-

Posts

819 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Store

Posts posted by Mike Adams

-

-

- Popular Post

- Popular Post

I am not surprised that insurance companies are becoming more careful about insuring large and heavy craft especially on tidal and fast flowing rivers. A lot of these wide beam things don’t seem to be designed to work properly as boats and their design often makes them difficult to manoeuvre anywhere other than on a static canal. Some Owners seem to lack experience and sometimes the physical capabilities to manage the vessel in difficult conditions. When things go wrong which they seem to do quite frequently now a lot of damage can be caused to the infrastructure, other craft and potentially the boat itself. Nobody wants more regulation but I guess something along the lines of the ICC would be a good route. I can’t see why people need such large boats to go boating - if you want to live on boat that’s fine by me but don’t clog up the system for everyone else.

-

5

5

-

Robbie came up the Basingstoke Canal last autumn. I was a bit disapointed, as a long term Basingstoke canal boater, that the view given in the program was the canal was difficult and shallow.

Yes there is some weed and a bit of floating pennywort but on the whole it is well maintained any easy to navigate. We have used the canal over many years with deep drafted boats and seldom had any serious problems and it is true that you have to book the locks but in practice we designed the lock open times many years ago to make it work for visiting boats. Please don't be put off from visiting our lovely canal. For those of us with long memories of canal boating in the seventies nothing is really difficult now.

-

3

3

-

-

On 07/04/2025 at 08:12, Biggles said:

As the alternator is a permanent magnet type I can't turn off the load electrically to initiate a soft start.

You just need to fit a small load resistor for starting and a contactor that brings in the load (batteries) when the engine is ready. If you fit a hydraulic system you could also put an electrically operated hydraulic valve across the load to act as a bypass or use a manual valve. A 20Hp vane motor for the engine should be easy to find as would be a pump for the alternator.

-

So am I correct in thinking that if the boat was constructed prior to the RCD coming into force then whatever changes you make to the vessel then you are under no obligation to tell anyone or comply with anything even if there is very little of the original boat left?

-

8 hours ago, MtB said:

I got well and truly stuck on the southern Oxford last year, right in the centre channel in a boat with 2ft 10in draft.

A canal supposedly good for boats of 4ft draft according to the CRT website...

The data on the CRT website is a work of fiction. You could, several years ago, get through with 3’ 6” draft but only with the canal full. I think my old boat White Heather was one of the deepest on the narrow canals and we did manage to get to a lot of places and failed to get to a lot as well. I think the OP’s boat is of a similar design although hard chine and I suspect when loaded up of a similar draft. White Heather is much happier up in the North East. Going back to the Oxford on our last trip the shallowest place was below the demolished railway bridge at Thupp which had a hard bottom. The problem with such draft is that you can never be sure of getting there or back on a trip. 6” off the summit and it’s a real headache. l found the worst problem was boats running their engines at moorings. I remember going hard aground in the middle of the. B and F where there was only just over 2ft of water in the channel but over 4ft at the bank where there were a couple of permanent moored boats.

-

Good to see the Gloucester out and about again. With a 3 foot draft you should be almost good to go anywhere. I had a similar boat but was 3'6" depth and managed to get most places. What you need to remember with the shape of this boat is there is much more pull down than an ordinary narrow boat - partly as a tug it needs to get a good grip on the water in order to pull effectively but this doesn't work on shallow canals. The Kelvin probably drives it too fast in those circumstances which is why you are going aground. The other thing to remember is you will not be able to slide off the mud sideways as with a conventional narrowboat. You need to reverse off until you get into deeper water.

I can't remember if your boat had raw water cooling from the canal or if it had a skin tank. If it is raw water cooled then if the strainer get blocked and the engine overheats beware of cracked cylinder heads or a blown head gasket which would result in the symptoms you have described. I found my Kelvin to be a poor starter in the winter unless you are starting on petrol? You didn't say if you were starting as a diesel (with or without heater) on on petrol. If you are really stuck I might be able to come and give you some advise although I am long retired now but I am not so far away. Kelvin parts are not that easy and cylinder heads are difficult to find.

-

My trojans were like this after about 5 years. The capacity was about 10% of new. Nothing to be done except scrap them. I thought they may have lasted longer.

-

1

1

-

-

It is probably better to wire the split charge relay to feed the starter battery and connect the main alternator output to the domestic batteries. The load on the split charge relay contacts is far less. Most of them were designed for caravans etc not for 400Ah loads. A switch to connect the engine and starter batteries together in an emergency is always a good Idea. You would be surprised how much voltage drop you get across cheap isolator switches and split charge relays and this can result in the batteries never getting fully charged.

-

1

1

-

-

In my experience most canal boat drive systems are very poorly engineered especially considering what would happen if you get a lock up on the propeller. Ideally the part that fails if the system cannot absorb the shock without damage should be cheap and easily replaceable. Something like a plastic R and D coupling in the prop shaft( you can remove the metal links). Most gearboxes used are far too small to do a proper job on a canal boat and the flywheel drive plates are too weak and don’t last. But of course the biggest problem is the operator who overrevs the engine when they get into shallow water and just pulls everything off the bottom instead easing off.

-

-

You have my sympathy. I am on my third boat with a wooden top over a period of 50 years. I doubt that you have 'real' marine ply so you have to accept it will have a limited lifetime of maybe ten years. There is usually a waterproof barrier between outside ply sheeting and the internal T and G boarding. Something like bitumen sheet or possibly plastic and this would extend down over the metal upstand. If you have no insulation on the cabin sides you are bound to get condensation when it is cold outside. The problem is if the ply is wet it will rot and any tiny crack will open out in the summer and is going let water in to the plywood. The best solution is to coat the outside with fibreglass cloth embedded in West epoxy as someone has mentioned. This can only be done if the ply is completely dry and not at all rotten. You cannot be sure that the plywood was sealed properly when it was fitted and the bottom edge is likely to suck up water like a sponge if it isn't sealed. You don't say how thick the ply is, and if it needs to be structural, but I would look at replacing the ply with something else - maybe some of these composite panels they use in bathrooms under tiles and fibreglass over the top which would give you some insulation as well. Another option is to pre-coat the plywood with west epoxy before you put it on. There are some people who will fit a steel skin over a wooden top but I don't know how well this works or how expensive it is.

-

9 hours ago, Alan de Enfield said:

There are many scientific papers that explain the whole process.

Does this help ?

Maybe these papers will give you some light weekend reading :

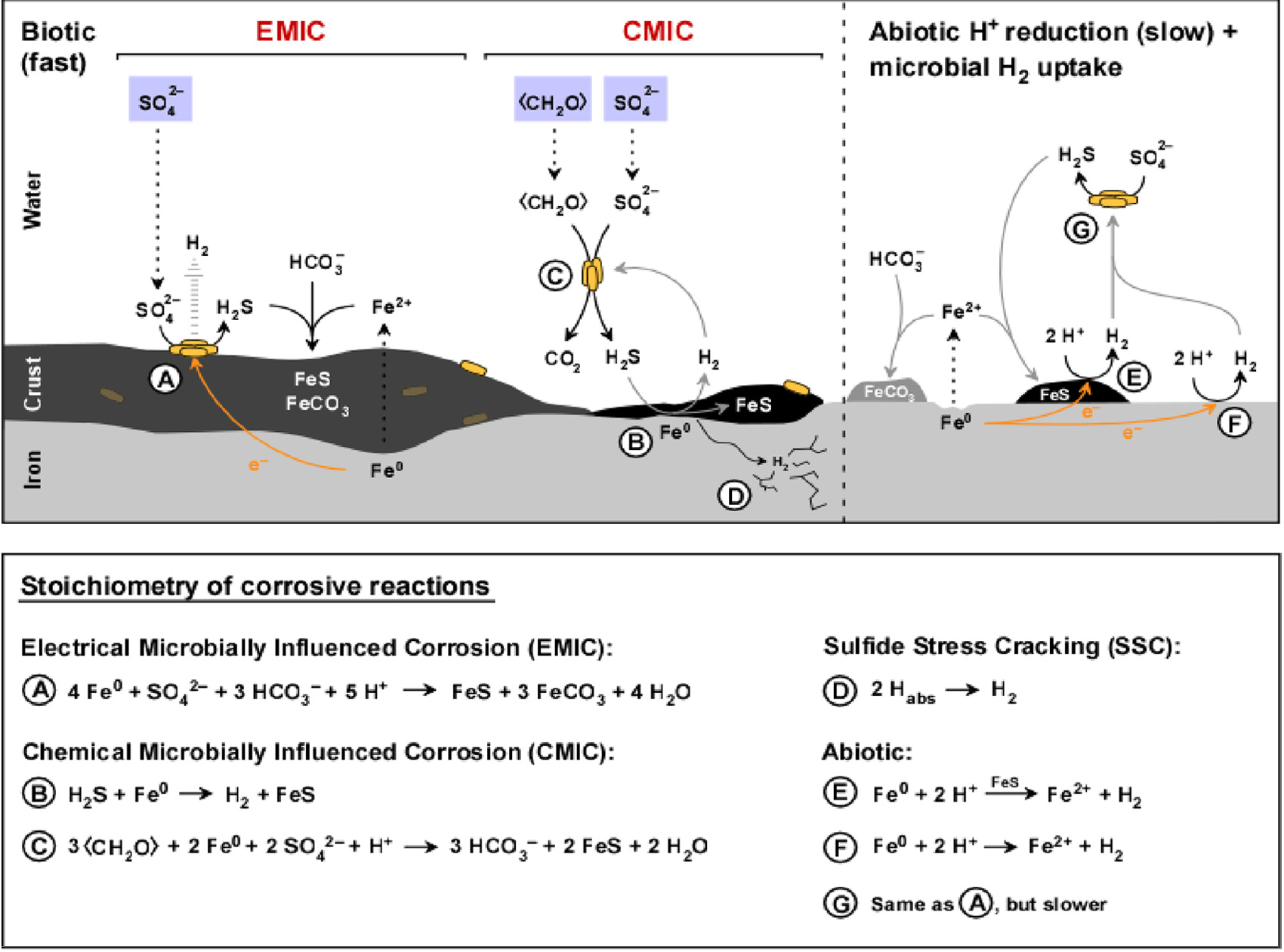

Thanks I will have a look at the weekend. Looks like you need a certain set of circumstanses not just pure water, microbes and iron!

-

6 hours ago, dmr said:

I would think the hot application would kill any existing microbes. A zinc coat and epoxy then protects the steel so I would think no chance of any corrosion.

What I don't know...

If the epoxy is scraped can the microbes eat the zinc?

If the epoxy and zinc are perforated does the local zinc provide any protection??

I don't understand how this corrosion works. Presumably the microbes don't eat the metal(chomp chomp) but create some sort of reaction that causes iron to turn to an oxide and then they use that compound in some way. Zinc is normally sacrificed in favour of the steel but do they eat zinc as well? I tend to think zinc is more poisonous but what do I know.

-

Do anyone know if the zinc spraying done by debdale prevents MIC?

-

19 hours ago, magnetman said:

Unusual situation currently as the part time storm weir is in use due to a sunk Boat blocking part of the main weir.

I wonder if it was another of those fly -moored residential boats blocking the weir? The unfortunate crew were from Weybridge rowing club, it was a four and support launch and one of the crew is still missing. Being a bit further away they may not have been so aware of the storm gates being open. All very sad. Not sure I shall be sailing above Teddington lock this weekend.

-

18 minutes ago, Scholar Gypsy said:

I believe this action by CRT was due to fresh water flows on the River Brent, which was making the High St bridge unnavigable. The conditions on the tidal and non-tidal Thames are not really anything to do with CRT.

It may be the case that the high street bridge is difficult to navigate but allowing boats to get off the river and moor in relatively safe conditions above Thames Lock is important. Not all boats will be coming from the non tidal Thames they could be coming from the Medway or even France as has been my situation in the past. I have never known the Brent to get up that much that you can't get under the bridge at some point in the tidal cycle. This is all typical cover your back nonsense. We used to go up and down the Thames on Red Boards and thought nothing of it except be a bit more cautious near the weirs. If you were coming downstream the lockeepers (When they had some) would phone ahead and have the lock ready and open so you could go straight in at full tilt.

-

I think the IWA should have another go at this outrageous behavior. As there is a PRN both sides of the lock it should be contested.

In the 1980's the lock, as I remember, was open from 4am until 10pm without booking and there was always a resident lockeeper on duty who would let you through on demand. The fact that the non tidal Thames is on Red boards is irrelevant. I think it is still classed as a commercial waterway so CaRT are well out of order.

-

1

1

-

-

I can see why connecting the two different battery types in series is a no no but not so sure about in parallel if they are nominally the same voltage. The LA will ensure a stable voltage, prevent the alternators being presented with an open circuit and the Lithium will cut in and out with its internal controller as it needs. I must be missing something here but the Li battery pack I had in mind doesn't mention this. Probably better if they have their own isolating switch when not in use.

-

9 hours ago, blackrose said:

I wrecked a set of T1275s by using cheap deionised water which I suspect was either poor quality or maybe just water.

I have always kept them topped up but used 'screwfix deionised water'. I will look into that further.

Regarding Lithium batteries I assumed that the prepackaged types had all the electronics to control them within and were intended as a direct replacement for a Lead acid battery. Anyway I think I will skip the Lithium Idea altogether and buy a couple of AGM batteries.

I am cycling the Trojans to see if they recover but it seems unlikely.

Thanks for the advise.

-

My 2 Trojan T-105 batteries are about 4 years old and have basically given up with only about 10% capacity available. As the boat is only used for cruising for a few weeks a year I think it was a bad decision to buy them as they never became discharged much and they were always kept charged with only the fridge overnight taking much power which I estimate to be about 10% battery capacity used.

This year they have developed a high internal resistance which means if you put a load on of 10A the terminal voltage drops from 12.6 to just over 11 volts.

Anyway I was thinking of a Lithuim of say 100Ah with a cheap 100Ah AGM in parallel which is about 80% of the Trojans capacity but about the same sort of price. I don't like the Idea of the Lithium on its own in case voltage spikes cause the electronics to fail so the AGM battery can stabilize the voltage to a certain extent. Or just two cheap AGMs in parallel. Looking for any recommendations.

-

1 hour ago, Nicknicknick said:

If it's only temporary you need it you could get a plate heat exchanger £40 ISH and cool it with raw water via a temporary pump. Not elegant but would work.

A better long term solution would be to either install a heat exchanger in the mannicooler and have a raw water pump(jabsco) on the front of the crankshaft or an electric pump and you would also need a raw water inlet, filter and outlet or alternatively fit a bowman type heat exchanger between the engine and skin tank. In my experience these engines don't like running too hot and are prone to fail if they do. I have adopted this solution for my Isuzu55. Bumbling along on a narrow muddy canal I just remove the two bolts holding the pump onto the crankshaft and move it away but usually and on the rivers I use the raw water cooling system. It means you can run the engine flat out all the time if you have to without worrying about overheating.

-

Looking at 20 year old 2-stroke Yamaha 40s / 50s they are over £1000. A modern 4-stroke 40hp is going to be over £2000.

eg (from apollo duck) 10 years old and not even with steering

For Sale: Yamaha 2014 40hp tiller control £2,800I really don't think the OP will get a boat and a reliable decent engine for £1500

I hope I have, everything works perfectly boat just needed a very good clean!

Only 20 hours on the engine, moored in a marina on the freshwater Thames. Owner just wanted out as he had moved abroad. There are bargains out there if you are prepared to hunt around. -

Funny but I am almost exactly in the same situation but a bit further along the Dorset Coast. Having finished the House I was looking for something that would go on a trailer so I could keep it safely ashore in the garden over the winter and save a lot of the costs. I did think about a sailing boat with an outboard well but in the end bought a 16ft Faulkland Fisher boat similar to an Orkney with a 40HP engine and a small cuddy. For the amount of use it will probably get It didn't seem worth buying a bigger boat unless you are going on much longer trips.

Being able to do 20knots or so is a great benefit if you are doing day trips around the Solent mainly in the summer. It is ideal for fishing and has high freeboard so good for the grandkids too. It only cost a tenth of your proposed budget and requires very little maintenance.

-

1

1

-

-

Whilst not the ideal boat for the continent a narrow boat works on most waterways (not Rhine or Rhone) but it is far cheaper and safer to get your boat transported to somewhere like Dunkirk or further inland on a lorry. You save all the cost of the seagoing equipment, insurance, waiting for a weather window etc. You could wait weeks for suitable weather in somewhere like Ramsgate and that would cost an arm and a leg in itself.

-

1

1

-

Commission Survey

in Waterways News & Press

Posted

The Basingstoke and Wey are similar and both have in the licence conditions that it is a maximum of 48hours in any one place unless you have an approved mooring. Allowances are made for stoppages,breakdowns and flooding etc but the rule is well inforced - basically you can only get a short term visitors licence unless you have a recognised home mooring. Of course the big problem on the CRT canals and the Thames is identifying the boat. A lot now don't have a visible name or index number so tracking for EA/CaRT must be a nightmare.