- Popular Post

-

Posts

2,335 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Bobbybass

-

-

7 hours ago, Alan de Enfield said:

Yup, Whilton do that and use it to convince newbies that they don't need to fork out £1000 for a survey "we have already done it for you".

There have been a number of boats that have had a Whilton Survey and then sunk as the buyer leaves the marina & takes 'them home'.

Yes.

My sister bought a Wilton boat with their own survey. Very unhappy. Stack of problems straight away. The BMC engine hadn't been serviced in years...the oil was thick tar and had gunked up the pressure switch. Wilton said it would be fine with a service...( Not!!)...the rev counter ...a standard one... didn't work so they found a small one that was obviously in the junk box and bolted it on to a roughly screwed in piece of wood.

Last week I shared locks with a couple who ( unwisely) bought a boat from Wilton via internet video due to being abroad. Funny how the video didn't show that the window frames needed to come out due to extreme rust...and Wilton "survey" had missed the fact that the engine mounts were totally shot!. When they phoned a week later they were told that it was a "secondhand boat..what do you expect!).

Get your own survey.

-

Re: The seller survey.

All the surveys that I have had.......have small print.

The small print on the bottom says that the survey was commissioned and paid for by the seller and the seller is not allowed to show it to anyone else without the specific permission of the surveyor...

It has also said that the survey is only ," on the day"... And the surveyor is not responsible for anything that arises after that point

A nice way out..no legal come back, in fact you are legally in the wrong if you allow a purchaser to see it.

Is this not still the case ?

-

I've had family...and a friend's experience of a major broker selling boats complete with the broker's survey.

Both times they encountered serious problems within weeks, that would have been thrown up if they had paid for their own survey. Both of them had the broker appearing kindly and pointing out faults during the buying process...which they then supposedly fixed ....to make them trusted.

In one case the seller of the boat had left it with the broker with a brand new set of batteries. When my friend viewed it...it had old batteries , with the broker saying " we'll put new batteries in it as a service to you"...ensuring my friend felt they could be trusted.

Phone calls within weeks.. when these other faults showed up brought the same response.." well..it is a secondhand boat".

Throw away any seller survey...even from major brokers...and get your own !

-

2

2

-

-

Hey !!!!?

You're not accusing me ?

The previous owner obtained this !!

-

10 minutes ago, TheBiscuits said:

Is it actually a certificate, or a notice of failure?

What does it say immediately after the line:

"Did the boat meet all the applicable minimum safety requirements?"

It will either be Yes or No!

It says...yes...????

-

Hi.

My boat is due a BSS next March.

I dug out the old one, and was puzzled?

There were various comments with the certificate that were never actioned.

" Gas leak from old hose in gas locker".

I checked with a meter and there is/was still a leak and the flexible hose is/ was ( not now ) dated 1991 !!.

" No gas shut off sign on kitchen cupboard".

There wasn't still a sign..I've just fixed one on.

" Fuel tank breather blocked".

The very obviously old breather was blocked and I replaced it.

My extinguishers were all date stamped 2000

I thought all of these items were supposed to be actioned before issuing a certificate ?..

Have I got that wrong ?.

Thanks.

Bob

-

On 01/09/2020 at 13:11, Tony Brooks said:

Thanks for the feedback. I suspected that is what you would need to do.

Yes....

It was far simpler than I had expected and the comments here gave me the confidence to tackle it.

Only took about an hour and a half.

Lucky I had a full tube of Loctite 577 but then...I wouldn't be without it.

My love life has been vastly improved by Loctite 577...

Thanks Tony.

Bob.

-

Hi all..

Thank you for your input.

I removed the stern greaser pipe and then the two bolts attaching the bearing to the cross member.

I then loosened the packing nuts and unscrewed the entire bearing assembly from the stern tube...about 1.5 inches of thread exposed.

Washed it down to remove all grease....coated threads with Loctite 577 and screwed it back down.... reinserting the cross member bolts...the stern greaser and finally the two packing bolts.

Gave it a long run....over the past few days.

Totally fixed...and not a drop of water or grease now.

All fine.

Thank you all ?

Bob

-

3

3

-

-

Hi all.

I'm not that familiar with this type of stern gear, so I'm asking you kind folk for advice.

If you look at my photo, you will see the adjustable part on the front....with two big nylock nuts.

The triangle part with the entry from the greaser in the middle....then...a big greasy mass behind that. When I use the stern greaser, it bubbles at that junction where the big hunk of grease is.

I'm using a lot of grease at present.

I can't decide is I should tighten those two nuts down and it would stop that ?. In my mind..that joint ..prop tube.....shouldbe sealed to the triangle section and thus the grease should not come out at that point ?.

Advice please...and a huge thanks.

-

Plus...with that number on board you will spend a lot of time at water points.

-

AstroTurf

-

42 minutes ago, OldGoat said:

Although it was a design fault - part of the problem is that folks run the engine at tickover speeds - which introduces 'chatter' and exacerbates the problem.

It's worth talking to Beta 'cos they're great folks and you may come to a compromise - but that might mean a different engine.

The later fix for smaller engines (up to 2903) was what I call 'the washing machine fix' - only because the pulley arrangement was made by Electrolux. It has the disadvantage (or did) that there were two pulleys and the smaller one was too small a diameter to drive a second alternator to get the same output from two. Well it didn't for me...

I kept the inner original pulley...and Beta provided me a new aluminium double pulley....that was one piece. I had the outer pulley machined off and fixed it to the remaining original pulley which gave me a larger diameter.

-

1 minute ago, Tracy D'arth said:

Its too late once it has come loose, the bolt alone will not hold it for long. The end of the shaft and the pulley inner bore will be damaged and will not lock together properly. Things will only get worse, sorry.

Exactly as I posted above.

Beta tried welding the nut without success.

-

Just now, canalboat77 said:

I’ve not seen what the plate solution looks like, I wonder if I could get someone to fabricate something to keep that nut from coming loose once it has been tightened?

It's not just the nut comes lose. The pulley starts to waggle and cuts a shoulder into the crank. The nut then comes loose.

Even if you welded the nut ( which Adrian at Beta told me they had tried ) the pulley will still waggle at some point. It then accelerates.

-

1

1

-

-

I relocated one of my alternators to the opposite side so the belt tension was even...but it took a huge amount of fettling.

-

-

6 hours ago, Tony Brooks said:

Not sure which post the above was replying to.

Yes, that drain screw shoudl be opened very regularly at first to see what you have caught, then as you understand how much water you are catching you can make it less and less often until, hopefully, its just every engine service.

The finer the filter the more readily it will block and you should have a fine pore engine filter after this one so either 100 or 60 micron elements should be fine.

My last post in this topic was intended to warn you that you do not need to fit a sedimentor AND an agglomerator because you have an agglomerator in the engine filter. the filter in question will also agglomerate and remove water. However it will tend to block more readily than a sedimentor but if it has not blocked on you yet its unlikely to as long as you drain/clean it regularly and keep the water out of the bottom of the tank.

Hi... thanks.

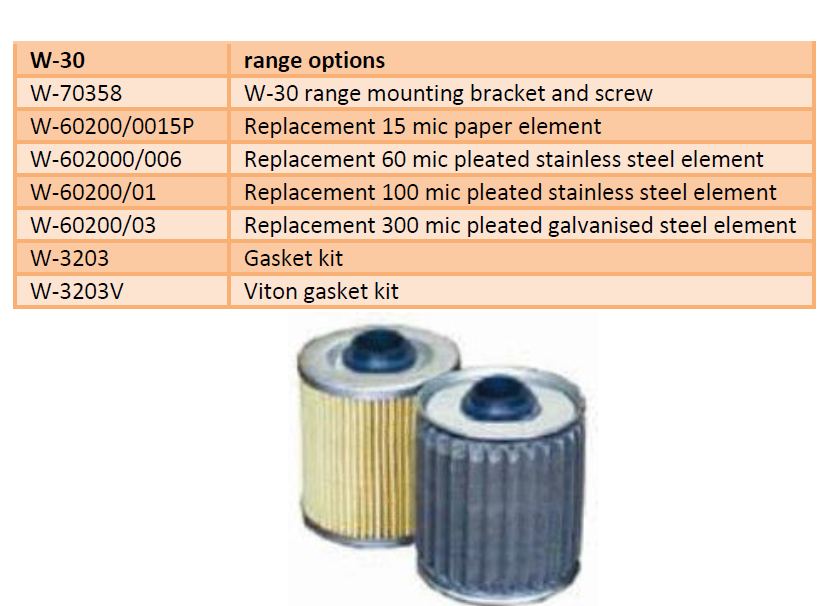

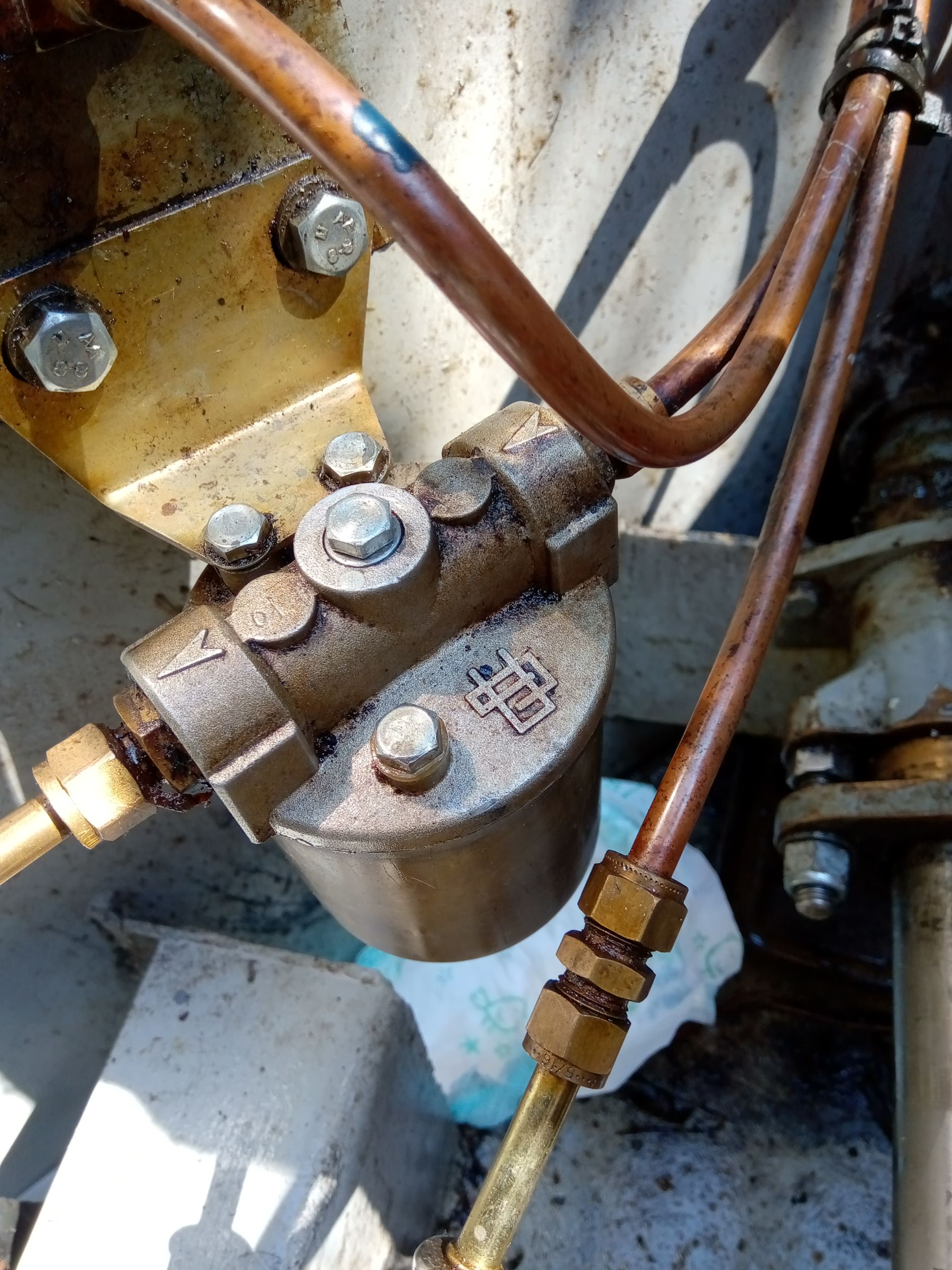

My engine is a Beta 37 with a screw on fuel filter that I change every 400 hours...every second lot of oil/ filter 200 hour changes. This filter ( in my first photo) is a pre filter before that...and has that water drain screw.

The element I show in the photo is totally shot. Rusty and the rubber seal is heavily distorted. It has years of ingrained fine dust that wouldn't shift...even soaking it in paraffin and using a stiff brush...to the point I may cause a hole.

There wasn't any water in the bowl...but it was full of years of accumulated crud .

I know the bottom of my tank is fairly clean as I have pumped several jars directly from the bottom.and there are only one or two specks in it.

Thank you for you advice.

Bob.

-

The housing...which you see in the photo ...has a water drain point on the bottom. It has a wing-type nut on the bottom, which has a cut away shaft to allow water to be drained from the bottom of the filter housing.

Is that what you mean ?.

-

-

-

My housing says " made in Italy " on top.

-

7 minutes ago, robtheplod said:

Cant you just wash it?

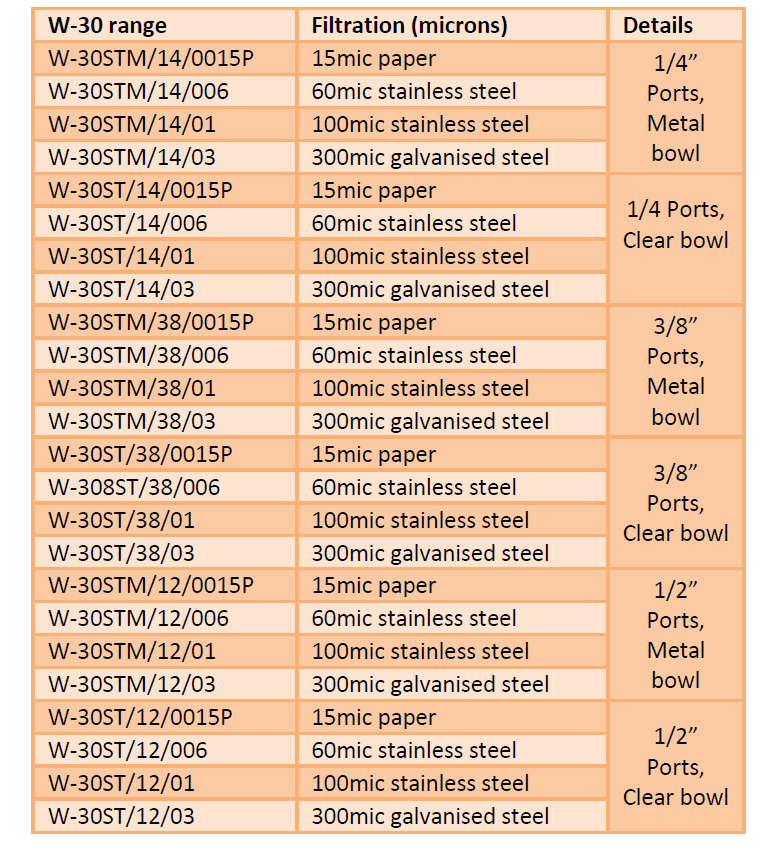

Looks like mine - A Wasp W-30STM/D Filter. I've got all the info on this but I cant seem to upload PDF's....

place to get parts is www.separ.co.uk

Hi

Thanks.

I took this out today to wash in some parafin.

Although the previous owner had paid huge amounts to an engineer for servicing, this hasn't been taken out for years. Also the rubber seal in the top which stops it bypassing is very distorted.

There is very fine dust of years embedded in the vanes ..and it would not come out.

It needs...a new one

-

Hi all.

I really need to replace my washable fuel pre-filter.

Any idea...what I need to order ?..

Thanks all...?

-

I used my Travelpower to power the battery charger for 6 years. I only had one set of batteries and alternator...and nothing 'cooked' ?

I would start the engine..then Travelpower..then battery charger.

We used it for the washing machine and also an electric kettle while travelling . I also had solar , so several forms of charging at the same time.

Only thing that was a serious problem...not just for myself but also a neighbour ...was the way the Beta engine was set up to power it.

My engine had a double pulley on the front...one before the other. My alternator and Travelpower alternator were on the same side and the subsequent force began to destroy the pulley and end of the crankshaft. At first it begins to work slightly loose on the taper, but once it gets underway it accelerates.

My neighbour had a 200 hour Beta engine and this happened. Once the pulley starts to wear a shoulder into the crankshaft you're doomed.

Beta eventually gave my neighbour a new engine and paid for fitting.

Its worth occasionally getting hold of the front end of the double pulley and waggling it. If you feel a slight movement, tighten the centre bolt.

An engineer told me that its fairly common and one of the root causes is that the crankshaft taper and pulley taper are slightly different. Whether that is true..I don't know ?

Unfortunately my engine wasn't under guarantee. I did come up with a 'fix' but it involved new style of pulley and much machining.

When this happened, I was in constant communication with Adrian at Beta. He told me that this was a recurring problem, and that they had tried several fixes, even welding the pulley and nut to the crankshaft, but the forces always won. I 'think' that if you have this type of setup , with double pulley, It would be OK if you

checked it for sideways movement. Get hold of it good and tight and wobble it. You can then catch it before it becomes serious.

checked it for sideways movement. Get hold of it good and tight and wobble it. You can then catch it before it becomes serious.

By the way...you need to remove the pullies to tighten the centre bolt....

checked it for sideways movement. Get hold of it good and tight and wobble it. You can then catch it before it becomes serious.

checked it for sideways movement. Get hold of it good and tight and wobble it. You can then catch it before it becomes serious.

Thetford....a golden experience.

in Boat Equipment

Posted

Hi.

I have just been completely amazed at the service I have received from Thetford.

15 months ago I purchased a Thetford Duplex oven from Midland Chandlers online and installed it on my boat. It was about £250

The grill was only used a few times but didn't want to stay alight..a few weeks back it refused to stay alight.

I did the usual things...take knob off...push in with pliars...but no.

Clean the ( not used...spotless thermocouple)

I looked at Thetford online who said in order to have a guarantee repair it needed to go to a service centre. Of course...this wasn't practical.

In line with the way the world is....I abandoned hope of getting it sorted.

I emailed them and they wrote back saying. " of course we don't expect you to do that when on a boat.."... They gave me the phone number of an engineer and said he would locate the boat and repair it.

I called the engineer... Jim's mobile Marine...about midday on Saturday. He said he was incredibly busy...but would come to us from Leighton buzzard to Market Bosworth at 6.20...

I was incredulous.

At 6.20 pm...there he was on the towpath!

He fixed the grill . It was a failure of the door open microswitch.

It was all totally covered by the guarantee.

In this day and age...who could ask for better service.

I'm......blown away.