Tractor

-

Posts

120 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Tractor

-

-

19 minutes ago, umpire111 said:

19 minutes ago, umpire111 said:Tx all now found it, what confused me was that I have an acoustic box round it and I thought the small inspection hatch would give access to it but I was wrong. Still not sure which bolt is the filler/ dipstick for the Prm 150 gearbox, any help please

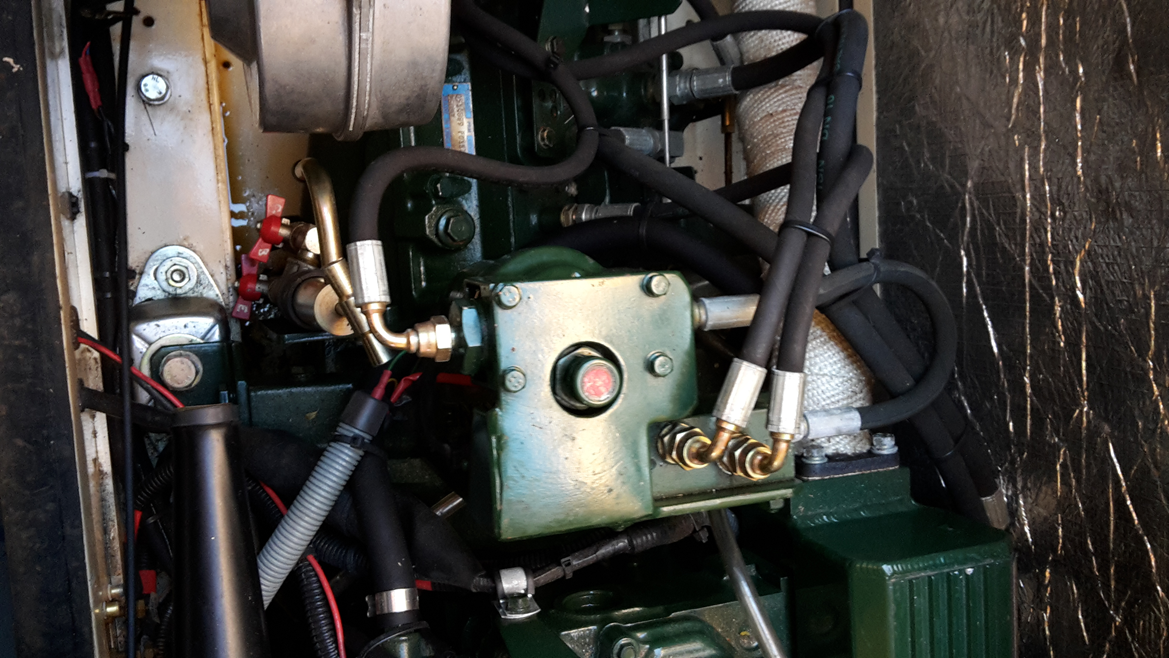

In the pic, the hex nut just south of the name plate. the nut has 'shoulders', I would put an arrow to mark it but missed the pic being posted........

-

I had the same snag, and with this type of regulator.

Press the over pressure button 'Hard', the clear plastic button, it will 'click', it will then be free to 'jiggle' about a bit. Hot weather recently has created the over pressure to trip.

Not my diagnosis, the site gas competent Engineer fixed this for me, having no gas would be a bit of the 'stopper' now we can venture out.

-

https://www.whateversleft.co.uk/other/the-foghorn-station-flat-holm-island

Gardner 3LW, 2 generators and a single Reavell air compressor, manufactured in Ipswich. A company subsequently sold by Howden’s to International Compressed Air Corporation.

The site was shut down in 1998, if the engines are still in situ I do not know?

-

My tiller is attached to the tiller post on a taper, held in place by a hex head screw. Take out the screw, waggle the tiller and it should lift off.

-

-

Yep, must get up to speed with the difference between Carbon dioxide and Carbon monoxide.........

From some reading, propane gas being twice as heavy as air goes to the floor; sensors then on the floor are subject to some contamination, working life then may be limited. Devices like Figaro semiconductor sensors need some time to stabilize, and also require a good heater supply.

https://www.bes.co.uk/amos-lpg-alarm-12-v-remote-sensor-13066, this link then looks useful, just what I need, thanks again for this.

Thanks again.

-

Thanks for the response, it appears that reliable Propane detection is more difficult to provide than carbon dioxide; detectors necessarily close to the floor are subject to contamination.

Thanks again

-

I have a 'dualwatch, combined gas and co alarm for boats', which is no longer supported. This device seems to be 'flaky', so will try to replace the propane gas detection element. This is for a narrowboat.

I would prefer a detector which is on all the time we are on the boat, so could run from the 12 Volt supply if necessary.

-

I am looking for a Propane gas detector, devices which look to be thin on the ground. Can anyone recommend a device please?

-

Each time the ‘Feeling good by water’ mantra is rolled out in support of these works, the effort and expense involved is demeaned. It must be surely be possible to drop the ‘marketing speak’, replacing it with the real investment in support of our heritage.

The management and maintenance of the canal real estate is a complex Civil Engineered task; these weak words of support from CRT, fail to do justice the the operation.

An ‘exasperated boater’.

-

This type of propulsion is more suited to high accuracy industrial applications, where a return on a large investment can be made.

Not for Narrowboat propulsion perhaps, but for a dive boat with a bell suspended beneath at many metres depth; here these systems earn their keep by giving millimetre accuracy in large North Sea swells.

Industrial electric motors, well tried in small boats, provide a quiet, infinitely variable speed control, do away with the need for gearboxes; but the need for energy is always present. A tank of diesel, or a stack of battery stored energy, each display some volatility, and damage to the environment.

Getting into dangerous waters now, these are just my impressions.

-

Permanent magnet Dc motors have been in industrial use for many years, powered by a DC drive the speed can be adjusted to suit the application.

Induction motors, or ‘squirrel cage induction motors, do not have magnets, but derive the magnetic force from an AC, Alternating Current, supply usually 3 phase 400Volt, they are relatively low cost, low maintenance, and rugged devices for industrial applications. For variable speed, inverter drive systems provide direction and variable speed.

The Rolls Royce device in the video will have ‘rare earth’ magnets, and very close tolerance manufacturing will produce high power, and high efficiency. The motor will have an electronic power drive for speed control, using embedded sensors in the ‘stator’ for monitoring and speed control. The design allows the motor package to be at the propellor as part of a swivelling pod, a system used for large vessels and oil rig’s essential for stability in high seas.

-

1

1

-

1

1

-

-

Check that the 'Matt' finish is not Bitumen. Wipe over a test patch with a cloth, wet with white spirit, if it comes off it will be Bitumen, and will not take any paint unless it is all removed.

-

Operation becomes intermittent, then stops, with the brushes failing to make contact. Checking the brushes in this way is the quickest ‘snag’ to eliminate. If this makes the motor run, I would then recommend lifting the motor out for a service to clean the commutator and re bed the brushes, checking the brush boxes for corrosion and brush dust.

-

Lift the brushes a few times under spring pressure, then push down. Brushes often stick due to damp and lack of use.

-

BB2 3AG, Screwfix, should be close by.

-

Their supply is only for the 'hire fleet', or 'Derv is not for public sale'.

-

A trip from Stratford on Avon to Cropredy,

Two sites on the Stratford Canal, three sites on the Grand Union, unable to sell diesel.

After a small amount of concern / panic, finally found Calcutt Boats, top of the Stockton Flight, with fuel for sale.

Clearly I need to invest in a couple of 'jerry cans' for the future.

Why is it difficult to find the stuff?

-

HATTON, going down (East), 21st Sunday, 0900hrs, excellent help from a Volunteer.

STOCKTON, going up (East), 23rd Tuesday, afternoon, again excellent help, from a Volunteer.

Cannot thank these guys enough.

-

When paralleling DC generators, the system requires a falling Volts load characteristic, in order to prevent one generator progressively taking all the load from the second generator, and load sharing is effective. Here this does not happen, when in use, I cannot see why this is the case? -

Look up CruisingThe Cut 80, latest VLOG, on Utube.

-

Yourex nr Benämning Pris exkl. moms: CA4512-53 Lister Petter Startm. 8778 kr Ersätter originalnr bl.a. Passar aggregat bl.a.  8778 kr

8778 krFabrikat CAV Ersättning Teknisk info 12V - 3.6kW, 11k, CCW Dimension Mer artikelinfo -

My heater, this is not pressurised, started tripping after I bled the rads, and failed to top up the header tank. I would not run for long, before stopping and then restarting.

I pulled a water hose back from the heater, let some water out, and then refitted the hose quickly, and all was ok after that. it is getting a bit ‘nippy’ out now so good luck with this.

-

Check the header tank level, and for air in the system, it mat be tripping out on overheat.

Handcuff key

in New to Boating?

Posted

The square drive, can anyone supply the dimensions. Sure I have one in my tool box to fit this, seem to be out of stock at CART.