-

Posts

752 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Kendorr

-

-

“There were a number of challenges associated with this unique structure, but the whole delivery team worked together tirelessly to ensure that each aspect of the works was delivered. The plan was monitored and adapted and each party’s needs were met so that the works could be completed safely and ultimately, so that the tracks were handed back to traffic on time.”

It's strange how so many are praising the work and how everything went to plan! The only 'party' who's needs are still not met are us boaters.

-

2

2

-

-

Also, if you're opting to wait for Keadby, join Trentlink FB group

https://www.facebook.com/groups/666937220961360

Single handing, I always prefer the Huddersfield Narrow canal, but that has more than it's fair share of problems too!!

-

1

1

-

-

-

-

-

Nice short video showing the task ahead!

-

1

1

-

-

16 minutes ago, Bee said:

double sided closed cell foam for windows

I've always used neoprene foam, 6 or 8 mm thick, depending on how out of shape the metal is. Used this on my new build and not had a single leak in 6 years, started using in when re-sealing the windows on my current project, I buy from Ebay, just type 'neoprene foam' in the search.

-

1 hour ago, David Mack said:

Where do you find reclaimed marine ply?

Facebook market place, at £10 for a 5*4 sheet of 25mm and £10 delivery, 6 sheets were a no brainer.

49 minutes ago, jonathanA said:I'm sure you have thought about how you can add/remove ballast once you are fitting out and maybe adding weight (e.g stove) on one side

I've removed quite a lot of weight, boat used to sit at 27", with what I've put back in she should sit nicely at 24". There will be a stove going in and I've got a few metal weights to be used in and around to trim the float balance.

-

-

Had nice weather yesterday so decided to put some ballast back in. Used some engineering bricks for the first 3 bays, the old broken up paving slabs will fill the rest, but that will wait for another day.

Somebody mentioned using the garden netting to create the air space and it appears to be a good call.

-

2

2

-

-

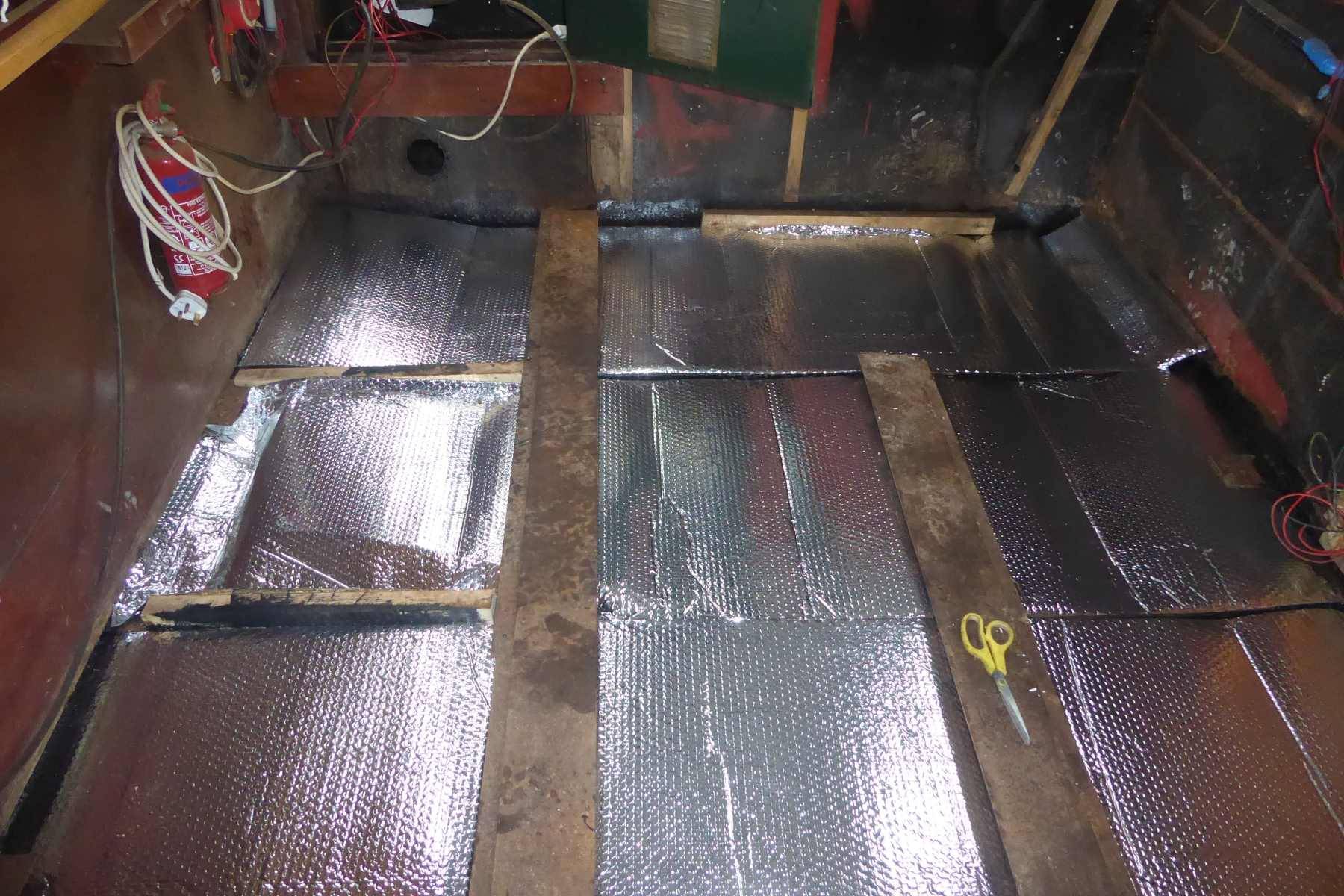

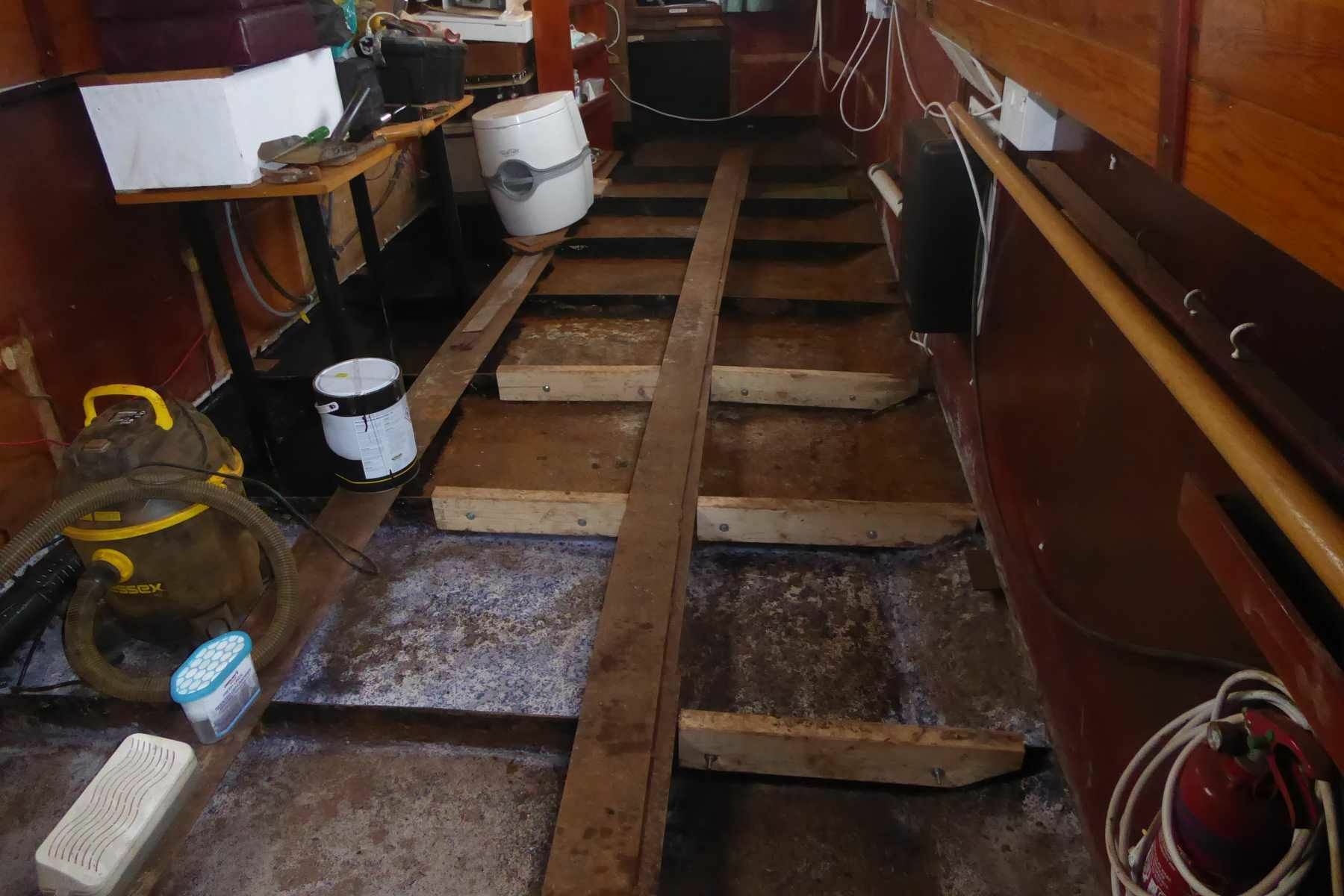

A good bit of progress made, removed all of the ballast and chopped the shower tray out. The steel at the stern was a bit rusty, but it has been cleaned and treat with Fertan. The rest of the baseplate had surface rust, but the original paint was still mostly intact. This has been cleaned and a new coat of blacking applied. The Fertan hadn't cured enough before I came home, so that will be blacked next time I go.

The baseplate thickness is between 4.8mm and 5.9mm, I'm happy with that for a 38 year old boat.

-

1

1

-

-

14 minutes ago, Midnight said:

Okay you edited out the bit where Duncan screamed and I sh*t myself. If it had got as bad as Simon's trip I would have left you there and got the bus. Never the less great video memories. Thanks Kevin.

It was a once in a lifetime trip for me Frank, my thanks go to you for organising it all. My new project only has a 10 hp single cylinder engine, I won't be taking her over, although I'll still be using the Trent.

I actually didn't edit it out, I've looked and listened very carefully and the camera didn't pick it up!!

Hope you both have a good 2024.

-

9 hours ago, Midnight said:

the wind got up to17mph NNE so the turn into the shipping lane was rather exciting.

Exciting maybe isn't the right word!

If anybody want's to look, nothing special, but a bit of film I managed to save.

-

14 minutes ago, truckcab79 said:

Bet your ears are ringing

Pardon?

🙂

The base was about 2 inch and the upstands about 5 inch. Glad it's out!

-

Here we are then, just over an hour hitting with a small sledge hammer and a bolster chisel and it was all out, never even took the drill out of it's box.

I cleaned a bit in the middle and used my thickness tester on it, showed 4.7mm, the metal does look in remarkably good condition.

Also, when cleaning up I've noticed a gap between the bottom step and the inside bulkhead, so any water which drains down the step comes into the boat, hence all the water inside. I'll be sealing this next time I go and drilling a 25mm hole to give drainage into the engine bilge.

Thanks again for all the advice, I'm going to have a rest now.

-

3

3

-

-

3 minutes ago, truckcab79 said:

If it’s new (think you said you were borrowing one mind)

Mate bought it 2 years ago to drill bolts into his garage base for extra security, so it is 'as new' - we shall see what tomorrow brings 🙂

-

11 minutes ago, truckcab79 said:

SDS just tickles it especially if it’s a lightweight one

Titan 1500W TTB279SDS - Never used one, so we shall see how we get on.

-

Wish me luck, tomorrow is the day.

I've got the SDS drill ready, along with the ear defenders, goggles and dust mask, I'll add a pic tomorrow to show how it went. Thanks again for all the advice.

On 22/12/2023 at 13:13, magnetman said:I get the idea its an old Boat about 1980 or something.

The info I have is that it was built by Delph Marine in 1985.

-

Have you got Canalplan set to not take you on rivers?

As there is little difference in time or distance, peace of mind would suggest sticking to the canals, if you want to cruise the River Severn, plan a trip from and back to your new base.

-

Personally, I used clear reinforced pvc pipe all the way, my shower trap is basically in the centre of the boat, it's now 5 years old and has been fine.

-

1 hour ago, Peugeot 106 said:

How about building a small fire underneath the boat.

Thanks, but I think I'll give that one a miss for now.

-

35 minutes ago, ditchcrawler said:

Dont forget the goggles

Absolutely, as retired Technology teacher I always practise what I drummed in to my students 🙂

-

33 minutes ago, David Mack said:46 minutes ago, jonathanA said:

I've found a SDS hammer drill on rotation stop to be a very effective device for breaking up concrete chiselling out brick work etc. Not necessarily very quick but a damn sight easier and quicker than a lump hammer and chisel. I'd use smallish chisel bit.

And if you don't already have one, worth buying a cheap corded 240V model from screwfix/toolstation/aldi/lidl just for the job. They usually come with a selection of bits which will be good enough for the job.

And I've just found that a very good mate has one with a couple of chisels that will be borrowed for next Thursday. I'll let you know how I get on.

Thanks again for all the replies.

-

19 minutes ago, magnetman said:

hit the area with a big hammer? Probably not but if so you might get an idea what the condition is like and whether there may be rust between the concrete and the steel.

Good idea, if nothing else it may break any bond between the concrete and the steel. It's sat on 2 sleepers, so only about 9 inch space, but I'll give it a go - I'm not intending going back 'till a week Thursday.

My new project

in Build Blogs

Posted

Basic wiring loom installed, upper walls insulated, upper wall panels all cut to size and the 2 bulkheads prepared and temporarily fitted in place.