-

Posts

79 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Maudesmaster

-

-

2 hours ago, jonesthenuke said:

Best wishes for the Hip operation.

Thank you

-

Thank you all for input

I wanted to know when to adjust tappet clearance but in a state as boat in midlands and me in Canterbury waiting for hip replacement this Saturday

Mind was going haywire

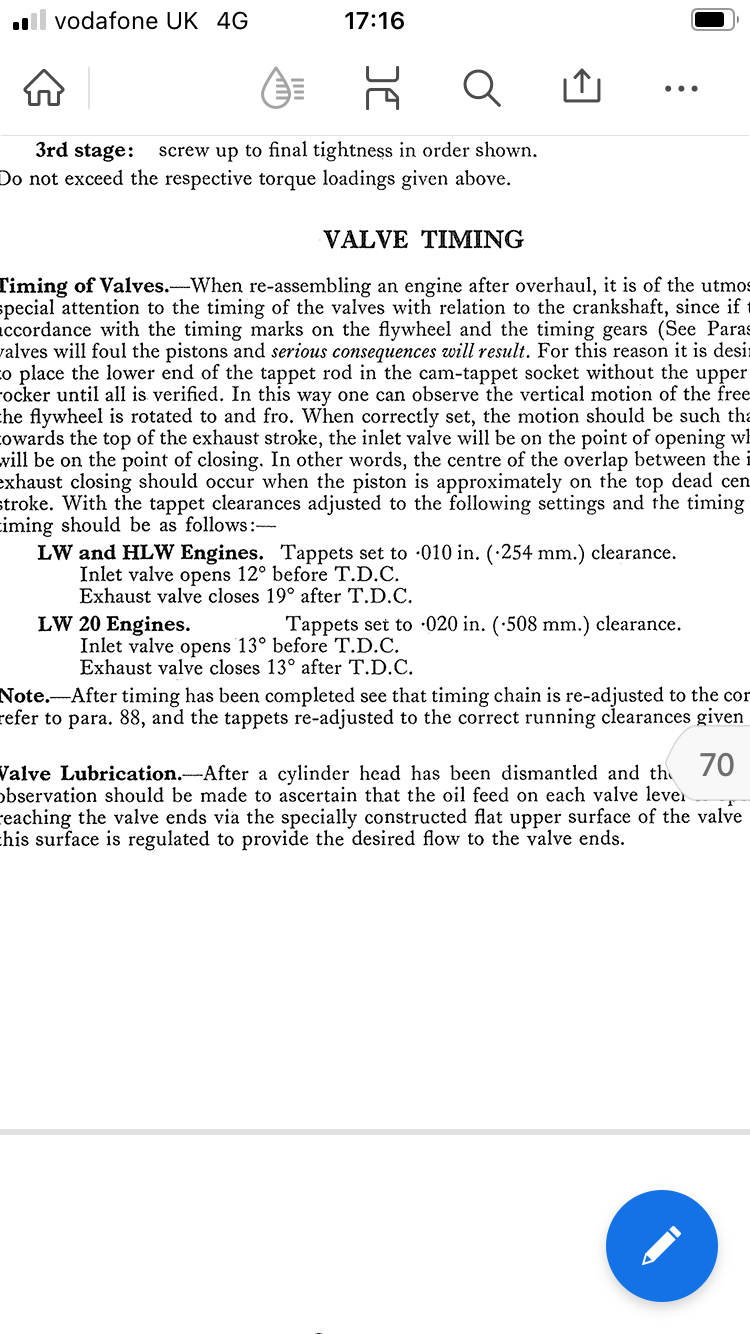

It is now clear to me tappet has to be set (.254mm or 10 Thou/in as per rocker cover /manual)when push rod fully down ie valve fully closed irrespective of stroke

will have to wait to get back to boat in about 5 weeks

thank you all again

Richard

-

-

1 hour ago, Tony Brooks said:

What are you asking, because I can't see where you tell us what you are trying to do.

Adjust the valve clearances?

Set the injector pump timing? But why you would need to do that for just a head change, I don't know.

Something else?

Assuming you mean valve clearances, the way I would do it on any three-cylinder engine is:

Turn the engine until one valve is fully down, and use a bot of chalk or crayon to put a witness mark on the front pulley or flywheel. Align it with any engine feature that is convenient.

Turn the engine one complete turn until the witness mark realigns.

Adjust the clearance on that valve.

Rub out mark and repeat for the other valves.

I have manual head torqued down and push rods for No 1 cylinder in place

trying to establish which stroke to adjust tappets

As an old Scottish ship mate used to say “Mar Heeds a boiling “ I now know what he meant going back to Canterbury to see if the experts there can explain it in dummy narrow boat owner lingo

thank you all for input

-

had Cylinder head refurbed by Gardner Marine

Head on and torqued downcylinder 1 approx 12 degrees before TDC and pump lever sloppy

.254 feeler in both valve tops

Am I good as away from Gardner’s

will do same with 2 and 3

-

Yes I make you right but takes 7/8 weeks to cast a new and 4 weeks to repair so now I’ll have a spare after one on boat now repaired 👍🖖

-

Thank you but boat in water I changed it from 21”-18 pitch to 21”-21 pitch 18 months ago heating prop on slipway and replaced whilst in the water but that got badly bent blades so was going to try home made puller to drop it off again in the water

I had a date 5th March to haul out but day came and went waited for new date but very allusive so just thought give it a go at least until new date comes up but have to be after Hip Op now

-

Thank you I thought it was 2 1/2” from memory but drilling back plate it looked small 🤞🏼It’ll be about right

-

1

1

-

-

I’m guessing for 1”1/2 shaft all going to be about the same amount of meat to where the blade begins

-

On 03/04/2024 at 20:17, Momac said:

You beat me to it.

That’s what we do Shower pipe out of porthole and galley tap through side hatch

-

Thank you all take off for engine was from diesel heater off take so when tank lowish I guess slopping fuel meant picking up air now taken from correct off take found smaller pipe inside take off pipe bit of a giveaway

Thank you all for comments

-

1

1

-

-

Anybody sitting near a 3 blade propeller 1”1/2 bore and can measure the diameter of the boss boat side

Anybody sitting near a 3 blade propeller 1”1/2 bore and can measure the diameter of the boss boat side

I’m making a puller and need to know distance from shaft centre to outside boss for threaded studding

have new prop but on boat in Penkridge I’m in Canterbury waiting hip op

lost the fag packet with dimensions on

thank you

-

My old girl been working fine after tappets adjusted by lad fro Walsh’s on the Bridgewater

did Leeds and back now on Staffs and Worcester

Engine slowed and shut down cruised to side to investigate bled to pump top couple seconds for air to clear

Ok changed water separating filters in the big double changeover for new

changed other fuel filter

diesel clean and no water started up was fine went past a few boats on tick over throttled up and engine missing skittering backed off throttle seems ok as long as not too much throttle

Any ideas please hoping not amal lift pump

-

2 hours ago, CIEL said:

Clements Engineering is where my prop was fettled.

A short taxi ride from Eaton Socon Lock on the River Great Ouse.

Or use carriers

Phone: +44 (0)1234 378814

Email: sales@clementsmarine.co.ukClements Engineering Ltd,

Unit 120,

The Industrial Park,

Little Staughton,

Bedford.

MK44 2BNChris

Thanks for that I think I’ll go through the insurance see if it’s covered going to cost a bit to get it out to remove

he. I had it re modelled to 21 pitch Cowroast marina hauled it up and got the prop of and I replaced in the water

used a Nordloc washer Half locking nut and half nyloc nut kept checking every day for a week then as and when hatch opened still tight

-

34 minutes ago, David Schweizer said:

Or get stuck solid and stop the engine. Something I have seen happen on a couple of occassions.

Happened behind the poachers pocket on the gollie last year Knocked it out with my Maul Axe

Just now, Maudesmaster said:Happened behind the poachers pocket on the gollie last year Knocked it out with my Maul Axe

Was a log

-

1 hour ago, Alan de Enfield said:

There must be a point where the gap becomes so small (1" ?) that pieces of wood and extraneous materials just cannot get stuck, bounce off the prop and continue on their way.

My way of thinking but dunno

-

3 hours ago, blackrose said:

I didn't realise they'd moved from Isleworthless. They repitched my prop 10 years ago and did a top job.

Yes great company did you walk through the workshop to the loo Amazing place like the TARDIS countless machines never seen the like of

-

11 hours ago, MtB said:

I had a 21 x 19 on the Kelvin K1 after a lot of experimentation. That was on a 1:1 final drive ratio and as you no doubt remember, it was fairly over-propped. I have a similar sized blade on the Gleniffer, also with 1:1 final drive ratio. Works well.

Given the OP's concern about clearances, rather than get a bigger diameter blade it might be an idea to experiment with final drive ratios. Its probably a PRM D260 on the 3LW and I think there are a variety of ratio gears available for the D260.

It’s a PRM D500 as originally wanted Hydraulic Bow thruster

-

On 28/09/2023 at 10:52, plato said:

Good tip , I might try that. I think you’ll have a Stirling burner in there , very common and no problem for an engineer to service.

If you’re of a practical bent it’s fairly easy to to change the nozzle. That will help but when my engineer does mine he analyses the exhaust gases and makes adjustments to get it burning efficiently. Which you wouldn’t be able to do. He charges £80 which is a lot less than heritage do.

my stove had been sat unused for 2 years in a boat that had been partly flooded. So it wasn’t running at all well when I first used it.

Heritage did send an engineer up to Gloucester from Cornwall but it wasn’t cheap. He did strip it down and did a very thorough job on it.

if you phone them them I’ve always found them to be helpful.

I put redex in my diesel and it definitely helps.

My engineer commented how clean the nozzle was when he serviced it. Generally they’re very sooted up.

Redex is often on offer in Tesco or Lidl so not costly for the benefits you get.

good luck with it and let us know how you get it sortedHow much red ex do you use I say 300 litres

-

I got the prop from Jonathan at Norris and had it re worked there as I will probably do again I just wondered if having a smaller gap would stop stuff getting trapped and damaging the blades

also 1 thought if I go longer blades I can have less pitch I dunno just wondering

I wish they were still in Isleworth as easier to get to without a car

With the damage slightly less speed but when reversing boat goes a lot more to the port side

luckily I had built in a bow thruster when ordered the shell

1 hour ago, dmr said:I suspect a 3LW could handle something much bigger than a 21x21, but with only 24" of space going any bigger than 21" might give problems, but chances are it would be ok.

A new 22" inch prop will cost a bit but if you have the money it would be nice to try it.

I assume it could be reworked down to 21 if it doesn't work out?

Are you happy with your current tickover speed and maximum speed?

You must have hit something big and hard to do the damage. I suppose a bigger prop very slightly increases the risk of it happening again, but its such a rare event its probably not worth worrying.

Max is ok tickover very slow almost stops but gets a bit of Patricroft smog with low revs so tent to up em a bit just yell sorry Gardner on min steerage

-

Eventually ordered a Left hand 21”x 18 pitch Propeller 3 years ago was ok but lacking thrust so had it remodelled to 21”x21 pitch 1 year ago worked fine but hectic on right hand bends until got used to the stern pushing to the right

Now then I have a throw of 12” ie 24” between skeg and uxter plate

Up on Leeds Liverpool just west of Wigan flight top lock picked up a big rock or something winding all three blade ends are like the top of an “r”

I am wondering if better to have 1” gap top and bottom and going for a 22” prop

62’ with a Gardner 3LW

not done anything about it yet as needed to descend the flight before it closed

-

-

11 hours ago, plato said:

If it takes over an hour to boil a kettle from cold there’s something drastically wrong with it.

I’ve used one for 10 years on my previous boat. And yes there is a knack to using them but once you’ve got it they’re great. In fact I liked it so much I’ve just had a new one dropped onto the base plate of my new shell. They’ve built the boat round it. Much easier and cheaper than having it stripped down and rebuilt inside the boat.

Thank you maybe we’re doing it wrong

we get up and turn temp to 180 when thermostat switches we lift lid and place kettle on back half it’s an hour before kettle boils

we dropped ours through the stern doors (semi trad) used rollers to position

-

It’s 240AC fan Diesel burner cooking only and was fitted by OFTEC people who deal with Heritage

3lw Gardner 2’3 draught

from cold takes over1 hr to boil a kettle

would not recommend and no after sales service sent E mails about flue when first fitted nothing back

3LW tappets

in Gardner

Posted

Thank you