-

Posts

10,068 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Tracy D'arth

-

-

9 minutes ago, BEngo said:

Is the alternator square to the crank pulley? If it is out of square then it is a job for shims behind the alternator mounting bracket. Old oil cans used to be the thing for making shims, but beanz tins work if you beat them flat.

If the alternator is square, but out of line ( too far forward or aft), there is (should be) a spring collar on the mounting pivot which can be moved to allow the whole alternator to go backwards or forwards to line up.

N.

The rear mounting has the sliding sleeve giving a bit of adjustment but to get the pulleys in line it is the front mounting that has to be dead right.

-

10 minutes ago, Polly Graff said:

Thanks for your replies. I'm told its usually the alternator that is misaligned because these engines were designed to work with a dynamo and alternator brackets have sometimes been cobbled together afterwards as an add-on. If there is misalignment of that type, is it just a question of correcting it using washers/shims - or does it need correcting in some other less bodgy way?

Washers will get the job done. The front swivel mounting is on the front engine plate so spacing with washers is the only way on that one. The rear mounting is a bracket that could be changed or moved, the adjuster has a thick spacer already.

The critical ones are the 2 mounts on which the alternator swivels, i.e. the rear one and the front one on the same axis.

-

There is a firm that organises renting space on private house drives.

-

Unless the bearing on your water pump is severely worn the crank and water pump pulleys will be in alignment as they are not adjustable.

The alternator pulley may be too far back or forward on its mounting so that the belt is bent sideways next to the pulley or it may not be at the same angle as the other pulleys because the alternator mounting is skew wift. Either will shorten belt life.

Check with a straight edge across the crank pulley and the alternator pulley, not easy but it is the way to do it. Alternatively a round rod about 10mm in diameter laid in the 2 empty pulley grooves with the belt removed will show up misalignment.

There is often the wrong width of belt fitted, most BMC engines need the wider "B" section belt rather than the "A".

There are some rubbish v belts around now that most cars are using poly vee belts. Buy Gates or Fenner preferably. Always use notched belts not plain ones with alternators.

Check the grooves for rust, it will shorten belt life too. If rusty, emery paper them smooth.

-

14 hours ago, MixingWizzard said:

I am shocked, never seen that before. It must have been very noisy. Going hydraulic is an option but not a simple swap. Dimensions are different, an oil cooler plumbed into the cooling system and hoses all add up to more expense.

PRM150 or PRM 280, much bigger, are the choices. Better with a PRM 125, current replacement for the 120.

-

1

1

-

-

15 minutes ago, Tony Brooks said:

I thought they were as well, but is it possible the OP is confusing the actual gears with splines for the cone clutch? If any are spur gears it would be noisy in operation.

Just checked the 120 and 125 manuals. The drawings in the 120 manual seem to show spur gear, but I think that is a drawing convention for any gear, so not fact. The 125 drawing is the same, but another picture clearly shows helical gears. I find this interesting, so hopefully the OP will come back with photos and more info when he has talked to PRM.

I too would have thought the noise with straight cut gears would be unbearable. I have looked at my service notes for PRM & older Newage gearboxes and they are all helical cut gears.

-

I haven't repaired many PRM120 boxes but I, from diminished memory, thought they were all helical gears, is yours very old?

Send the parts kit back for credit and swap the box in fo a new PRM125D2 is the best bet; then you have the guarantee as well.

-

Don't get out of bricks and mortar, sell the house if its too big and buy a small one to rent out, or even two.

Spend less money on a decent used 58 foot narrow boat which will have all the "as new" bugs sorted out. Enjoy a year or so of cruising then buy what you now know that you want.

Do you understand cruiser, semi-trad and trad?

-

2

2

-

-

8 minutes ago, MtB said:

I remain to be convinced on the inserts. When Hepworth launched their "Acorn" push-fit pipe system there were no inserts initially. They added then after about a year IIRC. I suspect the real problem was the ability of the pipe to pop out of the fitting if abused by being bent over hard and stressed on exit from the fitting. Inserts certainly help stop that!

So I reckon if the pipework is arranged nicely and not stressed at the fittings, the inserts don't really do anything. I always fit them though as 'no inserts' is the perfect way for Hepworth to wriggle out of a claim, should there ever be one!

My company did trade shows for Hepworth and Bartol before that. We did to destruction demos of Acorn.

The inserts (talking about the thin stainless steel ones here ) are essential on all hot water plumbing if you are to achieve the correct pull out force resistance.

With the inserts the pipe will stretch ( neck ) or the fitting will break before it will pull out.

I have no experience of the plastic inserts as I never use them, I think that they restrict the flow too much.

Guest's white pipe is much harder than Hep2O and I have seen it pull out.

-

Ask yourself why there are so many widebeams for sale?

Its because many are rubbish, they are too big to handle for most people on most canals, they will not go down the majority of canals and they cost more to keep now.

-

1

1

-

-

Not the way to work a staircase.

-

Doing there own plumbing is fine but tonight did anyone see any inserts being fitted into that push fit pipework?

Silly bath for a narrowboat matches the Esse stove.

-

Put your route into canalplanac website for navigation notes and timings. You can adjust to suit your preferred number of hours per day.

-

1

1

-

1

1

-

-

2 minutes ago, MrgrumpyNB said:

I’ve got the bolts at the gearbox side off as I need them off anyway and I have removed the four bolts holding the ring around the back am I to remove the four blocks held with the Allen key bolts ? Now that the prop is free to slide back I’ve currently got about 8-10mm clearance from the coupling to the drive plate on the engine and I don’t have the room to slide it any further will I have room to split the coupling ? Thanks

The allen bolts stay in. #

The shaft is held in the coupling by a taper collet which is release by removing all the 6 bolts in the rear of the coupling next to the shaft and replacing 3 of them in the presently empty holes next to the 6 which will jack the collet out of the coupling letting you slide the shaft even further back.

-

43 minutes ago, John Brightley said:

Concoform only had one ferro cement boat - see history here: https://www.concoformmarine.co.uk/history/

I think Davison Brothers of Sawley Bridge Marina built more ferro cement canal boats than anyone else - in the late '60's/ early '70's.

I had forgotten Davidson Brothers, are there any still left? I think some were finally used as bank protection.

-

There is not a lot of mooring space near the bridge for boats to queue up but then with the locks at Marple still out there maybe not so many boats.

-

24 minutes ago, Alan de Enfield said:

Of course boating on waters where you cannot get off and walk ashore may well be outside your areas of expertise.

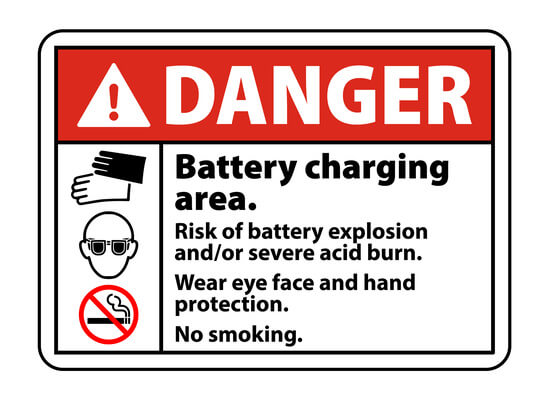

Every coastal / ofshore boat with an inboard engine I have been on has had bilge blowers, and of course, as there is no BSS to ensure our safety, we have to minimise the risk of explosive gases collecting below the deck when charging LA batteries.

Sense of humour transplant required?

-

15 hours ago, jam said:

To all accounts it is the hydraulic pump that has failed and a replacement is being sourced.

It will be a standard component available from many suppliers off the shelf. There are hundreds of stockists of hydraulic pumps, widely used on JCBs and plant machinery.

-

1 hour ago, Alan de Enfield said:

There's a sucker born every minute-----------------------------

-

I have broken a ferroconcrete hull, best way is a Stihl saw with a diamond blade and another with a steel disc to cut the thicker bars. Its incredible how much you can just fold up into a skip with a JCB.

-

1 minute ago, ditchcrawler said:

I think this was quite popular a few decades back, steel skeleton and chicken wire

There was a hire fleet of such boats years ago. Concoform?

-

You need to keep some funds back when buying any boat at there are always contingencies that crop up and have to be paid for immediately.

Its a good point about the quality of the builder, a well respected quality hull builder as opposed to a certain well known problematic corner cutting Liverpool tin basher.

-

3

3

-

-

7 minutes ago, JoeC said:

Wouldn't lack of water in the boat be better?

No, loading the bow with water in a bow tank would raise the stern, the deepest part of the hull, a bit so reducing the draft.

-

2

2

-

-

I have had this happen in the dim and distant past.

The SR3 engine had run away in a BW work boat. As it was needed pronto I ground shallow recesses in the pistons to restore clearance for the exhaust valves. Why it was only the exhaust rather than both valves I don't know. Ran Ok after.

Middle which mooring

in Cruise Diaries & Reports

Posted · Edited by Tracy D'arth

Moor near bridge 28 and there is a footpath into town avoiding traffic. Comes out on St Annes Rd. cross and there is a B&M where Tesco/Jack's was and Lidl and Morrisons are a short walk further.

Rings and piling from 28 down to the junction with the T&M. Gets busy after bridge 29, Noisy after 30.