Jo Green

-

Posts

56 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Jo Green

-

-

Thanks BEngo. Yes, it’s the external collar so mostly worried about rust. Don’t want to have to repaint too often!

-

Thanks Ray. Looks good.

-

Hi,

I have had a flue collar made for my stove chimney and I now need to paint it black. Any advice on which paint is best to use for quality and longevity?

Thank you

-

Good point. I hadn’t considered that the NRV could be part of the problem...

-

Thanks. I’ve installed a non return valve where the washing machine hose meets the skin fitting hose. Therefore given the washing machine hose necessarily loops up via the top corner of the washing machine it’s unlikely that it’s being filled back up by water running back down the hose.

Regarding the pump not being strong enough, this seems most likely but with the waterline being considerably higher than the top of the washing machine I’m not sure what I can do. Any thoughts?

thanks

-

We have plumbed a standard washing machine (Zanussi Lindo300) into our Dutch barge which is moored in a marina with 240v shorepower.

We have installed a skin fitting outlet which the washing machine is plumbed into via a couple of metres of hose (additional to the approx 2 metres of standard washing machine waste hose which comes attached). The skin fitting is approx 1 meter above the top of the washing machine.

We only installed last week and don’t seem to be able to get it to work. At the end of the cycle there is still a substantial amount of water in the machine.

Any thoughts or advice?

Thank you

-

Thanks everyone for your advice. I will look into calorifier + immersion heater. I wonder how many watts it needs? We are only plugged into 16amps.

I will also have a look at the potential Morco replacement.

-

Hi Dave,

we have space but because we live in a densely populated marina and have a big, loud engine, we don’t want to have to run it too frequently. We also have two very small children so the instant element of the LPG water heaters is appealing.

-

Hi Alan,

thanks for your reply. I have done a comprehensive search and the Morco F11 isn’t available anymore. I actually ordered one from EBC and they called me the next day to tell me that they’re no longer being produced and aren’t available. Their website just needs updating.

We don't currently have an LPG water heater on this boat. I had one on my last boat- not room sealed and with pilot light but I’m trying to increase safety this time round. Maybe not possible and will have to go for standard non-room sealed version.

-

Hi,

We’re looking to fit an LPG hot water heater in our boat. We are moored in a marina so have mains electric. We were planning to get the Morco F11 but it’s no longer being manufactured. Can anyone recommend a decent equivalent? Looking for room sealed with balanced flue and electric ignition (no pilot light.)

this is one option I’ve found..

https://www.amazon.co.uk/TTulpe-TTCM1230-C-Meister-P30-White/dp/B0744G9V9G

Thanks!

-

On 06/09/2018 at 21:58, TheBiscuits said:

That's more in line with my thinking - you can get different grades of IBCs for different purposes, admittedly at a cost. Sewage is quite a "nice" thing to store compared to some of the stuff you get in IBCs, so there will be one available for a straight swap if that route suits you.

Speak to a supplier of IBCs and tell them you want to store a ton of sewage in a living space and ask what type they recommend

Thanks for this info.

-

On 06/09/2018 at 21:34, Dr Bob said:

I am sure IBCs are not a good idea for this application. I have emailed a colleauge in work to get his 'very' expert opinion. Waste tanks made out of 'plastic' are normally HDPE (High density Polyethylene) and are made by rotomoulding (some people actually refer to the polymer as MDPE ie medium density PE as it is not quite as high density as HDPE). The end product usually has a thickness of 9-10mm and is stiff enough to support its own weight and the weight of the material it is holding. They are designed to last 20 years plus. They are very similar to the green oil storage tanks found in your garden if you have oil fired heating. These should last 25 +years out in the sun.

IBCs however are made via blow moulding and although the polymer is stronger and tougher than blow moulded PE, it will be much thinner in section. It does not need the rigidity of a rotomoulded tank as the metal frame holds the tank in place. I guess, it will be at least half the thickness if not more ie maybe 3-4mm - but this is what I am checking with my 'expert'. Thickness is the key for permeation of gasses (and hence smell) so it really will not be good to have that thinner section. I also have a feeling that IBC have a more limited shelf life and are designed to carry 'industrial' liquids but not for 20 years. I certainly wouldnt use one more than a couple of years. Polyethylene degrades in a number of ways but one is Environmental stress crack resistance (ESCR). IBCs will normally have very good ESCR but again, after 10 year, stress cracking will have put thousands of small cracks into the polymer which will enhance the permeation of the smell. A 10mm section is much better here.

I will report back tomorrow if I get any further information.

An alternative to HDPE waste tanks is Polypropylene tanks. I dont recommend those as PP becomes very brittle at temps approaching 0°C and could easily smash if you drop something heavy on them ie a hammer. Use HDPE. I have worked in plastics for 40 years and would much rather use a good rotomoulded HDPE tank than a steel, metal or PP one. I have one on my boat.

Thanks so much for this information Dr Bob. Really useful.

On 06/09/2018 at 21:40, Dr Bob said:Just an add on to my previous post. IBCs are used to carry a lot of different industrial liquids. The stress crack resistance of HDPE varies dramatically with what the IBC has contained. Some liquids are fine. Some are not. If say the IBCs you have are 2nd hand and have been used for industrial usage and say have carried a strong ESC actor....ie a strong detergent, then that could have put significant microcracking into the tank before it was put into your holding tank duty, making it even worse for the smell. Were these new tanks when installed or had they been recycled following industrial duty?

Hi Bob, I don’t know if the tanks were new when installed or recycled. They were already installed on the boat when we bought it. We could ask the previous owners. It seems we definitely need to replace the tank though.

On 06/09/2018 at 18:43, Boater Sam said:We had a boat with sewage smells which proved to be the twin wall reinforced polythene pump out pipe and vent running up to the roof in a wardrobe.

So the stink will permeate through the IBC tank for sure.

You need a metal tank to be certain though some makers assure that their plastic tanks are OK, I would not trust them.

You will have to look at the pipework too if it is polythene. I used solvent weld domestic waste piping and fittings on the hire boats with silicone rubber automotive radiator hoses and pipes where we needed flexibility.

Thanks for this very useful info

Sam.

-

2 hours ago, Boater Sam said:

We had a boat with sewage smells which proved to be the twin wall reinforced polythene pump out pipe and vent running up to the roof in a wardrobe.

So the stink will permeate through the IBC tank for sure.

You need a metal tank to be certain though some makers assure that their plastic tanks are OK, I would not trust them.

You will have to look at the pipework too if it is polythene. I used solvent weld domestic waste piping and fittings on the hire boats with silicone rubber automotive radiator hoses and pipes where we needed flexibility.

Thanks Sam, really useful information.

2 hours ago, Alan de Enfield said:Reckon you are 'right'

(The fill caps on the top of ours are about 10" across)

Is there any sign of the original tanks (or was it a sea-toilet) ?

No original tanks. What we have now is what was onboard when we bought the boat.

-

Thanks all for your advice. We bought the boat in Holland last year and this was the set up that we inherited when we bought it. The boat is a 1925 mussel boat, 26m x 4m.

The boat is moved to the pump out point in the marina when the tank is full.

So it seems the tank may be inappropriate as we thought.

Thanks for taking the time to reply.

jo

-

Hello,

Looking for some advice regarding our waste tank situation. The boat has a pump out toilet with large 1000l waste tank. It is quite smelly inside the boat and we’re trying to narrow down why this is. The tank is identical to the potable water tank on board. Could this be the issue? Not the correct tank? Link to the tank below:

If not we’ll have to investigate other possibilities. I’m thinking pipework, seals, tank lid, tank treatment- we use Elsan blue as this had been used previously so more organic options weren’t available to us.

Anyone got any ideas of most likely scenario?

Many thanks,

Jo

-

Thank you so much Jon. Very helpful.

-

-

Hi,

Thanks for all your previous help. We currently have the Kabola running. It’s easy to light and runs well, heating three radiators in the boat. Radiator one is small and the highest in the system. (See pic 1) It sits in the engine room, near the Kabola. Radiator two is larger than the other two put together and sits midway down the boat. Radiator three is small and towards the bow of the boat. Radiator one and three heat up quickly from top to bottom and seemingly have no air inside. Radiator two is quite obviously only half filled with water. You can clearly feel the heat ends about half way up.

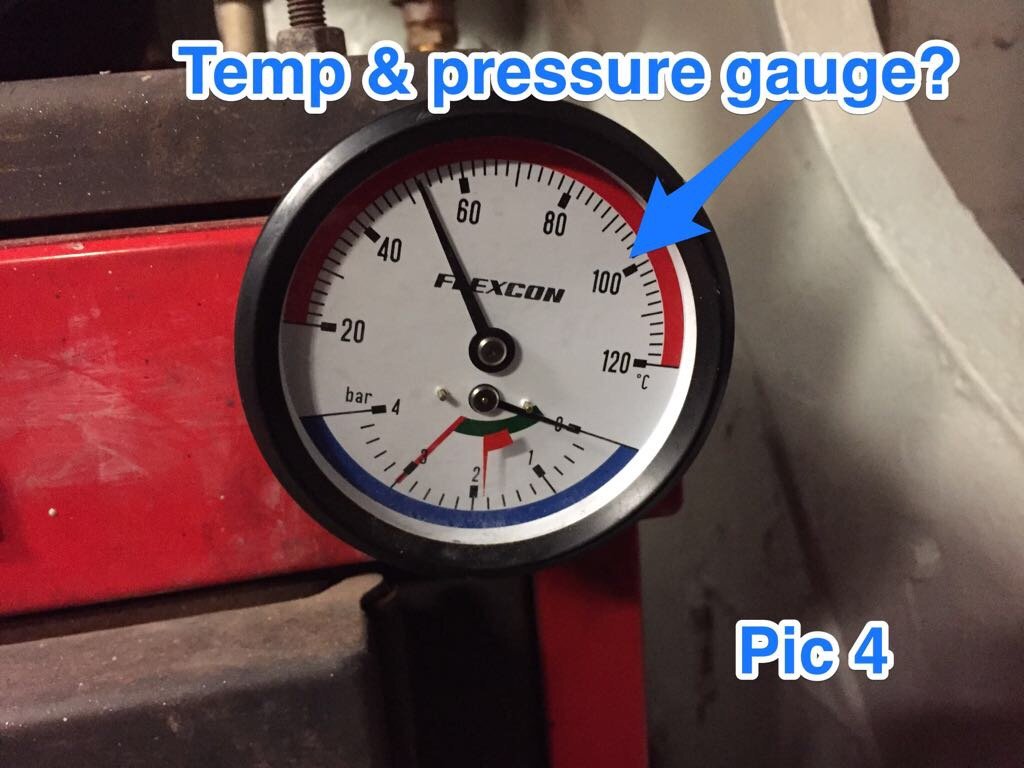

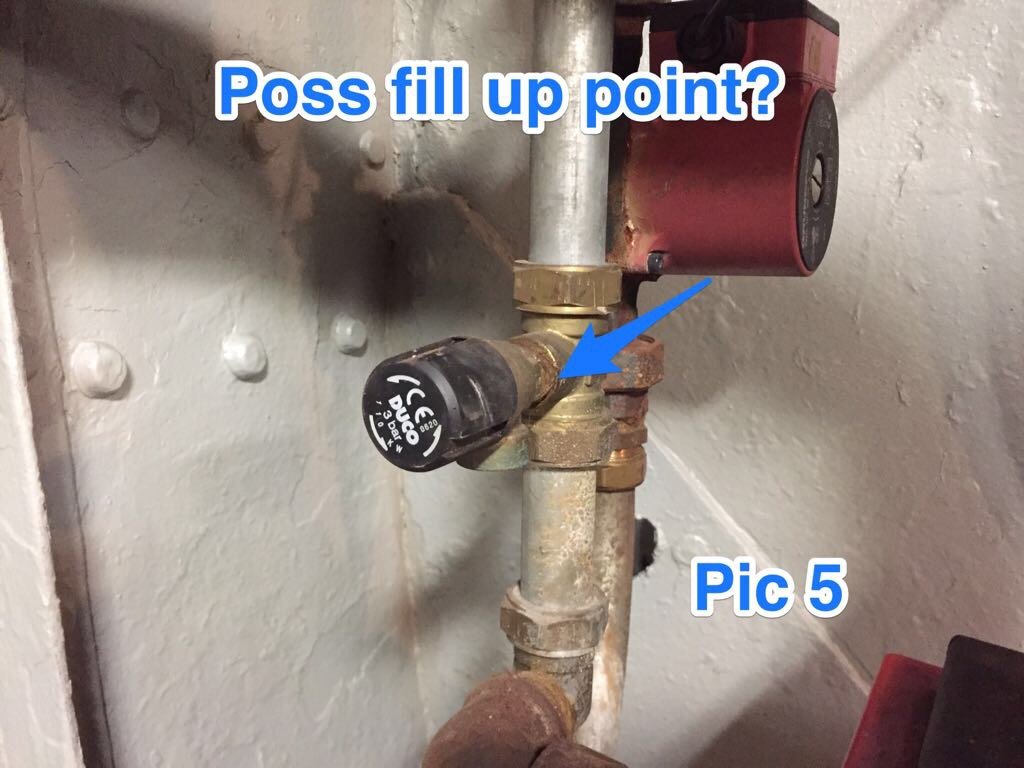

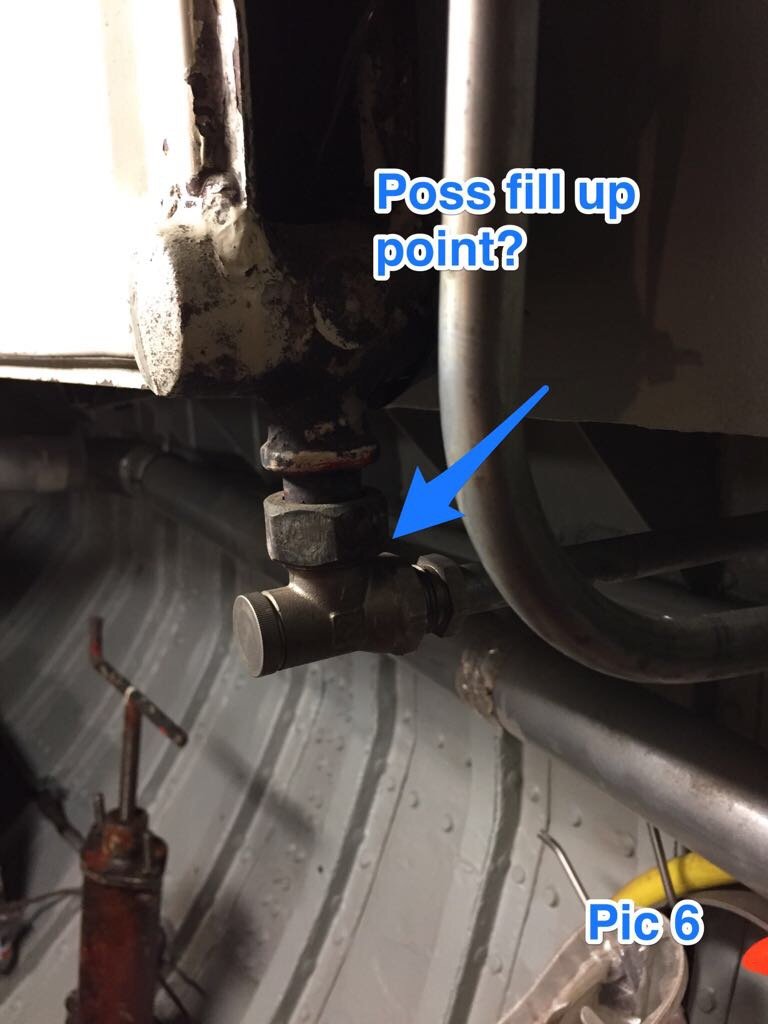

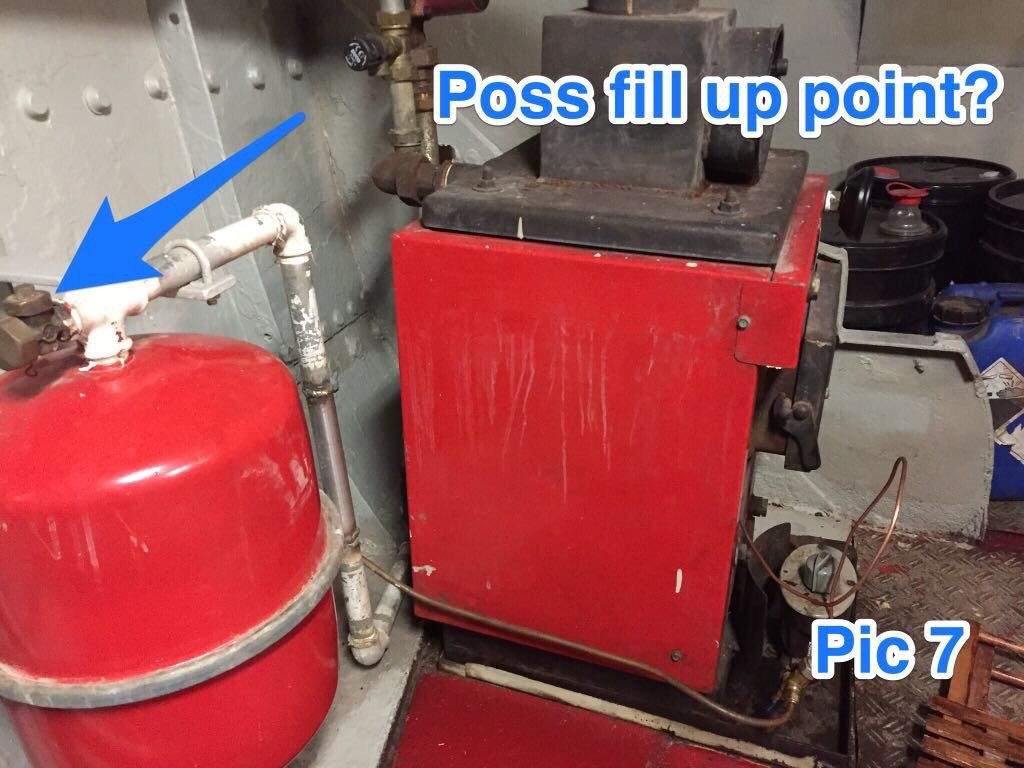

We have studied the system and we think we’ve found an expansion tank (see pic 2); a pressure relief valve (see pic 3); a temp and pressure gauge (see pic 4) and seemingly no fill up point. (Possible fill points- see pics 5, 6, 7.)

The pressure gauge indicator never leaves zero whether the boiler is running or not but the plumbers tape where it connects to the Kabola looks new and the gauge looks like the newest part of the system. (I’m hesitant to believe it’s not working.)

Please excuse the slighty rambling description. I’m trying to communicate everything as clearly as possible. Is it possible, given that the system seems to be only 60% full of water, that the pressure gauge is working fine but there simply isn’t any pressure in the system?

We can’t locate any obvious fill up point (certainly not two check valves in a row.)

What would the risks be in seeing if radiator 2 wants to bleed air?

Your advice and help is much appreciated.

Jo

-

Hi,

we have a Kabola E7 series which we now have up and running. There’s a bit of a safety issue though, which I’m not sure how to fix...

Every now and again the power cuts out in the marina. When this happens, the circulation pump stops working and the water is left boiling with nowhere to go. Would an overboil protection decide solve this problem? There’s isn’t currently one fitted.

Thanks,

jo

-

Hello,

the Kabola is working and bringing much needed heat! We are over the moon!

One more question- the main radiator is only hot at the bottom so presumably needs bleeding. With a pressurised system can I just go ahead and bleed to radiator? The last system I had (a mikuni) had a header tank so I could easily add more water to the system. How does it work with a sealed and pressurised system?

Thanks in advance,

Jo

-

Thank you for all your help. We’re working on it tonight.

-

Great. Thanks

-

Thank you. I've ordered a new thermocouple from Kuranda. Hopefully when that arrives and is fitted we might get it lit. I think there is too much of a build up of soot and oil in the bottom of the burner pot so need to get that sorted too.

Cuthound- we have no markings on the regulator as it's old and worn. Whereabouts is position 2, do you know?

-

Hello,

One thing I forgot to mention- we never saw the thermal shunt supplying fuel. It stayed dry and seemingly untouched by diesel each time we lit it even when we had the button of the fuel protection device depressed.

Should fuel have been dripping from this nozzle?

Working on the theory that this pipe could be blocked we sought to clean it out but unfortunately broke it. (See picture).

We've established that the fuel is flowing into the regulator fine from the daytank and the filters aren't blocked. The regulator is definitely working and allowing fuel to flow through.

Any advice?

Thanks!

Galvanic transformer

in Boat Equipment

Posted

Hi,

We are planning to upgrade from galvanic isolator to galvanic transformer. Our boat is currently on 32 Amp. I found this transformer and nearly went ahead and bought it, however, I’m not sure it meets the wattage requirements. (32 x 230 = 7360w), this transformer falls short. Any advice or recommendations of different transformers appreciated.

https://www.batterymegastore.co.uk/product/victron-energy-isolation-transformer-7000w-230v

Thanks

Jo