moiuk

Member-

Posts

186 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Everything posted by moiuk

-

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Sounds like the simplest approach tbh.. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Looking a bit further... The 'key' seems to protrude 4mm from the shaft, however when I measure the depth for the key in the taper lock it is only 3mm. This would obviously cause the issue of the taper lock cracking (as it has done). So I need to find a key that is a different depth, but I am having significant difficulty finding a key for sale, and would have expected it to be sold alongside the taper lock? What am I missing ? Ignore me - found them.. Just didn't come up in the search nicely... -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

The shaft is exactly 38mm. The taper lock is 1610-1.1/2" Taper Lock Bush and has a measured 37.4 inside diameter. A light tap and it fits nicely onto the shaft. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

I have ordered a micrometer to make the measurements needed... -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Thanks for this advice. I am certainly missing something as my second taper lock has now cracked when I checked before moving today. Not failed yet, but obviously it will. The engine mount is now solid after a good tighten so this was not the cause this time. The shaft seems to be in good condition, and the taper lock is a good snug fit on the shaft. When engaged, visually the shaft looks like it is spinning centrically on both sides of the coupling. I tightened the grub screws a small amount each and equally.. the only thing that looks off is that the slot on the shaft for the key is worn and not a perfect fit for the key. The key is the same that has always been there so I am assuming that it is not over height, but this is a possibility for the new taper locks I guess. Each time I have checked it since installing the second one (twice), one of the grub screws had become slightly loose (an 1/8 turn maybe), so I made sure that was tightened. At a loss at the moment what has caused it this time... -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Initially I had an issue with the weed hatch, which created a swimming pool of oily water all around the mounts and lower part of the engine. The engine mounts I believe are only a few years old, but I don;t think my weed hatch incident has helped... Yes these mounts look to be the same. Still concerned that the mounting bolt turns.. My adventure sounds very similar (although significantly less stressful) !! So, as an update for those that have followed this thread.. Despite checking the engine mounts before travelling, and keeping a close eye on the coupling, yesterday the taper lock sheared and broke off again (yes the new one!). I believe the engine mount to be the culprit, as checking the nut, it had worked its way loose again (and yes I tightened as much as I possibly could by hand). Have ordered 2 new taper locks, tightened the engine mount as much as possible again and will repair the coupling tomorrow when the parts arrive. Should be a much quicker job this time. Will need to keep a much closer eye on the engine mount.. When it is tight, the engine looks nice and secure with it running and under load, so I am thinking that its not the mounting bolt that has sheared, and simply a case of the nut needing to be tighter.. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Did a check today after travelling a little. The lower nut on the engine mount had worked it's way back down again. I have tightened it up again (was at least two full turns). Any suggestions on how to get it to lock into place, it is this an indication that something else is wrong somewhere? -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Only because of the help you guys have given me. Wouldn't have had the confidence to attempt it otherwise.. Thanks again.. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Mount seems to now be looking good. The flexible coupling is reassembled and have moved a mile to test everything is good and we look okay. So, all sorted for now I think.. Will check all the nuts again in a week and keep a close eye on that engine mounts. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Tightening the bottom nut has raised the engine up to the other nuts and we are now back into alignment.. Tony, I am also concerned that mount is not all's okay, but if it tightens up like it has, maybe it will be okay?? Will now reassemble the coupling. Having difficulty undoing the nuts on the shaft that attaches to the gearbox atm... -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Here is a better picture.. The top nuts are a few mm above the mount, (you can see the gap on n this photo). The bottom nut has either worked it's way down, or it has collapsed somehow.. Will try and raise the bottom nut. (Had to be the mount which is hardest to get to 😞).. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Really helpful, thank you for taking the time to write it. The prop side of the shaft seems to be fine. So I have started by checking my engine mounts. Three are nice and tight, but the forth ones nuts turns easily. But also the bolt also turns with it. With the shaft alignment, I am about 2-3 mm out on the x-plane. The mount that is loose is the one closest to the gearbox on the right hand side (looking from the shaft). I'm hoping that raising that mount will correct the alignment. I'm thinking that I need to tighten the nut/head under the mount to raise that leg up and make it right again, which should have the effect of adjusting the shaft back into alignment.?? Attaching a photo of the mount that is loose. Concerned now that if the bolt moves that maybe it has sheared? Should the bolt be able to move? Or should that be locked to the mount itself? -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Yes, there is another bearing there. Okay 👍 If you think that is the easiest approach then I'll do it that way.. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

-

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Yes. I found that in the bilge. Along with other destroyed pieces 😕. Key looks to be intact. Thanks. I'll loosen the stern gland and see if the prop shaft side moves freely to give me the space I need. The alignment concerns me. I plan to check the engine mounts to make sure none have come loose.. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

I have dismantled it, however the gap in the shaft is not wide enough for me to remove the plate. Also, it doesn't look aligned. Any suggestions on how best to make the gap bigger? -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Other probably unrelated thing that passed through my mind... Last year you guys helped me identify a loss of thrust, which we put down to a fuel issue. Indeed sorting the fuel issue out (there absolutely was one), helped. However, perhaps the taper lock was also starting to slip intermittently which would also have the same effect ? -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Before it completely broke, I noticed that the engine was moving a lot on its mounts. Its an old perkins engine, so wasn;t surprised by that alone, but maybe the amount of movement just became too much for the taper lock bush and finally gave up ? -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Thanks Glen. I can't find a replacement flange on ASAP Supplies. There seem to be a few different types of flanges, I think mine is a F70 type H (at least that matches the pictures best).. Best match I have found so far is at https://shop.eriks.co.uk/en/fenaflex-f70-type-h-flange-taper-bore-1610-f70h-fen/ for £60. I will take it apart next and be sure I have the correct matching replacement type. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

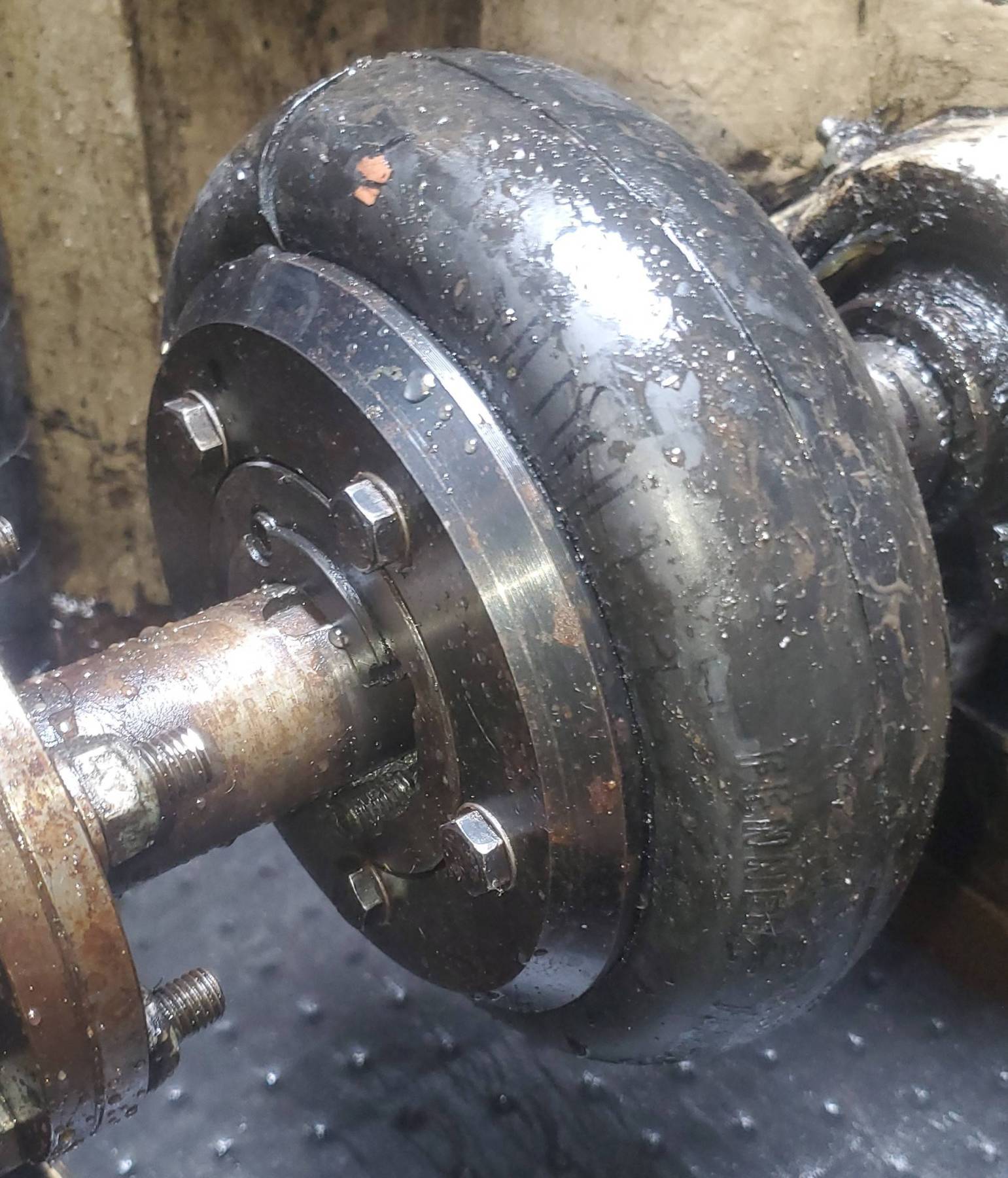

Have taken some close up pictures.. Hard to tell without taking it apart or being able to compare with how it should be, but there seems to be loose grub(?) screws and a section of the flange sheared off.. Have paused unscrewing it to consider my options, but feels like I need to order a replacement flange to insert into the coupling to grip the shaft? Thoughts? This seems to be a matching replacement?? https://e-rubber.eu/product/complete-shaft-coupling-interchangeable-with-fenner-f70-afm/ And this is a very helpful installation video that makes it clear my flange has sheared and needs replacing. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

The prop is free to turn freely. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Yes Yes No No Thanks. I'll take it apart tomorrow and check it. -

Propeller shaft flexible coupling 'broken? ?

moiuk replied to moiuk's topic in Boat Building & Maintenance

Very helpful. I'll take it apart tomorrow. I did have a bulge issue a while back and the shaft got submerged in oily bulge water so that probably didn't help if it doesn't like getting oily...