moiuk

-

Posts

157 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by moiuk

-

-

On 05/10/2023 at 17:56, Tracy D'arth said:

The fuel filter is likely to be a 296 or its equivalent. Is there a number on it?

It's has 712/2 written on it..

-

4 minutes ago, Tracy D'arth said:

The bottom of tank sample is contaminated with water, a lot of it.

Your second sample has had time to settle but there will still be water in places in the fuel system.

You will have to drain it all, every pipe, every filter, every pump all the way from tank to injectors to ensure that there is no water in the injection pump which is the item most likely to suffer damage and the most expensive.

Thank you.

Getting things together to do this. Watching videos on how to reprime the fuel after changing the filters, obtaining a few large containers for the old fuel and trying to work out which new fuel filter to purchase..

Thanks for all the appreciated help. Will update after I have completed the cleaning...

-

1

1

-

-

-

So I just tried to drain the water trap by opening the tap underneath.

Obviously I have a lot of water in my fuel, how how does it work normally? Will the tap under the water trap only capture the water so I drain it until it stops, or will it keep going effectively draining the diesel from the tank too?

Is it worth draining the tap now before I drain the main tank?

-

2 minutes ago, Tracy D'arth said:

These flush fuel caps rely on the "o" ring for a seal and are renown for letting water in.

I'll check it and replace it if needed. Don't want this to happen again if possible.

-

Yes it's is a flush fit fuel cap type, although I can't see how a significant amount of water could enter. I'm thinking that condensation is a likely culprit. In winter I keep the boat pretty warm and in the engine bay I get significant condensation on the outside of the skin tank which collects a good amount of water in the bilge that I need to pump out. If the same is happening on the inside of the fuel tank then that would be a good amount of water.

I intend to keep the tank full over this winter, but any other suggestions if this doesn't sound right would be helpful.

3 minutes ago, Tracy D'arth said:If it settles out properly it will be OK. May take several days to settle.

Unlikely to do any damage but don't delay in sorting it. Some injection pumps have steel springs in and these will rust if left with water in. From experience, Mitsubishi/Vetus for instance would suffer in this respect.

The old CAV pumps on Perkins will be more tolerant but its not good for them.

Thanks. I think I have found a few 25l containers so will get this done asap.

My thinking is that once I have new fuel in the tank, to run the engine to clear the bad fuel through and then replace the fuel filter and drain the water trap.

Does this sound a reasonable approach?

-

Thanks. I will Syphon all the fuel out.

Is it okay to just let the fuel.settle and then Syphon the diesel off the top and put that back, or is it going to be better to just dispose of everything and replace with fresh?

Is this likely to have done any lasting damage to.the engine?

-

Doesn't sound good!

Okay, my water trap is below my tank, so I'm gonna bleed that and see what comes out..

5 minutes ago, Alan de Enfield said:I syphoned it out from the tank by putting a hose in from the top. I got the hose down as far as I could..

The tank is down to about 50 litres because I didn't want to fill up before fixing this issue..

-

An update to this topic/issue..

Not been crusing very much after I got off the Thames as well as holidays etc.

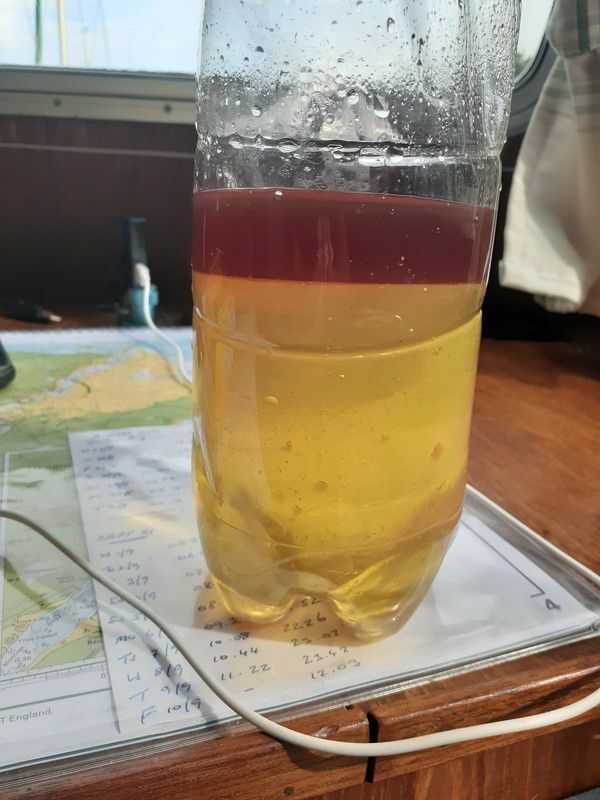

However, I have now managed to Syphon off some fuel into a glass bottle to see how it looks (photo attached). I will leave it for a week or two and compare.

Not sure what I am looking at, so opinions if this looks normal would be appreciated.

I still need to locate an engineer to help do a service on the fuel line/filter etc. Chertsey meads marina sounded perfect after I spoke to them, but I was unable to stop as I went past at a time when they were free, so that job still needs doing.

Considering learning how to prime it and do the job myself.

-

7 minutes ago, Tony Brooks said:

First, deal with whatever is in the bottom of the tank because once you have a length of hose and some milk cartons it is very easy to do with a typical narrow boat tank.

Lest see if this helps. I have shrunk your photos a bit, but you should still see the important bits.

The easiest first check is to see what is in the water trap. This image shows what I think is your water and the fuel filter.

At the bottom of the water trap is a tap, as shown in this photo:

As long as the fuel level in the tank is higher than the tap then put a carton or something under the tap and undo it. Whatever is in the water trap should trickle out, but you may have to take the tap right out and prod the hole. If you have trouble putting the ta back in then turn off the main fuel tap (should be marked as per the BSS), fit the tap but leave loose, turn on fuel and a sit leaks out tighten the tap. Try not to do this because it may then involve bleeding the system.

Back to the first diagram.

The fuel filter looks as if it is a standard CAV 296 type unit, so it consists of three parts, the head/top, the actual changeable element, and the sediment bowl. You will see a hexagon bolt head right in the centre of the head, about 1/2" AF or 11mm. If you undo this, the two parts will come off the head. It may need a geed twist to free the parts from the rubber seals. Any decent motor factors should sell the 296 element. The placing of the 3 or 4 O rings is critical, so for your first attempt my advice would be to leave them all in place and refit with the old ones. If you do remove the seals ensure the new ones go back in the correct place.

If you change the filter, you will definitely have to bleed the fuel system, so if you don't know how to do this you may be better to pay a professional.

Now the lift pump.

I think that it will look like this:

It will be about halfway down the engine cylinder block, probably on the same side as the filter, but don't hold me to that. One of the pipes will go to the fuel filter and the other typically comes from the water trap.

Not the single bolt in the top of the domed cover. If you undo that, it will normally expose a brass or plastic gauze above a sediment trap. There is a rubber O ring that fits into the cover. On no account remove this. They tend to swell, so you can never get it back in. The gauze needs cleaning and the sediment trap needs cleaning out. be aware that doing this will require the system to be bled.

If you have never bled the engine, then maybe pay a professional to change the filter and clean the lift pump gauze. If the tank fuel level is below the water trap, get the professional to do that as well. Make sure that you are present to see what is done and collect fuel samples from each item and take photos so was can advise on what is fund. It may be better to limp back to your home mooring where you presumably have contacts for such work.

Wow that is sooo helpful. Thank you.

I think I will find an engineer in London when I am off the river and watch/learn as he does it.

3 minutes ago, magnetman said:My Perkins P4 has some sort of bizarre vacuum operated throttle system. There is a butterfly valve in the air intake.

I don't know if the 108 has this setup. @Tony Brooks will know.

If it does is there a possibility there is something going on with the vacuum pipes?

Another thing which needs to be established is does the engine start to smoke excessively when the power loss occurs? If there is sudden appearance of black smoke this would indicate engine overloading.

I've got an unproven idea that one can also detect fuel dirt or bug problems from the smell of the exhaust.

Ears eyes and nose can be very useful sensors.

No significant increase in the exhaust smoke when it happens.

-

1

1

-

-

6 minutes ago, Bee said:

If this engine was still in its original home, a van or something like that and it was giving this trouble then the garage that you took it too would start by suspecting dirty fuel

Thank you. This certainly needs to be checked now then as many have suggested already. My faulty thinking and understanding has (incorrectly) asssumed that due to the correlation with temperature and how hard I'm running it that fuel was a low probability, but those that know better than me keep suggesting fuel so I wil need to get this checked next.

23 minutes ago, Tony Brooks said:How many times have you been told the fuel system is suspect and bug is a good candidate. Until you drain the bottom of the tank, inspect what the water trap has caught, cleaned the gauze in the top of the lift pump and change & inspect the fuel filter element, you can not rule this out. Draining the bottom of the tank is, in my view, many times easier than taking the engine water pump off.

PS, your rev counter might be driven by a cable from the engine using a thing like a car speedometer cable, but it is just as likely to be driven from the W terminal or a phase tap on the alternator. make sure the terminal on W is clean and tight. A faulty alternator will cause rev counter problems, even though many will think the alternator is still charging properly (it won't be). This also raises questions bout the alternator belt condition and tightness.

Thank you.

I will do the fuel inspections. Not done these before so will need to work out where they all are and how to do it. Will be simple after I have done it once. The fuel filter is probably due a change regardless.

I'll check the rev counter connections. I have a separate ammeter measuring the alternator charging which looks to be charging correctly. I checked the alternator belt when I changed oil last week and looked to be fine.

-

19 hours ago, magnetman said:

I think the hot fuel story could be relevant. Neutral and reverse seem to need less fuel in general and the OP did say things improve after everything is allowed to cool down.

Injector lubrication is an interesting thing as it relies on the diesel.

It does look like this problem is happening when the engine is being run under load. Its not an intermittent problem as it seems to happen reliably according to the temperature of the gearbox. The gearbox may not be too hot but the symptom IS related to engine load.

I reckon it is overheating and the temperature gauge is bust.

So I measured the temperature with an infrared monitor again today and the water going into the skin tank is showing 60 degrees (which matches the temperature gauge) and out of the skin tank is 30 degrees.

15 hours ago, Bee said:Have you a tacho fitted? how many revs is it usually running at? The terrible old Perkins that gave me problems was OK until I needed a bit more shove (like going against a current) when the b****** would drop back to a fast tickover) That was diesel bug and dirty fuel

The revs monitor doesn't seem to be reliable (I think it st is sometimes) but when the problem occures the revs drop.

15 hours ago, Stroudwater1 said:This is a fairly consistent time though when it starts to slow down, wouldn’t diesel bug dirt be a problem from the set off ir be intermittent maybe ?

it would help to see the water pump. It’s a pretty easy fix if it’s rubber impeller veins fitted that are a bit knackered (as long as veins aren’t in the system)! Someone I know changes their neoprene impeller annually.

Where is the water pump? Will that be on the back next to the alternator (assuming the belt that does the alternator also does the water pump? I can get a picture of that later if that is correct.

Untried something else yesterday/today which was to run the engine a little less hard and it made a difference in that the problem didn't occur until 2.5 hours of cruising instead of just over an hour when running it hard. The problem still occured though although it was less drastic. I still had a reasonable amount of power but still significantly less than when I first get going with a cold engine. Consistently the problem seems to occur when the gearbox measures above 65 degrees.

It seems repeatable for the problem to occur with how hard I run it/length of run time which indicates to me that it is a temperature issue ?? Any thoughts on this? Could fuel bug still be the culprit if it is consistent with time/how hard I run it?

The large circular plate behind the gearbox (not sure what this is if you can advise) measures at just over 60 degrees which seems to match the water temperature so guessing this is also normal ?

-

11 minutes ago, magnetman said:

John.k might well be onto something with the worn DPA pump. It does add up as it is quite an old engine. Presumably this would be caused by dirty fuel getting to it.

Interesting situation. Do you know how many hours the engine has done?

I don't know the history of the engine unfortunately. The previous owner seemed to know what he was doing and seemed to have taken care of it.

It smokes a little when I first start it, but mostly runs fairly clean.

-

1 hour ago, Tony Brooks said:

I would be more concerned about the engine overheating but your temperature reading suggest that it is about correct. The temperature on the pipe coming out of the bottom of the skin tank should normally be no more than warm, never hot.

According to Magnetman the gearbox temperature is within range which suggest the problem is nothing to do with the gearbox, and your engine temperature reading suggest it is not the engine overheating and partially seizing.

The fuel being the issue is starting to look more likely... it just seems so consistent with temperatures... I will need to get some siphoned off to test it.

I'll check the bottom skin tank pipe just in case the temperature gauge is broken.

1 hour ago, john.k said:Small engines can lose power when the fuel gets hot .........a sure indication is the engine will be hard to start when hot after a 5 or 10 minute stop...........its a result of a worn DPA pump ............In the days when the 4/108 was fitted to Bobcats ,this caused a good deal of trouble with high hour machines .

Thank you. Engine seems to start fine after a short 5 min stop.

One further observation from today's issues. When the issue starts I can hear the engine change so know when it happens. However I don't lose power straight away (a little, but not much). But when I then try and stop .. at that point I have very little forward or reverse power. (I get more from reverse than forward but both are significantly affected. A 30 minute rest and all is back to normal again.

-

8 minutes ago, Tony Brooks said:

If I understand your photo correctly then the gearbox oil cooler does seem to be in the return to the engine water pump, but I can't see the left-hand end properly, and the pipes look small to carry the full coolant flow, as I said above.

2. Most converted vehicle/industrial engines of that age tale the injector leak off pipe to the top of the engine fuel filter, where it fits into a banjo union with a 0.5mm hole in the side of the banjo bolt. That banjo has another pipe on it that runs right back to the tank. Sometimes an injector has a double banjo that gives the leak off pipe back to the tank. Your engine has the same fuel system (apart from injector detail) as the small BMCs. My description comes from the CAV fuel injection booklet. The idea is that if you have a minor air leak into the fuel system where it is under suction or if any air is dissolved in the fuel it can float to the top of the filter and be returned to the tank before it can cause running problems.

Your first photo shows the injector return/leak off pipe connected to a fuel filter or water separator at the same point as a main fuel line, so any air will build up in that filer rather than escape back to the tank. In fact, I suspect the "filter" you photographed is a water trap that your second photo shows the bottom of. This is how some returns are piped on proper ground up marine engines, but it does not work for long term reliability on marinised automotive or industrial engines. I doubt this is the cause of your problems because if it were the chances are that when the engine sloweed down/stopped you would have to bleed the fuel system to get it going, but it could cause problems at some time in the future.

Thanks for explaining that makes more sense now.

If the pipes are too small, I'm assuming that the temperature of the gearbox would increase higher than good operating temperature and then cause issues. The 65 degrees seems to be within normal range, unless I am measuring it incorrectly??

-

19 minutes ago, Tony Brooks said:

No normal oil cooler that I can see.

It looks like a horizontal on the baseplate skin tank, so apart from tracing the pipes from and to the engine I have no idea.

Another angle.

20 minutes ago, Tony Brooks said:Here are two more things.

1. If the elbow hose running to the T piece in your photo is the hot outlet from the thermostat housing, then I don't think that the hose that probably runs to the skin tank is large enough for river work. Let's have others' opinions on that.

2. The injector leak off seems to run to a fuel filter, and I can see no evidence of a leak off pipe running right back to the tank. that can be a recipe for suffering a build up of air/gas in the fuel system. Again other opinions welcome.

Later today, I will try running the engine at a slower speed to see the problem still occurs when not being run as hard.

Not sure I understand what you mean by number 2.

-

5 minutes ago, Tony Brooks said:

That is an oil bath air cleaner and as long as you don't overfill it with oil it will not be the problem ------ unless the wire mesh has never been cleaned, and it is clogged with dirt and hair.

Tracy is asking about the temperature of the air getting into the filter, and I add is there at least (say) six sq in of vent space to allow outside air to be drawn into the engine bay. Try running with any boards above the engine removed.

Is the water connection to your gearbox oil cooler in the feed to the skin tank or the return. It should be in the return. Beta once, in effect, put it on the feed side and cause problems. This assumes your engine is tank cooled.

Or is it after running at higher than normal canal speed that uses more fuel and at the same time allows everything to run hotter. My feeling is it may be t do with a higher than normal fuel flow rate, so could be a raft of bug floating about in the tank and getting drawn over the fuel inlet, but it is just a guess.

When I open the boards to measure the temperature it feels pretty cool down there, so i would say that the air getting into the cooler is okay.

Photo attached of the water connection. It seems to be connected to the lower skin tank connection (is that the feed or return?)

Still need to siphon off some fuel to check this.

-

1 minute ago, magnetman said:

PRM Delta I think or possibly a 150. They look the same but are slightly different.

Did you phone PRM Newage? In a thread from a while ago someone said the gentleman to talk to was called Andy.

The fact the propshaft spins freely seems like bad news if this is not a fuel problem.

Yes I called PRM Newage and left a voicemail, not had a call back yet.

If this is not too hot for the gearbox, perhaps I'm measuring it wrong. Infrared sensor on the top of the gearbox from about a meter away.

So still could be a fuel issue? It seems linked to the temperature.. my simple brain would have assumed that if it was the fuel it would show itself earlier or at random intervals. The problem is consistently as the engine/gearbox gets hotter.

-

48 minutes ago, Tracy D'arth said:

What gearbox is it? Is there an oil cooler for the gearbox? If so it, will get up to engine temperature after running a while, 65 is not too hot. What is the engine temperature? Is the engine sucking cool air?

Tony Brooks identified it as a PRM hydraulic gearbox from the photo posted previously.

The engine temperature gauge is showing in the middle of the dial around 80, but doesn't seem to increase too much after its up to temperature.

The engine has an air cleaner rather than a typical air filter. Not figured out how this works yet, but there is a small reservoir of oil inside which seems to be at the correct level. (Will try to add a photo).

Photo added. Air cooler is bottom right.

-

On 24/08/2023 at 08:01, Tony Brooks said:

In fairness, he has said that he has a syphon pump and will try cleaning the bottom of the tank. But if he wants to solve his problem, it is not a good answer because it goes no way towards eliminating the fuel system as the problem. Ditto the filters and the likely stainer in the lift pump. At present, it seems that we have the situation where the OP has decided on no apparent evidence that the fuel system is fine.

If I knew where about on the Thames he was/is I would have happily arranged to meet him and at least have a look at the strainer in the lift pump. That would have told us a lot about the fuel condition and servicing.

Diagnosis is all about taking the symptoms and seeing how they match experiences, then putting the causes of the past experience into order of most likely or easiest to test to the least likely/most difficult to test. Until the list of tests is completed, or the problem has been found, anything else is just guesses, and from what I see on here it is often guesses (made with the best of intentions) that is based on limited experience.

We don't know if he has a water trap on the supply pipe. If not, the strainer in the lift pump is likely to be very dirty unless it has been regularly cleaned as part of servicing. I don't recall being told how long ago the fuel filter was changed, and we know the 296 type filters, that I think the 4-10x series of Perkins use, are known for assisting in creating air leaks. I repeat, I am not saying this is a fuel problem but more than one of us has suggested it could be, so that needs eliminating. I am concerned there may be something floating about in the tank that gets drawn over the inlet pipe when running at higher speed and power, so I am looking for evidence to eliminate that possibility.

Hi Tony,

I'm just about to pass Maidenhead later today, we were stuck in Henley behind the lock closure this weekend so not been moving much to be able to repeat the problem.

The fuel being the issue I haven't dismissed, I just wanted to address the easier (for me) possibility first.

On 24/08/2023 at 19:26, ditchcrawler said:I am just wondering if he has removed the wire round the prop that he thought didn't matter

Hi Brian, when I say I dismissed it, I still cleared the prop fully however the wire was small enough that in my experience this would not of caused the issue, and indeed when the problem occured again (with the prop now clear) it seems now unlikely to be the cause. However, it is still possible that something is jammed that I didn't find.

So, now I have moved a couple of hours this morning, the problem has showed itself again and I can report that the prop moves freely by hand, however the temperatures look to be high.

The gearbox temperature when the problem occurs is up to 65 degrees. Thrust plate is 43, bearing is 38 and gland is 32. So it looks like the gearbox is overheating? And the heat is spreading down the shaft.

Does this sound right? Is 65 degrees too hot?

When it happened, I let it cool for 20 mins when going through a lock and the temperature dropped to 55. All seemed to be working fine again, but the problem occured again when the gearbox temp reached 65 again.

Does this narrow down the issue to the gearbox or could it still be one of the other options discussed?

If it is the gearbox, what could be causing it to overheat?

-

2 minutes ago, Tony Brooks said:

Assuming a typical narrowboat fuel tank locations.

Accumulate a number of plastic milk cartons, 2 litres seem the most manageable.

Get a length of clear plastic hose of say about 3/8" diameter and push a "wand" made of copper pipe in the end and bend it slightly.

Put a milk bottle on the baseplate with the other handy and one beside/behind it.

Put the copper pipe into the fuel filler and onto the bottom of the tank.

Now the bit you need to get used to the taste.

Give the other end of the plastic pipe a good suck and put your finger over the end of the pipe in your mouth to seal it.

Put pipe end with finger over the milk carton and release your finger, push hoes into the milk bottle so the syphon you created starts to drain the tank

Sweep the wand all over the bottom of the tank, paying special attention to the tank bottom to side joint areas.

As each milk carton fills move, a new one to be filled.

Keep going until there are no more dark bits coming up with the fuel and until the fuel in the plastic hose is a nice clear red colour.

Once you get the bits together, it should all be doe in 15 minutes.

You can stop at any time by lifting the hose higher than the fuel level in the tank, and even come back when you have accumulated more milk cartons.

You can use a syphon pump or in some cases an oil change pump or a Pella extractor but a length of plastic pipe and copper pipe is cheaper.

If you let the milk cartons stand for a week, the clean fuel can be carefully poured off, leaving the water, emulsified fuel and dirt in the bottom.

Post some photos of what settled out.

I have a Syphon pump, can I pull some fuel directly out from the bottom of the tank?

-

25 minutes ago, Tony Brooks said:

Which I suggested on 16th August and asked, as a diagnostic question, when was the bottom of the fuel tank last cleaned. Guess the reply.

My plan is to check a few easy things next time it happens.. the drive shaft still rotates by hand, and check the temperature of the parts when it shows itself..

If this doesn't narrow it down I'll look into the fuel which is a bit harder for me as I've not done that before.

Appreciate your input 🙂

-

Not been very far in last few days so not had the issue again yet. I did take some temperature readings after running the engine for 30 minutes which are below and look kinda normal, so whatever the problem is it seems to start all of a sudden after an hour or two.

Temperature readings:

Gearbox 43

Thrust plate 32

Bearing 29

Gland 25

-

Yuck ... Where did tomorrows forecast come from !!

Just above reading ATM.

Engine losing power after running for an hour

in Boat Building & Maintenance

Posted

Thanks 👍