-

Posts

4,825 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Theo

-

-

Do you remember "Holly" taken from Middlewich Narrowboats?

I never found out what happened with "Che Sera Sera".

-

A very useful blade for the Stanley is the hook shaped one with the sharp edge on the inside of the hook. This allows you to pull at bits of rope and cut through them and the same time.

-

1

1

-

-

The stoppage is current "Until further notice." Anyone know what's amiss? Any estimates of when the "further notice" will be issued?

Nick

-

... or whatever it's called. I'm talking about the bit that the pressure cap covers where you top up the enginne coolant.

The solder attaching the spigot on the side where you attach the overflow pipe is broken so it's leaking. I am mulling ove rthe best way to sort it.

- Replace the whole unit. I can buy a new one from Calcutt.

- Araldite it and see how it goes.

- Solder it.

If I do 1. then I need to be certain that I don't damage the aluminium header. I don't mnid damaging the filler assembly. I was thinking large pipe wrench and use ptfe tape when I screw the new one in.

If I do 2. I will need to clean up the assembly really, really carefully getting all round the spigot coupling. So I will need to remove the assembly anyway. Without damaging it.

Am I competent to do 3? I have soldered plenty of copper plumbing in my time using Yorkshire and capillary fittings but this looks more like a wiped joint to me. Lot's of sope for failure here. I would be using soft solder. Good enough?

All comments and suggestions eagerlyb read.

TIA

Nick

-

In the end I fitted a replacement supplied by Calcutt. I now have the old one in my workshop. If anyone wants to fit it with a new seal they are welcoe to have it. Sent me the postage or come and collect from HR5.

Nick

-

Sorry that I have been absent for a while. Thanks for all the hints and discussion. Jason suggest this which seems a good solution to me. He will add flexible engine mounts.

N

-

Theodora averaged 1.21 litres per hour over 2928 hrs while we wre living aboard.

N

-

Thanks Mr Ditchcrawler!

Here's a website for it. I looks as if it takes up much less room than the Python and is a small fraction of the price.

That's what Jason suggested but he couldn't remember the name at the time.

N

-

10 minutes ago, Tony Brooks said:

The Cetaflex B claims to allow for both angular and radial misalignment, but I suspect it is severely limited when compared with an Aquadrive or Pythondrive.

FWIW, I very much doubt he meant rubber engine bearers, probably rubber (flexible) engine mounts.

That's probably what he said. I may well have misremembered.

-

1 hour ago, Tony Brooks said:

I am sure Roger checked this, but as it is a 1.5, when the injector pump skew gear drive lubrication system blocks the skew gear can wear. One of the skew gears that drive the injector pump is on the camshaft, just in front of the rear bearing, and it is the same skew gear that drives the oil pump skew gear. You may wish to confirm that the camshaft gear was in good order.

Roger says:

The Camshaft is carefully checked, Tony is quite right, the skew gear can wear although the cross shaft driving the FIP has a pin drive to the female spline for the pump and the pin can get worn, we check this!

This is comforting to know but doesn't solve the mystery.

-

I have posted a thread in General Boating about Theodora's seized engine. Long standing readers may remember that Theodora has an unusual arrangement in her engine hole. The engine is mounted back to front with the gearbox on the forward end.

The order of units from aft to forward is Engine --> Gearbox --> stub shaft rotating between two plummer blocks with a triple V pulley between them.

The V belts connect with the propshaft which runs under the engine to a water cooled sterngland and then the propeller.

Problems: 1. The engine is mounted on wooden bearers which are very effective in transferring vibration to the hull and throughout the boat.

2. The two Plummer blocks and the gearbox need to be accurately aligned with each other. Any movement of the engine means that there are problems with the bearings. I last changed the stub shaft about 2,000 engine hours ago.

Jason Pinder suggests doing away with the belt drive, turning the engine around and mounting it about a foot lower in the engine hole. To me this seems a massive undertaking and would mean that the alternator and raw water cooling pump belt would be less accessible. He suggests rubber engine bearers to reduce transmitted vibration.

My favoured option is to leave the general arrangment as it is and fit something like a Python (I'm looking at the P60-B) drive between the gearbox and the stub shaft. The Python drive will mean that the engine would have to be moved aft a bit. I am not near the boat so I can't, at this stage say how much and whether it could be moved back far enough.

Are there any other flexible drives on the market that might take up less room? Jason mentioned something called Ultraflex but a Google search hasn't reavealed anything like a fexible drive.

All comments gratefully read!

Nick

-

Hello again.

The engine has been removed by Jason Pinder in Worcester. He took it over to Calcutt and the work has been done by Roger Preen and his mate(s). Roger sent me an email today to tell me that the works has been done. Here is the text of his sort of diagnosis. I still can't work out why it failed but then I don't understand the term "pick up" on a big end. He writes 1.8 in the las sentenc but that is a mistake. It's a short 1.5.

Dear Nick,

There was general wear ,as you would expect, but the failure was a seizure, of a main bearing and a pick up on a big end rendering a crankshaft replacement necessary together with appropriate new shell bearings and thrusts, the damage suggests a breakdown of lubrication, the oil pump was replaced but was not the problem neither was the pressure relief valve or any part of the oil train, the rear cam shaft bearing was slightly misplaced but this would only affect the valve train in which no significant wear was found, all camshaft followers were replaced, but this is always usual on the 1.8. I will send the “pick list” of what we used

Best Regards

Roger

Any comments?

Nick

-

22 hours ago, matty40s said:

Apparently the salt water inundated Teslas are self combusting too.

I've done a bit of investigation on this. It seems that it's another EV myth. A Little Book of EV Myths

N

-

1

1

-

-

I believe that Theodora's maximum beam is 6'10" but I would not want to trust that. Before I set of from Worcester I will make guage out of roof battens, set it to exactly 6'10" and check.

-

Theodora is presently sojourning at Jason Pinder's drydock in Worcester with the engine out and on its way to Calcutt for corrective surgery. She should be fixed in a couple of weeks. I would then like to get her back to her home mooring at Tardebigge Old Wharf.

SWMBO is a sensible lady and more cautious than I about the Severn as the weather changes so we will need a bit of careful planning before we set off to take Theodora up to Stourport to get home the long way. Doing the anticlockwise way down to Tewksbury and up the Avon is less appealing. The Avon can be a bit frisky in the winter. I last did a fast river winter trip up the Kennet in 2008 and it needed so quick action that I am less confident of achieving now.

I wonder if the Lock 58 repair will be a really long job like the one at Marple.

N

-

That's a frightening list of mishaps! Note to self: stay alert. Don't be complacent. Have someone cloise to the paddles.

N

-

We've been through a couple of times without incident but Theodora is relatively modern (1983) and only 6'10".

Anyone know the stuck boat?

-

Just had a stoppage notice. Cilling or something else?

Nick

-

Hugely helpful comments, thank you.

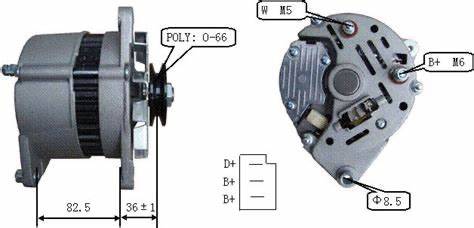

There was some squealing, which Jilly, Andrew's wife, noticed. She thought that it might be an alternator problem.

I'm about an hour and a half away from Theodora, unfortunately, so I won't be able to carry out the investigations for a bit.

I'm minded at this stage to get it to a boatyard and let the experts take over.

N

-

No. 1 son took his family for a four day cruise. He rigged the anchor saying "We'll never use that." before setting off down the river. After a couple of hours the engine seemed to lose power and then stopped. The starter motor could turn the engine which fired but could not keep going. Anchor deployed and waited to be rescued by a passing boat. Towed to a safe mooring. I went down to see him this morning and have listed below the signs of engine sickness:

- During the progressive failure no overheating detected.

- No excess smoke.

- Fairly rapid loss of power.

- Starter motor had difficulty turning the engine over.

I checked the following when I got to the boat

- Battery voltage: OK

- Alternator free to turn: OK

- Propeller and associated transmission free to turn: OK

- Crank shaft free to turn? (Spanner on the nut at in the middle of the pulley) Wouldn't budge. Seized, no rotation, not right! Aargh!!

I have inferred from this that our BMC 1.5 which has been 100% reliable over nearly 6,000 hours of cruising since we bought her in 2006 + whatever hours she had done from 1983 to 2006. (OIl and filter change about 200 hours previously.), that the oil pump failed so there was no lubrication of the crankshaft bearings or big ends or whatever else is fed with oil from the pump.

Is my inexpert inference likely to be correct?

I now need to make somes decisions in consultation with my sone and his family who want to take ove rthe boat and I am getting a bit on the ancint side.

- Repair that engine.

- Get a reconditioned BMC 1.5 from Calcutt or somewhere else and have it fitted by a professional.

- Get a different, more modern and quieter deisel engine and mount it in a more conventional way. This would mean a new propeller as the present on is left handed and I would like to turn the engine around rather than continue with the belt drive.

- Fit an electric drive system (series hybrid) This is a pipedream sort of idea from my son it sounds a very expensive option to me. Guesstimates of the issues and costs gratefully received.

The current cooling is indirect raw water. I like this and would like any replacement deisel to use the same system. It has never given us any trouble and if this can be done won't need a skin tank to be fitted.

What do you think?

Nick

-

23 hours ago, Eeyore said:

Yes, it does. Thanks

On 14/08/2024 at 11:10, beerbeerbeerbeerbeer said:How far you got along the Staff and Worcester?

There’s a good bus service along there that’ll take you in to Stafford or Rugely if you decide to find somewhere to recondition an alternator.

And the Hire Base at Great Haywood are very helpful, they’ll order parts up for you and I reckon they’d crimp up terminals and supply the wiring if you ain’t got the right bits and bobs on board

Thanks for the helpul hints. We have a deadline to meet and need to get back to Tardebigge on Friday so we will exist on battery and solar until then.

-

1

1

-

-

I'm looking for a repacement tunnel lamp for the good ship Theodora. I've had a look at tth Midland Chandlers web site but the range is very limited and the only one we somwhat liked was really expensive. Any ideas for alternatice suppliers?

-

3 hours ago, Tony Brooks said:

Yes, but you only need to clean the faces the belt runs against. If you left it, then the belt may well be worn away, but it would gradually get cleaned, it just depends upon how many belts to are happy to fit. I suspect many pulleys go rusty during winter layups, but few bothers to clean them in the spring. I have known the odd belt to rust onto the pulley. Best de-rust to minimise the possible danger of belt failure/premature wear.

That sound like good advice.

-

Lots of good advice thanks

1 hour ago, Tony Brooks said:1. I would use emery paper to clean up the V faces of the pulley.

2. Any alternator/starter shop or maybe a local garage will spin it off with an air or good electric impact wrench.

Can I infer from this that it's not advisable to leave it and let it clean itself up in use?

Canvas repairs

in Boat Building & Maintenance

Posted

I'm looking for someone near Kington, Herefordshire who can do some repair work on Theodora's cloths. Any thoughts? She is currently being painted in Worcester so that would be convenient too.

All ideas gratefully received.

Nick