-

Posts

332 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Steve56

-

-

It will be because the engine was built as an insulated earth system. This system allows for the battery negative to connect during starting, and removes once engine is running.

-

Give Lancing Marine a call. They are still in business and usually very helpful, especially as it appears to be one of there marinisations.

-

3 minutes ago, Mike Tee said:

Now that’s a cunning way to have a demountable moveable table, I like it, good idea.

Means I can have it out on the back deck when I want to sit outside.

-

-

6 hours ago, jonathanA said:

The standard sender is 1/8 npt which looks like it is still in place above the current one in the OPs pic.

Yes that's right. The unused one is 1/8. For the supply to the calorifier the larger 3/8 outlet was the one used by Lister when calorifier fittings were added.

-

For the flow to the calorifier you would remove the temperature switch/sender which can be seen in the first photo. Put a t price in its place. You can then put the switch/sender back into one side of the t peice, and the spare outlet becomes the flow to calorifier. The return from calorifier would then be teed into the suction side of pump. Probably best to go into the smaller pipe which runs below the manifold. If I remember correctly the temperature switch/sender unit is 3/8 BSP.

-

-

6 hours ago, Arthur Marshall said:

I've always been on farm moorings, and always paid a mooring fee to CRT (well, since they invented it about 25 years ago). The justification is that your licence lets you cruise, but the mooring fee lets you park up on their water for longer than the 14 days concession. Farm moorings get charged at what CRT consider half the going equivalent CRT mooring rate, which in my case is twice what I pay the farmer, much to my disgruntlement. I think they just make up a figure, to be honest.

Marinas just include this in what they charge you and make a bulk payment to CRT.

The licence fee just allows you to have your boat on the water. There is no guarantee or any right to cruise. If there are any problems or closures, then hard luck. CRT cannot be held responsible and there is no possibility of any refunds. Where as a CRT mooring just let's you have your boat on the water. But without being chased by CRT.

-

6 hours ago, StuartAdair said:

All,

A further update for you. We ran the boat this weekend and once again the water failed to heat. The guy who moors next to me is a plumber so took at look. With the engine stopped and the calorifier flow/return pipes disconnected we discovered that if the expansion tank cap was loosened then water would flow but then stop when the cap was replaced, so the initial suspicion was a cap causing some sort of airlock in the engine. However when we ran the engine again cap on and off there was very little water flow from the engine outlet, indeed you could stop it with your finger. After a bit of research I discovered that a water pump should put out about 40psi, and I think I've got about 4 psi on a good day. There's enough to stop the engine overheating but not enough pressure to flow through the calorifier which makes sense to me.

New water pump is on order so lets see if that does the trick.

Stu

That is what you would expect. When the cap is on it creates a vacuum so the water will not run out easily. When the cap is removed it allows air into the system so the water will flow out. As the pump is not a positive displacement pump it will not pump at any great pressure.I don't know where the figure of 40 psi comes from but the pump certainly will not give those sort of pressures.

-

Just a few comments that may or may not help. The engine is not a Canal Star it is heat exchanger model which is why it may look a little different. The T-piece is not a swept T but just a standard T. Oneside is the calorifier feed the other is the temperature sender. The thermostat shown in an earlier post is the one that should be fitted to the later engines as the one in the photo. It is important as it shuts the pump bypass off as the engine warms up.

-

21 hours ago, David Mack said:

Not sure that is the case for the TS engines. I think the shaft in the engine just has a pin through it, and the appropriately handed starter dog is on the handle.

That is correct. The handle shown is the correct one for the engine. As it operates on the camshaft, turning the handle anti clockwise will also turn the engine anti clockwise. When Lister give an engine rotation it is always as looking at flywheel from behind. Also the engine must be anticlockwise as To my knowledge the T range were never built as a clockwise rotation.

-

Maybe coming across from Cardiff. A few people do it.

-

11 minutes ago, cuthound said:

IIRC didn't Beta modify the Ford and John Deere engines to achieve a lower than standard tickover?

What is the rev range for the original Ford engine?

Beta certainly did a mod on the Ford engine. They altered the injector pressures to achieve a lower idle speed. I think the John Deere engine was left as standard. Not sure of the original idle speed of the Ford engine but would expect it to be around 800 rpm.

-

1

1

-

-

They were never the smoothest of engines. I've had experience of both the Lister and Beta versions. Both companies tried various things to try to improve the situation but never that successfully. Normally the best way of mounting was solidly on timber. Mount the engine to the timber, then the timber to the boat but do not use the same bolts. This was about the best way for a steel boat. Can't really comment on other materials. As you say I think the FSD is a much smoother engine.

-

5 hours ago, Timx said:

Thanks temp seemed ok although dodgy meter, so a temp alarm within the control.? Can’t understand if coolant levels are ok. Don’t know what to do.

From memory I think that this engine has a temperature switch which operates the warning light and alarm. Then a separate sender for the guage. Both are by the thermostat housing. When the alarm goes off you could try pulling the wire off the switch to see if it stops. If it does you then have to decide if the engine is really overheating or if there is a fault with the switch or wiring.

-

1

1

-

-

On 29/06/2022 at 23:35, commervan said:

Hi please can anyone help. We have a paguro 4000 cocoond built in generator in our narrowboat which has developed another water leak this I have traced to the exhaust manifold area which has a water jacket rapped around the manifold down pipe.

This again has cracked on one of the joints and leaking antifreeze.

I keep getting it soldered up but the vibrations set it off again. I was wondering what purpose it serves and could I bypass it. Water comes in at the top and excites and the bottom so maybe I could just use a pipe to join them together.

The water comes from a skin tank which it shares with the main boat engine so is cooled that way.

It was mentioned it could be an out let to heat water for the boat.

Please has anyone got any ideas.

Michael.

The reason for the water jacket is probably to stop the engine overheating. As you say it is a cocooned set so you need to get that heat away. Without the water jacket that exhaust will give off a lot of heat. If you decide to bypass this water jacket then at a minimum you could lag the exhaust with a good few layers of lagging to try and keep the heat level down.

-

3 hours ago, David Mack said:

Is Brenmarl no longer producing them?

As far as I'm aware they finished doing anything some time ago.

-

3 hours ago, Quattrodave said:

Thank you, I've had a look and yes there does seem to be a bit of a trend! This one has a temp guage the reads accurately, holding about 65 degrees all day long....

Yes, I've seen this before. Had the waterpump refurbished with new impeller, seals and bearings!

Ooooh interesting! Where did you source the parts from? Is there anyway of telling if I got a modified head gasket or not? Ah, so they ARE stretch bolts, I did suspect they were...!

At the time I was working as a self employed marine engineer and covering warranty work for Isuzu Marine as well as a few other major engine companies. Isuzu Marine have now become Engines Plus. Therefore all parts would have been supplied by them, and all genuine Isuzu parts. I don't really know what the parts availability is, but if stuck you could call Engines Plus and they may be able to advise.

-

On 19/06/2022 at 22:44, Mike Adams said:

There are various threads on here about the Isuzu 55 engine and head gaskets blowing. It seems to only occur on engines that have skin tank cooling and not on those fitted with a marine mannicooler/heat exchanger. I suspect that your underlying problem is down to overheating of the engine. These engines are not normally fitted with a temperature gauge so your running temperature could be too high without the alarm going off. As you said there is poor circulation to the calorifier I would suspect overheating to be the cause due to poor or restricted circulation.. Possibly check the water circulation pump first as you are taking the head off anyway. It could be a build up of scale/rust in the engine and skin tank on its own or in combination with a blockage of the water passages in the block or head. Skin tanks performance degrades over time with internal corrosion and build up on the external surfaces. Wash out the skin tank and engine and add corrosion inhibitor/antifreeze when you refill.

air collecting in the head depending on the cooling arrangement could also be causing the issue.

You are quite correct. The early Isuzu 55's did have an issue with head gaskets blowing. This was only an issue on the 55's and did not affect any of the other models. At the time the fix was to repair using a modified head gasket as supplied by Isuzu. I have done a number of these in the past and once fitted with a modified gasket there were no further problems. It was also recommended by Isuzu to replace the stretch head bolts at the same time.

-

3 minutes ago, reg said:

Many decades behind me and still learning new things.

Never knew that.

I've spent my whole life as a marine engineer. I certainly wouldn't claim to know it all. You can always learn something new, or a different way to go about things. If someone claims to know it all there probably best avoided.

-

2

2

-

-

14 hours ago, Norm55 said:

My new boat has a canaline 38 engine. In conversation with another owner i noticed the exhaust runs level, then down to exhaust manifold. Without a rise in pipe from the point it exits the hull, is there not a possibility water could run in and straight down into exhaust manifold, causing engine to hydraulic and seize ? Surely it should have an intial rise to allow water to drain back out ?

Any thoughts please ?

Should definitely slope uphill or have a Swan neck. Over the years I have had a number of boats with wrecked engines due to water down the exhaust. Just poor workmanship by the builder/engine installer.

-

6 hours ago, ditchcrawler said:

Could even be metric

Definitely imperial as indicated with the shoulder at the top. Metric fittings have the shoulder at the bottom. On odd occasions some of the manufacturers nowadays don't seem to bother with this. The pipe in the photo is probably 5/16. Don't mix and match metric and imperial fittings, it's just a bodge and is asking for problems further down the line. I would say the problem you have is that the pipe coming from the tank has a tapered thread and your fitting has a parallel thread. Obviously been forced on and caused the split. As someone else has already mentioned you should really have a ball valve fitted in the return line.

-

-

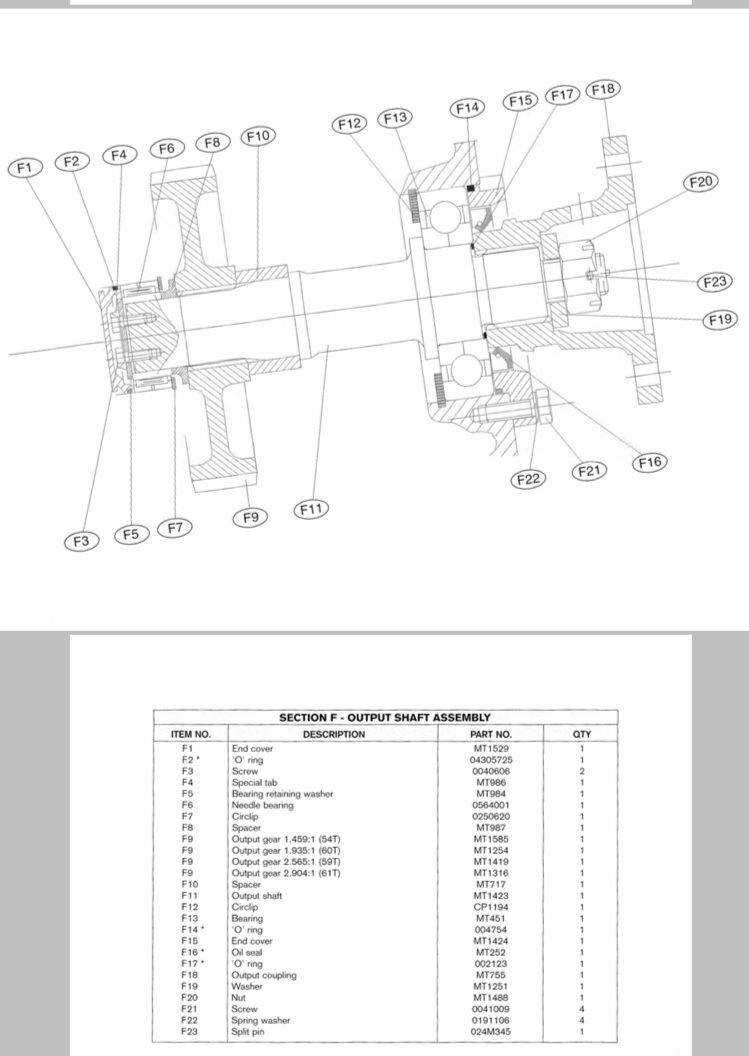

It sounds as if the oil is leaking along the output shaft and through the inside of the output coupling. Therefore not the output oil seal leaking. If I remember correcty when the output coupling is removed there is an o-ring on the shaft which stops the oil. Also when fitting the coupling it pays to put a little flange sealant on the flat washer that fits below the retaining nut. It may also pay to check that this coupling nut has not worked loose. I have come across this a number of times. It doesn't take much for an oil leak to start. If you take this apart it will pay to fit a replacement lock nut and ensure the correct torque setting.

PRM 500 gearbox

in Boat Building & Maintenance

Posted

Many years ago I had a similar issue on a Gardner engine. There was always a very noticeable clunk as it went into gear. To rectify I fitted the engine with a Centa Transmissions R type drive plate. This worked wonders and really smoothed out and quietened down the gear selection. I have used this plate on numerous engine installations with great success. I think the reason that the engine manufacturers don't use it as standard is as always down to costs.