Batavia

-

Posts

741 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Batavia

-

-

-

4 minutes ago, ditchcrawler said:

Are there actually any decent plans available for a Narrowboat hull?

Selway Fisher have a design for a narrowboat (and a wide beam!)- and have produced other designs in the past.

-

I normally use rigid uPVC conduit.

For 12 volt circuits I have just drilled holes into the conduit, fitted them with grommets and brought the wires out directly to fittings that are close.

For 230 volt circuits, I use normally use singles and proper conduit fittings throughout.

-

16mm LDPE pipe is widely used for irrigation systems and compression fittings (in addition to useless barbed ones) for it are readily available. No idea how its wall thickness compares with the boat piping.

-

Just now, Tonka said:

So are you Frank

No, I am Chris! Frank has kept his various boats there for decades too.

-

39 minutes ago, Tonka said:

So it is the house on the right with the slipway, while Lindy lives next door in the house on the left. So she has the garden and you have no garden. We'll overpriced then

Correct! You get the paved area fronting the canal and a microscopic garden round the back.

3 minutes ago, magnetman said:Do I recall a narrow boat with your username being moored there?

Your recollection is correct! We moored our boats (2 x Daedalus + Batavia) there, on and off, for 40 years.

-

52 minutes ago, Tim Lewis said:

Lindy Fosters House, once a Hire Boat Base, Bridgewater Boats.

No, its the house which was built next door about 11 years ago, on the site of the old boat shed (which was partially burnt down by a local juvenile arsonist after the boat hire business closed).

-

A little place for sale on the GU in Berkhamsted.

https://www.rightmove.co.uk/properties/137692502#/?channel=RES_BUY

-

On 14/07/2023 at 09:31, MtB said:

First time I've ever heard of electric paint. Do you have any further details please? Sounds jolly useful.

Try Aquadag!

-

20 minutes ago, system 4-50 said:

Some rads have air bleeeeds in the back rather than the ends!

We had one like this many years ago and the previous occupier had managed to break off the head of the bleed screw flush with the radiator, with the result that it was more or less invisible.

-

Another vote for them being a crap design! Apart from the "staying open" problem, the screw which secures the bottom end of the stay only had about 1 1/2 turns of thread engaged in the tapped block on the frame. One of ours fell out with a stripped thread. After that I removed the stays and adopted the wooden block approach.

-

6 hours ago, BEngo said:

Having tripped (on land) and dropped a running grinder plus wire wheel into my left hand, needing ten stitches at the base of the ring and little finger as a result, (it buggered the gloves up too), I certainly would not be having one dangling on a string near my bits thank you.

If a grinder falls in the water on the end of its wire I can always get it it back after the power goes off.

N

Also there are times when you might want to throw the angle grinder into the water!

I was using one with a flap wheel when a clump of flaps flew off and the wheel was then so out of balance that the angle grinder started vibrating so violently that I could barely hold onto it. As I tried to switch it off, the only other way of stopping it seemed to be to throw it into the water and hope that the RCD worked. A fraction of a second before I did this, I managed to switch it off.

Two lessons: First, flapwheels aren't necessarily as safe as one might think and second, only use an angle grinder with a very easy-to-operate On/Off switch. I once owned a Hitachi angle grinder which required two hands to operate the miniscule switch. Never again.

-

44 minutes ago, billh said:

There should be a fancy automatic voltage regulator, I don't think its built in the terminal box on the generator is it? Ours has a rather nice looking moving coil regulator that looks like a giant Avometer without a scale in a seperate glass fronted steel case, beautifully made and replacement would be expensive. It might be possible to build a modern electronic regulator at reasonable cost, though not something I would like to do!

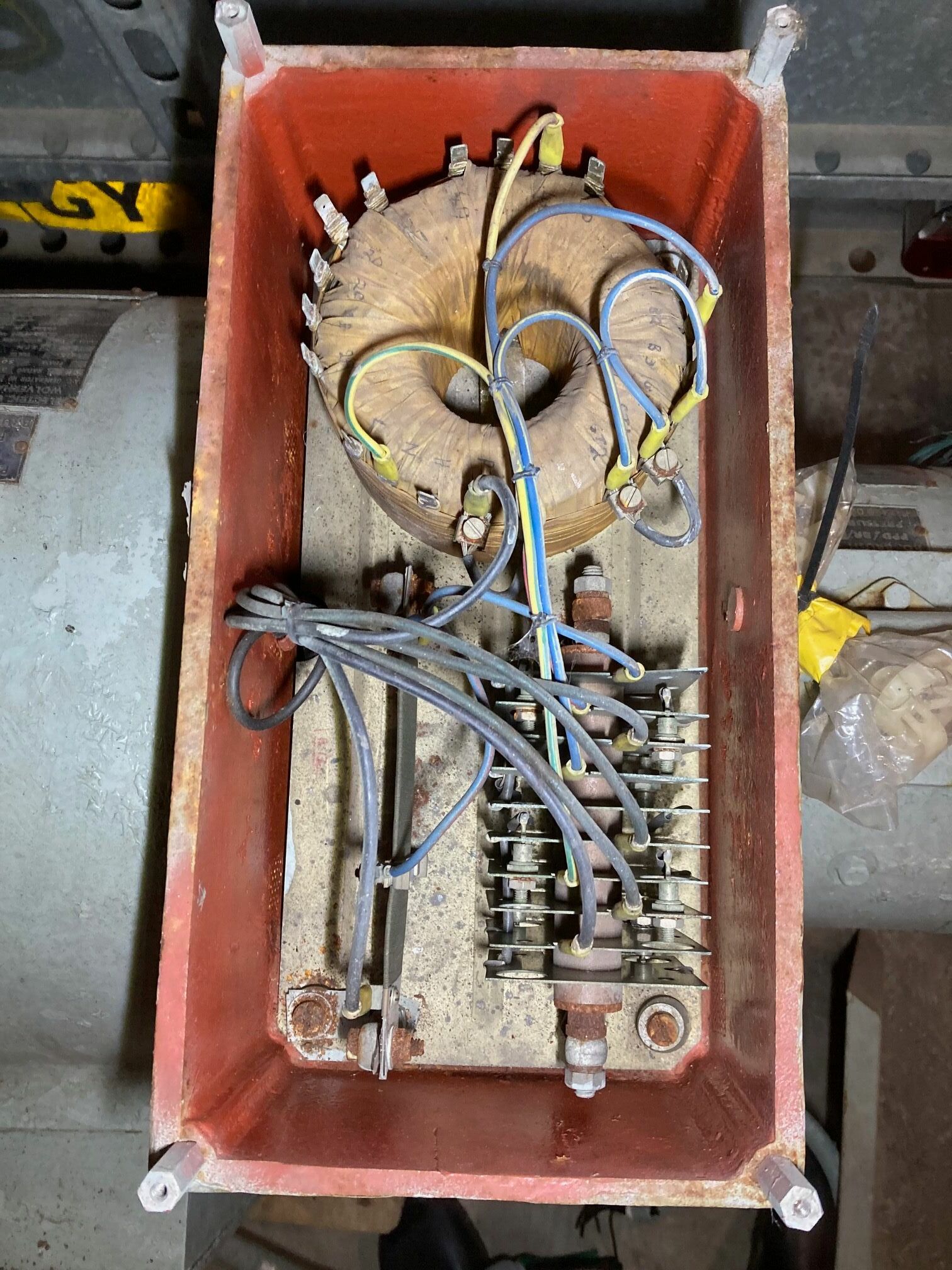

This is the inside of the box mounted on top of the alternator; all the exciter connections seem to come in here.

It looks like part (or all) of a voltage regulation system, especially if the toroidal thing is a saturable reactor. At first glance, the finned item looks like a selenium rectifier, but it actually has stud diodes.

I am away from the genset for a few days but will do some serious investigation at the weekend.

thanks again for your help

Chris

-

7 hours ago, billh said:

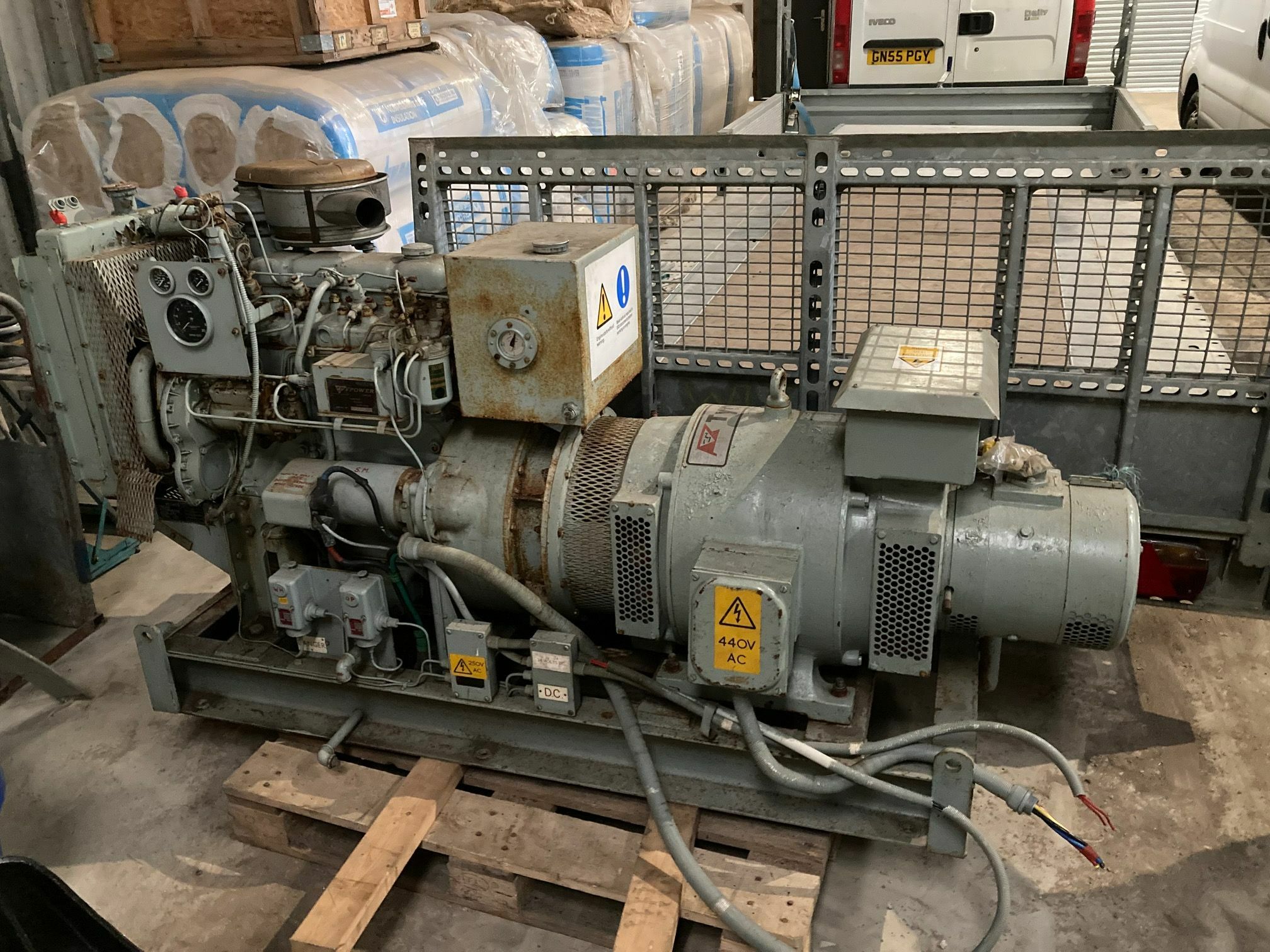

Looks like a 'phone exchange standby generator to me. The various control boxes at the base are to do with automatic start up and shut down. If it's anything like the much bigger one we have (straight eight Dorman engine), that tank on the top is a lube oil supply , not a fuel tank and there is a float valve connected to the sump that lets oil in from the tank if the sump level drops. There may also be a mains immersion heater (about 300watt) in the cooling circuit to keep the engine warmed for a quick start up. The square thing on the side of the engine is a solenoid stop valve connected to the fuel pump rack. The engine speed needs to be kept constant for all electrical loads to maintain the output at 50HZ.

Thank you for your very useful comments.

It has P.O. Brush Code labels on the alternator and exciter, so I had assumed that it was probably from an exchange.

If there is a mains immersion heater, it would explain the junction box labelled 240 Volts.

The solenoid stop is seized solid but apart from that, things are in reasonable condition and the exciter commutator shows very little sign of wear.

From the way it is plumbed in, I had guessed that the oil tank was part of a dry sump system but your suggestion of an automatic top-up arrangement makes more sense.

Unfortunately someone has cut off and thrown away the electrical control panel!

I will drag it out of the gloomy shed and start work on it.

The owner wants to install it for occasional use at an isolated farm, on the basis that people will be less likely to steal it than a more modern (and much lighter) genset, especially if we fix it down with rag bolts!

Chris

-

6 hours ago, john.k said:

Perkins 4/236 .......but also on the same block/head 4/212,4/236,4/248.

Thank you! I also received the same answer from another person in Australia!

-

Not in a boat but I was wondering if anyone here can identify this Diesel engine, which drives a 26 kVA genset. There don't seem to be any identifications on the castings but it has been suggested that it might be a Perkins.

Many thanks

Chris

Edited to add - It has a dry sump - the box with the gauge being the oil tank.

-

Two types of pipe were used - the flexible HAIS one and the steel HAMEL ones. The latter were 2" or 3" pipe.

-

31 minutes ago, buccaneer66 said:

Thats a multi product tank farm fed from the Isle of Grain, most of the defunk one fed airfields that no longer exist, & some airfields where fed directly by the GPSS.

Since the Sunbury Lane terminal, further upstream closed over 20 years ago, these tanks have been fed by dedicated Jet A-1 lines from IoG and Aldermaston. Fuel is supplied to Heathrow and Gatwick from these tanks.

I did many projects here over the years, including a solar-powered sheep shearing setup, for dealing with the sheep which at one time were kept to mow the mounds!

-

On the Thames, the Walton Weir site is still very much in use, alongside the cut above Sunbury lock.

-

43 minutes ago, BEngo said:

There was a stoppage at the top of the Northampton Arm a couple or three years ago when some bandits drilled a hole in the branch of The Pipeline that crosses by the first bridge.

One of the surprising things is that The Pipeline handles multiple sorts of fuel. Aviation keros, diesel, petrol, etc. all go down the same tube, one after another, and are sorted out by careful valve selection at the tank farms.

N

Strong emphasis on the word "careful" is required. When I was working on an airport tank farm in Asia, a 14 million litre tank of Jet A-1 was put off spec by some idiot cutting the interface badly on the incoming multiproduct pipeline!

-

Tim Whittle's book "Fuelling the Wars - Pluto and the Secret Pipeline Network - 1936-2015" is an excellent book on the subject. Tim is an engineer who worked for many years on the GPSS and the book is a result of extensive research.

-

10 minutes ago, nicknorman said:

Doubling up negative cables is fine, though in your case at 20cm it isn’t going to make any difference. Doubling up positive cables can mean that 2 fuses are required because really the fuse should be able to protect one remaining cable if the other becomes disconnected for some reason. However this is only going to be a problem if the max intended current flowing in both cable exceeds the max allowed on one cable on thermal grounds.

I would like to point out that fusing of individual parallel conductors is hardly ever done in electrical power installations - on the basis that the installation should have been done properly and that nobody would be stupid enough to disconnect a conductor. However, having seen some atrocious boat electrical installations...

-

1

1

-

-

5 minutes ago, cuthound said:

When I was working cables were often doubled, tripled or even quadrupled. Mind you as 630mm sq cable is the biggest you can get and the loads often exceeded its current carrying capacity there was no other option.

Providing the lugs are crimped properly and the bolted tightly to.the connectors there shouldn't be any problems.

Totally agree. I used to double up cables on largeish motors, as it is infinitely easier to install 2 x 70mm2 3 core SWA cables than, say, one 240mm2 in ducts. On a 1.6 MVA distribution transformer, the tails will normally be 3 x 630mm2 AWA per phase and 2 x 630mm2 for the neutral.

It relies entirely on good workmanship.

-

1

1

-

-

Another vote for Oxon. They did a fine job on Daedalus - which still appears in their video!

Chris G

Seal through bulkhead

in Build Blogs

Posted · Edited by Batavia

If you are serious about obtaining an excellent seal, then use a cable transit system, such as this:

https://www.powerandcables.com/product/product-category/roxtec-crl-cable-transit-frame/

Sit down before you start looking at prices!

Edited to add:

For single cables, just use plastic stuffing glands - cheap (in small sizes) and effective.