-

Posts

288 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by IanR

-

Cheers folks, the boat is 62ft. It isn't causing us any problems it was more a post to say just how much of a difference it has made and the speculated reasons for it. Thanks again, Ian.

-

We have re trimmed our boat to sit more level, as opposed to being fore end high. General manouvering is pretty much unaffected, although when going up in locks, the boat now gets pushed forwards when filling. In some locks it can be quite violent and requires a good chunk of astern to stop it bashing. Before, it used to generally sit quite happily stern against the bottom gates whereas now it seems to like nosing against the cill and top gates. I guess this must be quite normal (?) and is something we'll have to learn to control / change our methods to get used to. At the top Etruria lock the other day a 'helper' opened the paddles, fully and quickly, and the boat noticabley sat for end down with the counter out and the prop cavitating slightly as I stopped it from hitting the buffers. Any thoughts or explanations? Perhaps now the baseplate is more horizontal the incoming water is going all the way under the boat and coming out at the stern, pushing us forward. As opposed to when the baseplate was fore end high and the water taking the easiest route, infront of the boat? Ian.

-

We wanted it trimmed more level ie fore end in deeper, so this Rayburn is situated under where the mast box would be and did the job a treat! Ian.

-

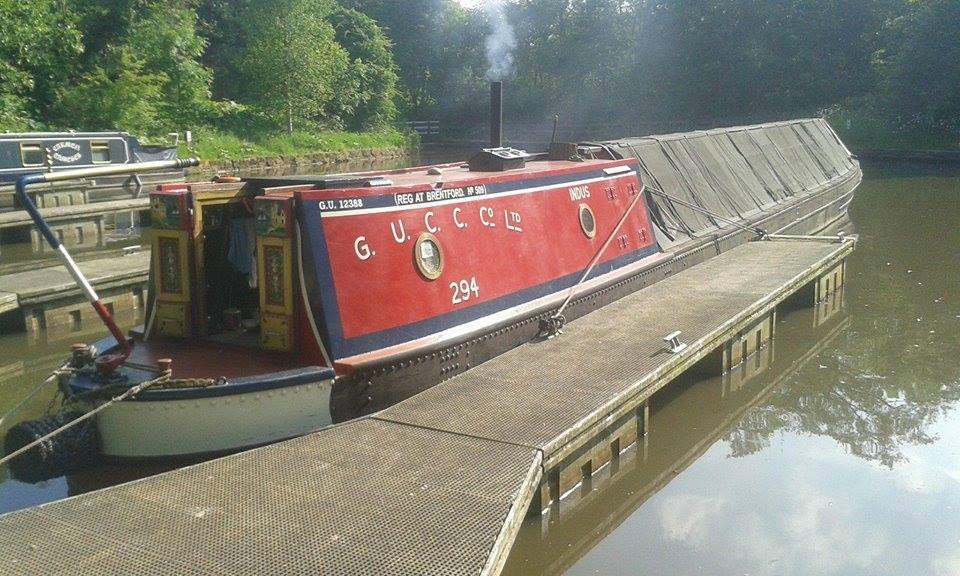

Finally had the time and weather to finish the writing on the cabin. The last docking date I haven't done (perhaps yet) but I've also noticed the letters S. W. on some GU boats of the period, just ahead of the dock date. Anyone know what this relates to? South West, Southern Waters??? It is amazing the variations in the writing on GU boats, some with full stops, some without, some with Reg and some with Regd, Registered.... Square full stops, round full stops... Fascinating. Ian.

-

I didn't mind the work being needed, I just didn't want to pay for it on top of the boat! Our surveyor was pretty accurate on how much the work would cost and also gave sage advice on what was the 'norm' when it came to negotiating the price reductions ratio against the cost of said work with the seller. The surveyor didn't say don't buy it, far from it in fact. In the end we got a sounder boat for about the same asking price as the unknown (knackered) boat. Whilst at the yard we also got a couple of other jobs done which I'd have initially struggled to do. Ian.

-

I was present at the hull survey of a boat we'd put an offer on, the seller wasn't. I was surprised at just how little of the boat was 'surveyed'. Two spots, high and low, every two foot I think. Plus the general visual look without touching. It was certainly good to have been there though the paperwork read much more extensively than the work carried out. The boat came out of it with shocking statements, a more memorable one was 'I don't know what is holding the bottom on!' Needless to say, being stupid and absolute noobies, we bought the boat and then took it up the Coventry, Trent and Mersey, out onto the Trent and up the Erewash for the rebottoming. Our surveyor advised what work needed doing in the survey, but when the yard started work, it required significantly more refooting than was originally quoted for. Ian.

-

Hi folks, more questions I'm afraid! I've stripped our old house' solid fuel Rayburn Royal down to its baseplate to refurb it and also lift it into the boat. It has (now) a cast iron back boiler and ready for me to put it back together with new bricks, side tins etc. We have vertical hot water cylinder which has two coils. Bottom one will be plumbed from the Rayburn, top one from the Ruston. The Ruston circuit has an expansion tank in the engine room, the Rayburn one will have an expansion tank higher than the highest point, each circuit will hopefully run a radiator as well, to be decided. So to the question! The domestic hot water in the cylinder, does that need a vent (plus a header to fill it, and therefore only gravity feed to the taps which would be a bit rubbish!) Or is it the norm to rely on a pressure release valve in the domestic circuit, giving pumped hot and cold from a single pump back at the cold water tank? Anyone got a schematic they could share specifically for a solid fuel cooker? We are hopefully going to be able to run the Rayburn circuit without any pumps (thermosyphon??) Anyone got any experience of this? Many thankings, Ian.

-

The back end the boat was given by BW in the 50's was simply a flat transom. This was removed when the boat was lengthened and put back into working trim with a motor stern. I suspect that the transom would have been riveted on too if that was when the rebottoming took place. Anyone know if there are any early BW converted hire boats still about in 'transomed trim'? Ian.

-

Indus was one of the early boats to get the chop, in the 50's it was cut to make two early BW hire boats, Water Willow (our bit) and Water Reed. It's possible that it was done at the same time perhaps. The holes in the bottom face of the chine angle has twice as many holes than that pic of Canis, perhaps they simply drilled another hole inbetween the existing when the riveting was done. I'll post the pic I have when I get back later. Ian.

-

Our boat, Indus was built with a timber bottom and riveted steel sides. Inside on the chine, the angle is riveted to the sides. The angle is also riveted to the baseplate at the same spacing. When the timber bottoms were replaced with steel, would they really have riveted them on, surely welding was commonplace by the time the bottoms were replaced? The bottom plank fixing up through chine angle wouldn't require so many holes (as many as the riveted sides) would it? Or is the chine angle a standard angle section that was mass produced with the holes on both faces and the workers used whichever holes most suited when attaching the planks? It's puzzled me ever since our original survey when I first noticed the rivets on both sides of the angle and the interest was sparked again with those series of photos from WWII posted in this section a couple of weeks ago when you could clearly see in a few of the pictures elements of how these things were put together. Ian.

-

It would seem Paragon (post 5695) has moved onto pastures hopefully more caring as it is heading towards Stone on the T +M, it doesn't seem to have moved off the Caldon for many years. Ian.

-

Fixing soundproof sheets in engine bay

IanR replied to Rigpig's topic in Boat Building & Maintenance

I thought that would be the likely answer, it was a thought after unknowingly dropping a rag into some wet paint in the bilge and it really did stick very well!! I've just bought the slab insulation today and might just try a sample to see.... Ian. -

Fixing soundproof sheets in engine bay

IanR replied to Rigpig's topic in Boat Building & Maintenance

Slightly related and perhaps a ridiculous idea but....... when applying insulation / soundproofing, could you press the bats into freshly applied sticky wet paint? Ours will be held up with battens, vapour barrier and internal cladding, I just though this idea might help to ensure the insulation is stuck to the steel all over with no voids for condensation to develop in? Ian. -

Another vote for Canal Cruising at Stone. We had the dock for a week last summer and they couldn't have been more accommodating. They give you 24 hr access, you can work for as long as you want and you could stay on the boat. You can park the car right next to the dock (that we used) which made the fetching, unloading of stuff very easy. We got far more done than the blacking we'd planned and will certainly be using them again. Ian.

-

Agreed, rubber belt would be better, though I don't have access to enough of that for nowt! It wouldn't the BSS either Jen!! Ian.

-

-

We are getting nearer to starting the fitout of our boat and have been scraping and painting the insides of the hull, a labourious task that has taken what seems like yonks to get done. It was a working boat up til about 2009 or so and then sold onto to someone who started to do what we are restarting to do. They didn't get very far with it for whatever reason and the boat was left in a bit of a state with lots of water in the hold for years. The bottom of the hold, under the wooden planks has concrete block ballast, these are sat on roofing felt which is in turn sat on what looks like years of applications of tar bitumen. The boat was left in a state that meant that massive amounts of condensation gathered to the point that on a hot day the hold was like a sauna, absolutely stiflingly hot and moist. There was lots of water in there, mostly condensation but some from a hull leak too. To the point anyhoo, this bitumen tar stuff is rock hard, like black glass and although it seems intact, in places isn't stuck to the baseplate and therefore leaves a void which retains any moisture that was there. I've spend more days than I care to remember chipping away at this, bucketing the waste by the couple of dozen or so. This bucketed waste is worryingly magnetic although the actual steel is coming up suprisingly well, ready for paint. When I come to refit the ballast, does it need to go back onto the same sort of stuff? I was thinking that I could sit the concrete blocks on runs of spare twin and earth household cable, say three or four strips under the blocks. This way the blocks wouldn't scrub the steel, but air could get around the lot and there'd be nothing but coats of paint to hide any nasties. Ian.

-

Thanks for that Richard, appreciated. Ian.

-

The engine is a Ruston Hornsby 4VSH, quite a lump. It has way too much power for boating but is great for stopping etc. It was suggested that a change to a smaller prop could be a simple way of using more revs to stop it coking up but perhaps a change in gearing might be an option if the different ratio boxes are interchangeable dimensionally. That said however, we've gotten used to the boat in its current configuration so don't plan on altering it, I was just working aound the gearbox today and realised I didn't have a manual so took the plate details to do a search. Constantly learning! Ian.

-

Hi folks, our boat has a PRM gearbox and that is about alls we knew about it. Reading the data plate on it and rooting about on tintyweb, it seems that the box is a 302D 1.5 Is this 1.5 perhaps the gearing as I can find reference to ratios of 1 to 1.5, 2, 2.5 and 3. On this plate, as well as the factory embossed details, there is an aftermarket X and an H stamped on the plate. Any ideas what they might signify? Also, with regard to this box, when we bought the boat, when we were out on a test drive, the seller mentioned that the gearbox was bulletproof and didn't need the revs winding back to tickover before engaging gear, or infact he said going from forwards to backwards either. This seems like an unbelievably harsh way to treat the drive train, are they really that 'bulletproof' !!??? It has to be said we have never subjected it to that treatment and doubt we ever will as it just seems wrong, but is it? Ian.

-

Although the house is less than a minute to the canal the land between it and us isn't ours, I doubt we'd get away with running a lead over the railway line either! I doubt we'll ever comply with the CC requirements though once we move onboard our pattern might change perhaps. As to the fairweather boater bit, far from it, we spent Christmas and New Year in the ice with only a back cabin, 'twas splendid. The problem with our gas situation is the height of the bottles. I think the maximum locker depth we have available (gunwale to waterline at the point just infront of the engine room) is 550mm. If we moved the locker into the undercloth bit, to gain any more height above the gunwale takes the gas bottles towards the middle of the boat due to the triangular nature of the undercloth bit. We plan on a 2 ring gas cooker or similar as the only gas appliance as we used the Rayburn more often than not when it was in a house. I appreciate that the Rayburn will probably not be used in the height of our summers though. It's all in the thinking stage at the moment so any comments and experienced opinions are welcomed. Ian.

-

We have workshops at the house that are in use every day by either one or both of us, so bunging washing in is hardly going to be an issue. We have a home mooring but already move about a fair bit, but mainly locally, within 20 miles or so, due to work. The boat is probably on its home mooring less than it isn't. We'll almost definately keep the home mooring even when we have the boat habitable.

-

I perhaps should have mentioned that we are keeping the house as it is next to (but sadly not alongside) the canal, about a minutes walk away. We both need the workshops we have there and one of us at least will be working from there every day. Like I said a bit up, the 180 litres is what I could cut the existing tank down to and get it to fit in the footprint I'd allocated in our plans, but it looks like I'll have to go back to those original plans and get a tank made that has the same footprint as the cut down tank, but could be nearly three times taller, making I guess 500 litres or so. Space is an issue for us, so the plan is to 'try' and work out what we need as opposed to taking up space with massive tanks and stuff that we might never get full value of. Gas bottles and locker gives us the same issues, space for a deep locker isn't available so we are limited to smaller bottles, but apart from the comparative costs, if you have two and a manual switch over then surely a small bottle will never be an issue?? Anyone recommend a tank maker? There's a local one here in Stoke but its always nice to hear recommendations. Cheers, Ian.

-

Thanks for the quick responses folks! Brian, what size calorifier would you imagine for two? Heating it will be a Rayburn Royal in one coil and the propulsion Ruston in tuther coil. Concensus seems to be pointing at needing a bit more than 180 litres! This 180 was arrived at through me cutting the tank we have down to fit in some of the space I'd allocated for water. The tank the boat came with is an underbed flat tank which we didn't want. Our plan is to have an upright tank from near base plate to gunwale so we might go back to that idea and bin the idea of recycling the unwanted tank we already have! Ian.

-

Hi folks, more questions!!! We intend to use our boat for living though we will keep our house and its washing machine etc. There are two of us and a dawg and we are already pretty frugal when it comes to water wastage etc (not in the slightest bit stinky though you understand) The idea is there'll be a shower and two sinks on board, plus a loo of some sort (composting or cassette) Question is, what size tanks do you have in terms of fresh water and calorifier? There was a new plastic tank in the hold of our boat when we bought it, about 360 litres. This seems far too big for our needs as we wouldn't want water to sit around for too long. I was thinking of a tank of about 180 litres or so, with a 70 litre ish calorifier. Next question, this plastic tank, is it feasible to cut it down and fit a new end. I would take it to a tank manufacturer and no doubt pay over the odds for the work, but at least the tank wouldn't be wasted! Some folks prefer stainless tanks, but the water tanks in houses are mostly plastic so are there any fores and againsts!!?? Thanks again fine people, Ian.