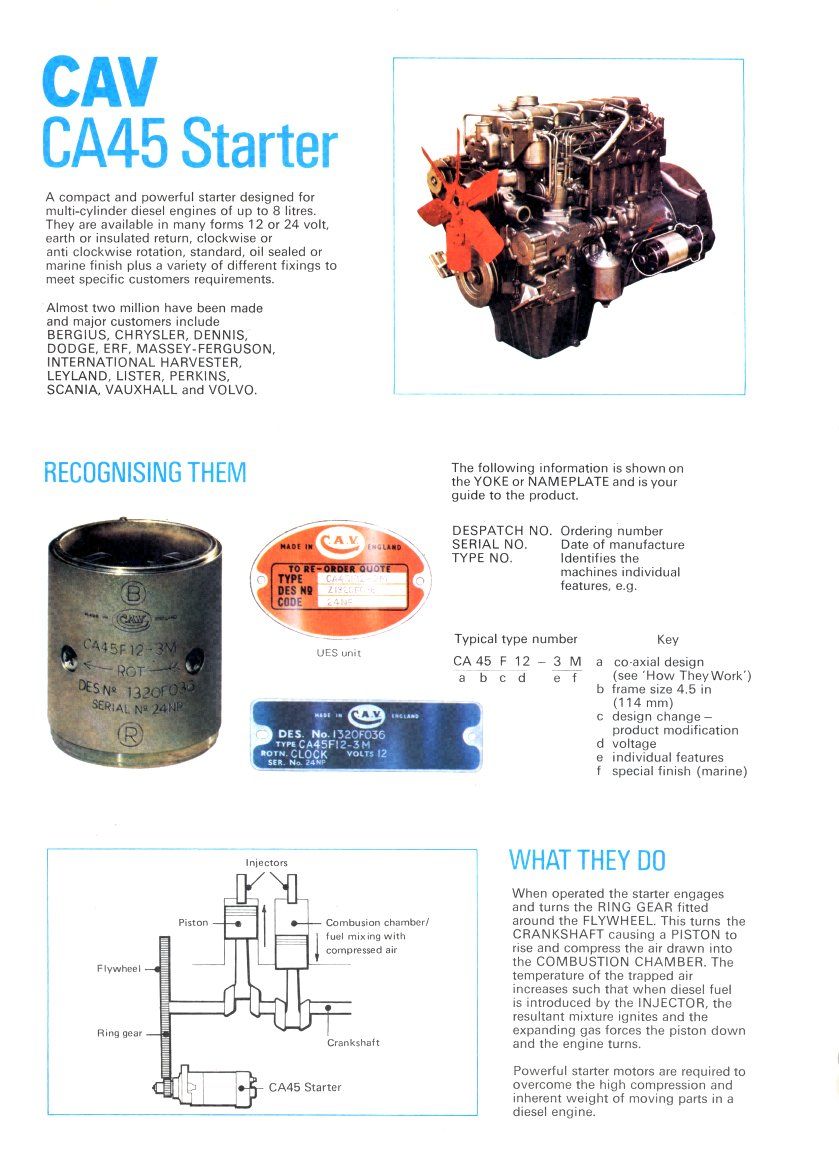

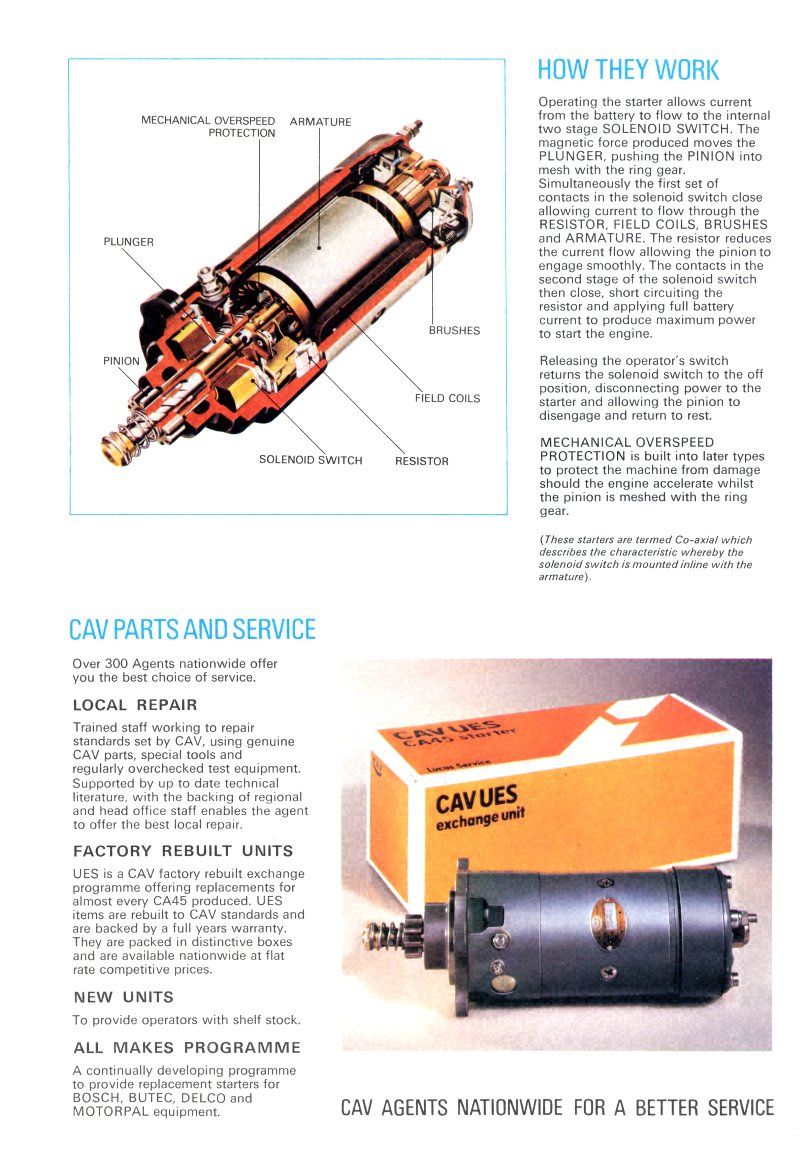

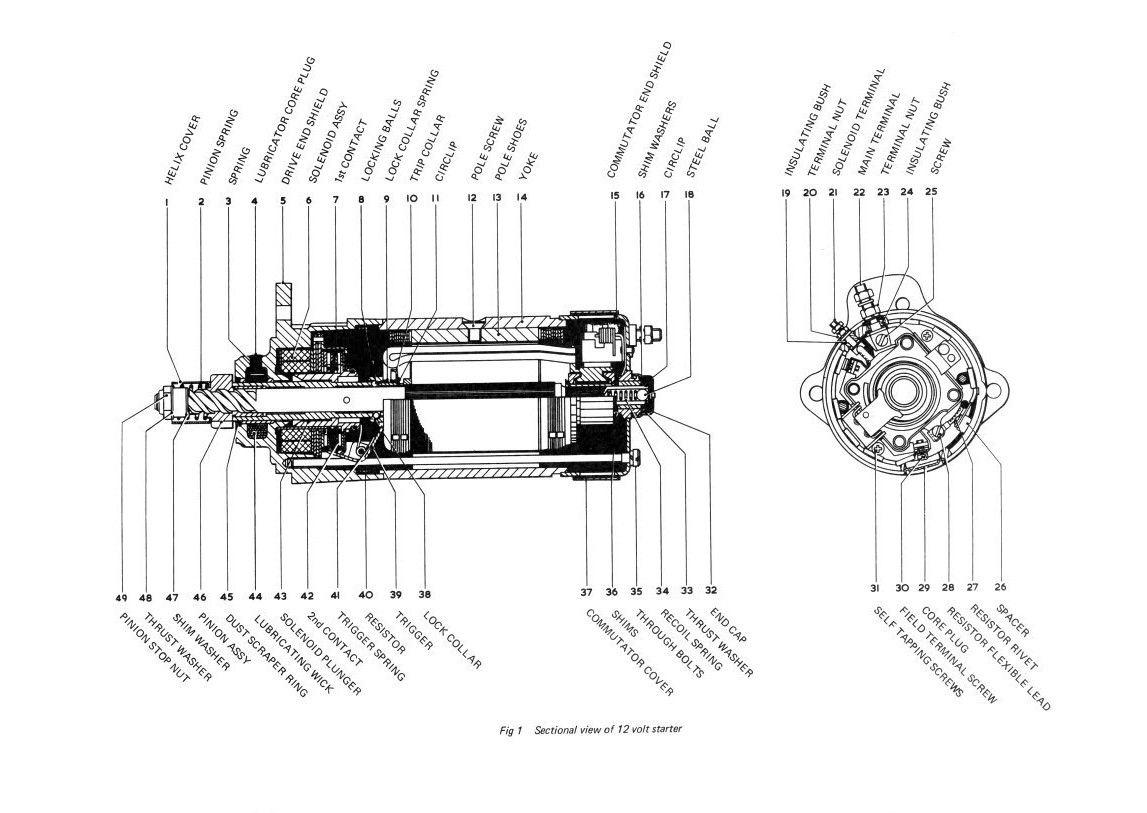

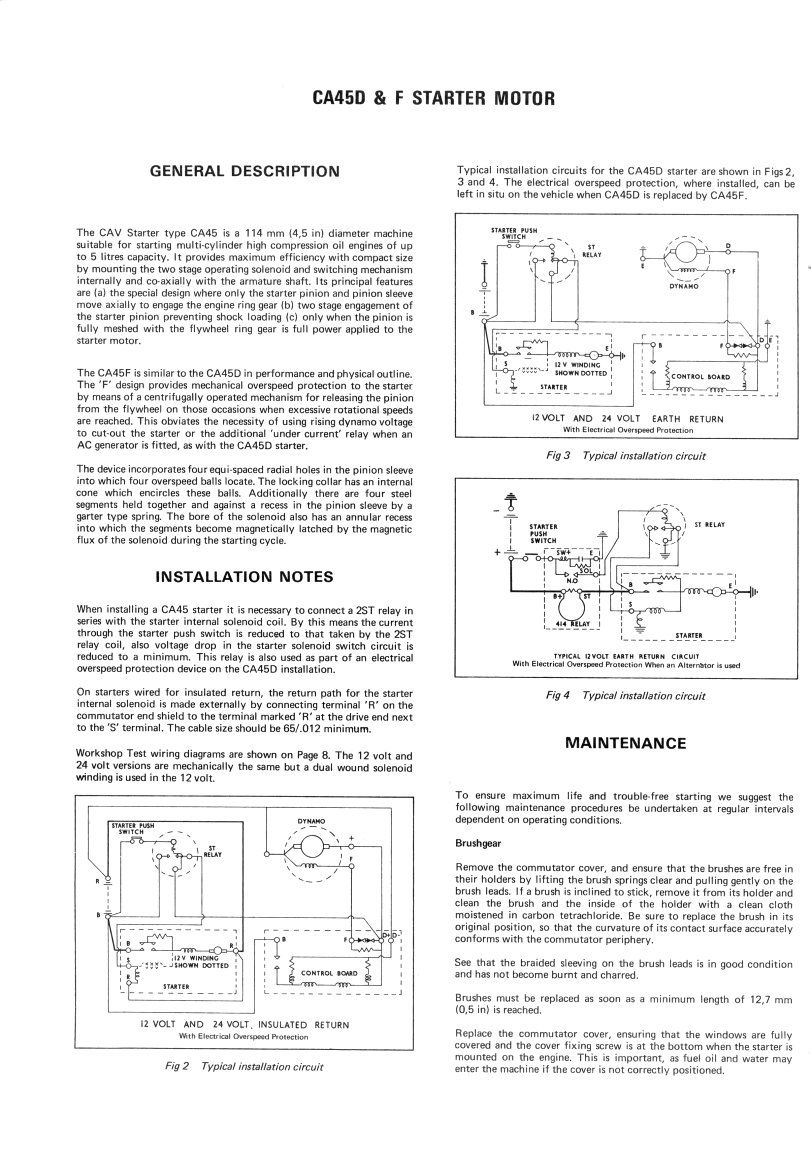

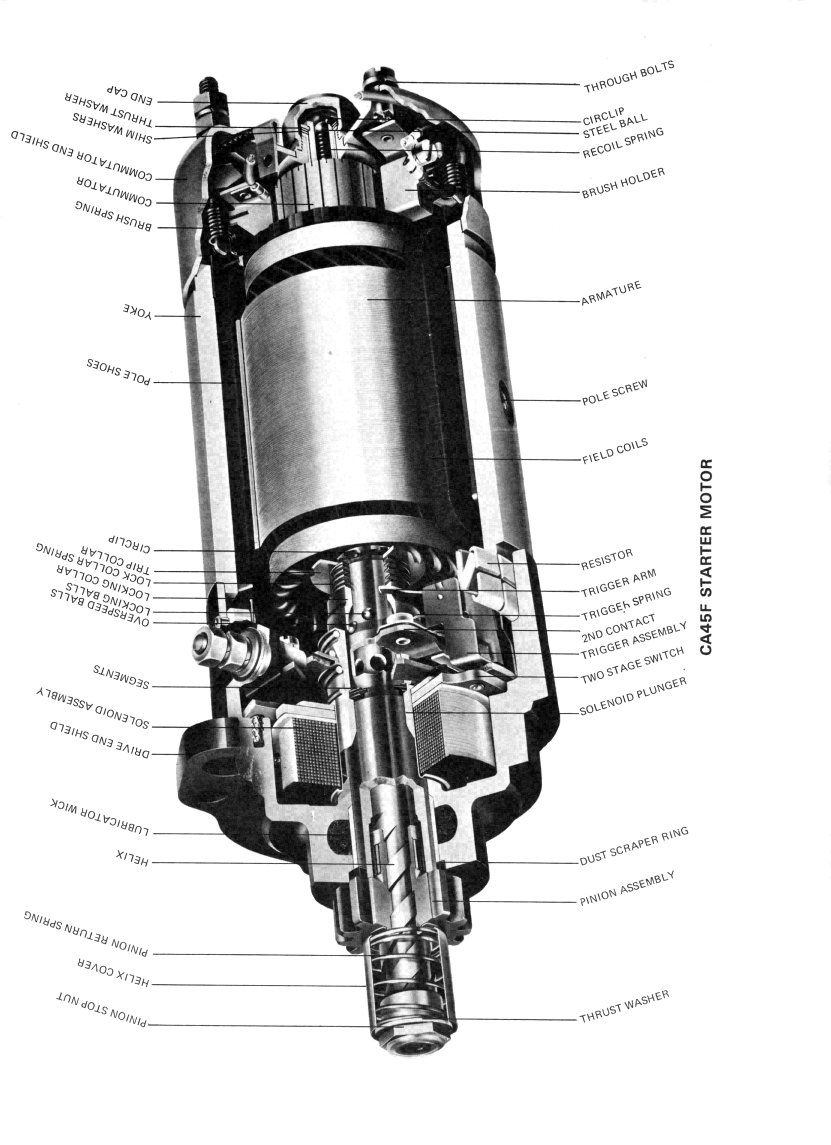

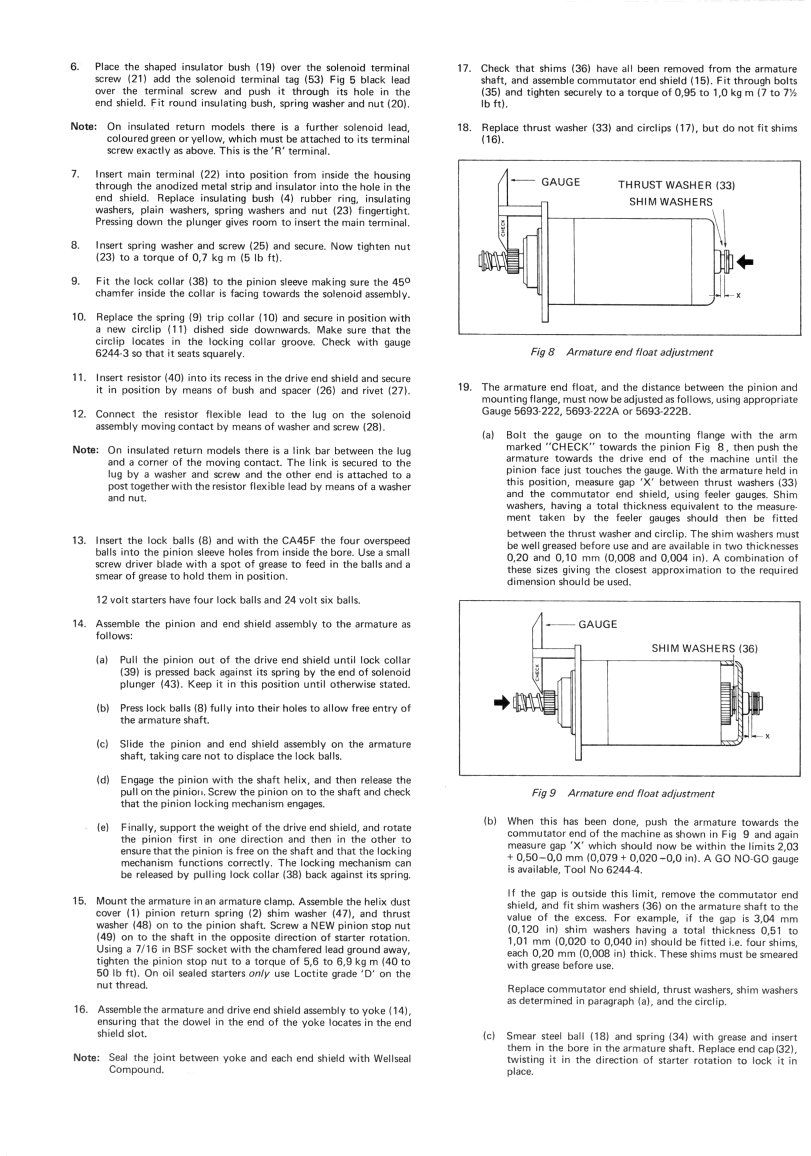

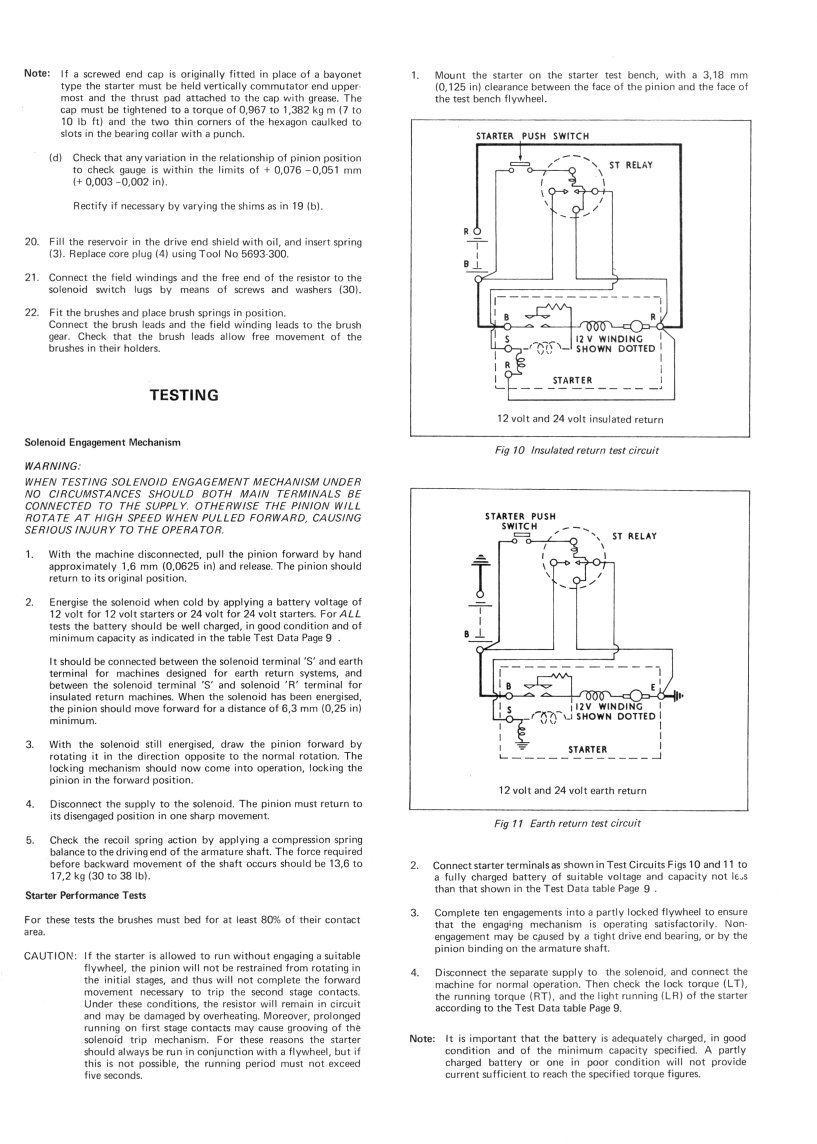

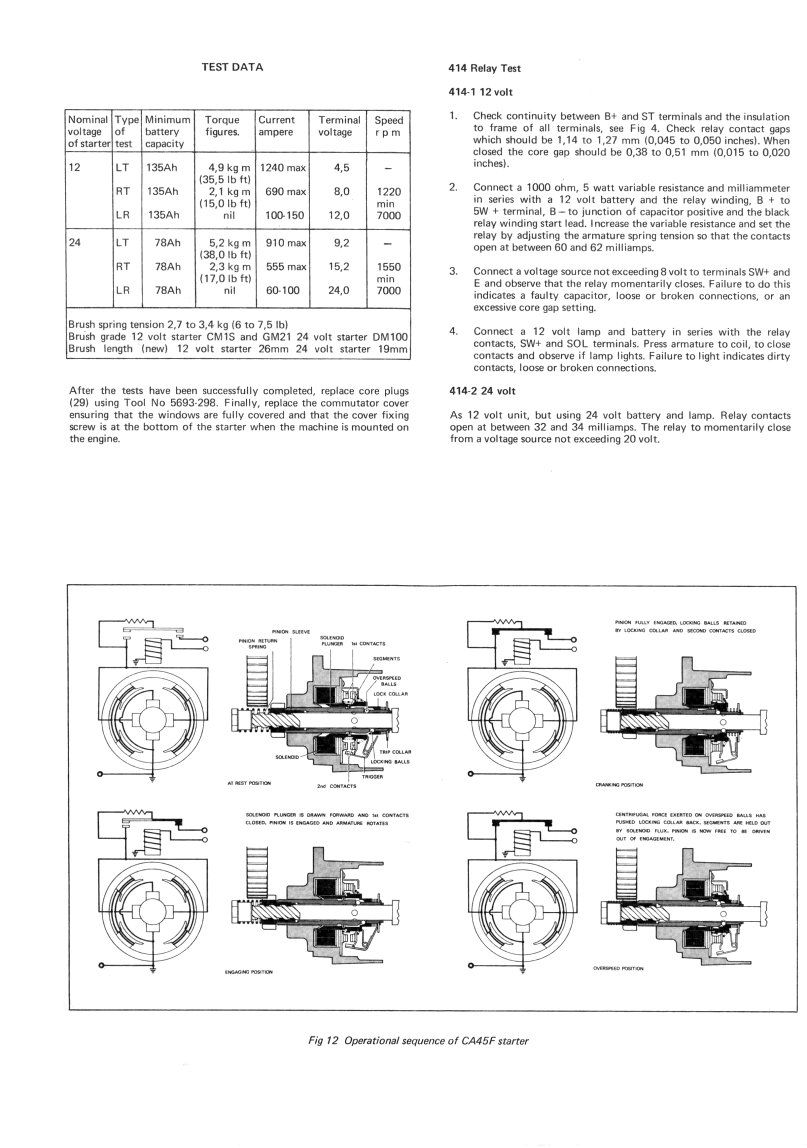

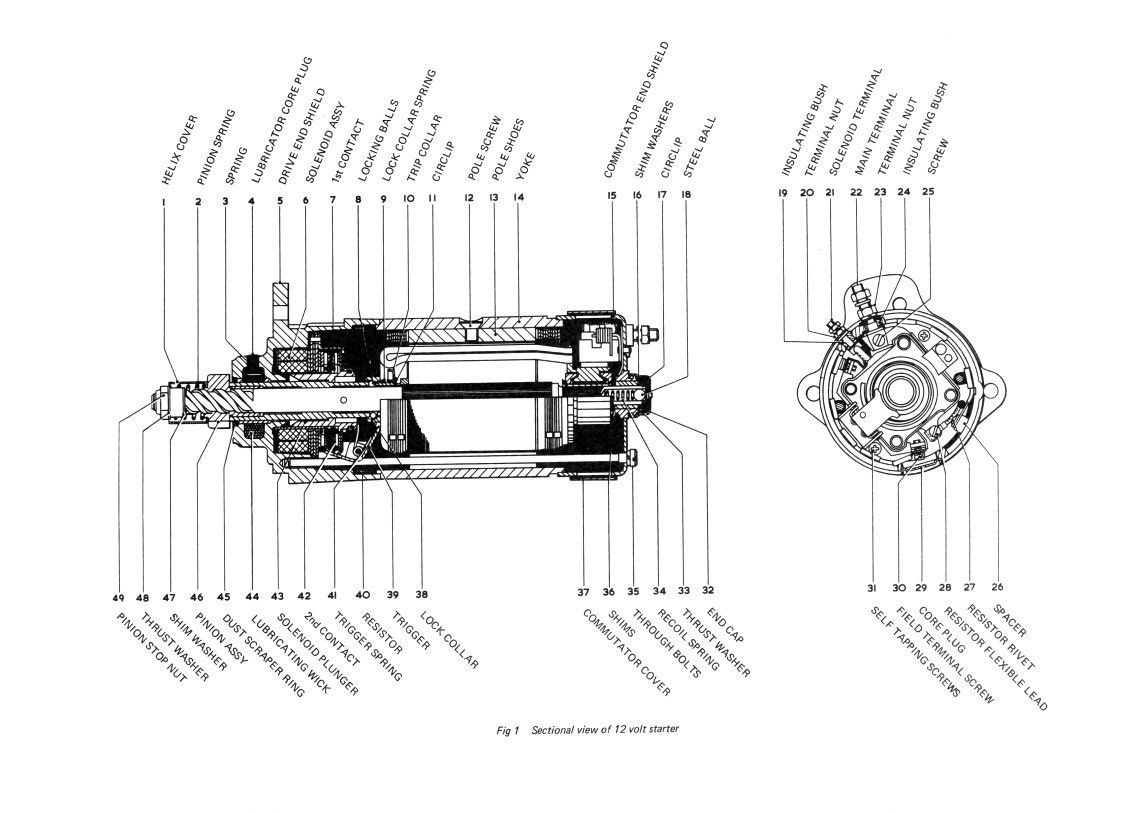

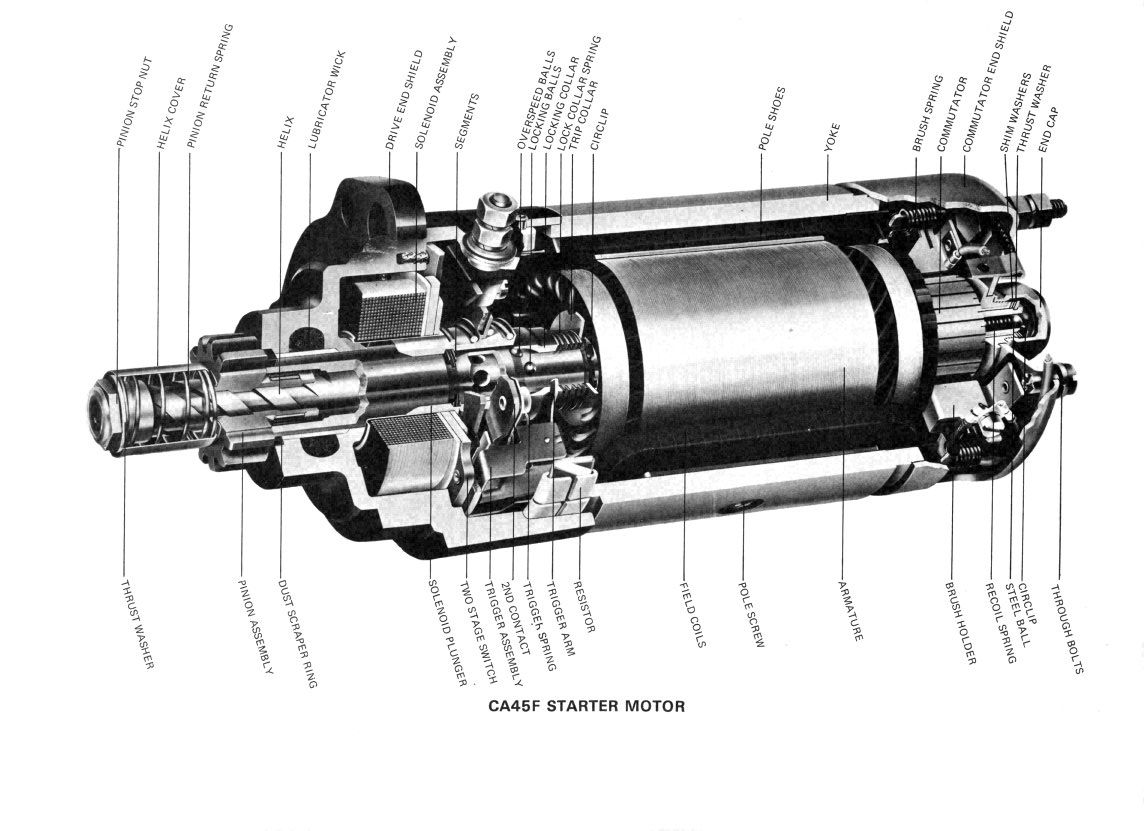

I suspect everything may be working OK but the pinion is not engaging with the flywheel properly. The assembly in the image is an overrun device to throw the gear out of engagement should the operator continue to hold the start button in after starting or trying to operating the starter whilst the engine is running.

This seems to indicate a lack of engagement due to , (a) damaged pinion teeth, (b) Starter too close to ring gear due to worn engine register hole.

If you slacken the starter mounting bolts slightly can the motor be pushed or pulled a little towards or away from engine gear ring?

-

"touches against the ring gear but does not engage fully and then just free runs at speed, clanging against the edge of the ring gear."

Is it possible the second stage of the solenoid is operating too early?

-

Sounds like something is stopping the pinion from running up the helical rod.

-

-

I would suspect the cam which gives the longest valve opening time will operate the inlet valves.

-

"as you lose the cushioning effect at tdc."

The cushioning effect is not present during the TDC at the exhaust/suction stroke with a 4 stroke engine.

-

21 hours ago, roland elsdon said:

Retrospective reading of the lister running in guide suggests basically starting up the new engine, making sure it’s ok then working it hard for the rest of its days.

IIRC, Lister generators had a life expectancy of 45,000 hours between major rebuilds in the 1960-70s

-

"But if I can't find a press, I could look out some scaffolding tube and a heavy hammer."

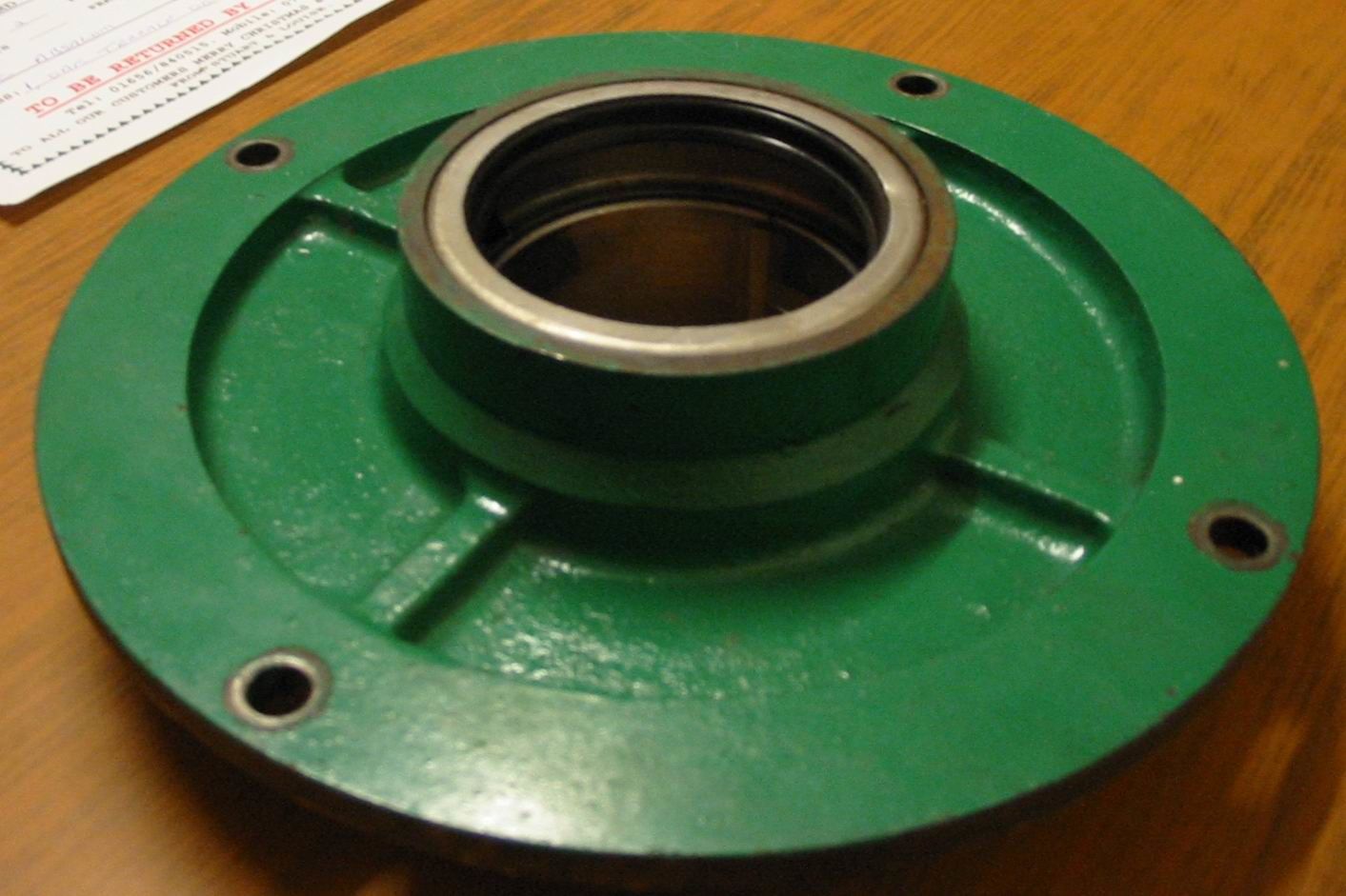

Whatever method you use make sure force is only applied to the appropriate race of the bearings, inner race when fitting to shaft, outer race when fitting to housing. i.e. try not to channel any force through balls or rollers.

-

" My question is : do they all need to be that tight a fit?" Yes they do.

You could refit the bearings and gear with a suitable hammer and some tubular drifts plus something flat and solid to stand the shaft on.

-

1

1

-

-

-

Do you have an image of the gearbox you can post to confirm the presence or lack of a reduction box?

Hope this info helps.

http://listerparts.co.uk/LM100.html

-

Do you have an image of the engine and alternator?

-

55 minutes ago, Steve56 said:

If it was a start-o-matic I don't think it would have had electronic governing or any of the air ducting fitted. More likely a marine gen set.

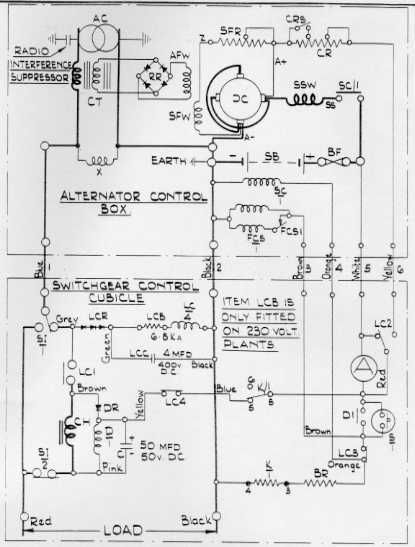

There were no electronic governors on 'Startomatic' sets, more like early relay logic to sequence start up/shut down events.

All HA generators are designed to operate indoors or in a protective enclosure and require the air ductwork to prevent recirculation of the cooling air.

-

12 hours ago, billybobbooth said:

If you mean mine it was part of a gen set well still is but i think I was or has been installed either in a boat / ship or a confined space as mine has the cooling scoop on the side for the hot air to be vented and also has a shield around the flywheel with a space between the engine and gen for air but also all the electrics are air cooled too and all have air outlet scoops of some sort. Its all a bit odd as everything is electronically controlled even the decomposition is

All easy read info is 10kva

Cycles 50

Single phase

240v

Slipring brushes 4

Do bushes 4

It sounds like you have a 'Startomatic' house set and associated control gear?

-

2 hours ago, billybobbooth said:

How did you get on with air flow threw the flywheel? Looks a big but nice setup.

My other option is to put a shaft threw to the box with a cover over it

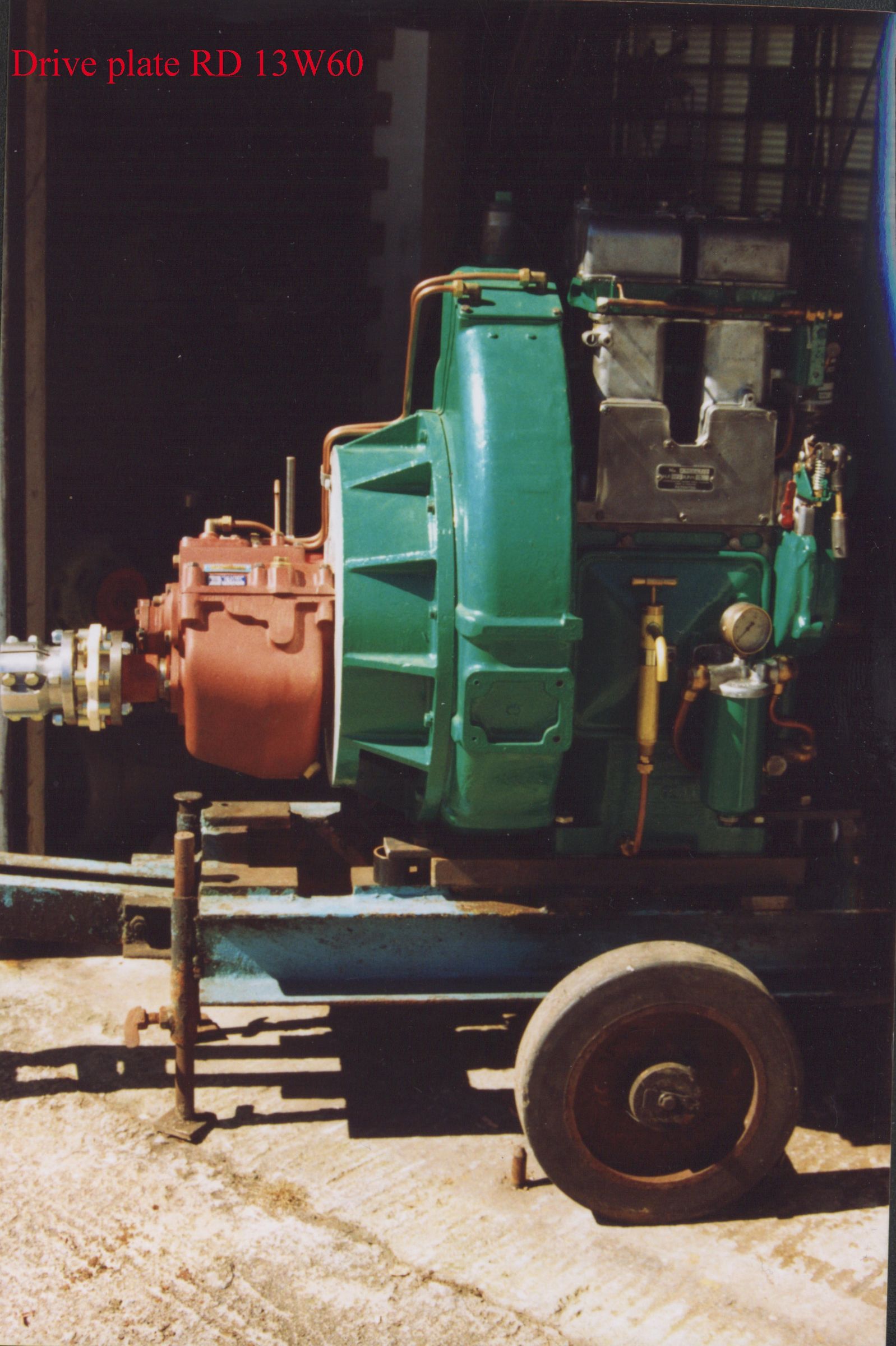

At least 1/3 of the bell housing forms the air inlet as per the image. There is a cast iron spool piece bolted to the flywheel register face with an enlarged portion which the gearbox drive plate bolts to and also provides the correct alternator drive ratio, (high charge at low reves).

-

2

2

-

-

-

It should 'wind off'.

-

Recommend some sealant on the shaft should there be any 'slack running' wear present.

-

Forgetting the high torque switch (and possible faults) for a while, is it possibly a case that the slow pre-engage torque is too low to rotate the pinion 1/2 a tooth into engagement?

-

-

Looking at some SR2 starter motors the bolt holes appear to be outside the flywheel starter ring? The SR2 manual also mentions 7/16 unified threads are used on this engine.

Our much larger HA2 has blind holes hence the shimming washers.

-

Thanks. That looks like the site, seems to have changed a bit since I was there last.

I will sign up and see if the mapping is as convenient as it was.

-

Not sure if this is the correct place to post. A while ago I had a link to a site with canal plans, cruising times and descriptions etc, lost the link in a drive failure.

Does anyone know if this site is still about?

Leaking 1.5 bmc fuel filter

in BMC

Posted

During our time in a private boat share we never changed any seals, same when we owned a Land Rover. Must have been lucky!