Mark R

Patron-

Posts

241 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by Mark R

-

Thanks Alan, can I ask how you put the light primer on and how did you sand it down ready for the top coat?

-

@agg221, thanks for your reply, it provides me with plenty to think about. I hadn't thought about a 2 pack undercoat, I'm sure that would be worth using if it adds to the overall durability. How many coats would I need? I'm assuming most single pack topcoats are able to be painted on an epoxy undercoat? I've seen this Hempel product, I'd assume that would be compatible, can you think of any others? https://www.boatpaint.co.uk/acatalog/Hempel-s-Light-Primer-45551-38428.html#SID=287

-

@dmr, easier in as much as just not having to mix a two pack paint or easier to 'blend' in? Excuse my ignorance but what do single and two pack paints fall under, I'm assuming some are oil based, some epoxy, but others?

-

Thanks @blackrose, in terms of sanding the orange peel down, I wasn't going to attempt to achieve too flat a finish, as @matty40s suggested, I'd use the undercoat to fill the valleys, I'm assuming that the prep you discuss is suggesting that too (i.e. not going too smooth with the epoxy sanding), sanding the peaks and finishing off with a rub over of Scotchbrite? It's an interesting thought regarding a 2 pack topcoat, for some reason I just thought the 'done thing' was to use traditional topcoat paints on narrowboats. I can ask the question when the quote comes through regarding the work. I'd love a deep shine to the finish, is this achievable with two pack systems? On a side note, I had thought of painting the roof of the boat myself as the finish on this isn't so important, given that it'll be covered with solar panels, accessories etc, and that it's pretty somewhat pitted anyway. In which case maybe I could consider a two pack paint that might provide better durability!

-

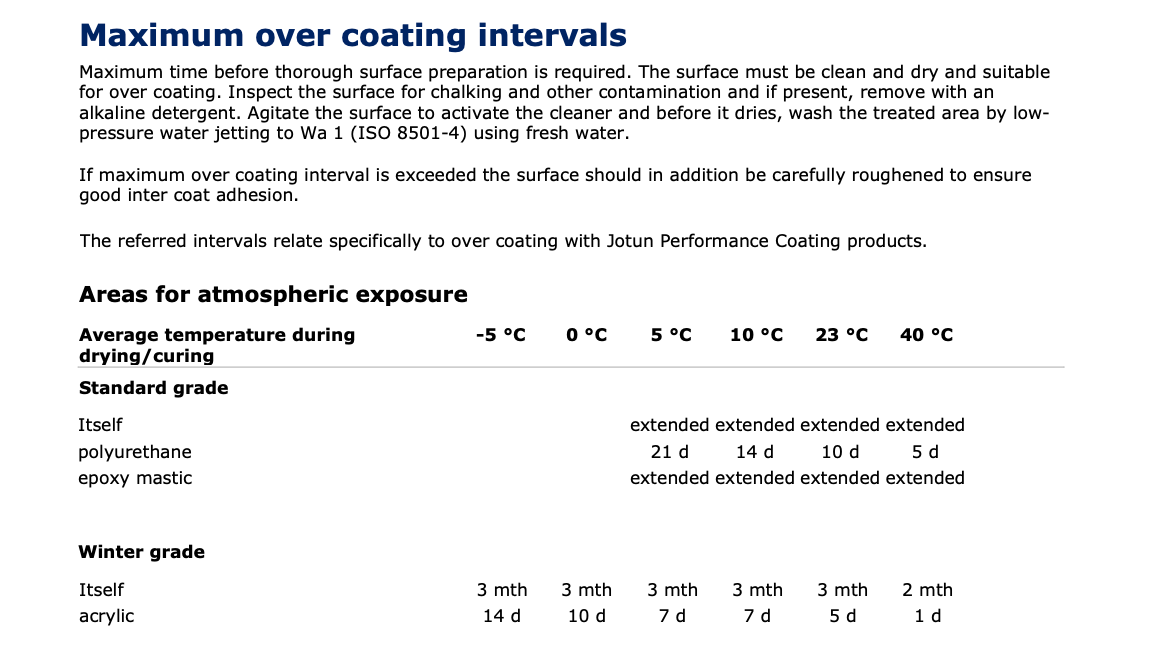

Thanks guys, as ever you've all been so helpful. I'm hoping to have the topcoat done by boat painters as they have a two week period available in their paint tunnel and although I can use the tunnel myself I think the finish they'd achieve would be far, far better than I could expect by doing it myself. As time is so limited I'm wanting to do as much as I can myself and deliver it to them in a state that they might just manage to complete the task in the time available. They typically use 'Manor Coatings' paints but are happy to use any paint I supply or request. Living only a couple of miles from Manor Coatings I went down for advice but they've told me that their products are a no go over epoxy. Craftmaster and Symphony were the two makes that stood, typically through discussions on here. Looking at the datasheet for Symphony, I assume that polyurethane paint is a type of alkyd paint @blackrose, interestingly the variety of paint types mentioned in application guide for Jotun 87 (non Aluminium) are less and the interval durations differ to that of Jotamastic 87 (Aluminium) and 90 (Aluminium). @matty40s, given the 'maximum overcoating intervals' I show below, I won't get the undercoat on within that period. Let's say I sand off the peaks, there are still going to be areas that haven't been abraded on the primer coat, is this an issue, if so should I maybe look at sanDing to a flatter finish or focussing on getting a coat or two of undercoat on ASAP?

-

Thanks guys, are any of you able to suggest a suitable paint that can be used as an undercoat over the Jotamastic? The reason I ask is because I happened to go to Manor Coatings, a local paint manufacturer (recommended by a boat painting business) yesterday to discuss which of their products might be used. I was told that I'd need a 2 pack undercoat to go over epoxy and that they couldn't recommend any of their products. This led me to phone Jotun and they recommended their Pilot II paint (an alkyd based, single system paint), I felt like the guy I spoke to wasn't really that experienced as he had to discuss this and another question with a colleague, he did invite me to send an email and I'd get a more detailed response - I'll post that here when it comes. Pilot II appears to be a top coat and not an undercoat, so not sure if this is wise. Two undercoat paints I've seen are: https://www.symphonynarrowboatpaint.co.uk/undercoats/undercoat-grey.765382 https://paints4trade.com/rapidguard--universal--primer-undercoat-paint-1094-p.asp?_=&variantid=274786

-

@blackrose, thanks for you comment. Yes the primer is above water level, the undercoat will be single part. I've read the technical data sheet several and have spoke to Jotun 3 times regarding the product too, one of which was to enquire about the differences between 87 and 90. Jotamastic 87 was chosen as it was in stock at the time and improvements of 90 weren't so critical given it's intended use. In terms of painting over the epoxy I'm aware that I have a bit of time before needing to key the surface, that's no concern, the peaks are more the reason for giving it a sand.

-

Thanks @dmr, sounds like I have enough coating to play with. I just need to be careful when sanding those curved edges!

-

Thanks @matty40s, that was my way of thinking too. One question if I may, prior to applying undercoat, I'd give a light sand of the epoxy to rough it up and get rid of any high peaks or imperfections, should I be worried about the undercoat not sticking to the pits of the orange peel epoxy as they haven't been touched by the sanding.

-

Morning all, I've finally primed my boat with 4 coats of Jotasmastic 87. This has been rolled on creating a coating thickness of around 200 microns. It has left an orange peel texture. My question is, should I sand this down to form a smoother surface for the undercoat, reducing coating thickness of the primer, or should I overcoat it with a number of coats of undercoat and then sand this down to a smooth surface, this would obviously also affect the combinded surface thickness but would be easier to do. I coud always apply another coat or two of undercoat on top of this. Any thoughts would be appreciated, Mark

-

Once I laid it off with a brush it was awful, whether or not the temperature of the substrate was too high I'm not sure as it was last week. I've got quite a bit of sanding ahead of me!

-

@ditchcrawler, @truckcab79 I might forget about the airless painting in that case! It sounds like the right way to go is as pretty much everyone has suggested, a roller and brush and get some practice in first. I suspect using a brush with the Jotun put me off as the finish was below the quality of just a roller. Using @rogher's suggestion of Owatrol might give me confidence in achieving a good finish. I'm a little annoyed about the orange peel effect I've got from rollering the Jotun on, I'll sand it down accordingly, hopefully the three coats I've put on will leave enough primer on the metal.

-

@Tonka it's 57', already stripped to bear metal, filled and primed, obviously this was only rollered on and not laid off with a brush. Each coat took about 6 hours, I appreciate that the top coats will each take longer. Did your 5 weeks include prep and priming? If so I've already had in excess of 180 hours to this stage. I'd only expect a single colour to be painted. @rogher, thanks for your input. I've got a feeling that it will be a roller and brush job, as there is a concern about the quality of finish. I've rollered the Jotun on which has given an orange peel texture, this is going to have to be sanded to get close to a good finish. Dust and dirt was problematic with with applying the primer, very annoying! I've had limited experience of spraying but non with airless. Interestingly I did have an automotive repair guy offer his services when he saw me painting on the canal side.

-

Hey all, Just out of curiosity has anyone attempted to paint a narrowboat (undercoat and topcoats) with an airless paint sprayer, if so, do you have any images of the results? While handy with a roller, I’m not so good with a brush! I’m looking at hiring a paint tent for a week or so and wondered if this would speed up application. I appreciate that preparation time would be greater in terms of masking etc and that more coats would be required. The boat is currently primed in Jotun Jotamastic 87. I'd be looking at using something similar to this.... https://www.amazon.co.uk/InoKraft-MaXpray-Airless-Paint-Sprayer/dp/B0D5HW68VY/ref=sr_1_1_sspa?crid=2LYLJF6BAYQBV&dib=eyJ2IjoiMSJ9.bcfrvyru4XGhWTXEM1i9Tnnfhb9rz-CNGulydlKehpk.vv8xwP92dhrLBxfNkEyPLmtz6fNu0cYSmiTevzcsEjE&dib_tag=se&keywords=InoKraft%2BMaXpray%2BM3&qid=1748262888&sprefix=inokraft%2Bmaxpray%2Bm3%2Caps%2C67&sr=8-1-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9hdGY&th=1

-

Surface preparation & Jotun Jotamastic 87

Mark R replied to Mark R's topic in Boat Building & Maintenance

Thank you for all your opinions. Just to answer a few questions, @smiler, I used wet sandblasting as it's an attachement to my pressure washer, dry sandblasting isn't an option. Jotun suggest this is fine and their product can be applied to moderate flash rusting without issue. @blackrose, I carried out the wet sandblasting myself. It was purely to remove the majority of the Bonda ready for final surface preparation. There were pits that I focussed on with the sandblasting, this removed all rust within the pits and left the surface a light grey colour (stupidly I didn't take a picture), I'm sure that'd be perfect for the application of Jotun, however it'd be really labour intensive given how pitted the surface is. I could bite the bullet and do this to the whole surface, it might take hours and cost more in sand but maybe that'd achieve the best finish? @dmr, I did think of a needle gun but would have thought wet sandblasting would have been quicker, less work and cheaper given I have the equipment. Would you consider wet sandblasting better than the application of Vactan to rust in the pits? I could go over it with a wire wheel/brush on an angle grinder but again, given the time that would take could just bust out the sandblasting kit! I'm not at the boat but will ask my boating neighbour to get some images of where I focussed the sandblasting on the pitted areas just to give you an idea of how it looked. -

Surface preparation & Jotun Jotamastic 87

Mark R replied to Mark R's topic in Boat Building & Maintenance

Thanks @dmr given the rust in the pits leeched through the original coat of Bonda I wasn't sure if it'd do the same and then cause issues with the Jotun. I appreciate your input regarding the effects of time. I'm assuming that Bonda would adhere to the Vactan, my fear of using Jotun directly on Vactan is that Jotun were pretty adamant that no rust treatment should be used. -

Morning all, I wonder if you experienced folk could offer me advice on to the best way forward with the priming of my narrowboat roof. I stripped it to bear metal during winter and gave it 2 coats of Bonda Primer, I didn’t treat the steel at the time due to the surface temperature. The roof is very pitted and although I used a wire wheel/brush attachment on the pitting the rust did start to leach through the primer as I’d expect. I’ve stripped this primer off using wet sandblasting. I plan to apply Jotun Jotamastic 87 but am unsure as to how to proceed in relation to the pitting. I have a number of options and hope you might pass comment on which you feel is the best. Rust converter/remover During my discussion with Jotun they suggest a rust converter/remover should not be used as this may affect the adhesion of their product. I’ve read on here that some of you would apply it and then prepare the area using a flap disc or similar with the rust converter/remover being left in the hard to reach areas. If this was your choice what product would you use on the rust? Rust converter/remover and primer This process would be similar to above but after applying the rust converter/remover, I’d apply a coat of Bonda Primer to act as a barrier between the Jotamastic and rust converter/remover. The product specification sheet for Bonda Primer suggests it is compatible with two component paints (but check suitability before use). Wet sand blasting I’m sure this might be the best way of dealing with rust in the pitted area but given the number of pits, it would be extremely labour intensive and still might leave rust within the pits, furthermore it’s adding water into the mix. Wire wheel/disc I could treat each area with an angle grinder with a wire wheel/disc, again this is labour intensive and might not get to all affected areas (as was shown by using this method previously). Jotamastic 87 Apply the Jotamastic 87 directly over the untreated area and carry out no other treatment. Any comments are, as always appreciated. Mark

-

To all that took the time to reply, I really appreciate your input. There was plenty to digest. Apologies for the delay in replying, I've had gearbox issues which took my mind away from the painting. You can always have a little laugh at my expense ... @blackrose, thanks for your advice, to answer a couple of the questions you asked, I'm painting everything above water level, cabin sides, roof, stern and bow. The Bonda Primer coat was to get me through winter. To wet-blast I use a pressure washer that 'sucks' up the media, so dry blasting isn't an option. I spoke to Jotun regarding this, they suggested it was fine providing the services were cleaned thoroughly after doing so. They suggested no rust treatment and if flash rusting occurred just to light sand it and the epoxy would be sufficient. They said I'd need 5 coats if rollering or brushing, seemed a lot to me, what are your thoughts? I'll be using the standard product. @agg221, again thanks for your advice, I hadn't thought of using the paint as a filler but that might help me on the roof section of the boat. Ideas for a filler for larger areas seem varied on here so a little more research is necessary. I found your advice on different paint systems really helpful. Given the prep of the finished surface I'll follow your advice relating to sanding, along with Blackrose's advice maybe 3 (coats) is the magic number. @David Mack thanks for the link to the mixing rations. If adding thinners as suggested do I add 10% thinners to the overall weight of the combined Jotun? Again, thanks for all your help!

-

@dmr, are you suggesting no undercoat? How many top coats? I'd like the best finish as possible but also recognise my skill set and experience. A deep gloss finish would be amazing but I'm realistic about it all.

-

Thank you all for the advice you've given. I shall start by phoning the manufacturer and get guidance on the product. In terms of rust I'll swerve the Vactan and again ask what they suggest. The idea of a flap disc, rust treatment and a flap disc over it again makes perfect sense. The boat currently has 2 coats of Bonda Primer on it, as the huge task (in excess of 160 hours) of paint removal took place over autumn and winter. I'm removing this prior to priming. There are patches where rust is starting to show under the primer, I can use grit disc or flap discs to remove this, an alternative is wet sandblasting, this would eliminate the rust in the pits but there is an issue that flash rusting occurs very quickly, I didn't know if this would be a wise way of prep or a complete no-no? What is the consensus on the number of coats of primer, undercoat and topcoats?

-

Morning all, I've just had some welding done to my boat and have a few areas that need filling. I'm going to prime my boat with Jotun Jotamastic 90 (based on previous comments/recommendations on here). I've read previous posts on here regarding fillers, my question is, should I be using a specific filler with Jotamastic 90, if not, what are you fillers of choice for above water line repairs? I see Jotamastic 90 primer is tintable, is this important as a primer? Do i need to know the topcoat colour prior to selecting the primer? I was under the impression that choosing the undercoat colour was based on the final topcoat colour. I've in the process of preparing the boat for the primer, there are areas of pitting where flap discs and wire wheels can't get in to. There are signs of rust in these pits. I'm sure I saw that epoxy paints shouldn't be used with a rust converter such as Vactan, Vactan say it can be used with all paints except cellulose based ones. Can anyone give their opinion on the matter? Yours, Mark

-

Thanks @agg221 and @Jen-in-Wellies, just to clarify, the steel is being used to block up some old windows on the cabin sides. I'm not replacing the entire sides themselves.

-

Hi all, I need some steel for my narrowboat sides, the existing thickness is 5mm. Having done a bit of research I understand that S275JR mild steel would be a suitable material. I've seen the plate below but that is only S275, is this infact the same thing, or does it have different properties? If different is it still suitable to use? https://www.fhbrundle.co.uk/products/3010845__Mild_Steel_Plate_2500_x_1250_x_5mm_Grade_S275?campaignid=21382354225&campgroup={campgroup}&adgroupid=177634406070&keyword=&device=c&gad_source=1&gclid=Cj0KCQjwhYS_BhD2ARIsAJTMMQaTv9oALP6Cgtrx4Y2EVE7j35zbfPAeQ3DTSCYgTCCHvRrCa_ZJrk4aAh8zEALw_wcB As always, thanks for your help. Mark

-

@agg221, finding a good welder is proving to be an issue. I got in touch with a guy who was interested in doing it and examples of his work had been praised by other welders but he's gone quiet on me, despite a couple of nudges. I like the idea of doing things myself but welding would be a complete no go! If anyone knows a decent welder in the Leeds/Bradford area feel free to comment!

-

I did think the curvature might be an issue, I'd still see the same issue with welding. I'll give that a bit of thought, but you've certainly provided me with a solution to my window issue!