-

Posts

39 -

Joined

-

Last visited

Profile Information

-

Gender

Male

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Cruiser_Boy's Achievements

Engager (3/12)

0

Reputation

-

Battery box / cage / holder for upcoming BSS

Cruiser_Boy replied to Cruiser_Boy's topic in Boat Building & Maintenance

I see what you mean but the base of the box is only a few mm into the frame it wouldn’t stop it tipping which is mentioned in the BSS document. So presumably if I had a fixing further up the box that would be sufficient? Do you mean opposite ends of the bank? In the picture they are on opposite sides. -

As the title says I have a BSS due in a few months and my main worry based on my reading of the BSS document is my battery container. It is currently a plastic box large enough to hold 6 batteries that sits on a tray on the swim. Someone replaced the leisure batteries at some time before I bought the boat and put only 3 in instead of 5. So there is a 2 battery space at the end of the box. There is nothing holding the box in place other than the weight of the batteries and the massive connector links. The box seems to be a replacement for the original which was just a wooden board in a recessed rectangular frame, approximately 15mm x 15mm angle iron. Reading the BSS document the batteries need to be fixed in place and unable to move up to an angle of 45 degrees. I cannot see any suitable cages or boxes online so will probably have to make my own. Does anyone have any ideas? Is wood suitable? Should I use all metal? What is a suitable way of holding the batteries down bearing in mind the ends are blocked by the connecting wires. See picture below. At the same time I am wondering if I need terminal covers. Currently the plastic box has a lid and the decking is just above. I have bought the biggest terminal covers I can find but they don't even come close to fitting the massive link cables, ~20mm diameter, or the various other 'always on' wires attached to the terminals. Is there an alternative method of doing this? I'm thinking of using some sort of rubber sheet fixed with cable ties.

-

Fuel filler cap assembly. Removal. 4 screw 38mm.

Cruiser_Boy replied to Cruiser_Boy's topic in Boat Building & Maintenance

Yes that sounds like mine. I can see no gap between top of tank and underside of hull. So the pipe can raise up without affecting the seal. I just need to find a way to seal the two part frame. I have to wonder why it isn’t all one part. Yes I was thinking of a welded part when I found this online. I know someone who can weld it but I’m worried about all the hassle of preventing the boat catching fire :-) -

Fuel filler cap assembly. Removal. 4 screw 38mm.

Cruiser_Boy replied to Cruiser_Boy's topic in Boat Building & Maintenance

No I think it is built in I was assuming again which is always dangerous :-) -

Fuel filler cap assembly. Removal. 4 screw 38mm.

Cruiser_Boy replied to Cruiser_Boy's topic in Boat Building & Maintenance

Ahh ok so the Deisel seal is the filler body to the hull surface? I assumed a separate tube from the tank which the filler body sealed to further down because filler bodies I have seen for sale have a metal pipe below the cap. Makes sense if the fuel tank is welded to the hull surface. Looking at that photo the lock is in two parts which means it could never be sealed with circular gaskets. I may have to shelve this idea. -

Hi, I am thinking of fitting a fuel filler lock like the one on Midland Chandlers. See photo. My filler is a 38mm flush screw cap and the outer containing body sits about 5 to 10mm high above the hull surface and has 4 screw holes to fix it in place. Can anyone tell me how this part is removed / replaced please? Taking the filler cap out it looks like it presses down on a rubber seal although this may be for the cap. If it does then surely fitting the lock under the cap assembly will hold it higher than before and it may not seal? The body is 'painted in place' and I am very wary of trying to remove things when I'm not sure what is holding them in place. In the engine bay the Deisel tank appears to fit flush with the underside of the hull so there is no internal access to the filler assembly. In fact I think it is part of the hull as I can see seam welds around it.

-

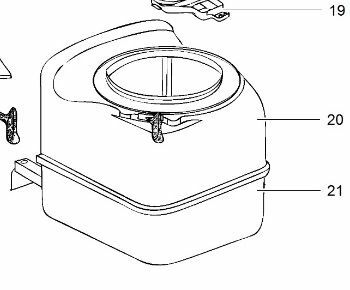

Thetford C200 base assembly / disassembly.

Cruiser_Boy posted a topic in Boat Building & Maintenance

Hi, I have had to remove my C200 toilet to work on the flush valve. Unfortunately the screws holding it to the floor were not in the recommended place and had rusted so much as to be impossible to unscrew. I had to cut the heads off to get the toilet out. Now to get at the valve area and to be able to screw the toilet back to the floor I would like to split the base in two. The Thetford spares list shows the base as an upper and a lower part so it must have at some time in its life been two separate parts - see parts 20 and 21 in attached picture. The lip of the top looks like it clips around the base part but I cannot get it to come off and I don't want to force it too much without knowing how it comes apart. Does anyone know how to split the two parts please? -

Peak Forest to Preston Brook single handed?

Cruiser_Boy replied to Cruiser_Boy's topic in General Boating

Ok to finish off this thread I was going to give my experience of the journey. Thanks to the tree blocking bridge 26 on the Ashton canal all my plans have been scuppered. I checked the alternate going right at Portland basin but that would be an extra 180 locks plus Standedge tunnel. If it had been earlier in the season I might have taken that on but decided not to mid August. Finally a big shout out to the excellent volunteers who took me down and later up the Marple flight. Also the Bosley crew. -

Peak Forest to Preston Brook single handed?

Cruiser_Boy replied to Cruiser_Boy's topic in General Boating

Thanks ditchcrawler I did not know I needed to do that. This site keeps putting my answer in the wrong place 🙂 -

Peak Forest to Preston Brook single handed?

Cruiser_Boy replied to Cruiser_Boy's topic in General Boating

Looks nice hope I can get in there :-) Ooh thanks I did not know I needed to do that. Ooh thanks I did not know I needed to do that. -

Peak Forest to Preston Brook single handed?

Cruiser_Boy replied to Cruiser_Boy's topic in General Boating

Is it for use by general boaters though? I don’t mind being locked in to moor overnight. -

Peak Forest to Preston Brook single handed?

Cruiser_Boy replied to Cruiser_Boy's topic in General Boating

If I can time it right I will moor up just below the Ashton locks then start on the Rochdale nine early the next morning. Hopefully then I can choose to stop at Castlefield or carry on onto the Bridgewater and more there. -

Peak Forest to Preston Brook single handed?

Cruiser_Boy replied to Cruiser_Boy's topic in General Boating

Thomas Telford basin looks fine. I don’t mind it being locked. Nothing against Manchester but I prefer the open country and watching the world go by. My main reason for coming this way is so I don’t backtrack over old ground and and I can go up and down the Anderton lift. -

Peak Forest to Preston Brook single handed?

Cruiser_Boy replied to Cruiser_Boy's topic in General Boating

Ok thank you everyone. I interpreted ‘no towpath’ as nowhere to moor. I have been through a lock like that. Can’t remember where it was but it was at a junction. I had to moor on the arm going the wrong way then cross a bridge go up a flight of stairs to the lock, work the lock then come back and turn around to go into the lock. -

Peak Forest to Preston Brook single handed?

Cruiser_Boy replied to Cruiser_Boy's topic in General Boating

Thanks dmr, Of course my Nicholson shows towpath everywhere 🙂 Do you remember which bit has no towpath? Looks like I would be going down so I guess I can just tie the front of the boat to the gate going in but not sure about closing gates coming out.