-

Posts

290 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Karen Lea Rainey

-

How to fit an expansion vessel?

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

Hi guys, thanks for your replies so far, perhaps it's not a surecal branded calorifier, And it's some other manufactured brand. Every pipe either going in or out of the calorifier is at 9 o clock, There are only 5 points of entry / exit fittings, there is no immersion fitted, the whole tank is covered from top to bottom in foam except for eberspacher in and out (2) Engine coil pipes in and out (2) PRV Exit pipe hose (1). All entry exit pipes are about 2 inches apart in a straight row along the length of the horizontal tank. -

How to fit an expansion vessel?

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

Thank you, There is an NRV (none return valve) on the cold feed in , hence the prv working correctly when the water heats up. So, will the water be generally held in the calorifier due to a vacuum being created, ie just a little spillage? -

My calorifier does not currently have either an accumulator tank or expansion tank fitted. Everytime I use either the engine or eberspacher for heating / hot water, my prv opens and sends drips of water into my bilge. I pride myself on having nice clean and dry bilge, given that there will be little work for the bilge pump to do except from the few drops of water from the stern gland. I am planning to fit an expansion tank in the hot water outlet from the calorifier, the plan is to put a 't' piece joint in the pipe and reduce the work that the prv is likely to do. I have a 55 litre surecal calorifier, with hydronic w5 eberspacher and engine coil dual ( twin coil internal pipes). The calorifier is under the bed, horizontal and all of the water feed pipes are positioned at about the 9 o clock position as you look at it end on. The pipes all then go 90 degrees of the calorifier to the floor and go off to the taps ,radiators, prv leak off pipe etc. And travel along the floor/ skirting board. I realise that I need to empty the calorifier somewhat before creating a 't ' piece in the hot pipe, but how do I make sure that the contents of the calorifier are "emptyish" and I dont get a flood of water everywhere when I break open the pipe. Should I turn of the feed in from the water tank ? and just run the hot tap until its empty? will it ruin the water pump to just pump air? Turn the prv valve to purge the water out? Or is there any other way to reduce the amount of water lost when fitting the 't' piece

-

My eberspacher wont fire up below 12.6 volts, start the engine let it run a while which will begin charging your batteries up, then switch your heater on, it should come on no problem.

-

I took my boat out last week because I'd been doing menial tasks of wiring, grouting and cleaning on the boat for a good few weeks. Off I set as a treat to enjoy the boat, within 1 mile, it was 100 yds forward, stop, reverse, get the leaves off the prop due to a feeling of going through a 'leafy custard', each time it cleared the prop, then forward again, stop, reverse again. Turned round straightaway and went back into the Joy's of the marina. Give it another few weeks and the leaves will have sank to the bottom of the cut. Oh well, get the kettle on, fire lit, on with the other little jobs once more.

-

There looks to be a tap ( on/ off) just above the engine in "text", its almost hidden, Is it partially closed screwed down restricting the flow through the calorifier. Open it fully and check your taps after half an hours engine running.

-

If you can feel the 2 grey plastic water pipes, engine in and engine out, They should both be more or less the same temperature to your hand, If they are not you obviously have a blockage / air lock in your engine circuit. Your webasto or ebershauer heater is a totally different water circuit, again these will be an in and out and the same temps to your hand. There obviously isnt any airlock in that system or you would not get hot water from switching it on. Start by feeling your skin tank pipes, same temp or not, air lock there, they will be different temps and so on.

-

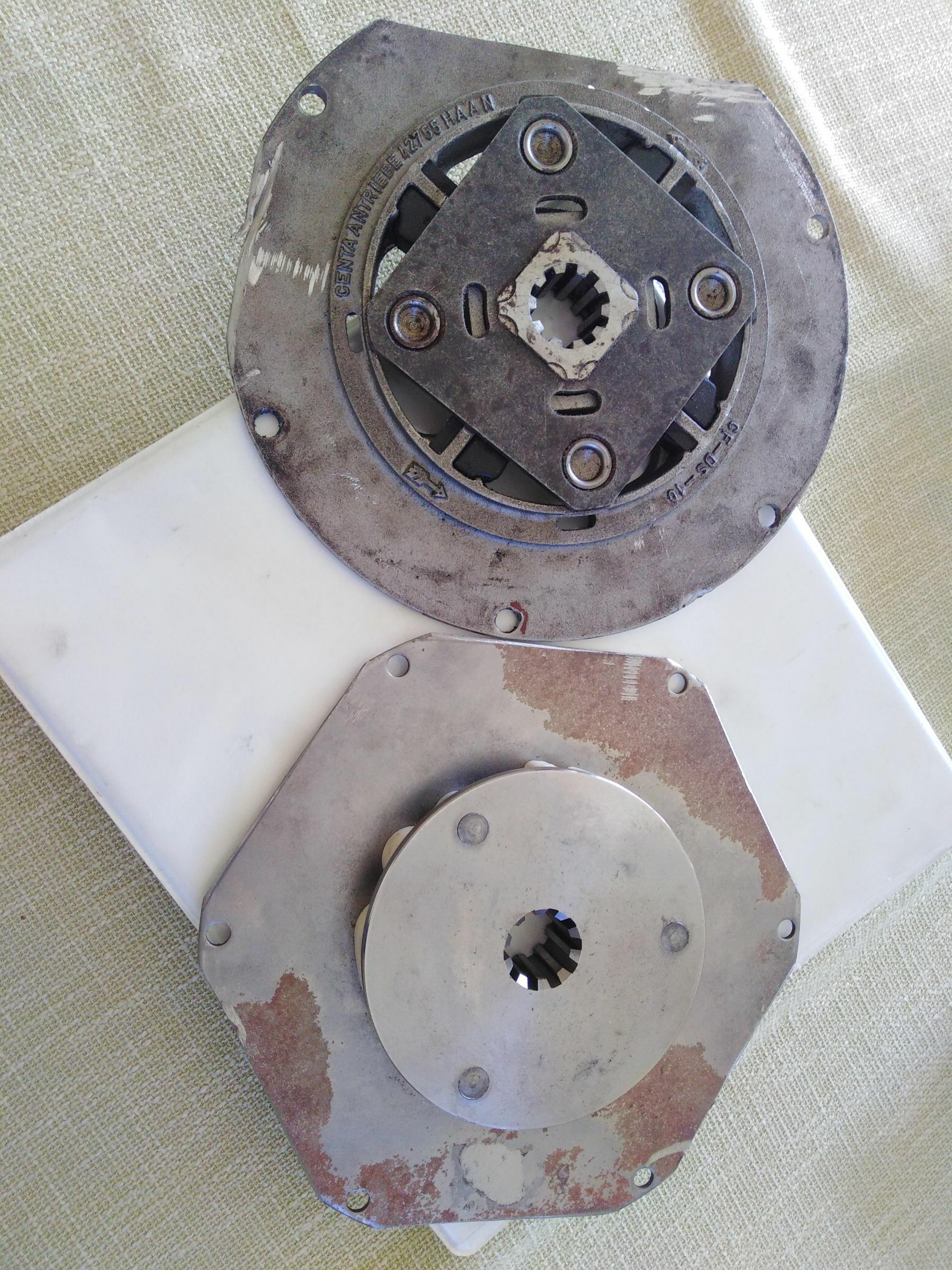

Grinder on existing drive plate, got it out easy, it was a CF DS 10, not a lot wrong with it to be fair, rubbers still in fact, just a bit out of cushioning quality. Anyway, gotta replacement from the local chandlers, no stock of the recommended 22 B 60, so matched one up with the same hole spacing g and the same size, it was a R and D 22 AM 95 but cost an extra £30, Cut the plate down evenly on all straights, it went in the housing like a charm. All back together now and no more rattles. Thanks for your help guys.

-

Hi Tracy, I'm a bit puzzled by this, if my bell housing is connected or welded to the long strut supports / feet. How can I then remove the bell housing without lifting the whole engine out. The long green struts / bars are one continuous steel bar, or is my bell housing part of the long struts in one long piece including the mounting frame for the forward feet, it doesnt make sense!

-

Hi All, I'm after some advice from anyone that has done a beta 30 driveplate change. Basically it's quite rattly in neutral, and almost disappears under load, goes into forward and reverse with quite a clunk. Anyway I have split the driveshaft, removed the gearbox prm 80, undone the six bolts holding the plate on the flywheel. Should be now able to pull the drive plate straight out of the bell housing ! I've tried all angles to slide the plate out, top to bottom, side to side etc and Visa versa. The damper plate is not coming out any which way. It's so very nearly out, but not. Took a break to think about it, rang Beta marine help desk. They say because of the age of the engine 2000 build, the drive plate would have been put on the flywheel first , before the bell housing, the engine mount struts are attached to the bell housing and you will have to lift the engine or Jack it up to remove the bell housing. Surely there is an easier way, Trying grinding the housing to create more space but I'm not having much luck at the moment, Can anybody offer another solution that works?. Pictures shown, your help would be appreciated.

-

This post cannot be displayed because it is in a forum which requires at least 10 posts to view.

-

Costs of replacing an engine.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

I originally thought the gear box which was on the red beta 28 was a PRM 120, it wasnt, when I purchased the green Beta 30 it had a Prm 80 on it, The Prm 120 had worn cones, so was swapped back out for the original gearbox, (the 80). -

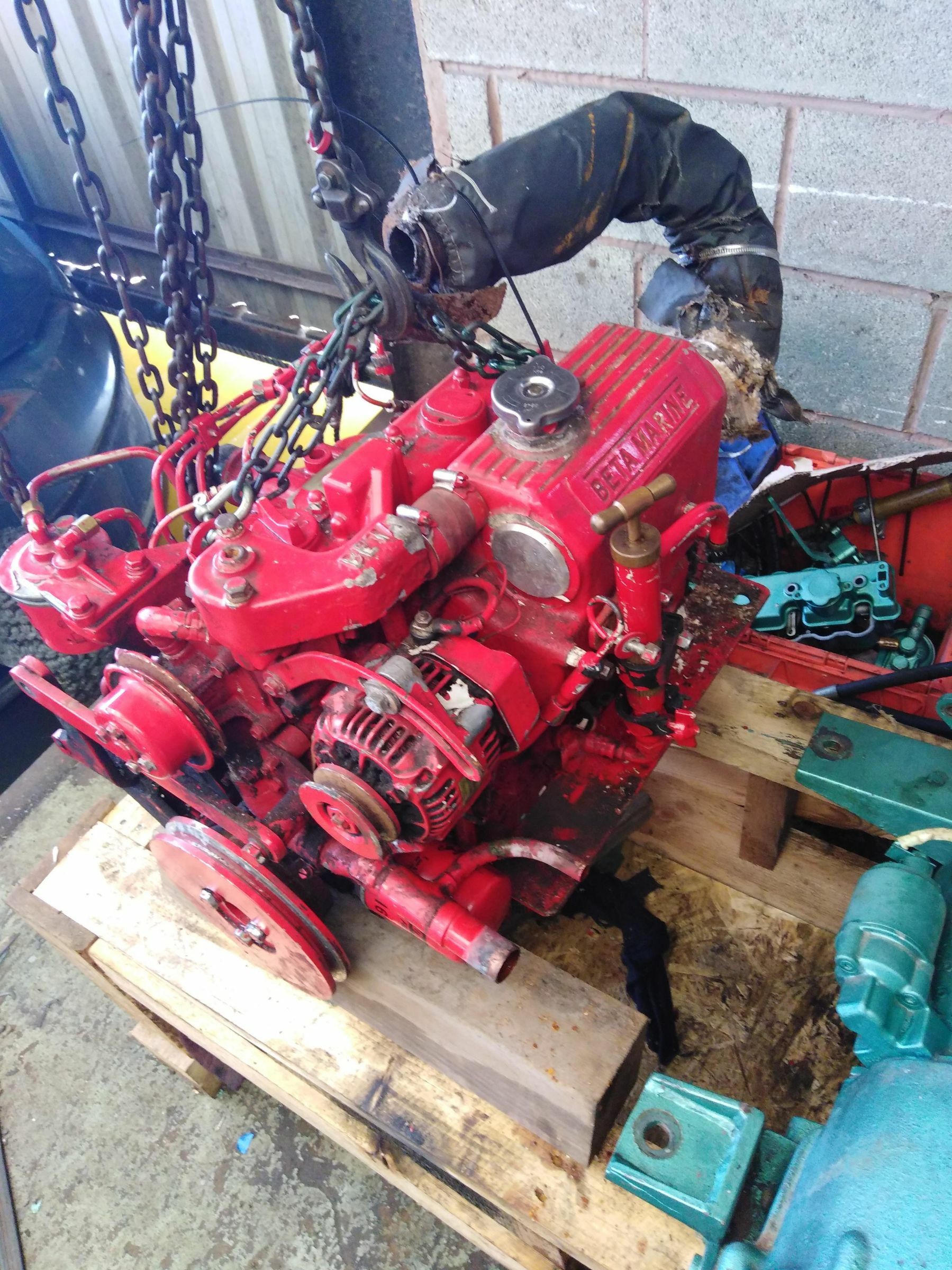

Hi All, Having just had the costs of replacing a seized engine, I thought it might be useful to show the costs involved. If you have seen any of my recent posts regarding a seized engine. I purchased a reconditioned year 2000 Beta marine 30 with mated gearbox PRM 80 D2 from reputable source for £3000 Less a trade in offer of £250 for the Beta 28 with the same gearbox. (Originally going to be £500 trade in until unit was seen). Courier arranged collection and delivery of both engines for £220 - it was 120 miles each way. Basically the cost of removing the Beta 28, taking the head off for inspection, putting in the Beta 30 came to around £2000. It included a complete new exhaust, silencer, flexi pipe bellows and some serious work to remove the last tail pipe, then welding a new eyebrow on the hull to prevent water ingress, then finally bandage wrapping the box and bellows. Replaced both teleflex cables to gearbox and throttle, Replaced both skin tank pipes and fittings. Aswell as some other minor consumables ATF, 1st fuel filter /water seperator and additional bits and pieces. So basically it has cost the grand total of £5000, give or take a few quid either way. I do believe the whole job has been done to a satisfactory and professional standard.

-

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

I have just had a phone call from Altham marine in Accrington, bearing in mind he gave me a very reasonable trade in value for my Beta 28 against a superb Beta 30 which will be fitted tomorrow. He has given me his wisdom findings after seeing all the associated parts, Block - not cracked Head - not damaged Crank - rusty but needs attention Rods - no sign of damage Pistons - rusted in but not serviceable Heat exchanger - still serviceable. His advice is , your exhaust is almost certainly pointing directly downhill, the rainwater & any washing and any other water has been running down the inside of the exhaust silencer and bellows/ flexi pipe and has entered whichever port is open via the manifold. This has seized the engine by probably hydro locking it initially and been left to continue until it's completely ruined. I had checked the exhaust earlier in the week, it needs complete replacement, silencer was rotten as can be, obvious standing water was left in the end connecting to the bellows with rusty sludge apparent at the joint. The silencer does indeed fall towards the engine in the first instance which continues downwards until it reaches the manifold exhaust exit flange and it is very likely that it was the original cause of the engine failure. The exit of the silencer through the hull is flush with side and no eyebrow over the fittings. His advice immediately is make sure the exhaust silencer / pipe goes slightly down hill before it exits the boat or you could possibly have the same problem again ( with no warranty) if that happens. -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

The head has not been touched since removal/splitting from the block, I now suspect that the engine has not been started for quite a few years. Streethay tell me it was towed in in February this year. It was moored in 2020 at Mercia marina about 10 miles and about 7 or 8 locks away. I now think that this boat hadn't left the marina berth for a couple of years prior to being towed. -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

Booked courier with Shiply, lots of quotes received varying from £200 to £380 for both collection and redilivery, Shoply looks a good website for delivery options. There and back in the same day, so hopefully engine put in and running within a week or so. Whoopeeeeeee. -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

Speaking to Steve at Altham marine, he suggests that this can happen if the cauliflower is above the height of the engine, general build up of rust, sludge in the pipes, skin tank,(a general neglect of maintenance, antifreeze,flushing out skin tank etc, or a cracked head will do it) Judging by the state of the internal pipework, I would be inclined to agree with him. I changed the prv on the cauliflower last week it was totally sludged up, if that's anything to go by,then I'm not surprised the engine waterworks are similar. -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

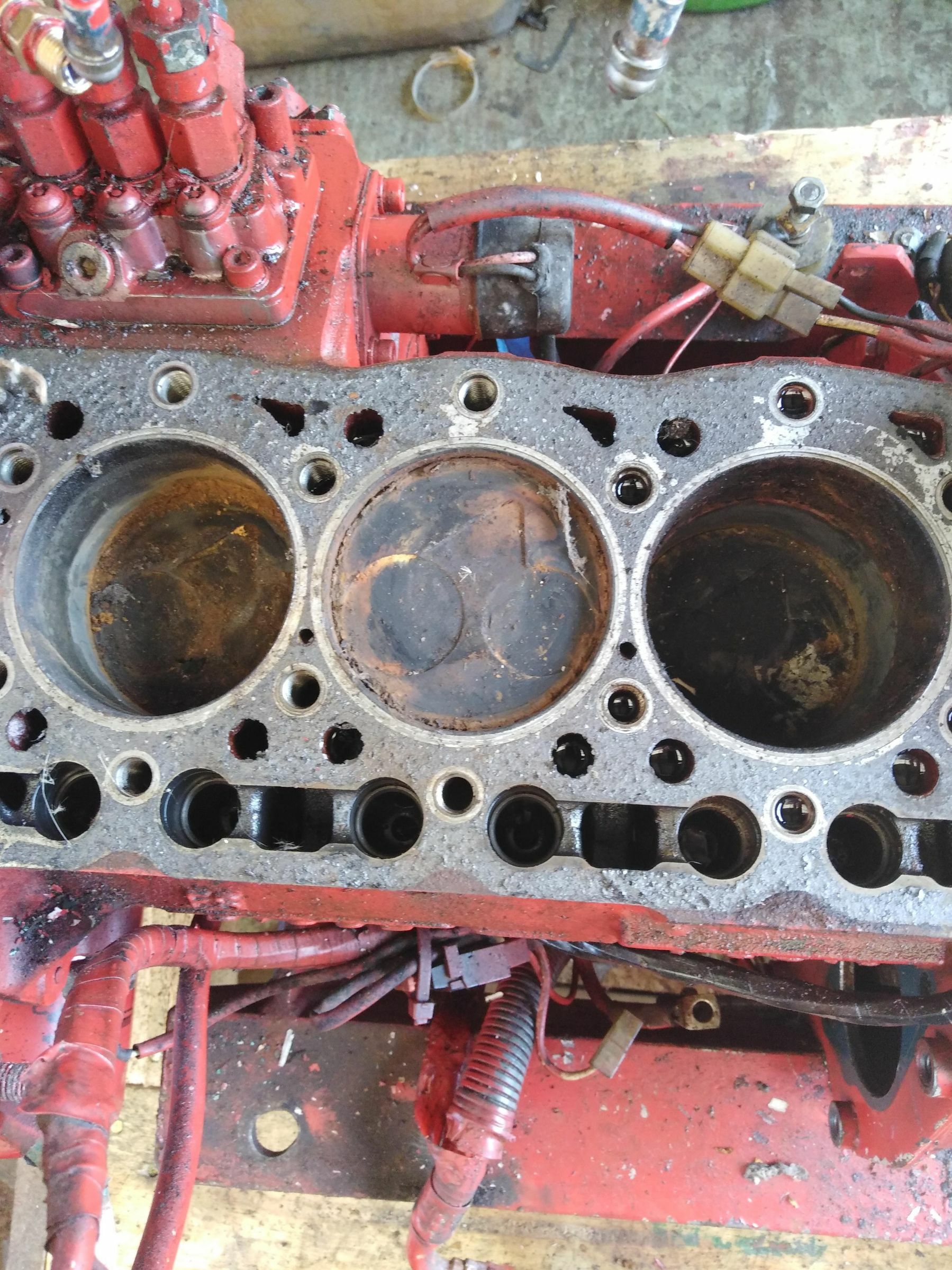

Heads off, very revealing, 3 seized rusted pistons in the block. Looks as though someone put water in the oil filling cap or similar ? Replace with a short block, possible reskim, big job to rework and get it serviceable again. I have decided that it's a better option to go with a beta 28 or beta 30 / straight swap from Altham marine. They have offered me some discount for it, which is better than nothing at all I need a courier now to take mine from lichfiel to Accrington and return with the replacement. Does anyone know a courier that will collect and return an engine.? Weights approx 130 to 150 kg engine in both directions. -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

Engines out, in estimation begins, Beta 28 pictures below. The crankshaft pulley wheel bolt is quite hidden and had a locking pin inserted down the length of the bolt, so still cant get a socket on the end of the nut. Never seen one like it before, it obviously stops it working it's way loose. -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

It is a liverpool boat, nice one though! -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

God I'm a plonker, I have mentioned before that you cannot get a big spanner on the crankshaft nut because there are just 3 x 14mm nuts on the crankshaft pulley. You cannot see due to the bulkhead and can only feel that any crankshaft nut is flush with the external face of the crankshaft pulley. Been racking my brain and looking at lots of Betas, they all have a large nut, why doesnt mine? Well it just dawned on me I have 2 alternators on an uprated pulley wheel. That covers and projects over the visible crankshaft nut. I have been prying the socket on the pulley wheel from an off central positioned / triangulate nuts. The leverage I could give it would be drastically reduced particularly as I could only get any purchase on the 3 nuts from an awkward angle. Tomorrow take off pulley wheel and try harder !!!doh!!!! -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

I took the remaining oil and water out today, put it in 3 clear plastic bottles, there was half as much water again in the first bottle. The boat hasn't been sunk, just suffered from being no TLC because the engine doesnt work. Inside is superbly fitted from new and well maintained -

Is this classic head gasket gone.

Karen Lea Rainey replied to Karen Lea Rainey's topic in Boat Building & Maintenance

Yep, definitely a 28, year 2000 build, I believe they built them( the red ones for sea/ marine inshore use, then modified the heat exchanger unit bits for use with skin tanks on canals.