-

Posts

199 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Wittenham

-

-

-

-

if I had to guess... there are drainage holes. That is because when I bought it, it had a lot of water in it and was floating on an angle. I pumped all the water out of it through a single access hole cut in the floor and it all came out [as far as i can tell, no water showed up in other parts of the boat during other works].

-

1 hour ago, Mike Tee said:

if it sinks it will be on its home mooring. Hopefully as shallow as the rest of the system.

It is on Agenda 21 in Oxford. For all I know it has already sunk and is sitting on the bottom... it would be hard to tell the difference.

-

2 minutes ago, Alan de Enfield said:

It doesn't use the internet to send phone calls, it uses the phone signals.

If there is no signal it cannot send anything.

It depends on how the phone is making calls... it using an app [say, Whatsapp] it does use the internet [well, a data connection]. For bog standard calls using the touchpad, it would use the phone signal.

Advice above on turning it on and off fixes most phone problems. Bonus points for taking out the battery for 15 seconds or so.

-

-

3 minutes ago, frangar said:

Depending on how good or not the internal framing is you might lose a bit of structural rigidly

It is a butty built by Hancock & Lane in, I think, 1987. Converted in 2010. I will try to post pictures of the pre-refurb inside that might shed light on the internal framing.

-

1 minute ago, MtB said:

Probably not actually! Other than it will make the boat look a bit weird.

I believe that is considered a feature at Agenda 21....

-

1 hour ago, MtB said:

Quite a bit I'd suggest. This is one of the ways a cheap hull is made cheap. Welding is EXPENSIVE. The rule of thumb when I worked in an engineering firm was a skilled welder was expected to weld a inch per minute. And ISTR a cost rule of thumb being £1 an inch but this was decades ago.

So measure the length of all the guard irons on your hull then you can work out some times and costings to weld them on properly. i.e. continuously along the whole length of every rail, top and bottom.

Then there is removal, cleaning up and prep work of the old rails before any welding gets done....

Thank you for the comprehensive reply. Given that the boat does not have an engine and only gets moved from its permanent mooring site for lifting/blacking, is there a downside to simply taking them off, making the surface smooth and repainting?

-

Just now, frangar said:

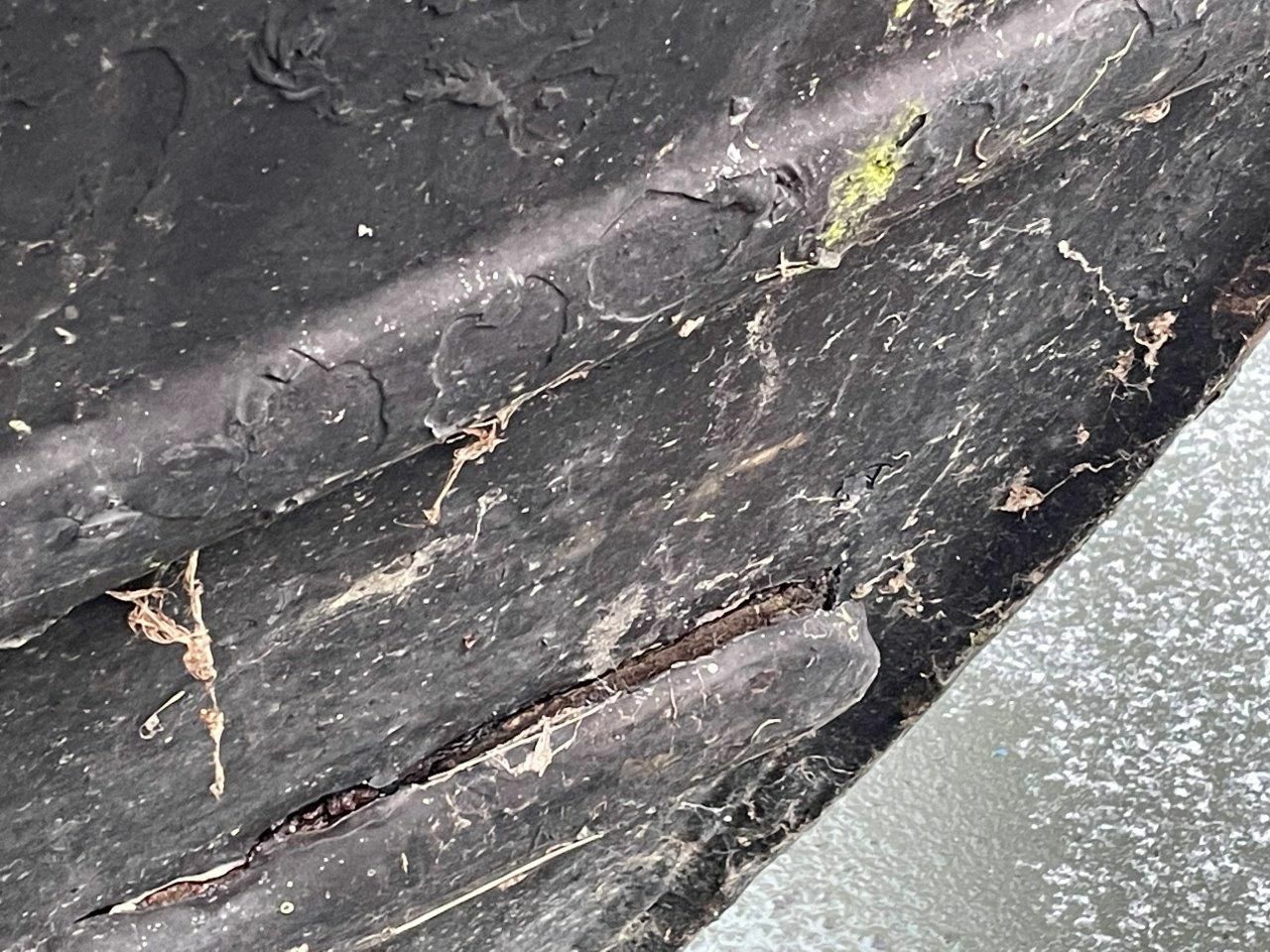

That’s the issue with just tack welding the rubbing strakes. There’s a new widebeam here that you can watch the rust forming as the rubbing strakes are just tack welded top and bottom. It costs a few quid more to seam weld them when the hull is being built but as you’ve found it saves a lot of pain later on.

Best thing is get the boat out the water. Grind the welds to get them all off. Shot blast the hull. Then seam weld them back and two pack the hull. Not cheap…you will need to see what insulation has been used as that might try to catch fire etc.

thank you, and the insulation is spray foam. Can I assume that problem is localised to the strakes?

1 minute ago, Feeby100 said:The strakes have just been spot welded which I hate as water get behind and rots

but that has no bearing on your hull really

ah. that is the answer i was looking for! Thank you.

-

1

1

-

-

I don't think so, but interested in the views of the CW collective. The boat was last lifted, examined and blacked in 2018, all was fine. I don't recall the depth of steel but it was well within tolerance.

Obviously, these strakes are above the waterline so they are not going to sink the boat, but what do they say about the state of the hull? How much work to repair?

thanks in advance

-

3 hours ago, David Schweizer said:

Whilst I have the greatest sympathy for the gentleman and his family, I have never really understood how so many cyclists manage to fall into the canal, unless it is due to careless, reckless or unobservant riding. As already mentioned towpaths are often narrow with obstructions, so why do cyclists fail to take these factors into account when using the towpath. Of course there are the head down and pedal like hell merchants who are destined to cause themselves (or someone else!) serious injury, but I am not a particularly fast or adventurous cyclist, and always slow right down when any potential hazard presents itself (also have a bell and loud voice!) In more than fifty years of being associated with the canals, I have never managed to cycle into, or fall off a bike, into the canal.

I fell in once, perhaps I may qualify for the 'reckless' label? My cycle commute was a shade over 20 miles one way, a bit of road, and then mostly Thames towpath and Basingstoke Canal. To avoid as much road as possible, I found a link up along the River Wey, but it could be very muddy. No problem with knobby mountain bike tyres, but i didn't fancy the drag of such tyres for the other ~19 miles. So I took on my chances on slicks, and one day it caught up with me. Sideways, and then backwards slip into the river. No damage done.

-

I have lost to people from all over the world on this one: Queen Alice Internet Chess Club - Play free turn based Correspondence Chess in your web browser!

-

1 minute ago, Loddon said:

Ok

The ones you have use a transformer, the plastic box, to convert mains 230v to 12v

GU10 are 230v but with a capsule lamp.

The ones I linked are 230v with inbuilt conversion to run tge LED lamp, so can be wired the same way as GU10.

Just remember to turn the power off at the fuseboard before working on the circuit

thanks again... so can I simply take the wire that is going in to the transformer and use that to connect up the ones you have linked? It would be a heck of a job to run new wire to all the lights in the ceiling. It is the ceiling of the ground floor, so there is no insulation to deal with.

-

26 minutes ago, Loddon said:

Personally I would junk the lot including the transformer and fit Something like this

You will have to pull new wiring through the ceiling as I did when I fitted them in my kitchen.

I dont like 12v downlights as the transformer is always a problem.

They do adjustable ones as well if you need them

Can you help me understand the difference? I have figured out the difference between these and GU10....

-

I tried to google it, wandered through electrician forums, and then figured I would come back here where I always get clear answers.

I have a sitting room/kitchen combined that has 11 LED downlighters. One of them went dim last year, the electrician who put them in [in 2014] took it away to see if there was a warranty claim - he has been hard to get hold of since... All ten are now dim and I want to replace them. With... what? This is the blurb:

230V, 12.4W LED, Mains Dimmable, White

810 Lumens, 2700K, 46 Degree

Diameter:80mm, Recess:100mm

At the time, the documents called them Orlu Quad70 recessed tilt dimmable... but I can find no lighting company called Orlu. I quite liked the look of these, but looks like I need to be... well, something other than what I am. Ecostar® | Ecostar® Products | Ecostar® Lighting (serenlighting.com)

Key requirements are that the light is bright, that I do not have to any more hole cutting [the hole is 70mm], and that they are dimmable. I do not really need them tilt-able. Finally, is the problem likely to be in that little plastic thing in my hand, or the light unit itself? Do both need to be replaced?

thanks in advance....

-

it is also possible to not be able to make a 999 call if you are using certain 'voice over wifi' services with or without a sim card [but out of coverage]

-

7 hours ago, john.k said:

A complaint to consumer affairs/small claims /....and a bad review for the repairer.....many are more scared of the bad review than consumer court.

small claims is tempting, and i am still trying to see if we can work it out. they have moved on from their early 'talk to the hand' approach, to at least some effort to get a resolution. Quite possibly when they reviewed the photos in the 'you did not send us the keys, because we have photos of what you sent us'.

-

1 hour ago, MtB said:

Ah I see, thanks.

Looks to me then as though the key communicates with the bit on the bike in much the same way gate code keys communicate with the gates. Each key will need programming so this might be why the bike was given to you! Or do you mean the people who replaced the battery lost the key?

the latter.... Apparently I did not send the key, although their directions included 'send us the key'. Instead, apparently I thought I would buy an expensive bike battery that i cannot use.

The bike came from a relative who did not use it for so long the battery was dead.

-

36 minutes ago, MtB said:

Sorry but I can't make ANY sense of your photo.

Can you zoom out a bit so we can see the context?

I can't see any keyhole for a key to go into. Are you perhaps using the term "key" rather more loosely than I do?

The device is a key, but it does not do anything but lay the bit of the key where your fingers go against that grey LCD surface - there is nothing to stick a key into. Here is a picture nicked from the internet:

-

ok, not really directly related to boating, but this seemed the right section. My wife was gifted an ebike with a dead battery, straightforward enough to get someone to rebuild the battery. But it came back without the key that switches on the battery and no amount of emails to the company is helping the key to reappear. 😡 The key touches that little thing on the handlebar to turn on the battery. The company is long gone from these shores... no vendors I have found can help, etc. Would the electrical types on here know if that funny looking thing [presumably some kind of reed switch?] can be cut away and a simple weatherproof toggle-type switch put in its place? I understand the implications to [lack of...] security, etc

EDIT: PS I tried just waving a magnet over it, but that did not work.

-

Very good and I do think this thread would be improved immensely by assigning real CWF user names to the Poster letters.

-

43 minutes ago, Tracy D'arth said:

Such is the value of used appliances these days, no one wants them even if they are working. Your hob will have a microprocessor inside and the makers will not release any service information, only a complete new PCB at as you have found a crazy price for something that probably cost $10 to make.

Do you get the impression that the makers don't want you to be able to repair it? They just want to sell new ones!

That is really too bad, and thanks for the insight. I see a growing trend of 'right to repair' legislation and I would support that. the old hob feels a high quality, heavy thing... quite a waste to just throw it in a skip.

-

in ~2015, I bought an ex display kitchen set up that included an induction hob. Last month the hob gave a generic error code and stopped working. A local firm came by and for **only** £500 they said they would replace the 'Power PCB' [which was >£400 of the total bill]. As a ceramic hob was about half that, I now have a non-working induction hob sitting in a back room.

Is there an option to getting working? An organisation to donate it to who can fix it and use it? Seems an awful waste to just chuck it in a skip.

Where am I, internationally?

in General Boating

Posted

That is the one, looking north from the Garden City Skyway to [I think] Lock 3. To be precise, it is the fourth Welland Canal, the remains of the others are scattered around parks and other waterways in the city of St Catharines.