-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Spoonman

-

Ignition system wiring for a127 / Lister sr2

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

-

Ignition system wiring for a127 / Lister sr2

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

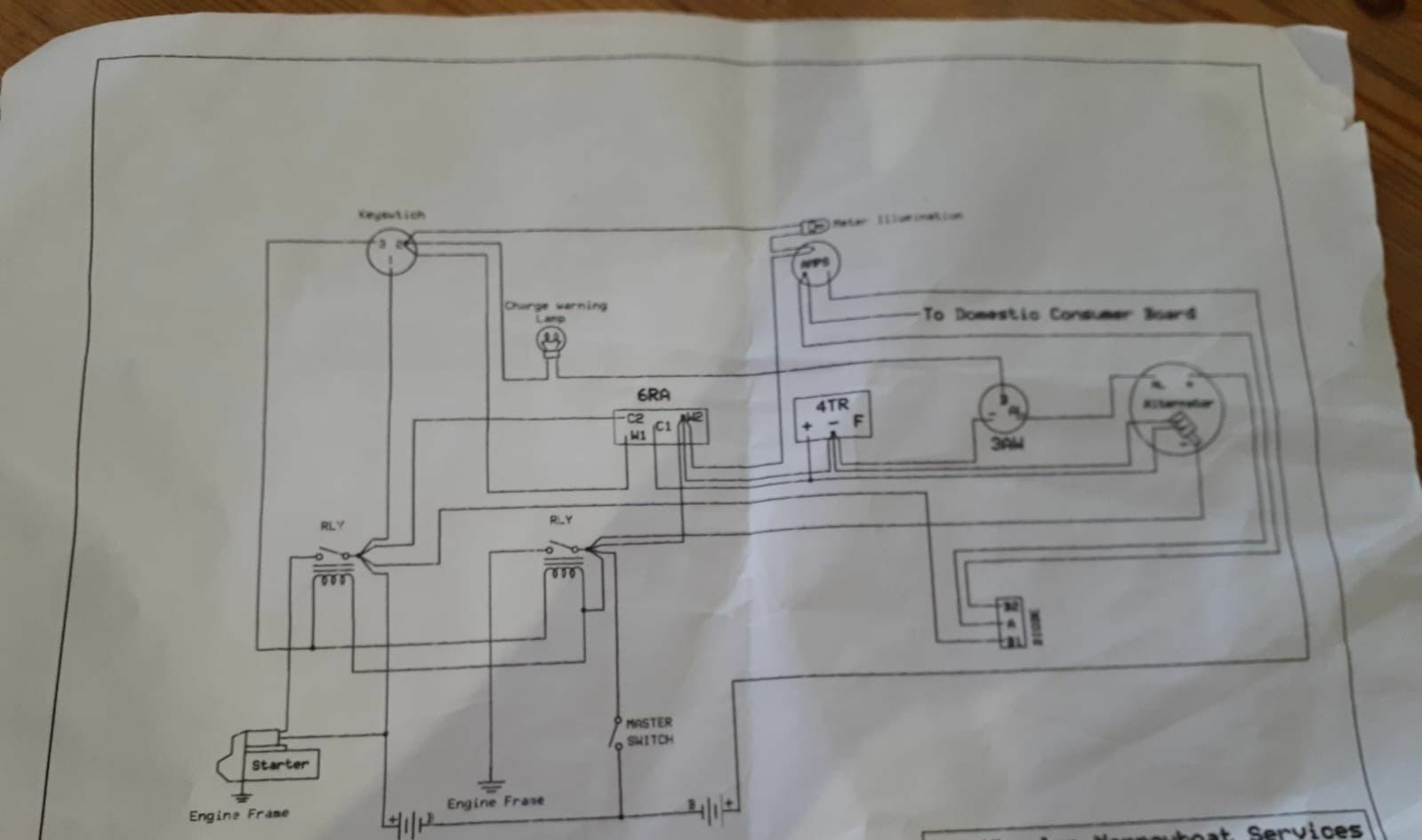

I mean in the starter solenoid there is a Blade terminal with a thinner wire which I'm guessing ultimately leading to the ignition switch , if you have also said that the solenoid can be used as junction box to get an engine battery pos feed. There is also much thicker one which I assume is going to starter battery positive ? (Then one going to the starter motor and and negitive earth one I believe?) Ok so the alternator b+ should be going to the domestic bank first and not the starter. Is there a difference between this and having it go b+ > starter battery > vsr > domestic battery. Hi I will have to check this specifically, but I think it has 3 positions off - on -ignition. I would be looking to install a voltage switch relay after crashing with the ignition system. I will attach diagram of the current electrics system which was apparently done in 2013.I have uploaded this in the past and it has been described as "ancient "😁 -

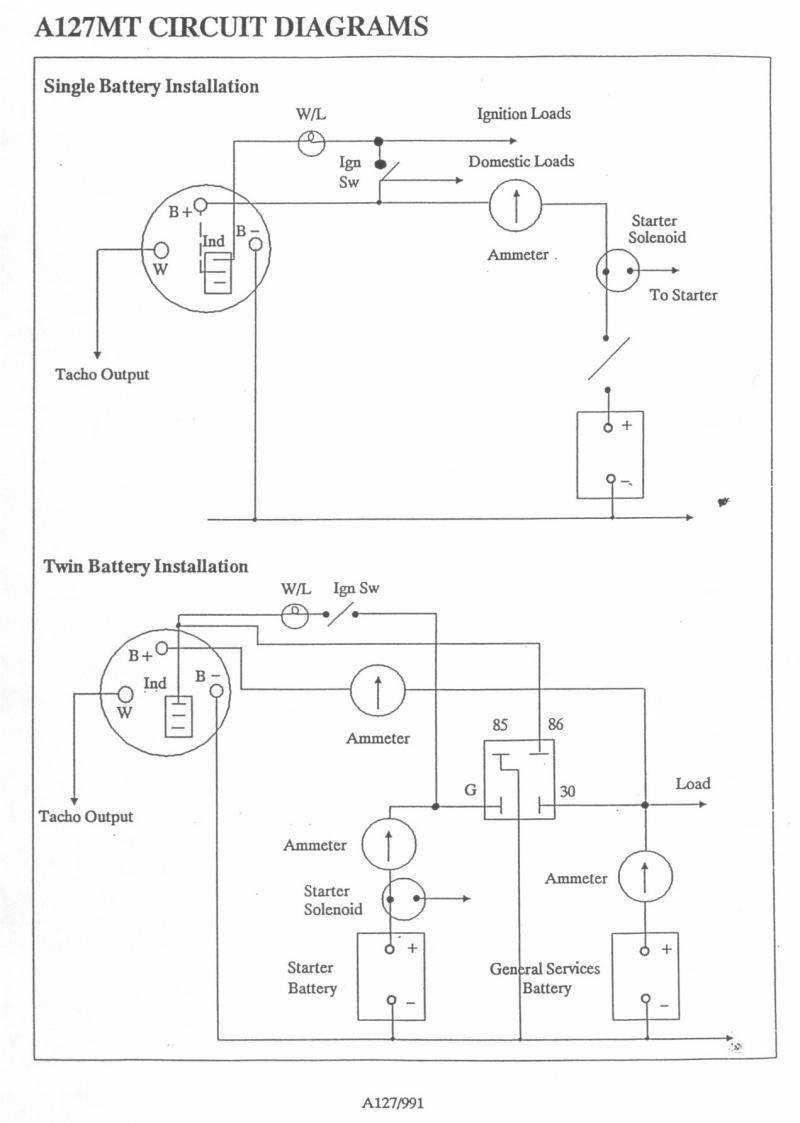

I have posted a few threads in the past about upgrading a broken 11ac Lucas alternator and charging system to a127 type alternator and ultimately putting in vsr charging system in the longrun. In the end our energy needs were met with about 500 watt of solar power to charge the domestic batteries for most of the year so the issue was put to the bottom of the list. Focusing on doing away with the 11ac external regulator , warning lamp relays,alternator relays etc... and installing the most simple igniton system I can, I have found this wiring diagram for the a127 (top one for starter only) and was wondering if it's accurate and if you could suggest any more resources or diagrams . Few questions 1. On this diagram it appears the b+ on the alternator goes via the ammeter and the solenoid + before going to the battery + terminal . However I thought the main charging cable was to go directly to battery + ? 2. I'm a bit confused about which terminals to use on the ignition switch, warning light and starter solenoid and how these all connect together and whether there is negative terminals that need to go to ground? From what I can gather - Alternator d+ > warning light of sufficient wattage > igniton switch "on" terminal Igniton switch "load" terminal > ampmeter> solenoid spade terminal - solenoid + ring terminal>master switch > battery + terminal What confuses me is whether the ignition switch needs to be connected to battery positive directly or does it get power from the spade connector of the solenoid ,as the solenoid is connected to battery positive? 3.I'm also unsure what type or gauge wires I should be using and where any fuses should be placed in the system?For example the b+ charging cable needs to be of suitable thickness got the current and presumably the solenoid large ring terminal to battery + aswell? But for the other connections are the wires thinner and will I be able to reuse most of that from the existing system anyway? 4. Also the current set up has an ammeter, is this optionally?

-

Ok i have my hands on the spill rail but the opening and threads to attach to the fuel lines is on the opposite side - so would be by the second cylinder not the first like it currently is - have i been sent the wrong type of spill rail for the SR2 or am i going to have to modify and extend the fuel lines?

-

I don't think there is any issue with leaking diesel getting in the sump as the engine oil level is normal. Just in to the bilge .

-

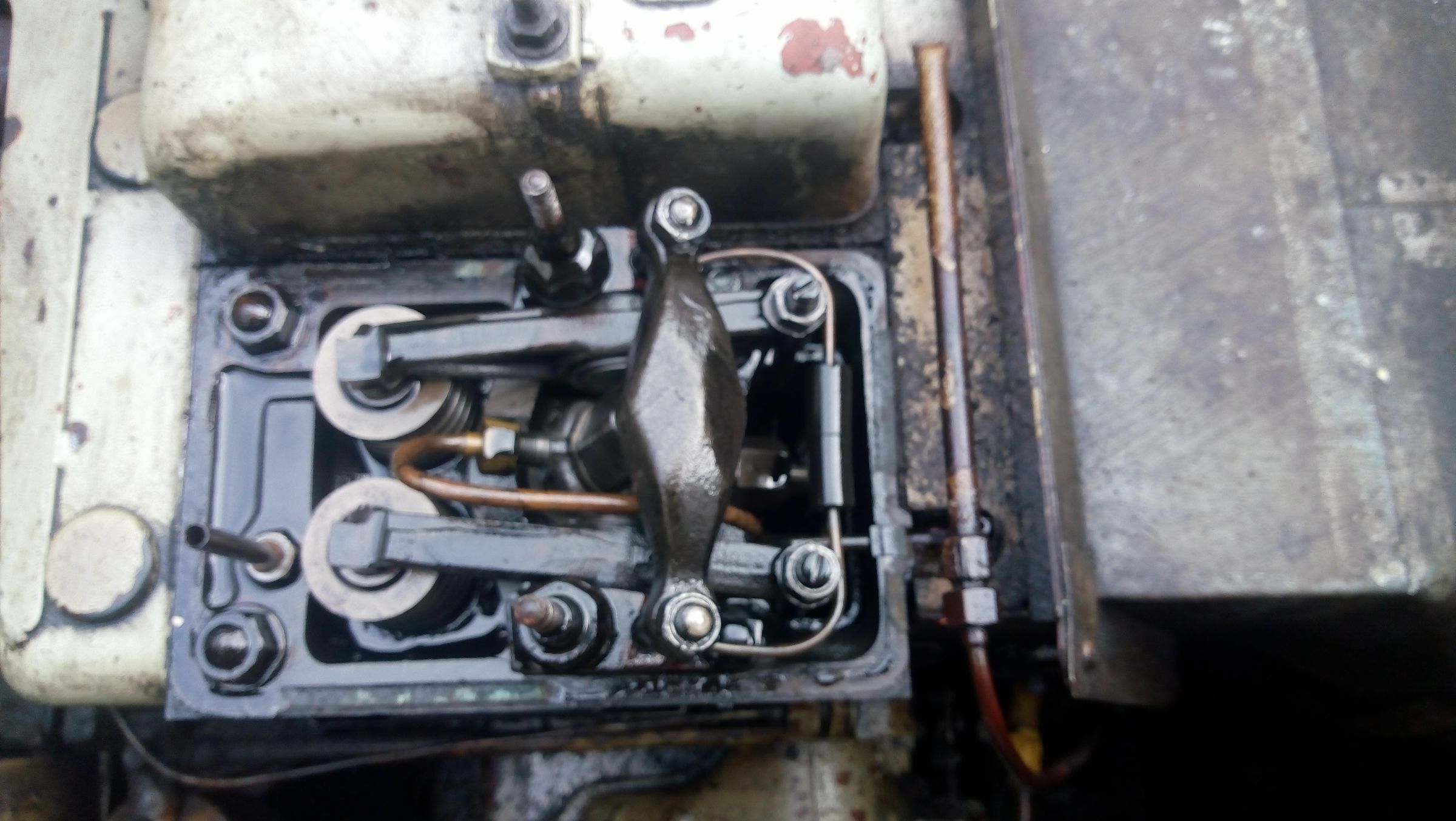

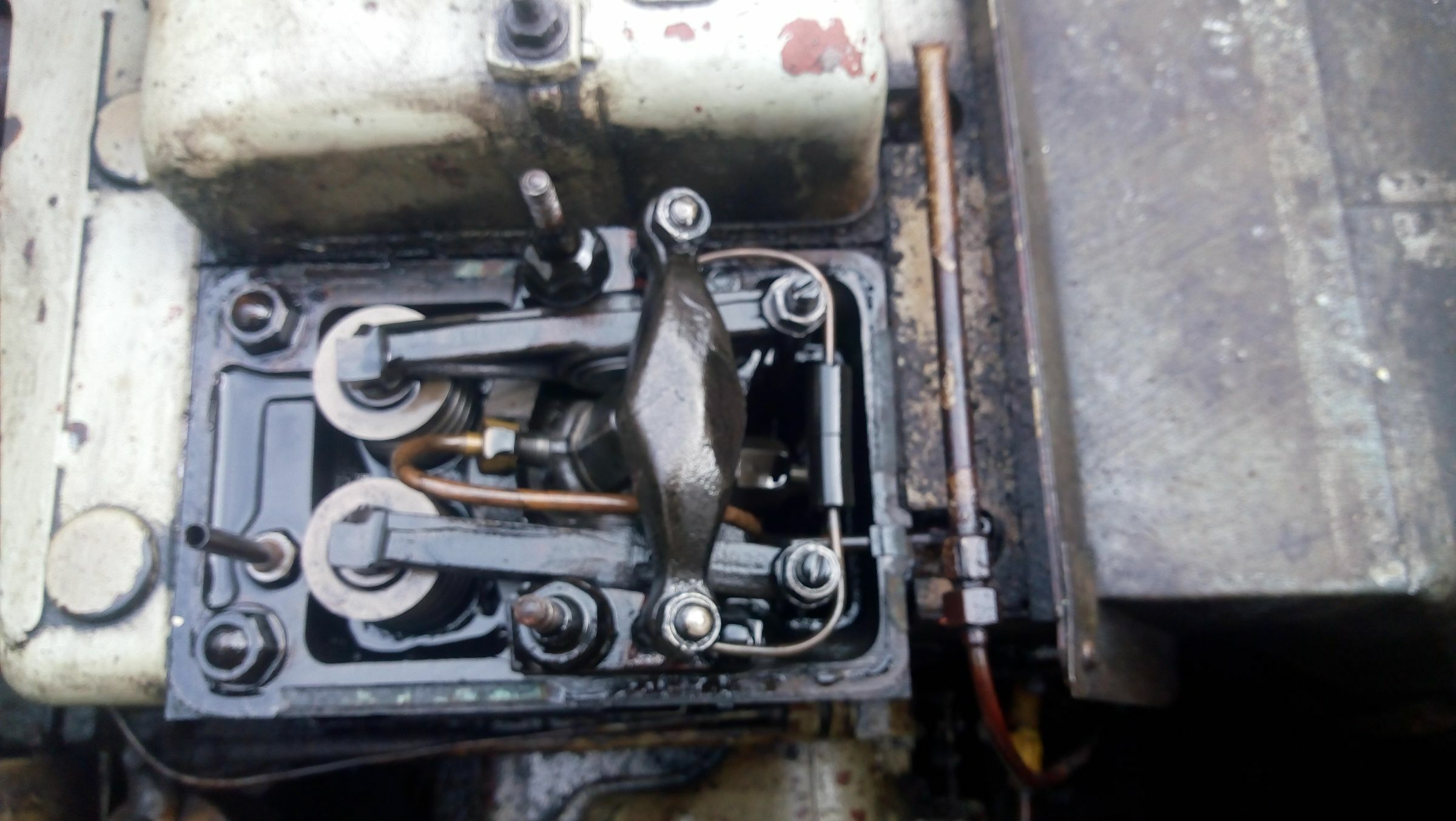

The spill rail has cracked at thejoint just outside the 1st cylinder probably due to engine vibrations. Please see the attached pictures Firstly is this something that could be repaired as opposed to replacement and would the both cylinders need to be replaced as they are connected? I contacted listerparts.co.uk (Or any other lister stockists? ) and they said they have spil rails in stock but need to know whether it is a standard or self bleed spil rail? Lastly is this a job a novice could complete my self , or does the whole injector system need to be dismantled first ? any suggestions for a Lister engineer in the northwest?

-

Although i get the process of replacing the fuel filter and the need of bleeding the engine afterwards as far as i can tell there is no fuel lift pump to manually push the fuel through the system when bleeding at the fuel filter. the100 gallon fuel tank is built in to the steel hull at the stern of the boat, going to the engine which is at a lower level so I'm guessing it is gravity fed? how would i go about bleeding the system without a fuel lift pump ? Actually running the engine instead ? Does it require tampering with the fuel injectors ?

-

Bluepoint marine only had 11ft c8 cable in stock so i declined. They didn't seem to think it being c8 would make much difference? I will take the old cable with me to match at the other supplier. As it happens there is a company called cable tec https://www.cable-tec.co.uk/ not far from the litherland services who focus solely on control cables but they don't stock the cables just manufacture to order or repair. So potentially could get the exact one depending on how long that would take.

-

Managed to get the old cable off and its 8ft , stamped on it it says T 8ft A8. At the chandlery in bootle they have a 9ft one on their website as teleflex 33c type c8 control cable Would this be suitable given that one says C8 instead of A8?

-

Thanks for clarifying this ,i was trying to push the throttle lever when in neutral, but when control was at max speed or max reverse it did move and did indeed rev the engine! So disaster averted. I'll have a look about for one of the morse 33c throttle cables at some chandlerys then .i think 5 -6ft would suffice but I'll take the broken one just to be sure. Is it likely i'd be able to find one at a normal garage as they are "universal" not necessarily just marine applications? Thanks again for everyone's help trouble shooting this! Always the same faces that give help when i post on here about the sr2 do really appreciate it. Will give an update if (and probably when😁 )i have trouble fitting the new one

-

Also see the attached picture of the clamp that the throttle cable goes through. Does this look ok ? This is about 1ft from the throttle lever in the engine Are there any other places that the cable may be clamped and could have come loose?

-

I will test this with fingers crossed. Would i need to remove the throttle cable from the throttle lever pictured first before trying to manually move it by hand because it does not move at all right now

-

There are two grey cables coming down from the single lever control in to the engine bay - I'm assuming one is for the gear box lever (which is working) the other for the throttle lever. If it was the control lever being broken wouldn't this effect both the gear and throttle lever. Looking inside the control box i believe the throttle cable is still connected to the lever as it will expand and retract when moving from neutral position either up or in to reverse (please see images) so not an issue with the trunnion? At the other end in the engine bay the cable goes through a clamp that is on a small metal plate and two screws either side hold it in place - both of these are tight and the cable doesn't feel lose . Therefore is it looking more likely that the cable is broken inside?

-

Hi thanks for the reference picture! Please see the attached picture , this is located in a very similar spot to the arrow placed , just to the side of the cam shaft. It seems to be attached to what i would describe as a small metal plate and then that is connected to a flexible cable which I'm assuming is the throttle cable going up to the throttle lever? There is a rubber washer that you can see on the image that is deteriorated and loose on this shaft. If this is the case, this component is definitely not moving when the throttle lever is moved up and down. I do actually have the original Lister maintenance manual and parts manual, what would these parts be listed as specifically? Cheers

-

Yes it is a lh150 gear box. Sorry just to confirm i have the right component please find attached two pictures one with the throttle fully up and one in reverse. So yes i believe the throttle cable is moving back and forth as normal The engine is running fine, sounds as it usually does when running in neutral but the throttle has no effect.

-

My narrow boat suddenly lost drive power yesterday. Engine is sr2 The engine starts fine but will not rev even when in neutral. When in gear there is some power going to the propeller when the lever is all the way up but the boat moves very very slowly and again will not rev up or rev in reverse. Been advised to open the weed hatch to check the propeller and it's clear. Also checked gear box oil and it is not low. Other people have mentioned it may be the taperlock between gear box and prop ? The prop shaft spins slowly when in neutral ( always has done) but I'm finding conflicting info on whether this is a good thing or not. Any ideas? In a bit of a pickle as we are in Liverpool dock and booked to leave on Saturday.

-

Adding more solar panels in parallel

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

the panels i am looking at both have an advertised Vmp of 18 volts. however for the 120 watt panels it says a Voc of 21.6 volts and for the 150 watt 20.3 volts ? is it the voc or vmp which is significant here? -

Adding more solar panels in parallel

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

thanks for clarifying this, I've obviously misunderstood , thinking everybit of wire in the array needs to be able to handle the total current of all the panels combined. would it still be worth using 6mm cable from the 3/1 connector to each of the solar panels preinstalled mc4 connectors,to account for any voltage drop( i guess given the nature of a narrow boat roof , 1 panel is going to be perhaps 10- 15ft further away from the controller than the nearest panel is) or could i just use 4mm aswell. -

i currently have a 150 watt ecoworthy solar panel on top of my boat , connected to a 30 amp epever solar controller. i would like to add two more 120 watt solar panels of the same make , to bring the total up to 390 watt which is the max total advertised for this controller. i would just like to just ask a few questions to see if my understanding of this is right.... firstly please take a look at my very professionally drawn diagram ? and let me know if this is how the 3 panels would be connected in parallel (increasing the amps not the voltage) 1. can i use "3 to 1 " mc4 connectors to do this, attaching to the prexisting 6mm wire i already have going to the first solar panel? or is it better to use several " 2 to 1" mc4 connectors. i have seen some " trident"looking ones and also ones that are more "whip" like, so 3 seperate mc4 connectors with seperate wires that are connected together. 2. As the solar panels come with like 1 metre of 4mm already attached i am going to have to replace this with 6mm solar cable to account for the higher amps the wire will be handling . is this simply a case of crimping terminals on to the 6mm wire i am going to be using, opening up the panel's junction box and unscrewing the 4mm wire , and reattaching the 6mm wire? 3. being an economically minded chap ,is it possible to reuse the individual mc4 connectors that will come attached to panels, or will i have to buy new ones. By my reckoning i will need two ( male and female ) " 3 way" mc4 connectors for the wires that attach directly to the controller , then three male and three female mc4 connectors for connecting the panels to the 3 way mc4 connectors? am i on the right track with all this?

-

Sr2 engine electrics upgrade - A127 alternator and VSR

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

I've uploaded some pictures. The pulley on the engine is approximately 8in diameter, but I'm not sure if there would be room to add a bigger one in the current position that the alternator bar and cam shaft pulley are in. The belt is a 6226MC. I would be looking for a right hand fixings on the alternator? -

Sr2 engine electrics upgrade - A127 alternator and VSR

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

This is something i will need to check , but i will assume it is the standard as little has been changed n to this engine in a long time. So increasing the size of this will increase the pulley ratio between the one on the alternator and the one in the camshaft, and lead to a higher rpm for the alternator? -

Sr2 engine electrics upgrade - A127 alternator and VSR

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

Ahh ok i misunderstood. On the attached picture the red arrow is the direction the fan belt rotates . -

Sr2 engine electrics upgrade - A127 alternator and VSR

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

I believe it is normal clockwise rotation ,as anticlockwise SR's have a letter A after the engine type? Looking from the stern end of my boat the fly wheel goes clockwise -

My boat has a SR2 MGR2 engine and its original lucas 11ac 45amp alternator thats on the blink and outdated engine electrics. I have been advised on this forum that a 70 - 75 amp A127 style alternator would be a suitable upgrade alongside installing a more simple VSR charging system. What factors do i need to take in to consideration when arranging this? . Would the current fan belt ,camshaft pully/alternator pulley be suitable to just install the A127 ,or would more modifications be needed accomodate it? Some are being described as "marine" versions (insulated terminals?) , others being sold for use on cars? In regards to the VSR system, i have seen some reasonably priced "split charge kits" online , where the relay is rated a certain number of amps. Would the vsr need to be "matched" closely to the alternator output (alongside output from solar panels ?) or would say a 140 amp vsr be suitable for any amp output that was under that amount . I have attached some screen shots of potential products I've seen and was wondering if these would be suitable for my purpose Any links to suitable products would be greatly appreciated.

-

Solar controller positive ground

Spoonman replied to Spoonman's topic in Boat Building & Maintenance

Thanks for the advice.You are right the alternator is an 11ac Lucas alternator. Surprisingly i removed it and the seperate regulator and had it tested separately and it was putting out a charging voltage so it maybe have been refurbished sometime between now and 1975? However i think the whole engine electrical system has not ever been upgraded. That diagram was done in 2013 by the previous owner! Everyone that has looked at it has just shaken their heads with bewilderment. The engine is an sr2. Am i right in thinking that a 70- 80 amp alternator would be the limit to upgrading without major modifications. As you mentioned i have seen the ac127 suggested for this purpose before. Are the regulators intergrated in to this alternator or would a separate one still be required?