Redwing228

Member-

Posts

8 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Tenby

-

Occupation

Electrical Engineer

-

Boat Name

Ceidwad

-

Boat Location

Pembrokeshire

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Redwing228's Achievements

Gongoozler (1/12)

0

Reputation

-

Yes, thanks. It is more of an experiment, the way I’ve tried it. The original seal had a ferrous spring and I must admit to not buying spares from the pump’s supplier, but from an industrial bearing retailer so do not know if a seal with stainless or other non-ferrous spring was available. Bill

-

Jabsco pumps, don’t you love them? 🤔 I had a Jabsco on a Beta engine that was leaking seawater from the body drain. When I stripped it down to renew the seal I found that it had been installed with the open side (with spring) facing the pump chamber. The spring had rusted away weakening the seal. I’ve installed the new seal the other way around and the leak has been solved for now. Pumping the raw cooling water means there is not much back-pressure on this pump delivery. Also, the cover on this pump has been replaced with one of those quick-change types and has a tiny ‘O’ ring in a machined groove to provide the cover seal. Bill

-

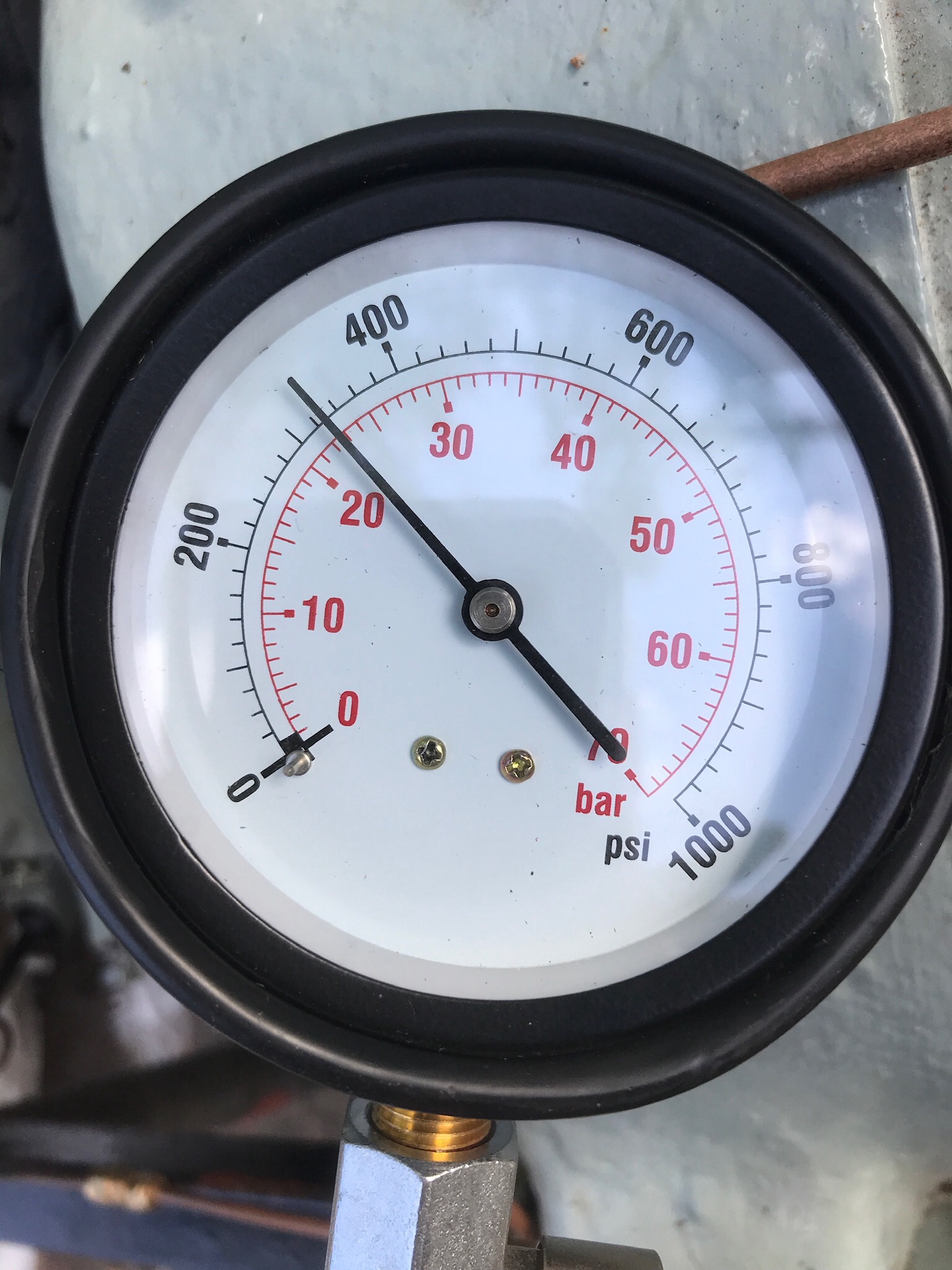

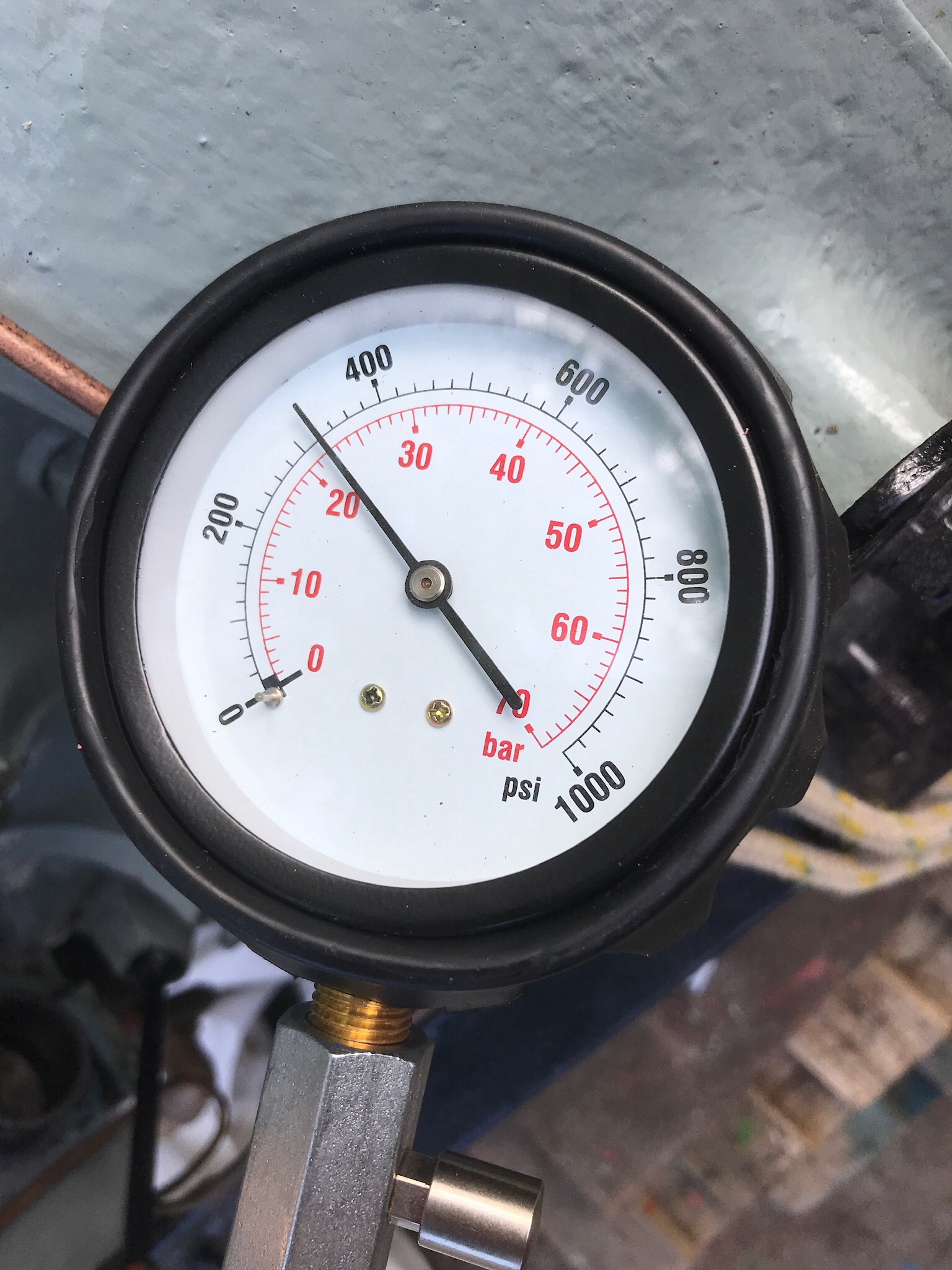

I’ve been busy making a control panel/dashboard for the Dorman as well as doing work on the boat. I’d been experimenting with the glow plugs after finding that I’d burnt out my originals by leaving them energised for too long; replaced with a new pair of Bosch plugs it started better but I wasn’t happy with the way it was idling as it seems to ‘fade away’ and just run on one cylinder. So I took the injectors out and turned them round to look at the spray patterns which looked like spurts rather than fine spray. The injectors have just come back from being serviced and having new nozzles fitted and I was talked into having the pump cleaned tested and calibrated. My spare injectors went in too, as it was pointed out that I had one CAV and one Bryce injector in each set, albeit with the same nozzles. The work was done by Minster Diesel Services in Haverfordwest. The pump plungers were OK but nozzle parts showed signs of water in fuel. It was suggested that I should also check the compression pressure and this I have been able to do now the injectors are refitted. With the engine cold it is achieving about 320 lbs per square inch in both cylinders. Given that the 2DSM is indirect injection and has a compression ratio of 17.5 to 1, is this acceptable? I’ve been told that 250 would be a minimum figure and a sign of excessive wear. This test was conducted ‘dry’; if one cylinder was a lot lower than the other I was intending to drop some oil in the bore to check for leaking valves/rings. Thanks, Bill

-

^^^ Thank you BEngo and billh for the suggestions, and Dave Mack for the positive comment. I will see if I can make contact with BRNC Sandquay, they still operate a fleet of GRP Motor Whalers but I don’t think they truly qualify as 3-in-1 these days. They have been fitted with Yanmar engines too... There used to be a similar maintenance setup at Jupiter Point on the Lynher in Cornwall with fleets of Cutters, Whalers, dinghies and even yachts for training. All gone now in favour of the ubiquitous RIB. Working on my old relic again; I’ve been drawing out the instrument layout on my new ‘dashboard’ and started cutting holes for the tachometer, temperature gauge and push buttons this evening. Bill

-

Hi and thanks N for this GA. My Cutter had long lost its cuddy and portable cabin top by the time she was ‘rescued’. Previous owners had built a crude cabin cruiser conversion on top of the original covering board and now this has been stripped away the signs of where the cuddy fitted can be seen but all the mounting hardware for the cabin top has been torn off and only the remains of the fastenings show where they once were. I have no service history although there has been some research done - and is ongoing - by a knowledgeable acquaintance. She’s odd in that she was built for or at Bombay Dockyard in 1944 and carries a boat number of a series that is different to boats ordered and supplied in the UK. We think she was issued to an HM ship being repaired at Bombay towards the end of the war, possibly HMS Protector. The boat is planked in teak and was built to a very high standard. It is this to this quality of materials and construction that she owes her survival since before she was saved she’d suffered years of neglect. Motor Cutters were rather lightly built and most were worked to death as fishing boat conversions after disposal by the MoD. I would like to be able to track down other survivors- if there are any! I know of one restored example at Chatham attached to HMS Cavalier. Here is my blog where the restoration of this and other boats are written up.. http://smallclinkerboat.blogspot.com I hope nobody minds me talking about a sea boat on a forum dedicated to inland narrow boats? It is great to have comments about the elderly machinery from the great pool of knowledge here. Many thanks Bill

-

Thanks N. I have sourced some push buttons for heaters and starter of a similar style to the originals having failed to find a match for the part numbers. Despite hunting for over a year I’ve failed to find a CAV D45 dynamo of the correct type so am installing a Lucas C45 enclosed model with a separate cut-out and regulator that I’ll fit to the back of the dashboard. If I eventually find the ‘correct’ dynamo in the future i’ll change it out. I do have another engine of the same type but partially dismantled and may build it up and get it running too. I’ve got lengths of 6mm brass rod to make throttle control link and oil filter indexing rod - the filter has its ratchet and lever in place. Thank you for the note about the prop. The boat came with a 16 x 10 LH that was to suit the Ford 4D engine who’s rusty remains were in her when saved from destruction. I’ll give this prop a try first. In my last post I was going to mention that an Ether injection appeared to be an option. Regards, Bill

-

Thank you everyone for the helpful comments and also BEngo for the scans from the manual. I have some photocopies of a manual and parts list but they are not as clear as these, so many thanks! The GA of the 25ft Motor Cutter installation would be very useful too, please, as It is a 25ft Cutter that I’m restoring- it’s one of the last ones left and being built in 1944 had a 2DSM fitted when originally built. The post-war Cutters had the air cooled Enfield HO2 - I’ve got one of these engines as well, but it’s the version from the 3-in-1 Whaler as it hasn’t got a reduction gear. My Dorman engine is missing its dynamo and a ‘V’ pulley had been fitted but there was no sign of any mounting for a generator or alternator. I’m restoring it to a dynamo as the low output is not a problem in the boat the engine is going into - loads are quite small, starting battery charging and just a few nav lights. The engine is totally enclosed - this dynamo drive shaft is the only external rotating part aside from the propellor shaft output flange! The original glow plugs had long burnt away and I have made some threaded adaptors to take metric glow plugs from a Land Rover engine, connected in parallel they operate directly from 12V and do not need the series resistors of the originals. Ether What I would like to find out though is the text on the nameplates and legend plates that were fixed adjacent to the controls. Many thanks again, Bill

-

Hi, I’m new to the forum but have been a boater for many years. I’m currently restoring a Dorman-Ricardo 2DSM for installation in an ex. Admiralty 25ft Motor Cutter, a boat for which the makers originally supplied the engine. I obtained a pair of these engines together but it has been many years since they were removed from the boats they powered and a lot of parts have been lost including the ‘dashboard’/instrument panels, and it is this that I’m currently working on. The question I’d like to ask is there anyone on this forum who owns or knows of an engine of this type that is complete with its original panel that I can have a reference picture of? In particular I’d like to see any name or instruction plates the makers fitted to this panel? Many thanks, Bill