-

Posts

177 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by chevron

-

-

There is no flange at the engine end just a screwed in 90 degree elbow at the bottom,it is a beta engine in a sound proof box only hope is that the big nut releases or cut it. Think it looks worst than it is, if it needs a new silencer it is not too bad but will still have a problem if it is seized the other end. Worked on Citroen cars for 27 years so am quite use to things being seized.

-

Thanks for that knew there had to be a way

-

Midland chandlers looks like the one thanks for the answers. I think with a bit of heat it will come off. But I have another problem above the silencer is a screwed in elbow and also one at the other end. Do I turn the threaded flange further onto the silencer so that the flexible unscrews and releases from the flange then remove the flexible at the other end. All the joints are screwed together the only way I can see to release the flexible is as above?

-

-

I remember cycling from Clayton and on approaching Market street (first time I had ventured that far) there was a line of sunken boats on the none towpath side of the canal. Well that’s what my memory was wish I had a picture of it.

-

Lived in the area and always remember the sunk line of boats near market street Droylsden. Canal used to be my playground love your pictures. Would love to see some of the sunk boats there

-

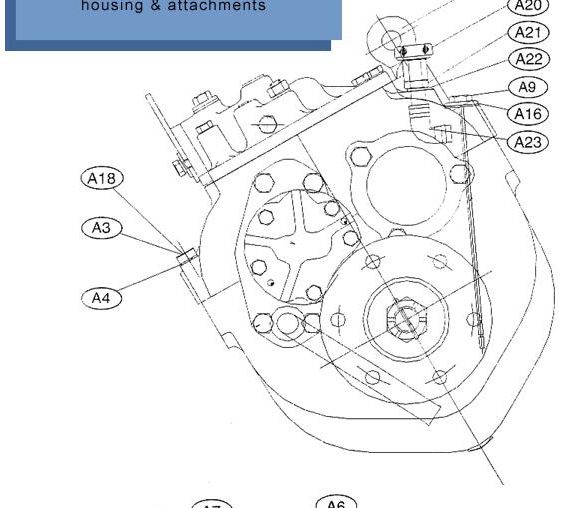

If the boat has the same generators set up as my boat I would walk away and not buy one again. Mine had a 7kw motor driven off an eight tooth rib belt off the front pully. Basically a ticking time bomb. Renowned for causing the front pulley to loosen destroying the crankshaft. The engine runs at 1000 rpm or 1500rpm when you press a button. The pram 500 gearbox then slips via the trolling valve. They did not make many of these and I believe they then changed to one driven by the back of the engine gearbox. Picture of bad set up.

-

One of the coal boats have put this on face book :Bosley & Marple Locks will close tomorrow until further notice. CRT make no mention of the real reason for this stoppage / closure which is due to not maintaining the feeder from Combs Reservoir which they have recently discovered is collapsed in Whaley Bridge So they now have both reservoirs on the Peak Forest inoperable, but at least they have as usual "consulted" (told us) about this. It's a shame they feel they have to take extra measures as they suspect boaters will "vandalise" the locks!

"To prevent unauthorised access through vandalism, measures may be taken to make the locks inoperable. "Think this is where the feeder feeds water to the canal via the Whaley bridge transport wearhouse pictures off there web site

-

-

I am getting a very slight mist from breather this is only since I have removed the trolling valve set up off detailed in another post. My guess is that the gearbox control lever valve is different on a none trolling valve set up. Everything is working ok so I want to look if the elbow is fitted and then possibly exstend the breather upright so the oil runs back in. When I removed the trolling valve there was a oilreturn pipe from the trolling valve to the of the gearbox I left this pipe on and not blanked off but higher than the gearbox everything was ok till I blanked this redundant return pipe off. I might just put it back as a second breather

-

Thank you that was my intention so the slight mist of oil runs back down the pipe.

-

-

Don’t think you have upset anyone.but think people are worried you may be stripping without knowing the cause of the the fault. We do not know your mechanical knowledge or experience and think I think you need some help with correct diagnosis. It will be worst when the heads off and you possibly not see anything wrong. Other ways water could get in by any water to oil coolers.is the coolant level dropping it should be if it is going in the oil? Is it worth removing injectors spinning engine over see if there’s water in the bores. I still think you need someone to have a look at it.

-

Agree with Sam owner needs help not to start stripping this down,if there is some fuel coming out the pipes on turning over the engine it’s unlikely to be the valve gear.I would remove the air cleaned and put hands over intake while turning over on starter and see if there is any suction,then bleed and check fuel flow from tank to pump. I as well think owner needs assistance

-

Water in the oil soon goes creamy coloured oil. Could it be a small amount of unburnt diesel which has ended up in the sump due to none start via rings? Think you need some assistance with locating fault if you feel it is outside your comfort zone and knowledge it could be something quite simple. If it was running ok before it was turned off cannot see it being anything that bad.

-

Follow the stop cable to where it is secured on the engine or diesel pump bet the cable or linkage is jammed in the open position disconnect the cable and work manually

-

HOSE 15MM X ½" X 300MM (63404)

10mm bore. Suitable for drinking water. EPDM rubber inner tube. Stainless steel braided hose.

View all: Unbranded Compression Hoses

-

Why not buy the same pump no messing about with pipes.the blue bit near the pipe on the pump is a quick release I think to detach pipes from pump without disturbing pipes. my pump does not need an accumulator in the system so I replaced pump with same pump.Also I replaced pipes near pump with the braided hoses to cut down vibration and noise?

-

1

1

-

-

Watching it as my mum loved the royal family think the queen and Charles in fact enjoyed the recent programs on Charles are ok don’t like the tax payer paying for all the hangers on even if they bring in a lot of money via tourists

-

They will shut down if there is air in the system they cut out if there is no water going through the system,so bleed it we’ll header tank needs to be above the level of unit. Thereis a very similar recent thread on this site with lots of advice about what to check if you do a search

-

-

I bought a kit off eBay with a second hand webasto and the bucket of water and a funnel to bleed was the method I used to make sure the unit worked before going to the time consuming job of fitting.At least it should prove if in fact the unit is faulty or if it is the way the unit has been installed. My own webasto system was then installed knowing what air locks can do and ran without bleeding at all due to the way the header tank and location of the units and pipes.

-

This is from the manufacture fault finding site The installation location of the heater should be as low as possible to ensure self-venting of the heater and circulation pump. This applies in particular to the circulation pump (Thermo Top E and C only), which is not self-sucking.

The circulation pump may be installed in the location provided on the heater or remote from the heater integrated in the coolant circuit. The correct direction of flow through the heater must be observed (coolant outlet on top, coolant inlet on bottom), otherwise malfunctions may result. Are you sure that the pipes are also the right way round connecting to system -

Said it was air at the start drop the webasto unit so it is near the floor it’s only three screws to do this as the exhaust and fuel pipe will bend this will make it so the water pipes supplying unit are not going uphill to unit getting rid of air traps

Exhaust flexible pipe

in Boat Building & Maintenance

Posted · Edited by chevron

Unfortunately my beta engine is in one of them suitcase type boxes. On looking again it was the same joint in the most inaccessible place as the joint at the silencer. I am not too fussed if I have to replace the silencer and coupling as long as I can get the flexible pipe out of the elbow near the engine. Have wrapped all the joints in pieces of cloth now and soaked them with penetrating fluid to start with.