-

Posts

54 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by jacob

-

-

Just to clarify - it is 40A, and says so at the top.

-

Thanks again all, I reckon it's fixed now. The 40A fuse leading into the engine hadn't blown, but it's legs are pretty scuffed up, so I reckon it wasn't making a good connection, pic below.

I replaced it with a new one (30A was the largest I had, will that cause an issue?) and the engine started first go without issue.

Thanks again all - as always you've been massively helpful in narrowing things down and helping solve the issue, would most likely have caved and called an engineer otherwise

-

Thanks again all for your ideas

I followed a red herring for a bit - tested continuity across the isolator and it appeared broken, so popped into Roydon marina (convienently moored 5mins away) and got another, but on replacing it it looks like the old isolator worked fine, and I just hadn't made a good enough connection with my multimeter because of the awkward angle.

1 hour ago, Paul C said:Its not the batteries or the isolator. You can bypass the ignition switch by putting +12V to terminal 50 of a starter (might be labelled terminal S), for example by shorting a spanner or screwdriver from the +12V big terminal (B or 30). That way you can test the starter motor.

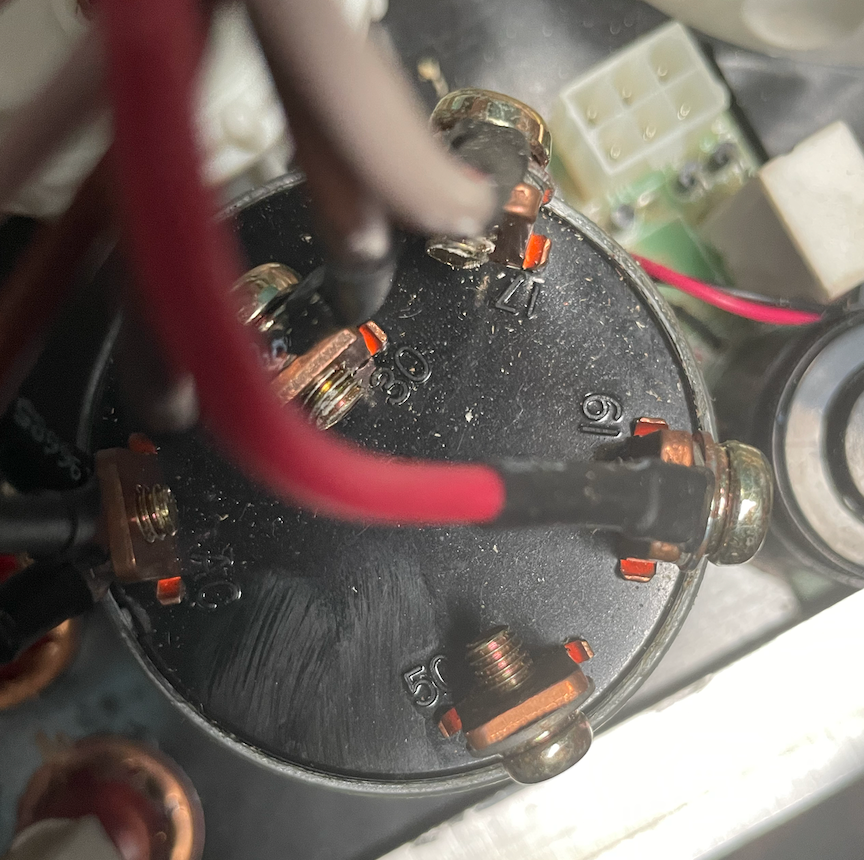

Paul - interested in this line of thought - measuring across 30 and the other terminals on the back of the ignition shows 12V, so power is certainly getting this far. However, shorting 30 and 50 does nothing. Also, there's nothing connected to 50 (pic attached), should there be?

-

Cheers for the quick responses

Here's some more info, apologies for drip-feeding- I installed a lithium batt a few months ago, and kept the old lead acids for ballast, disconnected from the system. They still show 12.4V, so these were the ones I connected it to as an alternative, although they are probably useless having not been charged for 2 months. The voltage across the starter does not change when the key is turned, neither do the terminals get hot. I've cleaned the terminals now, but no change.

The engine last run on Wednesday, for about 5hrs. The only thing that I can think of that's changed in the system since we last started the engine is that we filled up with diesel.

r.e. the isolator, there are two, one for the starter and one for domestic. I switched which battery was connected by changing the physical connections of the cables as opposed to flicking a switch.

-

Hullo all,

Happy sunday....

Tried to start up the engine today (Beta 43), ran into a bit of an issue. I turned the key to heat, and the lights + gauges came to life as normal, but after 5secs they faded out. I tried turning it to run, the lights lit for maybe a second, engine made a very feeble attempt at turning over, and then nothing. Now when I turn the key either way, there's no response at all.

At first I thought it was a dead starter battery, but measuring the voltage across it gives a healthy 12.7V. I tried switching over to our domestic batteries (measuring 12.4V), but still no luck, so I don't think it's a battery problem...

It also doesn't feel like a loose wire problem, or a problem with the engine itself - fading lights suggest a decrease of power, but as the batt's alright I've got no clue

Any ideas?

Cheers,

Jacob

-

1 hour ago, MtB said:

My own experience with panels laid flat on the roof, is in the dead of winter one gets about 1% of the peak summer energy output, not the 10% mentioned by others.

Just sayin'!

My plan's to install a 10,000Ah lithium battery and charge it up over summer to get us through winter

/s

-

We've got 3 of those Longi 410w panels on our 56ft NB, 2 on boxes and one on a mount. There's a chunk of roofspace left over, and not yet fallen in at a lock trying to navigate round them...

I put them in around April, and they've been supplying all our electricity since (CCing), although I'm sure we'll be relying on the engine come October/November to supplement them. This month they've supplied between 2-4KWh each day, with a solar dump setup heating our water to make the most of them.

-

Hey all - have managed to fix it. Here's what I think happened

The water pump drive belt was loose, which I think caused the original overheat, but during this the pressure tank cap must have failed (old, rusty and came apart in my hands), so even when I'd tightened the belt it continued to piddle water all over the place. I've replaced the cap, and run the engine for a few hours without incident so I'm pretty sure it's resolved now. Have also topped it back up with antifreeze

As for the buzzer, we had a service when we first got the boat and the mechanic said that these engines never overheat anyway so it wasn't worth fixing (hahaha). I reckon it's the overtemp switch that's broken, as the overheat light is constantly light up on the control panel. Hopefuly a quick fix.......

Cheers again all

-

1

1

-

-

7 minutes ago, Tony Brooks said:

Type of boat and what cooling system?

If it is a narrowboat then it is most likely to be skin tank cooled, but not all are.

Is the water pump drive belt (fan/alternator belt) in good order, in place and correctly tensioned.

If it is skin tank cooled, before starting to take parts off the engine, I would ensure that the mains pipes between engine and skin tank have no bows in the that are likely to trap air. If there is, then manipulate the hoses, so any air can run back into the engine, topping up as you go.

Then locate the skin tank bleed screws/plugs and vent the skin tank, again topping up as required.

Then try it again.

Remember that you will probably have to add antifreeze to keep the concentration around 25 to 30%.

Only if none of this solves the issue should you start removing the thermostat housing to check the thermostat.

If it is not tank cooled, report back.

Thanks so much! As always you're v helpful tony

Ah, sorry for not mentioning - it's a narrowboat with skin cooling. I'll have a play with the pipes and try and get any air out the system. Will pop in antifreeze once I know it's all sorted, didn't want to waste it if I only end up draining everything again

Will let you know how I get on

-

Hullo all,

I'm having some trouble with my engine, looking for some guidance. Coming up a lock, we noticed that there were much more fumes in the air than normal. When looking in the engine bay, it was thick with steam. We shut off the engine before it could cut out, so I'm pretty sure we've not damaged it through overheating, but we'll see. When we got the boat 3yrs ago the control panel kept beeping erroneously so I disconnected the buzzer, which of course has come back to bite me now.

I let it cool for a bit then had a look in the header tank - it was completely empty. I'd last checked it a few weeks ago and it was full. I filled up the header tank with fresh water, and ran the engine again. After around 20 minutes, it started giving off whisps of steam again.

I'm a bit stuck now as what to do next. We're near enough a boatyard to get an engineer to have a look, but if it's a potentially easy fix I'd rather do it myself. It's a beta 43.

Thanks in advance

J

-

Think I've fixed it - took the fuel filter off, only 1 o-ring to be seen. However, the bleed bolt just above was pretty loose, I think the fuel was coming out of there. Tightened the filter back on, bled it, nipped of the bolt, and it looks like it's fixed (fingers crossed)

Thanks all!

-

1

1

-

-

1 minute ago, Alan de Enfield said:

Who did your service ?

(It is a common mistak efor newbies doing their own service)

Not me! Had someone who came well recommended, seemed to know his stuff. I will have a look to see if there's another o ring up there and tighten it up at the same time

-

Hullo,

Hopefully just a quick fix, but wanted to double check as I know little about engines

Our fuel filter is leaking - there's diesel around the rim of it that reappears when wiped clean, and the engine bay smells more of diesel than usual. Also noting that it's a bit slower to start. Pic below.

Not too sure why this is happening - we had a full service of the engine a few months ago as we've just started CCing, and the filter was replaced as part of that. Is it a case of just getting another new filter? Or is there a seal or an o-ring kind of thing that needs replacing? The engine's a Beta 43

Thanks very much in advance

- Jacob

-

Worst we had was a small tyre that slipped itself quite neatly round the whole prop

-

Cheers both, have removed the two old batteries from the circuit

-

1

1

-

1

1

-

-

Morning all,

I'm having a bit of a headache with my batteries, wondering if you could help me diagnose the issue. For context, we're liveaboards at a marina, so we're almost always plugged in to a shoreline

Around 3 months ago one of our batteries started offgassing pretty badly - I assumed it was just a knackered battery, so took it out the circuit. Then a second battery started offgassing a day later. I did some fault finding and reckoned that the old dusty battery charger was the issue. I got another new battery and a shiny 12V 30A Victron blue smart charger. I set that all up and everything was working flawlessly...

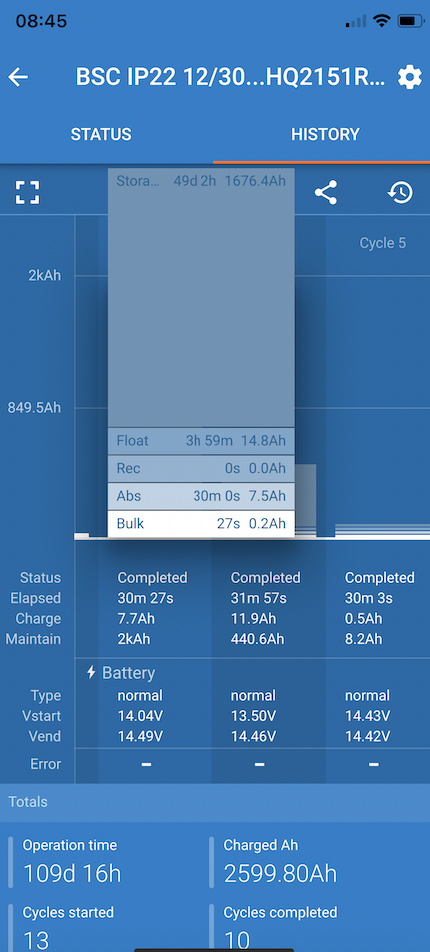

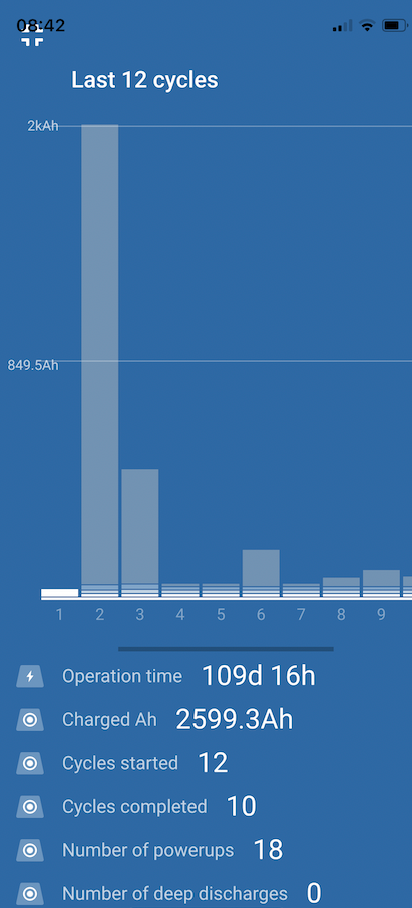

...until last night - at around midnight I noticed the smell again and another battery was offgassing. I disconnected everything from the circuit and this morning inspected everything. The dead battery is another of the old ones that came with the boat. Looking at the victron app (pictures attached) it seems the last cycle lasted 50 days and the vast amount of this was in storage mode. I've also attached a picture of the batteries, the duff one is the second from the bottom (although the bottom one has also lost its green 'healthy' indicator)

Any ideas what's going on? My plans for temporarily fixing this is to either remove the old battery from the circuit, or to go all the way and set up the charger as a power source, with no batteries connected. A long term fix would be much appreciated as I don't have the funds to replace my battery setup every 3months...

Thanks

-

26 minutes ago, bizzard said:

If any of them are let into the ceiling panels quite often roof condensation can short them out, more so during the winter.

13 minutes ago, nicknorman said:There is an intermittent high resistance connection upstream (ie battery side) of the terminal block, probably caused by corrosion. Slight vibrations, changes in humidity etc can make the difference between a good connection and a bad high resistance connection. When the issue is manifest (voltage at the terminal block 3v), trace the wiring back towards the battery and find out where 3v suddenly becomes 12v - that is where the problem is. Most likely corrosion on a fuse holder or any other place where there are connections.

Cheers both, I'll try tracing it back and see where that gets me

-

2 minutes ago, pearley said:

Try connecting each lamp one at a time to see if it's one of them causing the problem.

Hmm, I've given that a go but the problem is still there no matter which of the three are connected (and even when they are all disconnected)

The only other thing I could think of is something else being connected, but the only other things that are remotely near are the horn and the water pump, both of which are on seperate circuits.

-

Afternoon all,

I'm trying to fix a recurring problem we're having with the electrics. Every now and then, a string of lights (all on the same 12V spur) will stop working. This happens pretty randomly - today I dropped something heavy on the floor and they switched off, but other times it's happened with no apparent cause.

I've done some digging in the cables, this is what I've found. The problem is with a spur of 3 lights - a 12V strip light and two 12V touch led lights. When this spur is disconnected, the voltage across the terminal block is 13.5V. Once I connect the spur, the voltage drops to just under 3V. At this low voltage, the lights just don't turn on. When the lights are working and on, it measures about 12-13V across the terminal block.

I'm struggling to work out what the problem is, and why it's so intermittent. I'm fairly sure that it's only those 3 lights connected, but I can't easily access the wires as they're buried into the ceiling.

Any ideas what the issue could be, and any possible fixes?

Cheers,

Jacob

-

Cheers all - we drained it out, sprayed it down and shovelled out a carrier bag full of silt and crud from the bottom, it's running clear and fresh now

-

Evening all,

I recently repainted our well deck, which was pretty much caked in rust. The water tank hatch was also rusted down, so I drilled out the bolts and prised it out. The paint job was a success, but now about 5 days after the event our water smells of white spirits and has a bit of a chemically tang to it - I used white spirits to wipe down the metal before painting it, and reckon that a small amount got into the tank through now unsealed hatch.

Does anyone have any ideas for how best to go about flushing the system clean? My current thinking is to just leave the taps running and a hose in tank to cycle everything, but if anyone's got any experience with this fairly niche incident that'd be helpful

Cheers!

Jacob

-

Installed mine over the summer - £1360 for a Hobbit stove and flue kit, then maybe a good 2 days work building the hearth and installing it. At £50/hour, that'd come to roughly £2.5k all told

-

cheers all - I've dropped an email to Beta

-

Heya,

The belt for our leisure battery alternator is knackered so we need a replacement, and I'm struggling to identify the belt so I can get a new one online

It's a beta 43 engine, and the belt is 10mm wide. There's a few codes and numbers on it that are a bit worn, but from what I can make out they're 3108, 13AY1087, 661 1130 54940 161 and FA1 AUTOMOTIVE <something> - pic below

I've found this one at midland chandlers, but it doesn't match any of the codes on the belt so I'm not sure it's the one...

Any ideas?

Cheers,

J

Which marina is closer to me

in Moorings & Marinas

Posted

I think it's less the availability and more the cold that will slow down the curing that'd cause a problem. Aylsebury Canal Society has a heated dry dock, a little bit further along than P+S but maybe worth checking out.